Recycled aggregates, derived from processed construction and demolition (C&D) waste, represent a cornerstone of sustainable building practices. However, their widespread adoption in high-performance applications like structural concrete has been hindered by an inherent challenge: strength loss compared to virgin natural aggregates. This article systematically explains the mechanisms behind this strength loss and explores the multifaceted technological approaches—from optimized crushing and rigorous impurity control to advanced material modification—that are enabling the production of high-quality recycled aggregates for demanding engineering applications.

The transformation of rubble into a reliable resource is a complex process. It involves not just breaking down large chunks of concrete and masonry, but doing so in a way that preserves the integrity of the original rock within. This requires a deep understanding of material science and precise control over the entire recycling workflow, from the initial shredding to the final quality control of the aggregate product.

Core Mechanisms of Strength Loss in Recycled Aggregates

The strength deficiency in recycled aggregates is not a single issue but a result of several interconnected factors originating from the original concrete's life and the recycling process itself. The parent concrete, from which the aggregate is derived, has already undergone service loads and environmental exposure, creating a pre-damaged state. The subsequent crushing process, while necessary to liberate the aggregate, further exacerbates these weaknesses.

Understanding these mechanisms is the first step toward mitigating them. By identifying how and where strength is lost, engineers can develop targeted strategies at each stage of the recycling process to minimize damage and produce a more robust final product that can confidently replace natural gravel and crushed stone.

Damage to Parent Rock Structure During Crushing (Micro-Crack Propagation)

Industrial shredders and crushers apply immense mechanical forces to break down concrete rubble. While effective for size reduction, the intense impact and shear forces can cause existing micro-cracks within the natural rock particles to propagate and new ones to form. Research using electron microscopy shows that these micro-cracks, often less than 0.1mm in width, significantly reduce the aggregate's load-bearing capacity by creating stress concentration points.

The choice of crushing technology is crucial. Shear-type shredders can be gentler on the aggregate than impact crushers in certain stages, as they slice and tear the mortar away from the rock rather than smashing it. The goal is to liberate the aggregate with minimal additional damage to its internal structure.

Interaction of Adhered Mortar and Micro-Cracks (Weakened Interfacial Transition Zone)

Unlike natural aggregates, which are clean, recycled aggregates are typically coated with a layer of old cement mortar. This adhered mortar is more porous, weaker, and has a different coefficient of thermal expansion than the parent rock. This creates a weakened Interfacial Transition Zone (ITZ) around the aggregate. When stress is applied, cracks are more likely to initiate and propagate through this porous mortar layer and the network of micro-cracks connecting to it.

This weak ITZ is a primary reason for the reduced compressive and tensile strength observed in concrete made with recycled aggregates. The quality and quantity of this adhered mortar, therefore, become a key focus area for improving the final product's performance.

Increased Porosity Due to Impurity Inclusion (Deteriorated Cement Paste Structure)

Construction waste is rarely pure concrete. It often contains bricks, tiles, plaster, wood, and gypsum. Even small amounts of these impurities, if not removed, can be incorporated into the aggregate stream. These materials are typically more porous and softer than concrete or natural stone. Their inclusion increases the overall water absorption of the recycled aggregate, which can negatively affect the workability of fresh concrete and its final durability by introducing more voids.

High water absorption, often exceeding 5% compared to less than 1% for natural aggregate, is a critical indicator of poor quality. It signifies a high volume of pores and cracks that compromise the aggregate's structural integrity.

Cumulative Damage Effect of Multiple Crushing Cycles (Fatigue Failure Mechanism)

In complex recycling plants, material might pass through several size reduction stages, such as a primary primary shredder followed by a secondary crusher. Each cycle subjects the aggregate particles to repeated mechanical loading. This can lead to a fatigue effect, where the cumulative damage from multiple lower-stress events is more detrimental than a single high-force crush.

Optimizing the flow to minimize unnecessary recirculation and using the right type of crusher for each stage (e.g., jaw crusher for primary, cone crusher for secondary) is essential to prevent this cumulative damage and preserve the inherent strength of the aggregate particles.

Optimization Strategies for Crushing Process Parameters

The journey to high-quality recycled aggregate begins with the careful selection and operation of the crushing equipment. Modern recycling plants are not simply about brute force; they are about precision and control. By fine-tuning operational parameters, operators can significantly influence the physical properties of the output material, steering it toward higher density, better shape, and lower powder content.

