Bulky waste items like furniture, mattresses, and construction debris present significant challenges for modern waste management systems. Their large volume, heterogeneous composition, and high transportation costs make traditional disposal methods inefficient and expensive. Heavy-duty RDF shredders have emerged as a technological solution that transforms these problematic materials into valuable refuse-derived fuel. This examination explores the engineering principles behind these robust machines and presents real-world applications demonstrating their effectiveness in converting bulky waste streams into consistent, high-calorific fuel while achieving volume reduction rates exceeding 90%.

Characteristics and Processing Challenges of Bulky Waste

Understanding the unique properties of bulky waste is essential for designing effective processing systems. These materials differ substantially from typical municipal solid waste in their physical dimensions, material composition, and handling requirements. The irregular nature of bulky items demands specialized equipment capable of withstanding extreme operating conditions while maintaining processing efficiency.

Low Density and Large Volume Leading to Transportation Inefficiencies

Bulky waste items occupy disproportionate space relative to their mass, creating significant logistical challenges for collection and transportation. A single mattress can consume up to 25 cubic feet of space in a collection vehicle while weighing only 50-100 pounds. This volumetric inefficiency results in increased transportation costs, with some studies indicating that bulky waste collection can be 3-5 times more expensive per ton than regular waste collection.

Volume reduction through shredding addresses this fundamental economic challenge. Heavy-duty shredders can compress bulky items to just 10-15% of their original volume, dramatically improving transportation efficiency. This reduction enables more material to be transported in fewer trips, lowering fuel consumption and reducing greenhouse gas emissions associated with waste transportation.

Highly Heterogeneous Composition: Complex Material Combinations

The material diversity within single bulky items presents unique processing challenges. A typical sofa contains wood framing, metal springs, polyurethane foam, synthetic fabrics, and various plastic components. Similarly, mattresses combine textiles, foam, metal springs, and wood framing in a single unit. This complexity requires shredders capable of handling multiple material types simultaneously without jamming or excessive wear.

The varying material properties within these items demand cutting systems that can efficiently process both hard components like metal and wood and soft materials like textiles and foam. This heterogeneity also creates opportunities for material recovery, as the shredding process liberates individual components for subsequent separation and recycling.

Contamination Risks: Hidden Metal and Construction Debris

Bulky waste often contains hidden contaminants that can damage conventional processing equipment. Construction debris mixed with furniture may contain nails, screws, concrete fragments, or stones. These foreign objects pose significant risks to shredding equipment, potentially causing catastrophic damage to cutting elements and drive systems if not properly managed.

Heavy-duty RDF shredders incorporate specialized design features to handle these contaminants. Reinforced cutting chambers, wear-resistant materials, and intelligent monitoring systems help detect and manage unexpected hard objects. Some advanced systems can automatically reverse or adjust speed when encountering materials that exceed specified hardness thresholds.

Traditional Processing Methods and Their Limitations

Conventional approaches to bulky waste management have proven increasingly inadequate. Landfilling these materials consumes valuable airspace and generates methane emissions from decomposing organic components. Manual disassembly is labor-intensive, expensive, and poses potential health risks to workers from sharp objects and accumulated dust or biological contaminants.

Mechanical processing with heavy-duty shredders offers a superior alternative by automating the size reduction process. This approach maintains consistent throughput while minimizing human exposure to hazardous conditions. The resulting material has greater utility as fuel or feedstock for recycling operations, creating economic value from what was previously considered a disposal problem.

Design Features and Impact Resistance of Heavy-Duty RDF Shredders

Heavy-duty RDF shredders incorporate specific engineering solutions to address the challenges posed by bulky waste. Their design prioritizes durability, reliability, and continuous operation under demanding conditions. These machines represent a significant evolution from standard shredding equipment, with enhancements throughout their structural and operational systems.

Reinforced Structural Design: Heavy-Duty Frames and Large-Diameter Shafts

The structural integrity of a heavy-duty shredder begins with its frame, typically constructed from high-strength steel plates with thicknesses exceeding 2 inches in critical stress areas. These frames undergo rigorous finite element analysis during design to identify and reinforce potential weak points. The result is a machine capable of absorbing the tremendous irregular impact forces generated when processing large, dense items.

Rotating shafts represent another critical structural component, with diameters often exceeding 20 inches in large industrial models. These shafts utilize high-strength alloy steels with ultimate tensile strengths approaching 150,000 psi. The combination of massive diameter and premium material ensures sufficient torsional stiffness to prevent deflection under maximum load conditions, maintaining precise cutter alignment throughout the operating life.

