The global fashion and textile industry generates millions of tons of waste annually, from production off-cuts to end-of-life garments. Traditional disposal methods like landfilling are unsustainable. Refuse-Derived Fuel (RDF) production offers a promising energy recovery solution, but transforming fibrous textile waste into high-quality fuel presents unique challenges. Specialized RDF shredders are engineered to tackle the tough, flexible, and tangled nature of textiles, providing a key technological pathway for waste-to-energy conversion and supporting a more circular economy.

These industrial shredders do not simply crush; they systematically shear and cut fibers to a precise size, creating a homogeneous material with optimal combustion properties. The process involves overcoming significant hurdles like fiber wrapping, screen clogging, and dealing with mixed materials. By converting problematic textile waste into a valuable energy resource, RDF shredders turn an environmental burden into a sustainable fuel alternative, reducing reliance on fossil fuels and minimizing landfill use.

Physical Characteristics of Textile Waste and Processing Bottlenecks

Textile waste possesses a set of physical properties that make it notoriously difficult to process with standard machinery. Unlike brittle materials that shatter, fibers are long, flexible, and incredibly strong in tension. Their high tensile strength allows them to resist the shearing forces applied by a shredder, often leading to wrapping and jamming. Furthermore, the increasing prevalence of blended fabrics, which combine natural and synthetic fibers, adds another layer of complexity to the shredding process.

These characteristics create significant bottlenecks in a waste processing line. A machine that effortlessly shreds wood or plastic can be brought to a complete standstill by a load of tangled textiles. The fibers can worm their way into bearings, wrap around shafts, and create dense mats that block conveyors and hoppers. Understanding these inherent properties is the first step in designing a shredding system that can effectively and reliably process textile waste for RDF production.

Analysis of the Anti-Shear Characteristics of High-Toughness Fibers

High-toughness synthetic fibers like nylon, polyester, and aramid are engineered for durability, which directly translates to resistance against shredding. Their molecular structure provides high tensile strength, meaning they can withstand significant pulling force before breaking. During shredding, these fibers often stretch and deform under the force of the blades rather than immediately shearing.

This stretching absorbs a tremendous amount of energy, increasing the power demand of the shredder and generating heat through friction. Instead of a clean cut, the blades can sometimes tear or rip the fiber, resulting in long, frayed strands that are more prone to tangling. This necessitates shredders with extremely high torque and specially hardened tungsten carbide cutters that can apply sustained, focused pressure to successfully shear these robust filaments without simply stretching them.

The Blocking Mechanism of Fiber Entanglement on Equipment Operation

Fiber entanglement is the primary cause of downtime in textile shredding operations. As fibers are drawn into the shredder, they do not enter individually but as a tangled mass. Within the cutting chamber, rotating shafts and blades can act like a spool, winding the fibers around themselves and the shaft axles. This process is self-reinforcing; as more material wraps, it captures additional incoming fibers.

This wrapped mass creates a thick, dense cushion that prevents new material from reaching the cutting blades. The machine motor continues to strain against this immovable object, leading to overloads and automatic shutdowns. In severe cases, the wrapping can dislodge seals or damage bearings, requiring extensive and costly manual intervention to clear the machinery, often with knives and cutting tools.

Screen Clogging Phenomenon Caused by Long Fibers

After the initial shredding stage, material often passes through a screen or grate that determines the maximum output particle size. Long, flexible fibers pose a unique problem here. While a brittle plastic fragment will either pass through a screen hole or be broken further, a fiber can lodge itself in the hole, threading through and creating a bridge.

As more fibers follow, a network forms over the screen surface, effectively creating a new barrier that prevents even appropriately sized particles from falling through. This drastically reduces throughput and efficiency. The problem exacerbates with smaller screen sizes required for high-quality RDF, as the holes are more susceptible to being plugged by even short lengths of fiber, necessitating robust and continuous screen cleaning systems.

