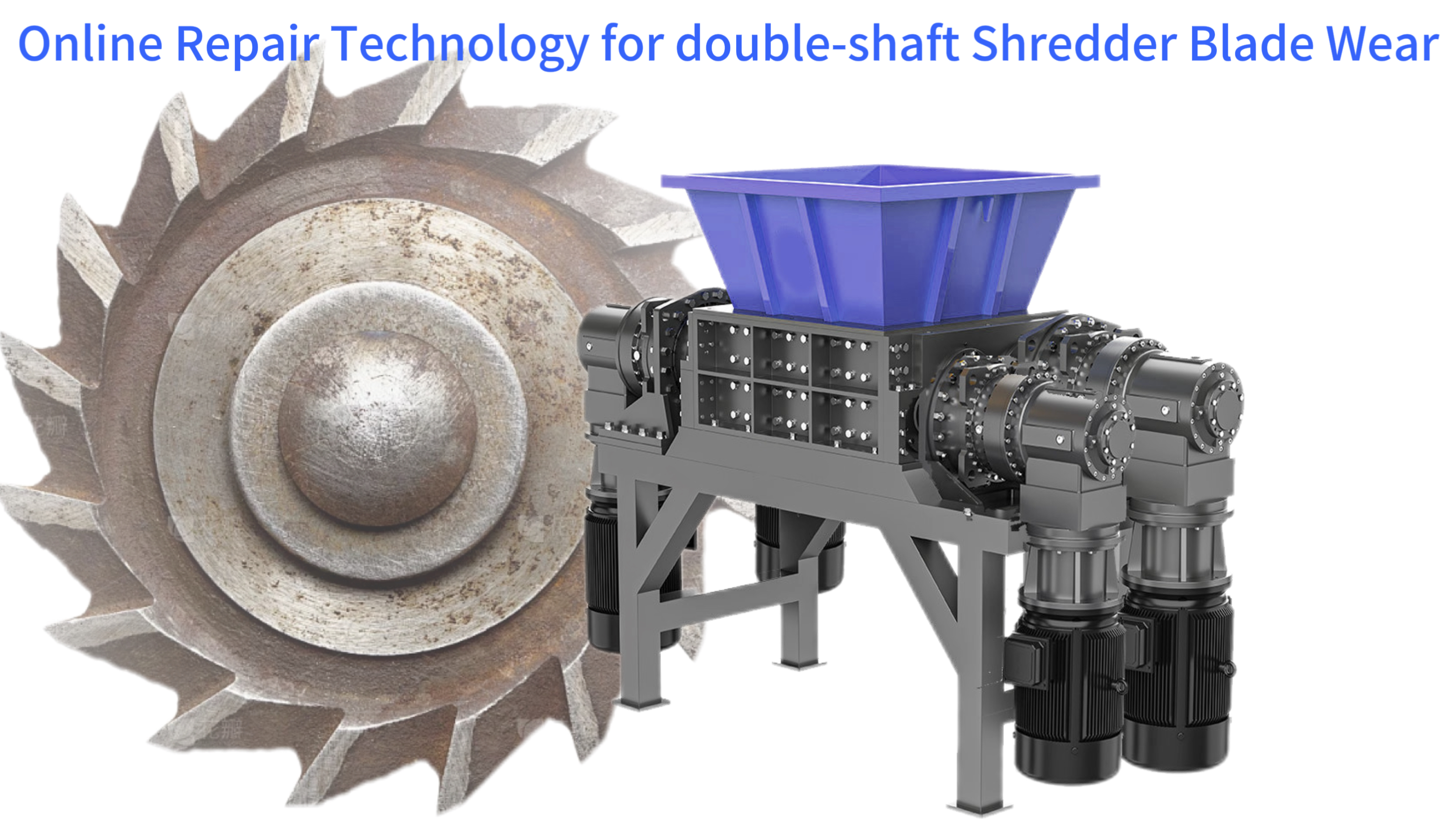

Dual-shaft shredders are workhorses in the recycling and waste management industry, consistently processing tough materials. Their blades, however, are subject to extreme wear. This article provides a systematic introduction to online repair technologies that address blade wear without requiring lengthy disassembly, offering businesses practical and actionable equipment maintenance solutions through technological innovation and material science advancements.