Power System Configuration: High-Torque Motors and Intelligent Drive Controls

Heavy-duty shredders employ powerful drive systems capable of delivering consistent torque under variable loading conditions. Electric motors ranging from 300 to 1,000 horsepower provide the necessary power, with some of the largest units exceeding 2,000 horsepower. These motors connect through heavy-duty gearboxes that multiply torque while reducing rotational speed to the optimal range of 15-30 RPM for most applications.

Advanced control systems monitor operational parameters in real-time, detecting conditions that may indicate potential problems. When sensors identify an overload situation, the system can automatically reverse rotation to clear jams or reduce speed to prevent damage. This intelligence extends equipment life while minimizing unplanned downtime, with some systems capable of distinguishing between temporary overloads and genuine obstructions requiring intervention.

Specialized Cutting Technology: Impact-Resistant Tool Holders and Replaceable Cutters

The cutting system represents the heart of any shredder, and heavy-duty models feature particularly robust designs. Tool holders manufactured from forged alloy steel provide secure mounting for individual cutting elements while absorbing the tremendous forces generated during operation. These holders employ sophisticated retention systems that prevent cutter movement under load while allowing relatively straightforward replacement when maintenance is required.

Cutting elements themselves utilize advanced materials like tungsten carbide inserts brazed onto tool steel bodies. This combination provides both extreme hardness at the cutting edge and toughness throughout the tool body. The geometric design of these cutters optimizes material grab while minimizing energy consumption, with some configurations reducing specific energy requirements by 15-20% compared to conventional designs.

Intelligent Monitoring and Protection Systems

Continuous monitoring systems track multiple parameters including vibration levels, bearing temperatures, motor current, and hydraulic pressure. Baseline readings established during commissioning allow the system to detect anomalies that may indicate developing problems. Vibration analysis can identify bearing wear or cutter damage before catastrophic failure occurs, enabling planned maintenance during scheduled downtime.

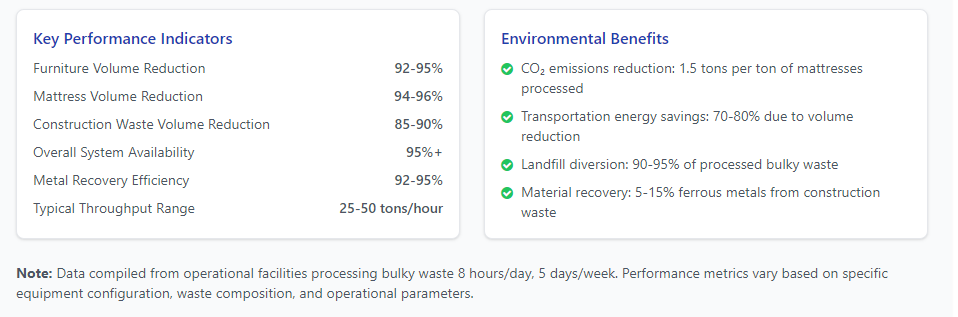

Thermal imaging systems monitor temperature distributions across critical components, detecting abnormal patterns that may indicate insufficient lubrication or developing mechanical issues. These advanced monitoring capabilities contribute to operational availability rates exceeding 95% in well-maintained systems, significantly higher than the 85-90% typically achieved by conventional shredding equipment.

Application Example: Large-Scale Processing of Furniture and Mattresses

The processing of furniture and mattresses represents a prime application for heavy-duty RDF shredders. These challenging materials benefit tremendously from the controlled reduction offered by modern shredding technology. Facilities specializing in these waste streams have developed sophisticated approaches that maximize material recovery while producing consistent fuel quality.

Feed Preparation and Pre-processing Requirements

Efficient processing begins with proper material handling before shredding. Incoming furniture and mattresses typically undergo initial inspection to remove obvious hazards such as propane tanks, chemical containers, or other dangerous items. Some facilities employ preliminary size reduction using guillotine-type cutters for exceptionally large items, though modern heavy-duty shredders can typically handle whole units without pre-processing.

Magnetic separation often occurs both before and after shredding to recover ferrous metals. Pre-shredder magnets remove large metal components that might damage the cutting system, while post-shredder magnets capture smaller ferrous materials liberated during the size reduction process. This sequential approach maximizes metal recovery while protecting equipment.