This optimization is a balancing act. It involves juggling factors like throughput capacity, energy consumption, and wear on the machinery itself, all while aiming for the highest possible aggregate quality. Data-driven operation, guided by sensor feedback and product analysis, is key to achieving this balance consistently.

Dual-Shaft Shredder Speed Control (Impact Force and Energy Consumption Balance)

In the initial coarse shredding phase, a dual-shaft shredder is often used. The rotational speed of its shafts directly controls the shear and tearing force applied to the feed material. A slower speed might generate higher torque, which is effective for breaking down reinforced concrete but may produce more elongated particles. A higher speed might create a more cubic product but increases wear and energy consumption.

Advanced systems use variable frequency drives to adjust the speed based on the load, ensuring optimal power use and consistent product size while avoiding excessive force that could fracture the valuable aggregate within the concrete.

Trommel Screen Aperture Selection (Aggregate Particle Size Grading Control)

After crushing, the material is screened to separate it into different size fractions. Trommel screens, with their rotating drums and specific aperture sizes, are commonly used for this task. The choice of aperture size is critical for achieving the desired particle size distribution, or "grading," which is essential for producing dense, strong concrete.

A well-graded aggregate blend packs together tightly, minimizing the voids between particles that need to be filled with expensive cement paste. Precise control over screening ensures the final product meets strict specifications, such as those for a 0-4mm fine aggregate or a 4-32mm coarse aggregate.

Air Separator Efficiency (Lightweight Impurity Removal Rate >95%)

Air classifiers or separators are highly effective for removing lightweight contaminants like wood, plastic, paper, and gypsum. These systems use a controlled upward stream of air to fluidize the crushed material. Heavier aggregate particles fall through, while lighter impurities are carried away. High-efficiency systems can achieve removal rates exceeding 95% for these deleterious materials.

This process is vital for improving the aggregate's purity and reducing its water absorption. The effectiveness of this separation directly impacts the performance of the final concrete product, making it a non-negotiable step in a modern recycling plant.

Multi-Stage Crushing System Design (Primary Crushing + Secondary Fine Crushing)

A single crushing step is often insufficient to produce high-quality, well-shaped aggregate. A multi-stage system is employed, where each stage is designed for a specific purpose. A primary shredder or crusher (like a jaw crusher) performs the initial breakdown of large debris. A secondary crusher (like a cone or impact crusher) then further reduces the size and improves the particle shape.

This staged approach is more efficient and allows for better control over the final product's characteristics. It prevents the over-crushing of already-liberated aggregate and allows for the targeted removal of impurities between stages.

Impurity Removal and Aggregate Purification Technology

The purity of recycled aggregate is paramount to its structural performance. Even small amounts of contaminants can act as weak points within concrete, leading to reduced strength and durability. Therefore, a sophisticated recycling plant functions as a purification chain, employing a series of specialized technologies to identify and remove different types of impurities.

This purification process is sequential and logical. It begins with the removal of large, obvious contaminants like rebar and progresses to the separation of finer, more embedded materials. Each technology targets a specific type of impurity, and together they ensure the final aggregate product is clean and consistent.

Magnetic Separator for Rebar Removal (Ferromagnetic Material Separation)

Powerful overband magnets or drum magnets are standard equipment placed over conveyors carrying the crushed material. These magnets generate a strong magnetic field that effortlessly lifts and separates ferrous metals—like reinforcing bar (rebar), wire mesh, and nails—from the aggregate stream. This is often the first and most crucial step in impurity removal, protecting downstream equipment from metal damage and recovering a valuable scrap metal stream.

The efficiency of modern magnetic separators is exceptionally high, often capable of removing over 99% of ferrous metals, ensuring the aggregate is virtually free of large metallic contaminants.

Eddy Current Separator for Non-Ferrous Metal Recovery

While magnets handle iron and steel, non-ferrous metals like aluminum, copper, and brass (often from conduits, wiring, and window frames) require a different technology. Eddy current separators use a rapidly rotating magnetic rotor to induce electrical currents in these conductive metals. These currents create their own opposing magnetic field, which repels the metal particles and ejects them from the main aggregate flow.

This technology is essential for producing clean aggregate and for maximizing the economic return from the waste stream by recovering high-value non-ferrous metals.

AI Optical Sorter for Lightweight Impurity Identification (Plastic/Wood)

Advanced sensors and artificial intelligence have revolutionized the identification of non-metallic impurities. AI-powered optical sorters use high-resolution cameras and near-infrared (NIR) sensors to scan the material stream. These sensors can identify the unique spectral signature of materials like wood, plastic, and rubber.

