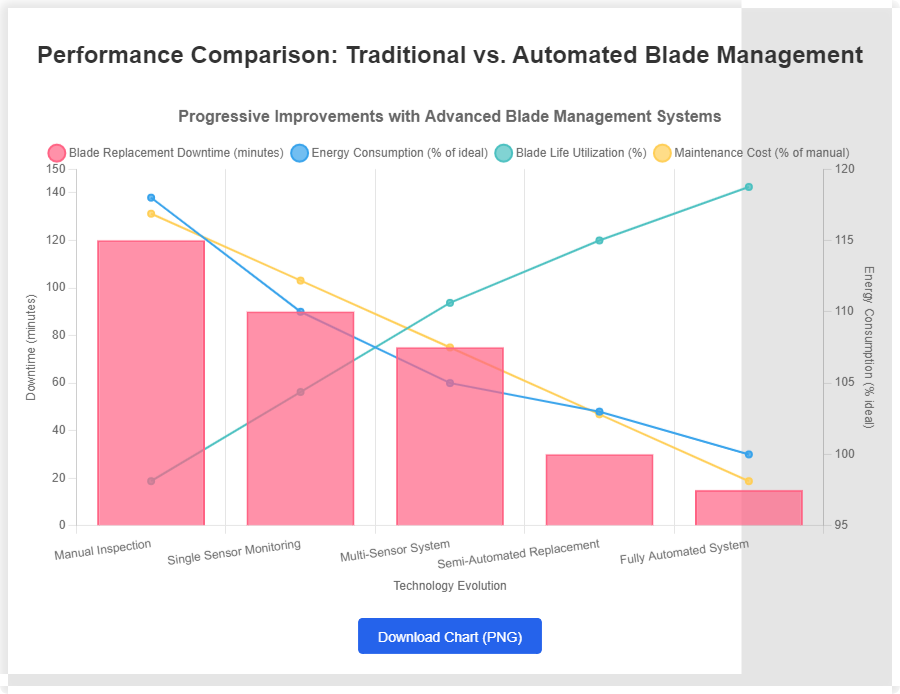

Blade wear represents one of the most significant operational challenges in industrial shredding operations, directly impacting processing efficiency, energy consumption, and product quality. Modern detection and automatic replacement technologies have transformed blade maintenance from reactive repairs to predictive optimization. These advanced systems utilize multiple sensing technologies and automated mechanisms to monitor blade condition and perform replacements with minimal human intervention, significantly improving operational efficiency and reducing downtime.

The average industrial shredder experiences blade wear that reduces efficiency by 15-20% before operators typically notice performance degradation. Automated detection systems can identify wear patterns when efficiency drops by just 3-5%, enabling proactive maintenance that maintains optimal performance. Studies show that proper blade maintenance can reduce energy consumption by up to 12% and increase throughput by 18-25% while extending overall equipment life by approximately 30%.

Technical Principles and Sensor Applications for Blade Wear Detection

Modern blade wear detection employs multiple sensing technologies that monitor different aspects of blade condition during operation. Vibration analysis detects changes in cutting dynamics that indicate edge wear, while thermal imaging identifies localized heating caused by increased friction. Laser displacement sensors measure dimensional changes in blade thickness, and acoustic emission sensors detect the high-frequency sounds generated by micro-crack formation and propagation.

The integration of these sensing technologies provides comprehensive monitoring that no single sensor could achieve independently. Vibration analysis typically detects wear patterns 200-300 operating hours before visual inspection would identify issues, while thermal imaging can identify temperature increases of just 2-3°C that indicate developing problems. This multi-sensor approach achieves detection accuracy of 95-98% for significant wear events, significantly reducing unexpected failures.

Multi-Sensor Fusion Detection Solutions

Advanced detection systems combine vibration, temperature, and visual data to create comprehensive wear models that predict blade condition with exceptional accuracy. These systems typically sample data at rates of 10-100 kHz, capturing detailed information about blade performance during each rotation. Data synchronization algorithms ensure that information from different sensors correlates properly, while advanced filtering removes noise and identifies true wear patterns.

The fusion of multiple data sources enables detection systems to distinguish between normal operational variations and actual wear development. Temperature spikes accompanied by specific vibration patterns might indicate adhesive wear, while dimensional changes without temperature increases could suggest abrasive wear. This discrimination capability reduces false alarms by 70-80% compared to single-sensor systems, ensuring maintenance occurs only when truly needed.

Edge Computing in Real-Time Detection

Local data processing at the equipment level enables real-time detection without the latency associated with cloud-based systems. Edge computing devices typically process sensor data within 50-100 milliseconds, allowing immediate response to developing wear conditions. This rapid processing enables automatic adjustments to operational parameters that can extend blade life while maintenance is scheduled.