The Rebound and Entanglement Problem of Elastic Fibers

Elastic fibers, such as those containing spandex or elastane, add a dynamic and challenging element to the shredding process. These fibers can store kinetic energy when stretched by the shredder blades. When the blade pressure is released or the fiber finally snaps, this stored energy is released, causing the fiber to rebound or "snap back" violently.

This rebound effect can fling material around the cutting chamber, reducing feeding efficiency and creating a safety hazard. More critically, the snapped elastic fibers retract into tangled knots that are even denser and more resistant to further processing. This behavior demands a shredder design that can contain this energy and control the material throughout the entire cutting cycle, preventing it from escaping the cutting zone before it is sufficiently reduced in size.

The Layered Fragmentation Challenge of Blended Materials

Modern textiles are rarely pure; they are complex composites of different fibers, binders, and coatings. A single item, like a piece of upholstery, may consist of a polyester face fabric, a cotton backing, a polyurethane foam layer, and a plastic film barrier. Each of these components has different physical properties and shredding requirements.

During shredding, these layers separate at different rates. The brittle foam may crumble instantly, while the polyester fabric resists. This asynchronous fragmentation makes it difficult to achieve a consistent output size and can lead to selective processing where one material is reduced while another remains in large sheets. Effective shredding of blends requires a mechanism that can grab, hold, and simultaneously shear all layers of material together, ensuring a homogeneous output product suitable for RDF production.

Technical Adaptability Design of RDF Shredders

To overcome the challenges posed by textile waste, standard shredders require significant design adaptations. Engineers have developed specialized RDF shredders with features specifically targeted at preventing wrapping, managing flow, and handling dust. These machines are not just stronger versions of standard shredders; they are intelligently designed systems that work with the material's properties rather than fighting against them.

The core of this adaptation lies in the cutting geometry, chamber design, and auxiliary systems. From the arrangement of the blades to the incorporation of automated cleaning devices, every aspect is optimized for fibrous feedstocks. This results in a machine that can maintain continuous operation, high throughput, and consistent product size, which are all critical for the economic viability of textile-to-RDF operations.

Optimized Arrangement of Dual-Shaft Shear Blade Sets

The heart of an effective textile shredder is its cutting system. Dual-shaft shredders with intermeshing, scissor-action blades are particularly effective. For textiles, the arrangement of these blades is crucial. They are often spaced closely together to provide a high number of cutting points per meter, preventing fibers from slipping through unchanged.

The blade hooks are designed to be aggressive enough to grab and pull in flexible materials but without deep pockets that could encourage wrapping. The rotational speed and torque profile are also tuned; slower speeds with higher torque provide the sustained force needed to shear fibers rather than just wounding them around the shafts. This optimized configuration ensures a positive feed and a clean, efficient cut through the toughest fabrics.

Dynamic Clearing Mechanism of Anti-Wrapping Comb Structures

A key innovation in textile shredders is the integration of stationary comb structures, also known as grooved or ribbed breakers. These combs are strategically positioned between the rotating shafts, very close to the path of the cutter tips. Their primary function is to prevent long fibers from following the rotation of the shaft and starting the wrapping process.

As fibers attempt to wrap, they are intercepted by the teeth of the comb. The relative motion between the rotating cutter and the stationary comb creates a shearing or tearing action that breaks the fiber's hold. Some advanced designs feature hydraulically powered combs that can oscillate or move in reverse periodically to actively clear any potential buildup before it becomes a problem, ensuring uninterrupted operation.

Flow Control in a Stepped Crushing Chamber

The design of the crushing chamber itself plays a vital role in managing textile waste. A stepped or tapered chamber design helps control the flow of material. The initial, larger volume of the hopper allows for the intake of bulky, tangled masses. As the material is drawn downward, the chamber narrows, gradually compacting and pre-conditioning the feedstock.

This controlled compression forces air out of the material, increases density, and presents the fibers to the cutting blades in a more organized and manageable state. It prevents the formation of air pockets and bridging, which can cause uneven feeding and sporadic machine operation. This steady, metered flow is essential for achieving a consistent output size and protecting the machine from shock loads.

