Twin-shaft shredders have become the cornerstone of modern electronic waste recycling operations, offering unique capabilities for processing complex material combinations found in discarded electronics. These robust machines utilize two counter-rotating shafts with intermeshing cutters that tear, shear, and rip materials apart rather than simply crushing them. This mechanical action proves particularly effective for electronic waste containing mixed metals, plastics, and hazardous components that require careful handling.

The global electronics industry generates approximately 53.6 million metric tons of e-waste annually, with only 17.4% being properly recycled. Twin-shaft shredders address this challenge by providing the versatility needed to process everything from computer cabinets to mobile phones while enabling material separation for recovery. Proper equipment selection and configuration can increase material recovery rates to over 95% while ensuring safe handling of hazardous substances like lead, mercury, and brominated flame retardants.

E-Waste Material Characteristics and Shredding Requirements

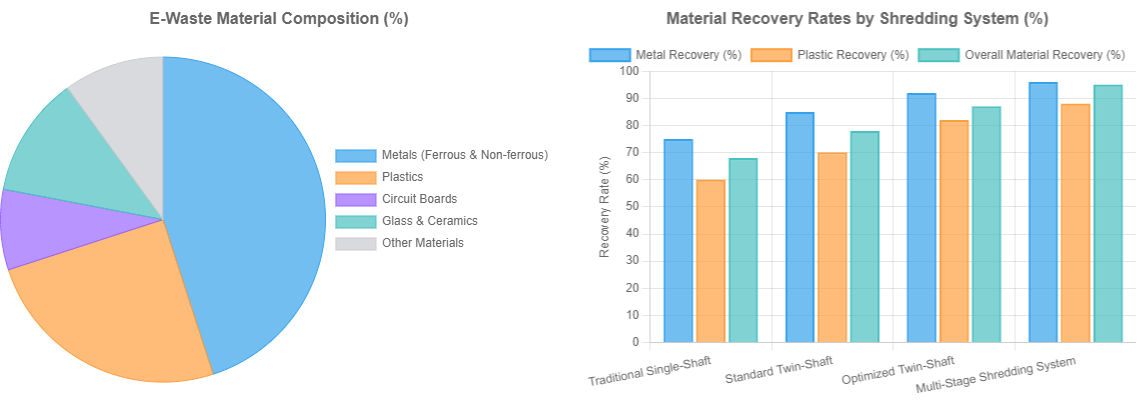

Electronic waste presents unique processing challenges due to its heterogeneous composition and combination of hard and soft materials. A typical mixed e-waste stream contains approximately 40-50% metals (ferrous and non-ferrous), 20-30% plastics, 5-10% circuit boards, and various other materials including glass and ceramics. This complex mixture requires shredding equipment capable of handling vastly different material properties while maintaining separation efficiency for downstream recovery processes.

The physical characteristics of e-waste materials demand specific shredding approaches. Metal components require high-torque cutting action, while plastic housings need tearing mechanisms that prevent melting from heat generation. Circuit boards contain both valuable metals and hazardous materials that must be properly liberated without creating excessive dust. Understanding these material properties is essential for selecting the appropriate shredding technology and configuration.

Layer Separation Technology for Metal-Plastic Composites

Many electronic products feature complex material combinations where metals and plastics are joined through mechanical fasteners, adhesives, or molded connections. Twin-shaft shredders excel at separating these materials through their intermeshing cutting action that progressively tears materials apart. The staggered arrangement of cutting discs creates multiple shear points that effectively separate bonded materials without excessive size reduction of metal components.

Low-temperature shredding techniques utilizing cryogenic or water-cooling systems prevent thermal degradation of plastic materials during processing. Maintaining temperatures below 80°C preserves plastic properties for higher-value recycling and prevents the release of hazardous gases from heated circuit boards. This approach increases the value of recovered plastics by 30-40% compared to conventional shredding methods.

Hazardous Substance Control Technologies

Modern e-waste shredding facilities implement comprehensive environmental controls to manage hazardous materials liberated during processing. Negative pressure dust collection systems capture airborne particles containing heavy metals and brominated compounds, typically achieving 99.9% collection efficiency. These systems prevent worker exposure and environmental releases while enabling proper treatment of captured materials.