Threshold settings and alarm mechanisms work in concert to provide appropriate warnings at different wear stages. Initial alerts might suggest inspection within 100 operating hours, while critical alarms could trigger immediate shutdown. These systems typically reduce unnecessary maintenance interventions by 40-50% while ensuring that genuine issues receive immediate attention.

Mechanical Design and Control Logic for Online Replacement Systems

Automatic blade replacement systems represent sophisticated mechanical solutions that require precise coordination between robotic components, hydraulic systems, and control logic. Modern systems utilize robotic arms with positioning accuracy of ±0.5mm to handle blade extraction and installation. Hydraulic systems provide the necessary force for blade removal while maintaining precise control during the installation process.

The control systems governing automatic replacement typically utilize Programmable Logic Controllers (PLCs) that communicate with the main shredder control system using industrial protocols such as PROFINET or EtherCAT. These systems incorporate multiple safety interlocks that prevent operation during inappropriate conditions and ensure that all safety requirements are met before initiating the replacement sequence. The complete replacement process typically requires 15-30 minutes, compared to 2-4 hours for manual replacement.

Blade Storage and Supply System Design

Automatic replacement systems incorporate storage magazines that typically hold 8-12 blades, sufficient for multiple replacement cycles between manual reloading. These storage systems maintain blades in precise orientation for robotic handling and often include environmental controls to prevent corrosion or damage. The storage capacity represents a balance between operational autonomy and physical space constraints.

RFID technology enables individual blade tracking throughout their lifecycle, from initial installation through multiple sharpening cycles to final retirement. Each blade typically contains embedded RFID tags that store identification information, usage history, and maintenance records. This tracking capability improves inventory management and ensures that blades are used in optimal rotation patterns.

Control Algorithm Optimization Strategies

Advanced control algorithms utilize wear prediction models to determine the optimal timing for blade replacements. These models consider factors including material processed, operational hours, power consumption, and detected wear patterns to schedule replacements during natural production breaks. The algorithms typically achieve 85-90% accuracy in predicting remaining useful life, enabling efficient maintenance planning.

Human-machine interfaces provide operators with clear information about blade condition and replacement schedules. These interfaces typically include visual indicators of wear progression, historical performance data, and recommendations for maintenance actions. The intuitive design enables operators with varying technical backgrounds to understand and manage the automated systems effectively.

Collaborative Implementation of Detection and Replacement Technologies

The successful integration of detection and replacement technologies requires careful coordination between monitoring systems and mechanical components. Detection systems must provide sufficient advance warning to schedule replacements during planned downtime, while replacement systems must operate reliably within the available time windows. This coordination typically reduces unplanned downtime by 60-70% compared to traditional maintenance approaches.

The balance between detection sensitivity and replacement frequency represents a critical economic consideration. Overly sensitive detection might trigger unnecessary replacements, while insufficient sensitivity could allow excessive wear to develop. Optimal systems typically maintain blade performance within 5% of ideal conditions while minimizing the total number of replacements required.

Integration of Preventive and Predictive Maintenance

Modern maintenance strategies combine scheduled preventive maintenance with condition-based predictive approaches. Wear data from detection systems integrates with equipment运行日志 to create comprehensive maintenance histories that inform future decisions. This integrated approach typically reduces total maintenance costs by 25-35% while improving equipment availability.

Machine learning algorithms continuously improve wear prediction models based on historical data and operational outcomes. These models typically become 10-15% more accurate with each year of operation, gradually reducing both unexpected failures and unnecessary maintenance. The iterative improvement process ensures that maintenance strategies evolve with changing operational conditions.

Centralized Monitoring Solutions for Multiple Devices

Cloud-based platforms enable centralized monitoring of multiple shredders across different locations. These platforms typically collect data from hundreds or thousands of sensors, applying advanced analytics to identify patterns and optimize maintenance strategies across the entire operation. The centralized approach enables benchmarking between equipment and facilitates best practice sharing.

Big data analysis identifies relationships between operational parameters and blade wear that might not be apparent at individual equipment level. These analyses might reveal that specific material combinations cause accelerated wear or that certain operational patterns extend blade life. The insights gained typically inform both operational practices and future equipment selection.

Industry Application Cases and Cost-Benefit Analysis

The automotive recycling industry has demonstrated significant benefits from automated blade monitoring and replacement systems. One major facility reported a 30% increase in blade life through optimized replacement timing and a 50% reduction in unplanned downtime. The facility achieved return on investment within 14 months through reduced maintenance costs and increased production availability.

Electronic waste processing operations face particular challenges with abrasive materials that accelerate blade wear. Implementing automated detection and replacement systems has enabled these facilities to maintain consistent product quality despite variable input materials. The systems typically pay for themselves within 18-24 months through reduced labor costs and improved processing efficiency.