The Modifying Effect of Low-Temperature Embrittlement Pretreatment

An innovative approach to handling tough, elastic fibers is cryogenic or low-temperature embrittlement. In this pretreatment process, textile waste is cooled using liquid nitrogen to temperatures below -100°C (-148°F). At these extreme temperatures, the polymers that make up synthetic fibers transition from a flexible, rubbery state to a hard, brittle, glass-like state.

Once embrittled, the materials lose their elasticity and ability to stretch and wrap. They become much easier to shatter and shred using conventional crushing equipment, significantly reducing the energy required and eliminating wrapping issues. While adding an extra step, this process can dramatically increase throughput and reduce wear on the primary secondary fine shredder for certain difficult-to-process materials.

Fibrous Dust Control via Negative Pressure Dust Extraction Systems

Shredding textiles generates a significant amount of fine fibrous dust, which poses health, safety, and operational risks. Inhalation of these particles can be hazardous to operators, and dust clouds can be explosive. To mitigate this, modern RDF shredders are equipped with integrated negative pressure dust extraction systems.

These systems use high-volume fans to create a vacuum within the cutting chamber and feeding hopper. This vacuum constantly draws airborne dust particles away from the process and into a collection system, such as a cyclone separator or baghouse filter. This not only protects the working environment but also prevents dust from accumulating on electrical components, sensors, and moving parts, where it could cause overheating, malfunction, or accelerated wear.

Crushed Particle Size Control and Fuel Quality Enhancement

The ultimate goal of shredding textile waste for RDF is to produce a fuel product with consistent and high-quality burning characteristics. The size and shape of the shredded particles directly influence the fuel's calorific value, density, and combustion efficiency. A well-controlled shredding process ensures the RDF meets the strict specifications required by cement kilns and power plants, making it a reliable and marketable commodity.

Achieving this quality involves more than just a single shredding step. It requires a holistic approach that includes multi-stage size reduction, efficient separation of contaminants, and careful management of moisture content. Each of these factors contributes to creating a homogeneous, energy-dense fuel that can effectively replace coal or other fossil fuels in industrial applications.

The Correlation Between Fiber Cut Length and RDF Calorific Value

The length of the shredded fibers has a direct impact on the bulk density and energy density of the resulting RDF fuel. Overly long fibers create a fluffy, low-density material that is difficult to transport and handle, and it may not flow or burn consistently in a boiler. Very short fibers, while dense, can be prone to creating dust.

Research and practical experience have shown an optimal cut length, typically between 20mm and 50mm, that provides a good balance. This size allows for efficient compaction into pellets or briquettes, achieving a bulk density of 0.5 - 0.7 tons per cubic meter. A higher density translates to more energy per shipment and stable, efficient combustion, directly enhancing the economic value and usability of the textile-derived RDF.

Particle Size Distribution Optimization via Multi-Stage Crushing Process

Single-pass shredding often results in a wide and uneven particle size distribution. To create a premium RDF, a multi-stage crushing process is employed. The first stage, often a coarse pre-shredder, breaks down large items into rough chunks. This material is then conveyed to a more refined secondary shredder, which reduces it to the target size.

This two-stage approach allows each machine to operate at its highest efficiency. The primary shredder handles the initial size reduction and contamination (like removing large buttons or zippers), while the secondary shredder focuses on creating a precise and consistent fluff. This process optimization leads to a homogenous output where over 90% of the material falls within the desired size range, ensuring predictable and efficient burning.

Impurity Separation System with Magnetic-Air Selection Linkage

Textile waste is rarely pure. It often contains non-combustible contaminants like metals (zippers, buttons, snaps) and inert materials (dirt, glass). These contaminants must be removed to prevent damage to combustion equipment and to improve the fuel's quality. This is achieved through a linked separation system following the shredding stages.

Powerful overband magnets remove ferrous metals from the conveyor stream. Subsequently, an air density separator uses controlled airflows to separate materials based on weight. Lighter textiles are carried over a barrier, while heavier non-combustibles (non-ferrous metals, stones) fall out. This linked purification process is critical for producing a clean RDF with high calorific value and low ash content.

