Twin-shaft solid-waste shredders are workhorses in waste management, handling diverse materials from construction debris to industrial scrap. At the heart of their operation are drive belts, which transmit power from motors to the shredding shafts. Proper belt tension is critical for these machines to function efficiently, safely, and cost-effectively. This article explores how frequency-based methods revolutionize tension checking and how retrofitting automatic tensioners can transform performance. By combining precise measurement techniques with adaptive tensioning systems, operators can reduce downtime, cut maintenance costs, and extend equipment life—key factors in the demanding world of solid waste processing.

The Critical Role of Belt Tension in Twin-Shaft Shredders

Belt tension serves as the foundation of reliable power transmission in twin-shaft solid-waste shredders. These machines operate under high torque to tear and shear tough materials, making consistent tension essential for transferring motor power to the rotating shafts without slippage. Optimal tension ensures that the belts maintain proper contact with pulleys, distributing loads evenly across components and preventing premature wear. Inadequate tension, by contrast, creates inefficiencies that ripple through the entire system, affecting everything from energy consumption to shredding output.

For twin-shaft models specifically, tension management is more complex than in single-shaft designs due to their synchronized operation. Both shafts must receive balanced power to maintain the intermeshing action critical for effective shredding. Even minor tension imbalances can lead to uneven loading, causing excessive stress on one shaft and reducing shredding uniformity. This makes tension control a vital aspect of maintaining overall machine performance.

Tension's Impact on Shredder Performance Mechanisms

Belt tension directly influences the contact angle between belts and pulleys, a key factor in friction generation. The contact angle determines how much force the belts can transmit without slipping; too little tension reduces this angle, while proper tension maximizes it. In twin-shaft shredders, where each shaft may handle varying loads as materials feed through, consistent tension ensures that friction remains stable, even as torque demands fluctuate. This stability translates to steady shredding speeds, which in turn improve material processing consistency.

Tension also affects the vibration characteristics of the belt system. Under-tensioned belts vibrate excessively, creating resonance that can damage pulleys, bearings, and even the shredder frame over time. Studies show that vibrations from loose belts increase bearing wear by up to 30% compared to properly tensioned systems. By maintaining optimal tension, operators mitigate these vibration-related issues, preserving both the belt system and surrounding components.

Common Failure Signs from Improper Tension

Slip-related issues are the most immediate indicators of insufficient tension. When belts slip, they generate audible squealing, especially during startup or when processing heavy loads. This sound arises from the friction between moving belts and stationary pulleys, a phenomenon that also produces excessive heat. Thermographic inspections often reveal pulley temperatures 15–20°C higher than normal in slipping scenarios, accelerating belt degradation. Over time, this heat causes belt rubber to harden and crack, reducing flexibility and service life.

Over-tensioning, while less obvious, is equally damaging. It places excessive stress on belt fibers, leading to premature stretching or snapping. More insidiously, over-tensioning increases load on shaft bearings, with studies showing that bearing failure rates rise by 40% when tension exceeds recommended levels by 25%. Operators may notice increased motor current draw as the system works harder against the excess tension, a sign that often precedes more severe mechanical failures.

Tension Requirement Differences: Twin-Shaft vs. Single-Shaft

Twin-shaft shredders demand more stable tension than single-shaft models due to their interdependent operation. Each shaft relies on the other to maintain proper material engagement; if one belt slips, the mismatch in shaft speeds disrupts the shearing action, leading to uneven particle sizes and potential jams. This interdependence requires tension levels to remain within a narrower range—typically ±5% of the manufacturer’s specification—compared to the ±10% tolerance acceptable for many single-shaft systems.

The higher torque requirements of twin-shaft designs further amplify tension importance. These machines often operate at lower speeds (20–50 RPM) than single-shaft shredders but with 2–3 times the torque, placing greater stress on belt systems. This high-torque environment makes tension fluctuations more consequential, as even minor slips can result in significant power loss and increased wear. For example, a 10% tension drop in a twin-shaft machine can reduce throughput by up to 15%, whereas the same drop in a single-shaft model might only reduce throughput by 5%.

Limitations of Manual Adjustment Methods

Traditional manual tensioning relies on operator experience and basic tools like tension gauges or deflection measurements. This approach is inherently inconsistent, as results depend on individual technique and judgment. A study of waste management facilities found that manual adjustments varied by 15–20% between operators, even when using the same procedure. This variability leads to inconsistent performance, with some belts operating too loose and others too tight within the same machine.