The traditional approach of shutting down a double-shaft shredder for blade maintenance is costly and inefficient. Online repair represents a paradigm shift, moving from reactive to predictive and even real-time maintenance. This technology is crucial for maintaining the high uptime required in continuous operations, such as processing construction debris or municipal solid waste.

The Mechanism and Challenges of Dual-Shaft Shredder Blade Wear

Blade wear in dual-shaft shredders is an inevitable consequence of their primary function: shearing and tearing through heterogeneous and often abrasive materials. The interaction between the rotary cutters and the counter knives under immense pressure leads to a gradual but predictable degradation of the cutting edges. Understanding the specific wear mechanisms is the first step toward developing effective countermeasures.

The challenges are multifaceted. Different materials cause different types of wear; for instance, processing electronic waste presents a different wear profile compared to shredding tires. Furthermore, the mechanical complexity of a dual-shaft system, with its precisely timed intermeshing shafts, means that even minor wear can disrupt the entire shredding process, leading to reduced efficiency and potential mechanical failure.

Main Types of Blade Wear (Abrasive/Fatigue/Corrosive Wear)

Abrasive wear is the most common type, caused by hard particles within the feed material scraping and micro-cutting the blade surface. For example, sand and grit in construction and demolition (C&D) waste can act like sandpaper on the blades. Studies on material processing indicate that such abrasive particles can remove 0.1-0.3mm of material weekly, significantly blunting the cutting edges.

Fatigue wear manifests as micro-cracks and eventually spalling on the blade surface, resulting from the repeated cyclic stresses of impacting and shearing materials. Corrosive wear is an electrochemical process accelerated by moisture and certain chemicals present in the waste stream, which attack the blade material and weaken its microstructure, making it more susceptible to mechanical abrasion.

Limitations of Traditional Offline Repair

Traditional repair methods necessitate a complete shutdown of the shredder. The process involves disassembling the entire cutting chamber, extracting the rotor assemblies, and then removing the blades for refurbishment or replacement. This process can take anywhere from several days to over a week for large industrial shredders, resulting in substantial production losses.

Beyond downtime, the costs are significant. They include labor for disassembly and reassembly, the cost of replacement blades or hardfacing materials, and potential costs from delayed production schedules. Furthermore, each reassembly introduces the risk of human error in achieving the precise tolerances and alignment required for optimal shredder performance.

Core Advantages of Online Repair Technology

Online repair technology offers a transformative advantage: the ability to address wear without stopping production. This real-time intervention is facilitated by systems integrated directly into the shredder, allowing for continuous monitoring and maintenance. The approach is fundamentally data-driven, using sensor inputs to make precise decisions about when and where to apply a repair.

The continuity of operation provided by online repair directly translates to higher annual throughput and profitability. It also allows for more consistent product quality, as the shredder's cutting gap can be maintained at its optimal setting continuously, preventing the gradual degradation in shred size that occurs as blades wear down.

Common Technical Bottlenecks Faced by the Industry

The industry faces several hurdles in adopting widespread online repair. Material compatibility is a major concern; any repair material added online must metallurgically bond with the existing blade substrate without causing thermal distortion or weakening the core of the blade. The automation level required for precise application in a hostile environment inside a shredder is another significant challenge.

Furthermore, developing a system that is universally adaptable to the vast array of shredder designs, from a double-shaft e-waste shredder to a tire shredder, requires versatile and intelligent engineering solutions that are only now becoming feasible with advances in robotics and sensor technology.

Core Working Principles of Online Repair Technology

The foundation of online repair is a closed-loop system that continuously monitors blade condition, processes the data, and executes precise repair actions. This system operates as a peripheral function to the main shredding process, intelligently intervening during operation or during planned micro-pauses to apply corrective measures based on a digital model of the blade's ideal state.

This technology integrates mechanical engineering, materials science, and digital control systems. It transforms the shredder from a passive tool into a self-sustaining system that can maintain its own cutting efficiency, representing a significant leap toward fully autonomous industrial recycling operations.