Influence Curve of Moisture Content on Crushing Efficiency

Moisture content is a critical factor in shredding efficiency. The relationship is not linear. Excessively dry textiles can be dusty and static-prone, while wet or damp materials are tough and fibrous, causing them to wrap and clog the machine. An optimal moisture content range, typically between 10% and 20%, provides the best shredding performance.

Within this range, a small amount of moisture helps to suppress dust and adds enough weight to aid in the feeding process without making the material too elastic. Operations in humid climates or those processing wet waste may need to incorporate pre-drying steps, while those with very dry material might add a slight mist to condition the feed, ensuring the shredder operates at peak efficiency and produces a consistent product.

Screen Cleaning Strategy with Automatic Reverse Blowing Device

To combat the persistent issue of screen clogging by fibers, advanced shredders are equipped with automated screen cleaning systems. One highly effective method is an automatic reverse blowing device. This system consists of a series of nozzles strategically placed on the clean side of the screen.

At programmed intervals, or triggered by a detected pressure drop across the screen, a quick-acting valve releases a short, powerful burst of compressed air backwards through the screen holes. This blast dislodges any fibers that have begun to plug the openings, ejecting them back into the cutting chamber for further reduction. This automated process maintains optimal throughput without requiring manual intervention, representing a significant advancement in reliability for textile shredding.

Typical Application Scenarios and Process Adaptation

The principles of textile shredding are applied differently across various industry segments, each with its own unique waste stream characteristics. A one-size-fits-all approach does not work. The shredding parameters, pre- and post-processing steps, and even the machine configuration must be tailored to the specific type of textile waste being processed, whether it's clean garment off-cuts or contaminated industrial waste.

This tailored approach ensures maximum efficiency, output quality, and equipment longevity. By understanding the nuances of each application, operators can fine-tune their systems to extract the highest possible value from what was once considered worthless waste, supporting both economic and environmental sustainability goals.

Parameter Setting for Cutting Waste from Garment Factories

Garment factory waste typically consists of clean, consistent batches of woven or knitted fabrics, often of a single material type. This relative homogeneity allows for very precise parameter optimization. For pure cotton or polyester cuts, the shredder can be set for a finer output size, as there is less risk of elastic fibers causing issues.

The feed rate can be higher due to the clean and predictable nature of the material. Since this waste is dry and free of contaminants, the separation stages can be simpler, often requiring only a light air classification to remove any minimal dust generated. The resulting RDF is of very high quality, with a calorific value that can reach up to 18-20 MJ/kg, making it a sought-after fuel source.

Multi-Layer Structure Separation Technology for Used Carpets

Used carpets are one of the most complex textile waste streams. They are composite structures typically comprising a synthetic face fiber (nylon, polypropylene), a latex or PVC backing, and often a separate jute or synthetic secondary backing. Shredding a whole carpet without preparation leads to a mixed, low-quality output.

Advanced processing lines therefore incorporate a primary separation stage. This can be a mechanical process that slices the carpet into strips and then uses rollers to peel the layers apart, or a granulating system that exploits the different grindability of each layer. After this liberation step, the face fibers can be shredded separately into a high-quality RDF, while the backing materials are routed to other recovery or disposal pathways.

Density Separation Pre-treatment for Blended Fibers

Post-consumer textile waste is often a mixed blend of natural and synthetic fibers, which have different properties and values. To handle this, density separation pre-treatment is used. The shredded textile mix is fed into a hydrocyclone or air classifier, which separates materials based on their specific gravity.

Lighter materials like polypropylene and polyethylene will report to one output stream, while heavier materials like cotton and nylon will report to another. This allows for the creation of more homogeneous RDF fractions. For instance, a synthetic-rich fraction will have a higher calorific value, while a cellulose-rich fraction may be better suited for biochemical recycling, maximizing the overall resource recovery from the mixed waste.