Pre-shredding separation using magnetic and eddy current systems removes easily liberated metals before fine shredding, reducing the quantity of materials that require intensive processing. This approach decreases energy consumption by 15-20% and reduces wear on cutting components. The strategic placement of separation equipment throughout the process stream optimizes both material recovery and environmental protection.

Core Component Selection Criteria for Twin-Shaft Shredders

The performance and durability of twin-shaft shredders depend heavily on the proper selection of core components matched to specific e-waste processing requirements. Cutting systems, drive mechanisms, and structural elements must work in harmony to handle the abrasive and sometimes unpredictable nature of electronic waste. Investment in high-quality components typically returns value through extended service life and reduced operating costs.

Component selection requires balancing initial investment against long-term operational expenses. Premium materials and designs often command higher purchase prices but deliver lower cost per ton processed over the equipment's lifespan. The optimal selection depends on processing volume, material characteristics, and availability of maintenance resources.

Cutting Tool Wear Cycle Prediction Models

Tungsten carbide cutters have become the industry standard for e-waste applications due to their exceptional wear resistance against abrasive materials like circuit boards and metal coatings. Advanced wear prediction models incorporate material hardness, processing volume, and operational parameters to forecast replacement intervals with 90% accuracy. These models enable proactive maintenance planning that prevents unplanned downtime.

Surface treatments including Titanium Nitride (TiN) and Chromium Nitride (CrN) coatings extend cutter life by 40-60% by reducing friction and preventing adhesive wear. The micro-hardness of these coatings typically exceeds 80 HRC, providing exceptional resistance to the abrasive components in e-waste. The additional investment in coated cutters typically pays back within 6-9 months through reduced replacement frequency and improved processing consistency.

Power System Configuration Solutions

Electric motor selection requires careful matching of power characteristics to anticipated processing demands. For typical e-waste applications, power requirements range from 55-150 kW depending on shredder size and intended throughput. High-efficiency IE4 motors provide 3-5% energy savings compared to standard models, with payback periods of 12-18 months in continuous operation.

Variable frequency drives (VFDs) enable soft-start functionality that reduces mechanical stress during startup by limiting inrush current to 150% of full load current instead of the 600% typical across-the-line starting. This gentle starting approach extends equipment life and reduces peak power demand charges. VFDs also allow operational speed adjustment to match material characteristics, optimizing performance for different e-waste types.

Feeding System and Shredding Efficiency Coordination

The feeding system represents the critical interface between material preparation and shredding operations, directly influencing overall system efficiency. Properly designed feeding mechanisms ensure consistent material flow that maximizes shredder utilization while preventing overload conditions. The selection of feeding equipment depends on material characteristics, processing volume, and upstream preparation processes.

Advanced e-waste facilities typically employ conveyor-based feeding systems with integrated metering and monitoring capabilities. These systems maintain optimal shredder loading between 85-95% of capacity, maximizing throughput while preventing motor overload. Integrated sensors detect non-shreddable materials and automatically reverse feeding mechanisms to prevent damage.

Automated Feeding Control Strategies

Load cells integrated into conveyor systems provide real-time weight measurement that enables precise feed rate control. This weighing technology typically achieves accuracy within ±1% of actual weight, allowing operators to maintain optimal shredder loading. The data collected also provides valuable information for production tracking and efficiency analysis.

Metal detection systems positioned before the shredder identify ferrous and non-ferrous metals that might damage equipment or require separate processing. These systems typically operate at sensitivity levels capable of detecting metal particles as small as 3-5mm, triggering automatic diversion or shutdown sequences when necessary. This protection mechanism prevents an estimated 80% of potential damage incidents from metallic contaminants.

Multi-Stage Shredding Process Design

Efficient e-waste processing typically employs two or three shredding stages to achieve optimal material liberation with minimal energy consumption. Primary shredding reduces whole items to 100-150mm particles, while secondary processing achieves the 20-50mm size range ideal for material separation. This staged approach reduces total energy consumption by 25-30% compared to single-stage size reduction.

