Selecting an efficient RDF shredder is crucial for waste processing facilities aiming to minimize operational costs and environmental impact. The choice between high-torque/low-speed and low-torque/high-speed models directly influences energy usage, which can account for up to 40% of a plant's operating expenses. This analysis provides a detailed comparison of these two dominant shredder designs, examining their power consumption patterns under real-world conditions. By understanding the engineering principles behind each type, operators can make informed decisions that balance performance with sustainability.

Understanding Core Energy Consumption Metrics for RDF Shredders

Evaluating a shredder's energy efficiency requires looking beyond basic specifications like motor horsepower. Key performance indicators such as specific energy consumption (kWh per ton) and power factor provide a more accurate picture of operational costs. These metrics help distinguish between machines that may have similar rated power but vastly different efficiency profiles when processing heterogeneous waste streams.

Rated Power Versus Actual Operational Power

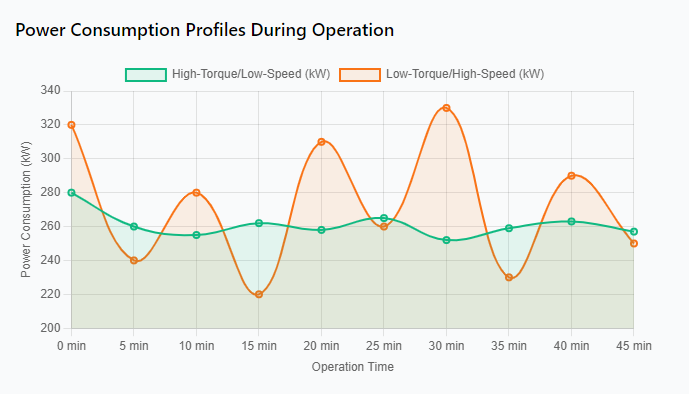

The nameplate power rating of a shredder indicates its maximum potential output under ideal laboratory conditions. However, actual power draw during operation fluctuates based on material density, composition, and feed rate. For instance, a shredder rated at 300 kW might consistently operate at 250 kW when processing standard municipal solid waste, but peak at 350 kW when encountering dense materials like wood or mattresses.

Monitoring the average power consumption over time reveals the true energy footprint. Data from industrial installations show that high-torque models often maintain a more stable power curve, typically within 10% of their average load, while high-speed models can exhibit fluctuations of up to 25% during operation. This stability contributes to better predictability in energy budgeting.

Specific Energy Consumption as a Key Performance Indicator

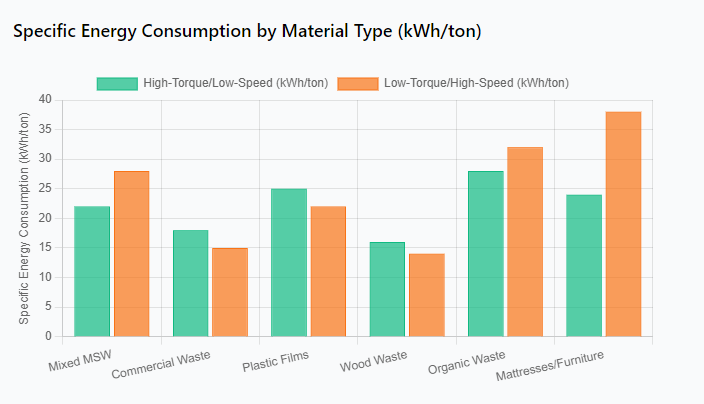

Specific energy consumption measures how much energy is required to process one ton of material, expressed in kWh per ton. This metric allows for direct comparison between different shredder technologies regardless of their size. Studies indicate that well-optimized RDF shredders achieve specific energy consumption values between 15 and 30 kWh per ton for typical waste streams.

The value varies significantly based on material characteristics. For example, shredding high-moisture organic waste might consume 25-35 kWh per ton due to the additional energy needed for cutting through fibrous material, while processing dry commercial waste might require only 10-20 kWh per ton. Regular measurement of this KPI helps identify maintenance needs and operational inefficiencies.

Power Factor and Its Impact on Electrical Efficiency

Power factor represents the ratio between real power (which performs work) and apparent power (which supplies the system). Shredders with low power factors draw more current from the electrical grid to deliver the same amount of useful work, resulting in higher electricity bills and potential penalties from utilities. Most industrial shredders operate at power factors between 0.75 and 0.90.