Wear-Resistant Fragmentation Solution for Industrial Fabrics

Industrial textiles, such as conveyor belts, tarpaulins, and geotextiles, are designed for extreme abrasion resistance and durability. They are often reinforced with fiberglass or steel cords and coated with PVC or other polymers. Shredding these materials causes exceptionally rapid wear on standard cutting blades.

The solution involves using shredders equipped with extreme-wear components. This includes tungsten carbide cutters with specialized hard-facing, reinforced shredder shafts with oversized bearings, and perhaps a slower, more powerful cutting action to grind through the material rather than attempting to shear it quickly. This wear-resistant design is essential for maintaining operational uptime and controlling maintenance costs when processing these abrasive materials.

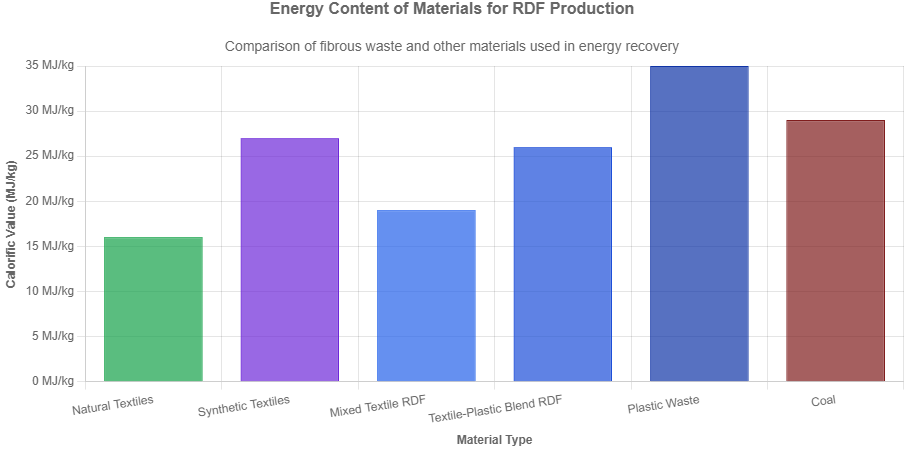

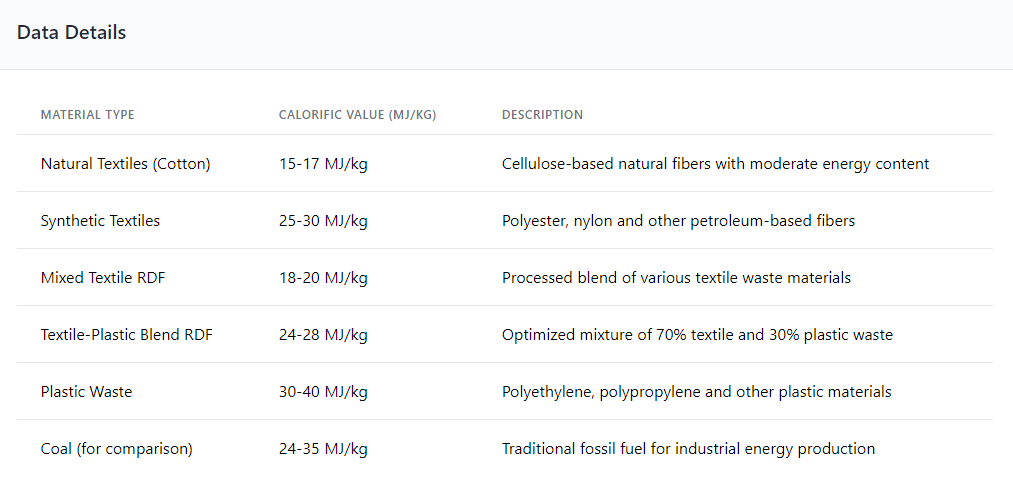

Blending Process of Fibrous RDF and Plastic Waste

To create an RDF with a consistent and high energy value, fibrous textile waste is often blended with other waste streams, particularly plastics. Plastics typically have a very high calorific value (30-40 MJ/kg) but can melt and create clinkers during combustion. Fibrous RDF has a lower calorific value but burns in a stable, aerated manner.