Once identified, a precise array of air jets is triggered to blast the impurity particle out of the stream. This technology achieves a level of purification previously impossible, targeting specific contaminants with incredible speed and accuracy.

Water Washing Process Parameter Optimization (Control of Clay Lumps<5%)

For the highest quality applications, aggregates are washed. Log washers or scrubbers use water and mechanical action to dislodge and remove adhered dirt, clay lumps, and other soluble contaminants. Optimizing water pressure, flow rate, and retention time is key to effective cleaning without eroding the aggregate itself.

Washing can reduce the content of clay lumps and friable particles to below 5%, significantly improving the aggregate's quality. The resulting wastewater is then treated in settling ponds or clarifiers to remove solids before recycling the water, ensuring an environmentally closed-loop process.

Reinforcement and Modification Methods for Recycled Aggregates

When mechanical purification reaches its limits, material science offers solutions to enhance the aggregate itself. These strengthening techniques aim to directly address the weaknesses of recycled aggregate, such as its high porosity and the weak adhered mortar. By modifying the surface or internal structure of the aggregate particles, engineers can create a product that rivals, and in some aspects surpasses, the performance of natural aggregate.

These methods range from simple mechanical processes to advanced chemical and biological treatments. The choice of technique depends on the desired final properties of the aggregate and the cost-effectiveness for the intended application, whether it's for high-strength concrete or road base layers.

Mechanical Activation Treatment (Ball Mill Grinding to Enhance Interfacial Bonding)

This process involves tumbling the recycled aggregate in a ball mill. The gentle abrasion between particles grinds away the sharp edges and weak, protruding parts of the old mortar, resulting in a smoother, more rounded particle. More importantly, it exposes a fresher, harder surface of the parent rock, which improves the bond with the new cement paste in concrete.

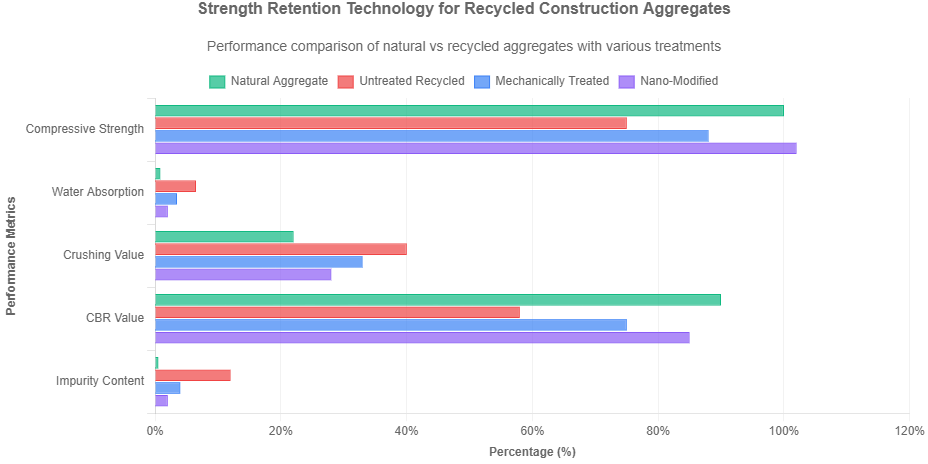

This mechanical activation can increase the compressive strength of resulting concrete by 10-15% by creating a stronger Interfacial Transition Zone (ITZ) between the aggregate and the new mortar.

Chemical Impregnation Modification (Silane Coupling Agent for Enhanced Hydrophobicity)

Silane-based water repellents are used to treat recycled aggregates. These chemicals penetrate the porous mortar layer and react with the silicate minerals within, forming a hydrophobic layer. This treatment significantly reduces the aggregate's water absorption, often by more than 50%. A drier aggregate means less water is added to the concrete mix, leading to better control over the water-cement ratio and ultimately higher final strength and better freeze-thaw resistance.

This process is particularly valuable in climates where durability against weathering is a critical concern for concrete structures.

Nano-Material Doping (SiO₂/TiO₂ Nanoparticle Enhancement)

This cutting-edge technique involves coating recycled aggregates with a slurry containing nano-sized particles of silica (SiO₂) or titanium dioxide (TiO₂). These particles are so small they can fill the ultra-fine nanopores within the adhered mortar. When the aggregate is used in concrete, these nanoparticles also act as nucleation sites for the hydration products of cement, leading to a denser and stronger microstructure in the new ITZ.