Induction motors commonly used in high-torque shredders typically benefit from power factor correction capacitors that can improve values to above 0.95. Modern high-speed shredders with variable frequency drives often maintain power factors above 0.98 throughout their operating range. Improving power factor from 0.75 to 0.95 can reduce apparent power demand by approximately 20%, leading to significant cost savings.

Startup Current and the Role of Soft Start Systems

Electric motors can draw up to six times their normal operating current during startup, creating stress on electrical infrastructure and potentially triggering protective devices. This inrush current is particularly pronounced in high-torque shredders that need to overcome initial inertia to begin rotating their massive cutting assemblies.

Soft start systems gradually ramp up voltage and current to the motor over several seconds, limiting startup current to typically 1.5-2 times the full load current. This not only protects electrical components but also reduces demand charges from utility providers. Some facilities report payback periods of less than two years for soft starter investments through reduced peak demand charges.

Design and Energy Consumption Characteristics of High-Torque/Low-Speed Shredders

High-torque, low-speed shredders operate on the principle of applying massive cutting forces at rotational speeds typically between 10 and 30 RPM. This design philosophy prioritizes tearing action over impact, making them particularly suitable for processing tough, heterogeneous materials commonly found in RDF streams. The fundamental engineering approach focuses on delivering consistent performance rather than maximum throughput.

The "Slow but Powerful" Working Principle and Advantages

These shredders utilize twin shafts with intermeshing cutters that grab material and shear it between the rotating blades and stationary bed knives. The low rotational speed allows for greater contact time with the material, enabling the cutters to work through tough items methodically. This results in a more predictable particle size distribution with less fine material generation compared to high-speed alternatives.

The tearing action produces less dust and airborne particles, reducing the energy requirements for dust collection systems. Operational data shows that dust generation can be 30-50% lower than with high-speed impact shredders, which translates to smaller and more efficient air pollution control systems. The consistent load also enables better energy recovery through regenerative drives in some advanced models.

Motor Selection: Asynchronous Motors and Hydraulic Drive Systems

High-torque shredders predominantly use heavy-duty asynchronous motors (induction motors) known for their robustness and ability to deliver high starting torque. These motors typically operate at efficiencies between 92% and 96% when properly sized and maintained. Some manufacturers offer permanent magnet synchronous motors that can achieve efficiencies up to 98% under optimal conditions.

Hydraulic drive systems represent an alternative approach, where a constant-speed electric motor powers hydraulic pumps that then drive the cutting shafts. While slightly less efficient in energy conversion (typically 80-85% overall efficiency), hydraulic systems offer exceptional control over torque and speed, with the ability to instantly reverse direction when jams occur. This can prevent damage that would require energy-intensive restart procedures.

Energy Consumption Curve Analysis: Stable Load Characteristics

The power consumption profile of high-torque shredders shows remarkable stability during operation. Once the machine reaches operating speed, the power draw remains relatively constant, with variations typically within ±10% of the average value. This predictability enables better energy management and reduces the need for oversizing electrical infrastructure to accommodate peak demands.

Data logging from multiple installations reveals that these shredders maintain their efficiency across varying feed rates better than high-speed models. When feed rate decreases by 50%, power consumption typically drops by only 30-40%, indicating that a significant portion of energy goes into maintaining the cutting action rather than solely processing material. This characteristic makes them suitable for applications with fluctuating input volumes.

Energy Efficiency Advantages with Bulky and Tangled Materials

When processing challenging items like furniture, carpets, or tangled plastic films, high-torque shredders demonstrate superior energy efficiency. Their gradual tearing action requires less peak power than the repeated impacts needed by high-speed machines to break apart these materials. For example, shredding a mattress might consume 15-20% less energy in a high-torque system compared to a high-speed equivalent.

The ability to process materials without extensive pre-processing contributes to overall system efficiency. Facilities using high-torque shredders often eliminate or reduce the need for pre-shredders, saving the energy that would otherwise be consumed by multiple size reduction stages. This streamlined approach can reduce total system energy consumption by up to 25% according to some case studies.

Design and Energy Consumption Characteristics of Low-Torque/High-Speed Shredders

Low-torque, high-speed shredders operate on the principle of applying numerous rapid impacts to fracture materials through kinetic energy. Rotational speeds typically range from 500 to 1,200 RPM, with some specialized models reaching even higher velocities. This design excels at processing homogeneous materials where consistent fragmentation is prioritized over handling extreme contaminants.