Real-Time Wear Monitoring Systems

Continuous monitoring is achieved through a network of sensors. Vibration analysis sensors mounted on the shredder shaft bearings can detect imbalances caused by uneven wear. Temperature sensors can identify overheating due to increased friction from dull blades. Advanced systems may employ internal optical or laser scanning systems to create 3D profiles of the blades during rotation.

This constant stream of data is fed into the shredder's PLC control system, which uses algorithms to model the wear rate and predict the remaining useful life of the blades. This allows for repairs to be scheduled at the optimal time, maximizing blade life without risking failure.

Dynamic Compensation and Repair Mechanisms

When monitoring indicates wear beyond a set threshold, the online repair mechanism is activated. Techniques like laser cladding use a high-power laser to create a melt pool on the blade surface into which a wear-resistant powder is injected, building up the worn area layer by layer. Cold spray technology accelerates powder particles at supersonic speeds to bond them to the surface without significant heating.

These processes are executed by robotic arms or automated nozzles that can access the cutting chamber through specially designed ports. The path and material deposition rate are dynamically controlled to precisely match the wear pattern identified by the monitoring system, ensuring a perfect restore of the original blade geometry.

Intelligent Control Algorithms

The brains of the operation are sophisticated software algorithms. Adaptive path planning allows the repair toolhead to navigate the complex geometry of the shredder blades, adjusting its trajectory in real-time based on feedback. Material ratio optimization algorithms calculate the exact blend of metal powders needed to match the base blade's properties while providing enhanced wear resistance.

These algorithms learn over time, creating a digital twin of the blade set. This allows them to predict how wear will progress and to plan pre-emptive repair strategies, further optimizing the maintenance cycle and material usage.

Multi-Sensor Data Fusion Technology

Decision-making is not based on a single data point. Multi-sensor fusion technology combines inputs from vibration, temperature, optical, and even acoustic emission sensors to form a comprehensive and accurate picture of blade health. This redundancy eliminates false positives and ensures that repair actions are only taken when truly necessary.

The data fusion engine correlates information from these disparate sources, cross-validating readings to confirm that a detected anomaly is indeed wear-related and not an artifact of a changing feed material or other operational variable. This results in highly reliable and confident decision-making.

Key Repair Materials and Process Innovations

The success of an online repair is contingent on the materials used. These materials must not only possess superior wear resistance but also be compatible with the online application process, bonding securely to the existing blade substrate under less-than-ideal conditions. Innovations in material science have been pivotal in enabling this technology.

Similarly, the processes themselves have been refined from other industries, such as aerospace repair, and adapted for the harsh environment of an industrial shredder. The focus is on techniques that minimize heat input, ensure consistent quality, and can be automated for precision and repeatability.

High-Performance Wear-Resistant Alloys

Cobalt-based and nickel-based superalloys are frequently used for their excellent hot hardness and corrosion resistance, making them ideal for repairing blades in metal shredders where temperatures can spike. Tungsten carbide composite coatings are the gold standard for abrasion resistance, often applied in a matrix of a tougher material to prevent chipping.

The choice of alloy is critical and depends on the primary material being shredded. A blade in a e-waste shredder might be repaired with a tungsten-carbide-rich coating to crush circuit boards, while a blade for plastic might use a different alloy optimized for sharpness and resistance to adhesive wear.

Nano-Enhanced Coating Technology

Nano-technology has entered the realm of shredder maintenance. By incorporating nano-sized particles of ceramics like titanium nitride or boron carbide into the coating matrix, material scientists have been able to dramatically increase the hardness and fracture toughness of the applied layers.

These nano-enhanced coatings exhibit a finer microstructure, which leads to better cohesion within the coating and stronger adhesion to the blade substrate. This translates to a repair that is more resistant to cracking and spalling, significantly extending the service life of the refurbished blade compared to conventional coatings.

Low-Temperature Repair Processes

Traditional welding-based repair methods generate significant heat, which can distort the precision-machined blades and anneal (soften) the surrounding base material, creating a weak zone. Online repair processes like cold spraying or specialized low-heat-input laser cladding minimize this thermal effect.