The Shredding Process: Transformation from Whole Items to Homogeneous Fragments

The shredding process itself demonstrates the remarkable capability of these machines. Whole sofas or mattresses enter the cutting chamber through a hydraulically powered ram that maintains consistent feed pressure. As items engage with the rotating cutters, they're progressively reduced to fragments typically measuring 2-4 inches in largest dimension.

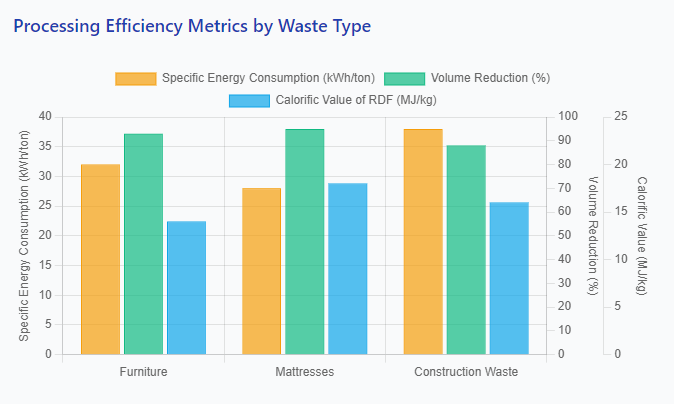

This transformation occurs through a combination of shear and tear forces rather than impact, resulting in a more controlled particle size distribution. The process typically consumes 25-40 kWh per ton depending on material composition, with denser items like wooden furniture requiring more energy than lighter upholstered pieces. Dust suppression systems control airborne particles throughout the operation.

Output Characteristics Analysis: Quality Assessment of RDF Produced

The resulting material exhibits consistent physical and chemical properties suitable for use as fuel. Particle size distribution analysis typically shows 85-90% of material passing through a 4-inch screen, with minimal fines generation. This controlled size distribution promotes efficient combustion in energy recovery facilities while maintaining good handling characteristics for transportation and storage.

Calorific testing of furniture-derived RDF typically shows values between 12-16 MJ/kg, while mattress-derived material often reaches 16-20 MJ/kg due to the high plastic and textile content. Contaminant levels, particularly chlorine and heavy metals, generally fall within acceptable ranges for most industrial energy recovery applications, though continuous monitoring ensures compliance with end-user specifications.

Economic and Environmental Benefit Assessment

The economic case for shredding bulky waste continues to strengthen as disposal costs increase. Landfill tipping fees for untreated bulky waste often exceed $100 per ton in many regions, while processing costs typically range from $30-50 per ton. The resulting RDF commands prices of $15-35 per ton depending on quality, creating a net processing cost of $15-50 per ton versus $100+ for direct landfilling.

Environmental benefits include significant reduction in greenhouse gas emissions compared to landfilling. The diversion of one ton of mattresses from landfill prevents approximately 1.5 tons of CO2 equivalent emissions according to life cycle assessment studies. Additional benefits include reduced transportation emissions due to volume reduction and recovery of metals for recycling.

Application Example: Resource Recovery from Construction and Demolition Waste

Construction and demolition waste represents another substantial stream that benefits from heavy-duty shredding technology. The composition of this material differs significantly from furniture and mattresses, requiring specific processing approaches to maximize resource recovery while producing quality fuel fractions.

Unique Compositional Characteristics of Construction Waste

Construction and demolition debris typically contains wood, drywall, plastics, metals, and various other materials in proportions that vary by project type. Wood often constitutes 20-30% of the total stream, representing a valuable feedstock for both recycling and energy recovery. The presence of contaminants like concrete, rocks, and dirt requires robust processing equipment capable of handling abrasive materials.

Size reduction liberates these different materials for subsequent separation while creating a more homogeneous fuel product. The irregular shapes and sizes of construction debris make efficient shredding particularly important for downstream processing. Heavy-duty shredders can accept material with maximum dimensions of 6 feet or more, reducing it to fragments of 4 inches or less in a single pass.

Process Design: Integration with Air Classification and Magnetic Separation

Effective processing of construction waste typically involves multiple stages of size reduction and separation. Primary shredding reduces overall particle size while liberating composite materials. Magnetic separation then removes ferrous metals, which can represent 5-15% of the total weight in construction debris. This recovered metal has significant scrap value while improving the quality of the remaining fraction.