Research has shown that nano-silica treatment can improve the compressive strength of recycled aggregate concrete by 15-20%, effectively upgrading its performance class.

Microbially Induced Calcium Carbonate Precipitation (MICP Technology for Micro-Crack Repair)

This bio-inspired technology harnesses specific bacteria (e.g., Bacillus genus) and a nutrient solution. The treated aggregate is immersed in a solution containing these bacteria and urea. The bacteria metabolize the urea, producing carbonate ions and increasing the local pH. In the presence of calcium ions (from the cement paste), this leads to the precipitation of calcium carbonate (CaCO₃) directly inside the micro-cracks and pores of the aggregate.

This biologically produced mineral effectively "heals" the micro-cracks, sealing the surface and increasing the aggregate's density and strength. It is a promising sustainable method for aggregate enhancement.

Engineering Application Cases and Performance Verification

The true test of any enhanced recycled aggregate is its performance in real-world applications. Laboratory studies provide essential data, but large-scale pilot projects and commercial use cases are what build confidence among engineers, architects, and developers. Across the globe, successful projects are demonstrating that properly processed and treated recycled aggregates are more than capable of meeting the demands of modern construction.

These applications range from lower-grade uses like road sub-base to high-grade structural concrete in buildings. Each application has its own set of specifications and performance criteria, providing a comprehensive validation platform for the various strengthening technologies.

Recycled Aggregate Concrete Mix Design (30%-50% Replacement Rate)

Numerous studies and practical projects have established that a replacement rate of 30% to 50% of natural coarse aggregate with high-quality recycled aggregate has a minimal negative impact on the concrete's workability and strength. For instance, concrete with 30% recycled aggregate typically experiences a compressive strength reduction of less than 10%, which can be easily compensated for in the mix design with slight adjustments to the water-cement ratio or the use of supplementary cementitious materials like fly ash.

This level of replacement represents a massive diversion of waste from landfill and a significant reduction in the environmental footprint of construction projects.

Road Base Material Performance Verification (CBR Value ≥80%)

Recycled concrete aggregate is an excellent material for road base and sub-base layers. Its angular particles interlock well, providing high shear strength and stability. The California Bearing Ratio (CBR) is a key measure of a material's strength for road construction. Well-processed and compacted recycled aggregate consistently achieves CBR values exceeding 80%, which meets or exceeds the specifications for base courses in many highway and road projects.

This application consumes large volumes of material, making it a critical market for the recycling industry and a proven, reliable use case.

Precast Component Production Practice (>90% Compressive Strength Compliance Rate)

The precast concrete industry, known for its controlled production environment and high-quality standards, has successfully incorporated recycled aggregates. Factories producing concrete blocks, paving stones, sewer sections, and other structural elements use treated recycled aggregates to manufacture products that consistently comply with compressive strength standards, achieving a pass rate of over 90%.

The controlled batching and curing conditions in precast plants are ideal for maximizing the performance of recycled aggregates, demonstrating their suitability for standardized, high-volume production.

Long-Term Durability Monitoring (Carbonation Depth/Chloride Ion Penetration Coefficient)

Long-term monitoring of real structures is the ultimate validation. Studies of buildings and infrastructure elements constructed with recycled aggregate concrete track key durability indicators. Data on carbonation depth (the rate at which concrete is neutralized by CO₂) and chloride ion penetration (which causes rebar corrosion) show that well-designed mixes with high-quality recycled aggregate perform comparably to those with natural aggregate.

These long-term studies are crucial for updating building codes and expanding the permitted uses of recycled aggregates in aggressive environments.

Technical Standards and Quality Control Systems

For recycled aggregates to be widely accepted and trusted, they must be produced to consistent, verifiable standards. National and international standards provide the technical specifications that define different classes of recycled aggregate based on their properties, such as density, water absorption, and content of impurities. Adherence to these standards, backed by rigorous quality control, is what transforms a waste-derived product into a reliable construction material.

A robust Quality Assurance (QA) system encompasses every step of the process, from incoming waste inspection to final product certification, ensuring that every truckload of aggregate meets the promised specifications.