By blending them in a controlled ratio—often 30% plastic to 70% textile—operators can create an optimal fuel. The textile fraction provides structure and allows for air circulation during burning, while the plastic fraction boosts the overall energy content. The shredding process for this mix must be capable of handling both flexible fibers and brittle plastics, often requiring the robust twin-shaft shear system designed for mixed waste.

Equipment Maintenance and Operational Cost Optimization

Operating a shredder on abrasive and challenging materials like textiles incurs higher wear and tear and energy costs than standard applications. Therefore, a strong focus on predictive maintenance and operational efficiency is critical for economic sustainability. By implementing smart monitoring systems and optimized procedures, facilities can significantly reduce their cost per ton of processed material, making the entire RDF production process more viable.

This involves moving from a reactive maintenance model (fixing things when they break) to a predictive one (replacing parts just before they are expected to fail). It also requires a deep understanding of the relationship between machine settings, material input, and energy consumption to find the most efficient operating point.

Blade Wear Monitoring and Intelligent Replacement Cycles

Cutting blades are the highest-wear component in a textile shredder. Traditionally, blades were changed on a fixed time schedule or after a set tonnage, which could mean replacing them too early or too late. Intelligent monitoring systems now use a combination of data points to optimize this cycle.

Power consumption sensors can detect a gradual increase in energy use, indicating duller blades are working harder. Vibration analysis can identify imbalances caused by uneven wear. Some systems even use laser scanning to measure the actual profile of the blades in situ. By analyzing this data, the system can predict the optimal time for blade rotation or replacement, maximizing their service life and ensuring consistent shredding quality while avoiding unexpected failures.

Online Early Warning System Design for Fiber Entanglement

Preventing a full machine jam is far more efficient than clearing one. Online early warning systems are designed to detect the initial signs of wrapping before they escalate into a shutdown. These systems monitor the amperage draw of the main drive motors in real-time, looking for a specific signature: a slow, steady climb in current indicates that the shafts are beginning to accumulate wrapped material and are working harder to rotate.

When this signature is detected, the system can trigger an automatic response. This could be a momentary reversal of the shafts to unwind the material, an activation of the hydraulic comb cleaners, or simply an alarm to an operator for a manual inspection. This proactive approach prevents catastrophic jams and maintains continuous production flow.

Low-Temperature Adaptability Improvement of the Lubrication System

For facilities operating in cold climates, the lubrication system must function reliably to prevent damage during startup. Standard grease and oil can thicken significantly in low temperatures, failing to flow to bearings and gears when the machine is started, leading to metal-on-metal contact and accelerated wear.

Improving cold-weather adaptability involves switching to synthetic lubricants with a low pour point, ensuring they remain fluid at sub-zero temperatures. Additionally, heaters can be installed on lubrication reservoirs and critical bearing housings. These heaters, often thermostatically controlled, maintain the lubricants at an optimal viscosity, ensuring immediate and proper lubrication from the moment the shredder is started, regardless of the ambient temperature.

Mathematical Model Construction of Crushing Energy Consumption and Output

Understanding the relationship between operational parameters and energy use is key to cost optimization. Engineers build mathematical models that correlate variables like feed rate, material density, moisture content, and blade sharpness with power consumption and throughput.

These models, often developed through historical data analysis and machine learning, can identify the most efficient operating window. For example, the model might show that running the shredder at 85% of its maximum feed rate for a given material reduces energy consumption per ton by 15% compared to running at 100%, because it prevents overloading and inefficient straining. Operators can use these models to run the plant at its most cost-effective setpoints.

Modular Management Mode of Spare Parts Inventory

Downtime is the enemy of productivity. Waiting for a single critical spare part can halt operations for days. A modular management approach to spare parts inventory minimizes this risk. Instead of stocking every individual component, the focus is on stocking key modular sub-assemblies.