Air classification systems separate lighter organic materials like wood and plastics from heavier inert materials like concrete and rocks. This separation is crucial for producing quality RDF, as mineral contaminants reduce calorific value and increase ash content. Well-designed systems can achieve purity levels exceeding 90% for the combustible fraction.

Output Applications: Suitability as RDF or Solid Recovered Fuel

The processed material from construction waste typically meets specifications for RDF or the higher-quality solid recovered fuel classification. Wood-dominated fractions exhibit calorific values of 14-18 MJ/kg with low chlorine and heavy metal content, making them suitable for various energy recovery applications. Some facilities further process this material to produce specification-grade fuel products for specific industrial users.

Cement kilns represent particularly suitable end users for construction wood-derived fuel, as the mineral content of the fuel ash can be incorporated into the clinker product. This synergy creates economic value while reducing the need for primary raw materials. Other applications include dedicated biomass power plants and industrial boilers seeking alternative fuel sources.

Operational Data: Throughput, Operating Costs, and Return on Investment

Typical processing facilities handling construction waste achieve throughput rates of 25-50 tons per hour depending on material characteristics and system configuration. Operating costs generally range from $12-25 per ton processed, including labor, maintenance, energy, and other variable expenses. These costs must be evaluated against the value of recovered materials and avoided disposal fees.

Return on investment calculations for construction waste processing facilities typically show payback periods of 3-7 years depending on local market conditions. Factors influencing profitability include tipping fees, energy prices, recovered material markets, and transportation costs. Government incentives for renewable energy production can significantly improve economics in some regions.

Integrated Solutions: From Single Machine to Complete System

While the heavy-duty shredder serves as the core of any bulky waste processing operation, its effectiveness depends on proper integration with auxiliary equipment. A systems approach ensures optimal performance while maximizing resource recovery and minimizing operating costs. Modern facilities incorporate sophisticated material handling, separation, and control systems that work in concert with the primary shredder.

Front-End Feed Systems: Apron Conveyors and Loader Integration

Consistent, controlled feeding is essential for optimizing shredder performance and longevity. Apron conveyors provide the most reliable method for feeding bulky items, offering the strength to handle heavy, irregular materials while withstanding the abrasive conditions of waste handling. These conveyors typically feature heavy-duty chains and flights capable of transporting items weighing several tons.

Loader operations must be coordinated with conveyor feeding to maintain optimal shredder loading. Either overfeeding or underfeeding reduces efficiency and increases wear. Modern systems often incorporate load-sensing technology that automatically adjusts feed rate based on shredder motor current, maintaining operation within the optimal power range while preventing overload conditions.

Back-End Sorting Systems: Magnetic, Air, and Screening Integration

Material exiting the shredder requires separation into various streams to maximize value recovery. Overband magnets effectively remove ferrous metals, with modern designs achieving recovery rates exceeding 95% of ferrous content. These systems typically employ continuous self-cleaning belts that discharge captured metal into separate collection containers.

Air classification systems separate materials based on density differences, directing lighter organic fractions toward fuel production while removing heavier inert materials. Screening systems further classify material by size, ensuring the final RDF product meets specification requirements. This multi-stage approach maximizes both material recovery and fuel quality.

Dust and Noise Control System Requirements

Dust generation represents a significant challenge in shredding operations, particularly with dry, brittle materials common in construction waste. Baghouse filtration systems typically achieve collection efficiencies exceeding 99%, controlling airborne particulate emissions while recovering potentially valuable material. Proper system design includes hooding at transfer points and adequate ventilation throughout the process flow.

Noise control requires a combination of source reduction and transmission path interruption. Enclosures around the shredder itself contain the highest noise levels, while acoustic barriers along property boundaries protect neighboring communities. Modern facilities typically achieve noise levels of 70 dB or less at property boundaries, complying with most regulatory requirements.

Automation Control Systems for Enhanced Operational Efficiency

Modern processing facilities employ sophisticated programmable logic controller systems that integrate all operational components. These systems monitor equipment status, track material flow, and optimize process parameters in real-time. Centralized control rooms allow operators to manage the entire facility while accessing detailed performance data for analysis and reporting.

Advanced systems incorporate predictive maintenance capabilities that analyze equipment vibration, temperature, and performance trends to identify potential problems before they cause unplanned downtime. This proactive approach increases overall equipment effectiveness while reducing maintenance costs through better planning and parts management.