The "Fast and Frequent" Working Principle and Advantages

These machines typically employ hammer mills or high-speed cutting systems where swinging hammers or fixed blades strike materials with substantial velocity. The repeated impacts cause materials to fracture along their natural fault lines, making this approach particularly effective for brittle substances like glass, certain plastics, and dried organic matter. The high throughput capability makes them suitable for facilities processing large volumes of pre-sorted waste.

The rapid action produces a more uniform particle size distribution when processing consistent materials, which can improve downstream sorting efficiency. This uniformity can reduce energy consumption in subsequent processing stages by 10-15% according to some operational data. The smaller particle size also facilitates more efficient combustion in energy recovery systems.

Motor Selection: High-Speed Motor Efficiency Characteristics

High-speed shredders often utilize specially designed induction motors or permanent magnet synchronous motors optimized for operation at elevated rotational speeds. These motors typically achieve peak efficiencies of 94-97% when operating within their designed speed range. Many modern units incorporate variable frequency drives that allow the motor speed to be adjusted based on processing requirements.

Direct drive systems eliminate the energy losses associated with gearboxes, which typically account for 3-5% of total energy consumption in traditional designs. Some advanced models use high-frequency motors that operate at speeds up to 3,600 RPM without mechanical transmission systems, achieving overall drive efficiencies exceeding 96%. These designs particularly benefit applications requiring frequent speed adjustments.

Energy Consumption Curve Analysis: Fluctuating Power Demand

The power consumption profile of high-speed shredders shows significant variation during operation. Instantaneous power demand can spike to 150-200% of the average value when encountering dense materials, followed by rapid decreases during lighter loading periods. This fluctuating pattern requires electrical systems capable of handling brief but substantial peak demands.

Data analysis reveals that these shredders respond more directly to feed rate changes than their high-torque counterparts. A 50% reduction in feed rate typically results in a 40-50% reduction in power consumption, indicating a more linear relationship between material processed and energy consumed. This characteristic makes them well-suited for applications with consistent feed rates and material composition.

No-Load and Light-Load Energy Consumption Considerations

High-speed shredders consume significant energy even when processing minimal material due to the power required to maintain rotational momentum. No-load power consumption can represent 20-30% of the full-load consumption, compared to 10-15% for high-torque models. This makes operational discipline particularly important for energy efficiency.

Automated load-sensing systems that adjust motor speed based on material feed can reduce light-load energy consumption by 15-25%. These systems monitor current draw and automatically reduce speed when material flow decreases, then ramp back up as feeding resumes. The implementation of such controls has become standard in energy-conscious facilities processing variable waste streams.

Key Factors Determining Actual Energy Consumption: A Comparison

Beyond the fundamental design differences, several operational factors significantly influence the energy consumption of both shredder types. Understanding how these variables affect each technology helps operators optimize their processes for maximum efficiency. The sensitivity to these factors varies considerably between high-torque and high-speed systems.

Sensitivity to Material Composition and Feed Size Distribution

High-torque shredders demonstrate greater tolerance for variations in material size and composition. They can process large items and mixed waste streams with relatively stable energy consumption. In contrast, high-speed shredders show more pronounced energy spikes when encountering oversized or non-friable materials, sometimes requiring pre-processing to maintain efficiency.

The presence of abrasive materials like sand or glass affects both systems differently. High-torque shredders experience gradual wear that slowly increases energy consumption over time, while high-speed shredders may show immediate power increases as cutting efficiency decreases. Regular maintenance scheduling can mitigate these effects in both cases.

Influence of Knife Geometry, Material, and Wear Condition

Cutting tool condition profoundly impacts energy efficiency across all shredder types. Sharp knives with optimal geometry can reduce energy consumption by 15-25% compared to worn tools. The effect is more immediate in high-speed systems where cutting efficiency directly correlates with impact effectiveness.

Advanced materials like tungsten carbide significantly extend maintenance intervals while maintaining cutting efficiency. Some facilities report energy savings of 8-12% after upgrading to premium cutting tools, with payback periods of less than one year in high-throughput operations. The investment in superior tooling often represents the most cost-effective energy efficiency improvement available.

The Amplifying Effect of Worn Knives on High-Speed Shredder Energy Use

As cutting edges dull in high-speed shredders, the energy required to achieve the same size reduction increases disproportionately. A 10% reduction in cutting sharpness can lead to a 15-20% increase in energy consumption due to the transition from cutting to crushing action. This makes regular inspection and maintenance particularly critical for energy efficiency.