By keeping the base material temperature below critical levels, often under 200°C, these processes preserve the original heat treatment and mechanical properties of the blade. This is essential for maintaining the structural integrity of the blade, which must withstand tremendous shear and impact forces during operation.

Modular Replacement Structure Design

Complementing online repair is a design philosophy focused on modularity. Some modern shredders are designed with blade cartridges or segmented cutting discs that can be quickly rotated or replaced as a unit without full disassembly. While not strictly "online repair," this design philosophy works in tandem with it.

A worn segment can be automatically indexed out of the cutting position and into a maintenance position for online refurbishment, while a fresh segment takes over the cutting duty. This design maximizes overall system uptime and simplifies the online repair process by presenting the worn component in an accessible manner.

Typical Industry Application Case Studies

The practical implementation of online repair technology varies across different shredding applications. Each sector presents unique challenges in terms of material abrasiveness, contamination, and operational demands. Examining specific cases illustrates the adaptability and value of this technology.

From the complex mix of an e-waste stream to the sheer bulk of municipal solid waste, online repair systems must be tailored to the specific wear patterns and operational constraints of each application. The following cases highlight its successful deployment.

Electronic Waste Processing (WEEE)

In e-waste shredding, blades face a combination of abrasive circuit boards, brittle plastics, and occasional metals. Online monitoring here often relies heavily on vibration and acoustic sensors to detect impacts with hard components like connectors and heat sinks. Repair typically involves the application of extremely hard, tungsten-carbide-based coatings via laser cladding to restore edges designed to fracture rather than deform materials.

The value proposition in this sector is high due to the critical need for data destruction and the high value of the recovered materials. Minimizing downtime ensures a continuous, secure processing line and maximizes the recovery of precious metals from the shredded output.

Construction and Demolition Waste (C&D Waste)

C&D waste is highly abrasive, containing sand, concrete, and gypsum that rapidly wear down blade edges. In this application, online repair systems are configured for frequent, small interventions to combat abrasive wear. Cold spray technology is particularly advantageous here for its ability to apply thick, abrasion-resistant coatings without thermal distortion.

The economic driver for online repair in C&D is the high volume and low margin of the material. The technology enables facilities to operate continuously, processing thousands of tons of material without stopping for blade changes, thereby significantly improving the bottom line.

RDF Fuel Preparation Systems (MSW Processing)

Processing Municipal Solid Waste (MSW) into Refuse-Derived Fuel (RDF) requires shredding a highly inconsistent and corrosive mix. Blades suffer from both abrasion and chemical attack from organic acids and moisture. Online systems for RDF shredders use corrosion-resistant nickel-chromium alloys for repair and may incorporate more frequent cleaning cycles to remove adherent material before applying new coatings.

Uptime is critical in MSW processing because the incoming waste stream is continuous. Online repair ensures that the primary shredder remains operational, preventing bottlenecks that can halt the entire waste reception and processing line.

Metal Recycling Lines (Urban Mining)

Metal shredders represent the most demanding application, subjecting blades to extreme impact and fatigue stresses. Here, online monitoring focuses on detecting micro-cracks and stress fractures using advanced ultrasonic or eddy-current sensors embedded near the blade roots. The repair process often involves a two-step approach: first using a tough material to rebuild the blade's core structure and then applying a hard-facing layer for wear resistance.

For large scrap metal shredders, where a single shutdown can cost tens of thousands of dollars per hour, the ability to perform repairs online is a game-changer, drastically improving annual throughput and asset utilization.

Implementation Key Points for Online Repair Systems

Successfully integrating an online repair system into an existing or new shredder requires careful planning and execution. It is not merely a bolt-on accessory but a core subsystem that must interface seamlessly with the machine's mechanical, hydraulic, and control systems. A methodical approach to implementation is crucial for achieving the desired return on investment.

Key considerations include the physical compatibility with the shredder, the training of personnel to interact with the new technology, and the management of the data it produces. Furthermore, the implementation must adhere to all relevant environmental and safety regulations.

Retrofitting and Compatibility Design

Retrofitting an online repair system to an existing shredder requires a detailed engineering assessment. This involves analyzing the cutting chamber geometry to identify access points for repair nozzles and sensors, ensuring structural integrity is not compromised, and verifying that the existing PLC control panel can communicate with the new repair system's controllers. For new shredders, these systems are now often designed as integrated options from the outset.