Manual adjustments also require significant downtime. Shutdowns for tension checks and adjustments can take 30–60 minutes per machine, adding up to 5–10 hours of lost production monthly in facilities with multiple shredders. Additionally, manual methods often involve accessing tight spaces around moving components, increasing safety risks for operators. These limitations highlight the need for more precise, efficient tension management solutions.

Economic Cost Analysis of Tension Issues

Belts that operate under improper tension significantly increase operational costs. Under-tensioned belts wear 2–3 times faster than properly tensioned ones, requiring replacement every 2–3 months instead of the typical 6–9 months. With replacement costs ranging from $200–$500 per belt (depending on size), a single twin-shaft shredder with four belts could incur $1,600–$4,000 in annual replacement costs due to under-tensioning—triple the cost of proper maintenance.

Energy waste adds another layer of expense. Slipping belts reduce transmission efficiency by 10–15%, meaning motors consume more power to achieve the same output. For a 50-horsepower shredder operating 8 hours daily, this inefficiency translates to an additional 1,500–2,200 kWh consumed annually, adding $180–$330 to utility bills (based on average industrial electricity rates). When combined with maintenance and downtime costs, tension-related issues can increase total operating expenses by 20–30%.

Safety Risks Associated with Tension Problems

Belt failure due to tension issues poses significant safety hazards in shredding operations. A snapped belt can whip violently, potentially striking operators or nearby equipment. In one reported incident, an over-tensioned belt failure caused $15,000 in damage to a shredder’s rotary cutters and required a full day of downtime for repairs. Loose belts also create pinch points as they slip and shift, increasing the risk of entanglement accidents.

Beyond immediate physical risks, tension-related equipment failures can create secondary hazards. For example, uneven shredding due to belt slippage can cause material buildup in the cutting chamber, leading to jams that require manual clearing—one of the most dangerous tasks in shredder operation. Proper tension management reduces these risks by minimizing unexpected failures and maintaining stable machine operation.

Principles and Advantages of Frequency-Method Tension Checking

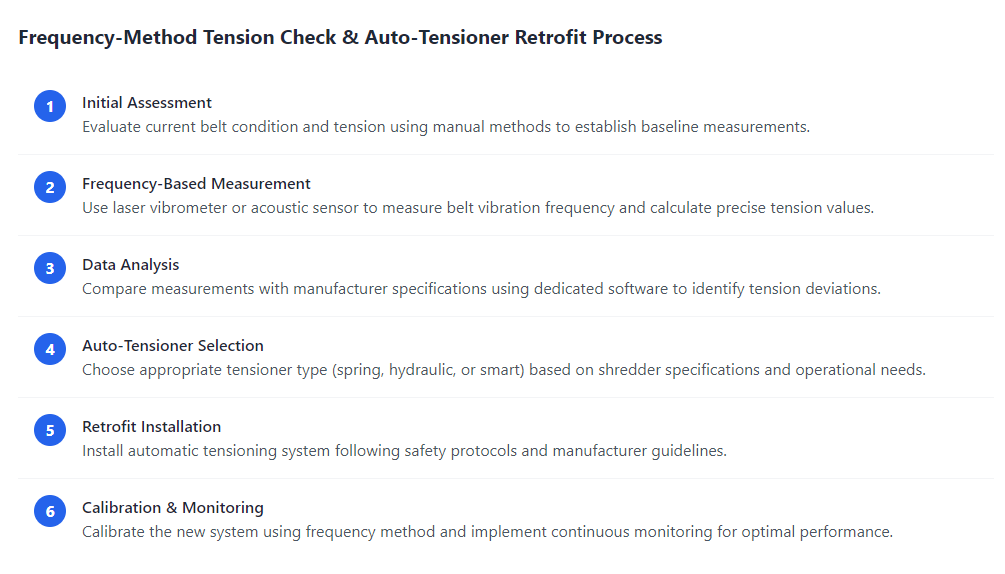

The frequency method for tension checking revolutionizes how operators measure belt tension by leveraging the physical properties of vibrating strings. When a belt is struck or plucked, it vibrates at a natural frequency determined by its tension, length, and mass. By measuring this frequency, technicians can calculate tension with far greater precision than traditional methods. This approach eliminates the subjectivity of manual checks, providing quantifiable data that forms the basis for consistent tension adjustments.

Unlike static methods that require shutdowns and physical contact with belts, frequency-based systems often work while the machine is idle or even during operation, reducing downtime. This non-invasive nature makes them ideal for twin-shaft shredders, where accessing belt systems can be challenging due to the machine’s compact design. The result is a more efficient, accurate, and safer way to manage belt tension in demanding waste processing environments.