GB/T 25177-2010 Standard Compliance Testing

In China, the national standard GB/T 25177-2010 "Recycled coarse aggregate for concrete" sets the benchmark. It classifies aggregates into Category I, II, and III based on key performance indicators like crushing value, water absorption, and content of harmful substances. Regular testing in accredited laboratories—for properties such as particle density, sulphate content, and chloride ion content—is mandatory to certify compliance and ensure the material is fit for its intended structural purpose.

Similar standards exist globally, such as EN 12620 in Europe and ASTM D7084 in the United States, providing a common language for quality.

Aggregate Grading Curve Optimization (Meeting Continuous Grading Requirements)

A continuous and well-balanced grading curve is essential for creating dense, strong concrete. QC labs perform sieve analysis on aggregate samples to ensure the distribution of particle sizes follows the optimal curve. A gap-graded aggregate (missing certain sizes) will lead to a higher volume of voids, requiring more cement paste to fill them, which increases cost and can lead to higher shrinkage and cracking.

Modern processing plants use automated screening systems and feedback loops to maintain a consistent and optimal grading from their final product.

Crushing Value Index Control (≤30%)

The Aggregate Crushing Value (ACV) test is a fundamental measure of an aggregate's mechanical strength. It determines the resistance of the aggregate to crushing under a gradually applied compressive load. A lower ACV indicates a stronger aggregate. For use in structural concrete, a crushing value of 30% or lower is typically required. High-quality recycled aggregate, especially after strengthening treatments, can consistently achieve this target, demonstrating its structural competence.

Controlling this index is a direct result of optimizing the entire crushing and processing chain to minimize internal damage to the aggregate particles.

Digital Quality Traceability System (Blockchain Technology Application)

Innovative plants are implementing digital traceability systems. Using IoT sensors, each batch of aggregate can be tracked from its origin (e.g., a specific demolition project) through every processing step (crushing, screening, washing), with key quality data (e.g., ACV, absorption) recorded at each stage. This data can be stored on a secure, immutable blockchain platform.

This provides a transparent and verifiable "quality passport" for the aggregate, giving engineers and developers ultimate confidence in the material they are specifying and using, and fostering a circular economy built on trust and data.

Technology Trends and Breakthrough Directions

The field of construction waste recycling is dynamic, driven by advances in digitalization, automation, and material science. The future points toward smarter, more efficient, and more sustainable processes that will further elevate the quality and acceptance of recycled aggregates. These trends are not just incremental improvements but represent fundamental shifts in how we view and process construction waste.

The integration of advanced technologies will enable the production of recycled aggregates with tailored properties for specific high-value applications, moving beyond being a mere substitute to becoming a material of choice for innovative construction.

Intelligent Crushing Equipment Development (Adaptive Force Control Technology)

The next generation of shredders and crushers will be equipped with smart sensors and AI that allow for real-time adaptive control. These systems will continuously monitor the feed material's hardness and size and automatically adjust parameters like rotor speed, hydraulic pressure, and crusher gap to apply the optimal force needed for liberation with minimal damage. This maximizes the yield of high-quality aggregate while reducing energy consumption and wear on the equipment itself.

Building Information Modeling (BIM) Integration (Full Lifecycle Management)

BIM is expanding from designing new buildings to managing their entire lifecycle, including end-of-life deconstruction. A "Deconstruction BIM" model can inventory the types and quantities of materials in a structure slated for demolition. This information can then be used to pre-plan the optimal recycling process, ensuring that concrete, metals, and other materials are separated at source and sent to facilities equipped to handle them, resulting in higher purity and quality of recycled output from the very beginning.

Carbon Capture, Utilization, and Storage (CCUS) in Recycled Aggregates

This promising technology involves exposing recycled aggregates to a controlled atmosphere of carbon dioxide (CO₂) within a sealed chamber. The CO₂ reacts with the calcium hydroxide and calcium silicate hydrate in the old cement mortar, forming stable calcium carbonate. This reaction not only permanently sequesters CO₂ (up to 5% of the aggregate's weight) but also densifies the mortar, reducing porosity and increasing the aggregate's strength and hardness. It turns the aggregate into a carbon sink.

3D Printing with Recycled Aggregate Concrete (Heterogeneous Material Adaptability Research)

3D concrete printing (3DCP) is an emerging technology that requires specialized concrete mixes with precise rheological properties. Research is actively exploring the use of recycled sands and fine aggregates in these mixes. The controlled particle shape and grading of processed recycled aggregate can be beneficial for printability. This application represents a potential high-value market that aligns with the sustainable ethos of additive manufacturing, pushing the boundaries of how we use recycled materials in construction.