Adaptation Differences Across Material Processing Scenarios

Blade wear characteristics vary significantly between different material types. Metal processing typically causes gradual abrasive wear, while plastic processing often involves adhesive wear that requires different detection approaches. Wood processing creates unique wear patterns involving both impact damage and abrasive wear. Understanding these differences is essential for proper system configuration.

The economic balance between blade quality and replacement frequency differs across material categories. Tungsten carbide blades typically provide the best value for metal processing applications, while specialized coated blades might be more economical for plastic processing. The optimal selection depends on specific material characteristics and operational patterns.

Spare Parts Management Optimization Strategies

Effective spare parts management requires balancing inventory costs against the risk of production interruptions. Automated monitoring systems provide accurate predictions of blade life, enabling just-in-time inventory management that reduces capital tied up in spare parts. These systems typically reduce inventory costs by 30-40% while maintaining equivalent service levels.

Collaboration with third-party service providers can further optimize maintenance costs for organizations without specialized expertise. These partnerships typically provide access to advanced monitoring technology and specialized maintenance skills without significant capital investment. The hybrid approach often delivers the benefits of automation while minimizing financial risk.

Environmental and Safety Compliance Requirements

Automatic blade replacement systems must comply with stringent safety standards including ISO 12100 for risk assessment and ISO 13849 for safety-related control systems. These standards ensure that automated operations do not create new hazards for maintenance personnel or operators. Compliance typically requires multiple layers of protection including physical guards, safety interlocks, and emergency stop systems.

Environmental regulations govern the disposal of worn blades, particularly those used in processing hazardous materials. Automated systems typically include procedures for safe handling and containment of worn blades that might contain contaminated material. These procedures ensure compliance with regulations while protecting workers from potential exposure.

Dust Control and Fire Prevention Measures

Blade replacement operations can generate significant dust emissions unless properly controlled. Negative pressure dust extraction systems typically maintain containment during replacement operations, capturing 99%+ of generated particles. These systems ensure that replacement activities do not contribute to environmental contamination or worker exposure.

Spark detection systems monitor the replacement area for ignition sources that might originate from blade contact or electrical systems. These systems typically respond within 500 milliseconds of detection, activating suppression mechanisms that prevent fire development. The comprehensive protection approach ensures that automated operations maintain or improve safety compared to manual methods.

Noise Control and Occupational Health Protection

Automatic replacement systems typically operate within noise levels of 75-80 dB, requiring hearing protection for nearby personnel. Acoustic enclosures can reduce noise levels by 15-20 dB, bringing operations within acceptable limits for extended exposure. These enclosures typically incorporate transparent sections that allow visual monitoring while providing acoustic insulation.

Hearing conservation programs establish procedures for protecting workers during automated operations. These programs typically include noise monitoring, hearing protection requirements, and regular audiometric testing. The systematic approach ensures long-term protection of worker hearing while enabling efficient operation of automated systems.

Future Technology Trends and Innovation Directions

Digital twin technology is revolutionizing blade maintenance by creating virtual replicas of physical systems that simulate wear patterns under different operational conditions. These digital models typically achieve 90-95% accuracy in predicting real-world performance, enabling optimization without physical experimentation. The technology allows operators to test different scenarios and identify optimal maintenance strategies before implementing them in physical systems.

Self-healing materials represent another promising direction for blade technology. These innovative materials can repair minor damage automatically during operation, potentially extending blade life by 200-300%. While still in development, these materials could eventually transform maintenance approaches by significantly reducing the frequency of replacements.

Breakthrough Points for Artificial Intelligence in Detection Algorithms

Deep learning algorithms are achieving remarkable success in recognizing complex wear patterns that traditional algorithms might miss. These systems typically require extensive training data but can eventually identify subtle patterns indicating developing wear. The technology shows particular promise for applications involving variable materials where wear patterns might change significantly based on input characteristics.

Transfer learning enables knowledge gained from one application to inform others, reducing the training required for new installations. This approach typically reduces implementation time by 40-60% while maintaining high detection accuracy. The ability to leverage existing knowledge makes advanced detection more accessible across different applications and industries.

Standardization and Industry Specification Development

International standards such as ISO 21876 provide guidelines for blade condition monitoring and maintenance procedures. These standards establish common terminology, measurement techniques, and performance requirements that ensure consistency across different systems and manufacturers. Compliance with these standards typically facilitates technology adoption by reducing implementation uncertainty.

Industry associations play important roles in promoting best practices and facilitating technology exchange. These organizations typically develop recommended practices, conduct training programs, and provide forums for knowledge sharing. The collaborative approach accelerates technology adoption and helps establish industry-wide standards for performance and safety.