The goal is to create a seamless integration where the online repair system functions as a natural extension of the shredder's capabilities, without impeding its primary shredding function or creating new points of failure.

Operator Training and Certification Systems

Introducing advanced technology necessitates upskilling the workforce. Maintenance technicians must be trained not just to operate the new system, but to understand its principles, troubleshoot its components, and interpret its data outputs. This requires a structured training program covering mechatronics, material science basics, and software interface management.

Certification ensures that personnel are qualified to perform critical tasks, enhancing safety and system reliability. This shift often changes the maintenance role from a manual, hands-on job to a more analytical, technology-focused position.

Maintenance Data Management Platform

The online repair system generates vast amounts of valuable data on wear rates, material consumption, and machine health. This data is stored and analyzed in a centralized maintenance data platform. Using predictive analytics, this platform can forecast future maintenance needs, optimize inventory for repair materials, and provide detailed cost-benefit analyses of the online repair strategy.

This platform becomes a central knowledge base for the life of the equipment, allowing for continuous improvement of maintenance protocols and providing concrete data to justify the investment in the technology.

Environmental Compliance Requirements

Any industrial process must comply with environmental regulations. Online repair processes, particularly those involving powder spraying or laser cladding, must incorporate engineering controls to capture any overspray or fumes. This often involves integrating with the shredder's existing dust extraction system or adding a dedicated containment and filtration unit for the repair process.

Compliance ensures that the benefits of online repair are not offset by environmental violations or workplace safety issues, making the solution sustainable and responsible in the long term.

Technology Trends and Future Outlook

The field of online repair for industrial shredders is rapidly evolving, driven by broader trends in digitalization, automation, and sustainability. The technology is moving from being a reactive tool to a predictive and fully integrated component of the smart factory. The future points toward even greater autonomy and efficiency.

Emerging technologies like digital twins and AI-powered optimization are set to redefine what is possible, potentially leading to self-maintaining shredding systems that operate for years with minimal human intervention.

Application of Digital Twin Technology

A digital twin is a virtual, dynamic replica of the physical shredder and its blades. This model is fed real-time data from the online monitoring sensors, allowing it to mirror the wear and tear happening in the real world. Engineers can use the twin to simulate different repair strategies, predict outcomes, and optimize the timing and method of intervention without any risk to the actual equipment.

This technology enables true predictive maintenance, where repairs are conducted at the scientifically optimal time, maximizing component life and minimizing costs. It also allows for virtual commissioning of new online repair systems before they are physically installed.

Development of Biodegradable Lubricant Materials

While not a direct repair technology, the development of advanced biodegradable lubricants supports the overall goal of sustainability. These lubricants, often based on synthetic esters, reduce the environmental impact of any potential fluid leaks and simplify the cleanup process before applying online coatings. They are designed to provide superior lubrication performance while being non-toxic and readily biodegradable.

The use of such lubricants is part of a holistic approach to environmentally responsible shredding operations, complementing the efficiency gains of online repair.

5G and Industrial Internet Integration

The high-speed, low-latency connectivity of 5G networks is a key enabler for advanced online repair systems. It allows for the massive data transfer required for real-time high-resolution monitoring and enables remote expert support. A specialist located anywhere in the world can virtually oversee a complex repair procedure, providing guidance and ensuring it is performed correctly.

This integration facilitates the creation of centralized monitoring hubs where experts can oversee the health and maintenance of multiple shredders across different sites, optimizing expertise and resource allocation.

Servitization Transformation under the Circular Economy Model

The circular economy model is driving a business model shift known as servitization. Instead of selling shredders, manufacturers may sell "shredding as a service" or "uptime as a service." In this model, the manufacturer retains ownership of the equipment and is responsible for its maintenance and performance, using online repair technologies to guarantee a certain level of availability and output.

This aligns the manufacturer's incentives with the operator's: both benefit from maximizing uptime and efficiency. Online repair technology is the crucial technical enabler that makes such business models financially viable, as it allows the manufacturer to maintain the equipment at peak performance remotely and at a predictable cost.