For instance, a facility might keep a complete pre-assembled rotor unit with blades, shafts, and bearings already mounted and balanced. If a failure occurs, the entire module can be swapped out in a matter of hours, getting the line back online quickly. The damaged module can then be refurbished offline at a slower pace and returned to stock as the new spare. This approach transforms maintenance from a prolonged repair job into a swift exchange, maximizing equipment availability.

Environmental Benefits and Resource Recovery Pathways

The conversion of textile waste to RDF via shredding is not just an operational process; it is a cornerstone of a circular economy model with profound environmental benefits. By diverting waste from landfills and creating a substitute for fossil fuels, this technology addresses two critical environmental issues simultaneously: waste management and climate change. The process also opens up pathways for recovering other valuable materials embedded in the waste stream.

A comprehensive life cycle assessment of this process typically shows a significant net reduction in greenhouse gas emissions compared to both landfilling and traditional fuel production. Furthermore, the ancillary benefits, such as dust management and metal recovery, contribute to a cleaner and more resource-efficient industrial ecosystem.

Carbon Reduction Effect of Fibrous RDF Replacing Fossil Fuels

The most significant environmental benefit of textile RDF is its ability to displace coal and natural gas in industrial boilers and cement kilns. While burning RDF does release carbon dioxide, this is considered biogenic carbon for natural fibers (like cotton) and part of a circular carbon loop for synthetics (derived from petroleum). It does not add new fossil carbon to the atmosphere.

Lifecycle analysis shows that for every ton of textile waste used as RDF, approximately 1.5 to 2 tons of CO2 emissions are avoided compared to coal combustion. This is because the energy-intensive mining and transportation of coal is eliminated, and the methane emissions from the alternative (landfilling the textile waste) are prevented. This creates a substantial carbon negative outcome, making it a powerful tool for industries to decarbonize their energy supply.

Collection and Reuse of Process Dust

The fibrous dust collected by the shredder's dust collection system is not merely a waste product to be disposed of. This fine material, primarily consisting of short cellulose and polymer fibers, still possesses a high calorific value. Rather than sending it to landfill, it can be compacted into pellets or briquettes.

These dust pellets can then be fed back into the RDF stream, ensuring a 100% yield from the incoming textile waste with zero process waste to landfill. This complete utilization maximizes the resource recovery from the original material and enhances the overall economics and environmental credentials of the operation.

Fiber Interception Technology in Wastewater Treatment Systems

Some textile shredding operations may involve wet processes or cleaning steps that generate wastewater containing microfibers. Preventing these fibers from entering the municipal water system is crucial. Industrial wastewater treatment systems for these plants employ specific fiber interception technology.

This typically involves a multi-stage process: screening to remove larger fibers, dissolved air flotation (DAF) to separate suspended solids, and finally, membrane filtration to capture even microscopic fibers. The captured fiber sludge is then dewatered and can be added back to the RDF production line. This closed-loop water management system ensures that the shredding process does not contribute to microplastic pollution in waterways.

Closed-Loop Design for Metal Recovery from Incineration Ash

Even after efficient pre-sorting, a small amount of metal (like zipper teeth and hooks) may remain in the RDF and end up in the ash after combustion. Instead of landfilling this ash, a closed-loop design involves its further processing. The ash is screened and passed under powerful magnets to recover ferrous metals.

More advanced systems may use eddy current separators to recover non-ferrous metals like aluminum from the ash. These recovered metals are then sent to smelters for recycling. This final recovery step ensures that the maximum value is extracted from the original waste stream and aligns with the principle of zero waste to landfill, completing the material's lifecycle in a truly circular manner.

Carbon Emission Accounting via Life Cycle Assessment (LCA)

To truly quantify the environmental benefits of textile RDF, a comprehensive Life Cycle Assessment (LCA) is conducted. This ISO-standardized methodology evaluates the total environmental impact of the process from "cradle to grave," including raw material collection (waste), transportation, shredding, and final combustion.