Air separation systems following shredding stages remove light materials including plastics and foams from heavier metals and circuit boards. These systems typically achieve 85-90% purity in both light and heavy fractions, significantly reducing the load on downstream separation processes. The strategic placement of separation equipment between shredding stages optimizes overall system efficiency and material quality.

Environmental and Safety Compliance Requirements

E-waste processing facilities must comply with increasingly stringent environmental and safety regulations designed to protect workers, communities, and the environment. European CE certification requires noise levels below 85 dB(A) at operator positions and incorporates comprehensive safety systems to prevent accidents. These requirements influence equipment selection, facility design, and operational procedures.

ATEX directives govern equipment operation in potentially explosive atmospheres that can occur when processing certain electronic components. Compliance typically requires explosion-proof construction, proper grounding, and explosion suppression systems. These safety measures add 15-20% to equipment costs but are essential for responsible operation.

Fire and Explosion Protection Systems

Lithium-ion batteries present significant fire risks when damaged during shredding operations. Inert gas suppression systems using nitrogen or argon reduce oxygen levels below the 15% concentration needed for combustion, preventing fires from developing. These systems can detect and suppress incipient fires within 500 milliseconds, minimizing damage and downtime.

Spark detection and extinguishment systems monitor material flow for ignition sources using infrared sensors capable of detecting sparks as small as 1mm. Upon detection, water mist or chemical suppression activates immediately, cooling materials and preventing fire propagation. These systems typically prevent 95% of potential fires from developing into significant incidents.

Occupational Health Protection Measures

High-efficiency particulate air (HEPA) filtration systems capture airborne contaminants including heavy metal dust and plastic particles with 99.97% efficiency at 0.3 microns. These systems typically process air at rates 4-6 times the volume of the processing area, maintaining negative pressure that prevents contaminant escape. Regular filter maintenance ensures consistent performance and prevents secondary contamination.

Acoustic enclosures reduce noise exposure to operators, typically achieving 20-25 dB noise reduction when properly designed and installed. These enclosures incorporate viewing windows, maintenance access points, and integrated lighting that allows visual monitoring while providing hearing protection. The investment in noise control typically pays back through reduced hearing protection requirements and improved worker comfort.

Life Cycle Cost Optimization Strategies

The total cost of ownership for e-waste shredding equipment extends far beyond the initial purchase price, encompassing maintenance, energy consumption, and component replacement costs. A comprehensive life cycle cost analysis typically reveals that operational expenses exceed initial investment within 2-3 years of operation. Strategic planning can significantly reduce these ongoing costs while maintaining processing performance.

Equipment selection should balance initial investment against projected operational costs, considering factors including energy efficiency, maintenance requirements, and expected component life. This holistic approach often justifies higher initial investments in quality equipment that delivers lower operating costs over its service life.

Spare Parts Inventory Management Models

Cutting tool replacement cycles typically range from 600-1,200 operating hours depending on material processed and cutter quality. Maintaining a strategic inventory of wear components prevents production interruptions while minimizing capital tied up in spare parts. Advanced facilities utilize computerized maintenance management systems that track component life and automatically generate purchase orders when inventory reaches predetermined levels.

Bearing lubrication intervals depend on operating conditions, typically ranging from 500-2,000 hours between services. Synthetic lubricants often extend service intervals by 30-40% while providing better protection against wear. The additional cost of premium lubricants is typically offset by reduced maintenance requirements and extended component life.

Energy Consumption Optimization Pathways

High-efficiency IE4 motors reduce energy consumption by 3-5% compared to standard efficiency models, with payback periods typically under 24 months in continuous operation. Power factor correction systems further reduce energy costs by minimizing reactive power charges that can add 15-20% to electricity bills. These systems typically achieve payback within 12-18 months through reduced demand charges.

Heat recovery systems capture waste thermal energy from hydraulic systems and motors for facility heating or other processes. These systems typically recover 40-60% of wasted heat, reducing heating costs by 20-30% in colder climates. The return on investment depends on local energy costs and climate conditions, with payback periods ranging from 2-4 years.