String Vibration Theory in Belt Testing Applications

Frequency-method tension checking is rooted in the physics of vibrating strings, described by the fundamental equation: f = (1/(2L)) * √(T/μ), where f is frequency, L is belt length, T is tension, and μ is linear mass density. This equation shows that frequency increases with tension and decreases with belt length and mass. By measuring frequency and knowing the belt’s length and mass, technicians can solve for tension without direct force measurement.

In practice, this means placing a sensor near a belt and inducing vibration—either by tapping the belt or using an electronic exciter. The sensor captures vibration frequency, which is then processed by software to calculate tension. For standard belt types, manufacturers provide linear mass density values, simplifying calculations. This method achieves accuracy within ±2% of actual tension, far exceeding the ±10% typical of deflection-based tools.

Introduction to Testing Equipment (e.g., Laser Vibrometers)

Laser vibrometers are the gold standard for frequency-based tension measurement, offering non-contact operation and high precision. These devices emit a laser beam that reflects off the belt surface, detecting tiny vibrations and converting them into frequency data. Modern models integrate with tablets or laptops, displaying tension values in real time and storing measurements for trend analysis. Entry-level laser systems start around $1,500, while industrial-grade units with advanced features can cost up to $10,000.

Alternative tools include acoustic sensors that detect vibration via sound waves, though these are more susceptible to environmental noise. For facilities on a budget, smartphone apps with built-in microphones can measure frequency, though their accuracy (±5–8%) is lower than dedicated equipment. Regardless of the tool, the key advantage is the shift from subjective to objective measurement, enabling data-driven maintenance decisions.

Accuracy Comparison with Static Methods

Static tension measurement methods, such as the deflection test, rely on applying a known force to a belt and measuring how much it sags. This approach is prone to error because it depends on operator judgment in applying force and reading deflection. Laboratory tests show that deflection methods have an average error of 8–15%, compared to 1–3% for frequency-based systems. In one study, 10 operators using deflection tools on the same belt produced tension readings varying by 22%, while a laser vibrometer produced consistent results within 1%.

The difference is particularly pronounced in twin-shaft shredders, where belt access is limited and deflection measurements are hard to perform accurately. Frequency methods eliminate the need to reach around components or apply force in awkward positions, reducing both error and injury risk. This accuracy translates to better tension control, with facilities reporting 30% fewer belt-related failures after switching to frequency-based checking.

Adaptability in Dynamic Operating Conditions

One of the greatest strengths of frequency-method checking is its ability to measure tension in dynamic conditions, including during machine operation. Advanced systems can filter out background vibrations from motors and shredding activity, isolating the belt’s natural frequency. This allows technicians to monitor tension changes as the machine processes different materials—a critical capability because tension can fluctuate by 5–10% under varying loads.

Real-time dynamic measurements reveal how belts respond to operational stresses, such as startup torque spikes or sudden material overloads. This data helps identify tension drift patterns, enabling proactive adjustments before failures occur. For example, a facility processing mixed construction waste found that certain materials caused tension to drop by 8% during shredding; using this insight, they adjusted initial tension settings to compensate, reducing slip-related wear by 40%.

Data Logging and Analysis Software

Modern frequency-measurement tools integrate with software that logs tension data over time, creating a historical record of belt performance. These programs generate graphs showing tension trends, highlight deviations from optimal ranges, and send alerts when values fall outside acceptable limits. Some systems connect to a shredder’s control panel PLC HMI, allowing tension data to be correlated with operational parameters like load, speed, and material type.

This analytical capability transforms maintenance from a reactive to a predictive activity. For instance, software might identify that tension decreases by 2% per week in a particular belt, indicating a need for adjustment before it reaches critical levels. Facilities using such software report a 25% reduction in unplanned downtime related to belt issues, as maintenance can be scheduled during planned shutdowns rather than in response to failures.

Industry Standards References

Several standards govern belt tension measurement, providing guidelines for accuracy and procedure. ISO 1813 specifies methods for determining belt tension in power transmission systems, including frequency-based approaches, and sets accuracy requirements of ±5% for industrial applications. The Rubber Manufacturers Association (RMA) also publishes guidelines recommending frequency measurement for critical systems like twin-shaft shredders, citing its superior precision over static methods.

Compliance with these standards ensures that tension measurements are consistent across facilities and over time, facilitating benchmarking and best practice sharing. Many certification programs for waste management operations, such as ISO 14001, require documented tension management processes, making frequency-based methods—with their detailed data records—an ideal choice for compliant facilities.