The LCA accounts for all emissions, including those from diesel fuel for trucks and electricity for the shredder. The results are then compared to the baseline scenario of landfilling the textiles and burning an equivalent amount of coal. Consistently, these studies show a significant net negative carbon footprint for the RDF pathway, often in the range of a 60-70% reduction in overall greenhouse gas emissions, providing solid, data-driven evidence for its environmental superiority.

Technological Innovation and Development Trends

The field of waste shredding is continuously evolving, driven by the need for higher efficiency, lower costs, and better environmental outcomes. The next generation of RDF shredders is being shaped by digitalization, advanced materials science, and novel processing techniques. These innovations promise to make textile waste recycling smarter, more autonomous, and even more effective.

Trends point towards systems that can self-optimize, predict their own maintenance needs, and handle an even wider range of materials with minimal human intervention. The integration of Industry 4.0 principles into shredding technology is transforming it from a brute-force process into a precise and intelligent manufacturing operation for recycled fuel.

Artificial Intelligence Blade Wear Prediction System

Moving beyond basic monitoring, AI-powered prediction systems represent the future of maintenance. These systems ingest vast amounts of operational data: power consumption, vibration spectra, acoustic emissions, feed rates, and even real-time imagery of the output material. Machine learning algorithms are trained on this data to recognize the subtle patterns that precede specific failure modes.

The AI can then not only predict the remaining useful life of a set of blades with high accuracy but also diagnose the root cause of wear, such as an imbalance in feed material or the presence of an unexpectedly abrasive contaminant. This allows for hyper-efficient planning of maintenance windows and spare parts logistics, virtually eliminating unplanned downtime and optimizing blade life to the absolute maximum.

Low-Temperature Plasma Pre-treatment Technology

Low-temperature plasma (LTP) is an emerging pre-treatment technology for challenging waste streams. In this process, the textile waste is briefly exposed to a plasma field—a highly energized cloud of ions and electrons—at near-room temperature. This treatment has a dual effect: it partially etches and weakens the surface of synthetic fibers, making them more brittle and easier to shred.

Perhaps more importantly, LTP is highly effective at sterilizing and deodorizing the waste, killing bacteria and breaking down volatile organic compounds (VOCs) that cause odors. This is particularly beneficial for processing post-consumer textile waste from uncertain sources, creating a cleaner and safer working environment and a more stable final RDF product.

Rapid Changeover Design of Modular Crushing Units

To maximize flexibility and uptime, manufacturers are developing shredders with quick-change modular cutting units. The entire cutting assembly—including shafts, bearings, blades, and housing—is designed as a self-contained cartridge. This cartridge can be disconnected and rolled out from the main machine frame using integrated rails.

A pre-assembled and pre-tested spare cartridge can then be rolled into place and connected, reducing changeover time from days to a few hours. This allows a single shredder to be quickly adapted for different materials (e.g., switching from textiles to plastics) or simply to undergo a full cutter change with minimal production loss, representing a significant leap in operational flexibility.

Application of Digital Twin Technology in Process Optimization

A digital twin is a virtual, real-time replica of the physical shredding system. It receives a continuous data feed from sensors on the actual machine, allowing it to mirror the machine's condition and performance exactly. Engineers and operators can use the digital twin to run simulations and test "what-if" scenarios without any risk to the physical equipment.

For example, they could simulate the effect of increasing the feed rate of a new type of carpet waste or test a new set of blade geometries. The digital twin predicts the outcome in terms of power draw, output size, and wear rates. This allows for perfect optimization of the process before any changes are made in the real world, reducing risk and accelerating innovation.

Special Treatment Solutions for Biodegradable Fibers

With the growing market for polylactic acid (PLA) and other biodegradable fibers, new shredding challenges are emerging. These materials can have different melting points and mechanical properties than conventional plastics. Furthermore, the goal for these fibers may not be energy recovery but rather composting or biochemical recycling back into monomers.

Specialized treatment solutions are being developed that involve gentler, low-hear shredding to preserve the polymer chains, followed by targeted biological or chemical processes. This requires a separate and carefully controlled shredding line to avoid contamination with conventional plastics, ensuring that these next-generation materials can be effectively recycled within their intended circular pathway.