Monitoring power consumption trends provides early indication of cutting tool wear. A gradual increase in specific energy consumption (kWh per ton) of more than 10% typically signals the need for knife maintenance or replacement. Implementing predictive maintenance based on energy monitoring can optimize tool life while minimizing energy waste.

Constraints of Screen Size and Output Particle Size Requirements

The size of discharge screens directly influences energy consumption in both shredder types. Smaller screen openings require more size reduction, increasing energy use by approximately 5-10% for each 25% reduction in opening size. High-speed shredders generally achieve finer particle sizes more efficiently, while high-torque models excel at intermediate sizes.

Balancing particle size requirements with energy consumption involves considering downstream processes. Over-grinding wastes energy while under-processing may necessitate re-handling. Lifecycle analysis often reveals optimal screen sizes that minimize total system energy use rather than focusing solely on the shredding stage.

Full Lifecycle Cost Analysis: Energy Consumption as One Component

While energy costs represent a significant operational expense, a comprehensive evaluation must consider the total cost of ownership over the equipment's lifespan. This includes initial investment, maintenance, downtime, and eventual replacement costs. Energy efficiency should be balanced against these other factors to determine the most economical solution.

Initial Investment Cost Comparison

High-torque, low-speed shredders typically command a 20-40% higher initial purchase price compared to similarly sized high-speed models. This premium reflects the heavier construction, larger components, and more sophisticated drive systems required to generate and withstand high torque loads. The investment must be justified through operational benefits.

High-speed shredders offer lower capital entry points but may require additional investments in feeding systems and pre-processing equipment to handle variable waste streams effectively. The total installed cost difference often narrows when considering these ancillary systems. Financing options and available incentives can further influence the economic analysis.

Maintenance Costs and Wear Part Lifecycle Differences

Maintenance regimens differ significantly between the two technologies. High-torque shredders typically require less frequent but more extensive maintenance interventions, with major overhauls occurring at 15,000-20,000 operating hours. High-speed models often need more frequent but simpler maintenance, particularly regarding cutting element replacement.

The cost of wear parts varies substantially. High-torque shredder cutting systems generally last 2-3 times longer than those in high-speed machines but cost 50-100% more to replace. The total maintenance cost per ton processed often favors high-torque designs in applications with abrasive materials, while high-speed models may prove more economical for cleaner waste streams.

Downtime Economics and Production Loss Calculations

Unplanned downtime represents a significant cost beyond direct repair expenses. High-torque shredders typically achieve availability rates of 92-96% in well-maintained operations, compared to 88-92% for high-speed models. The difference translates to 200-400 additional operating hours annually for high-torque systems in continuous operations.

The value of increased availability depends on the facility's operational model. For base-load waste processing facilities, each percentage point of availability can represent tens of thousands of dollars in annual revenue. The economic impact of downtime often exceeds the difference in energy costs between technologies.

Comprehensive Efficiency Model: Calculating Payback Period

Developing a total cost of ownership model requires integrating all cost components over the expected equipment life, typically 10-15 years. The model should factor in energy costs, maintenance expenses, downtime values, and residual equipment worth. Sensitivity analysis helps understand how changes in key variables affect the economic outcome.

Payback periods for energy efficiency investments typically range from 2-5 years in waste processing applications. High-torque shredders often show favorable economics in operations exceeding 4,000 hours annually, while high-speed models may be more appropriate for seasonal or intermittent use. The specific electricity rate structure significantly influences these calculations.

Selecting the Most Energy-Efficient Solution for Your RDF Project

Choosing between high-torque and high-speed shredder technologies requires a systematic evaluation of project-specific parameters. There is no universally superior option—the optimal choice depends on the unique characteristics of the waste stream, operational requirements, and economic constraints. A methodical selection process ensures the best alignment between technology and application.

Assessing Your RDF Feedstock Characteristics: The Essential First Step

Comprehensive waste characterization forms the foundation of technology selection. This involves analyzing material composition, particle size distribution, moisture content, and contaminant levels. Seasonal variations should be considered, as waste characteristics often change throughout the year. Historical data from similar facilities provides valuable benchmarks.

Laboratory analysis of representative samples determines critical parameters like calorific value, ash content, and chlorine levels. These factors influence not only shredder selection but also downstream processing and energy recovery efficiency. Investing in thorough characterization prevents costly mismatches between equipment capabilities and actual operating conditions.

Optimal Application Scenarios for High-Torque/Low-Speed Models

High-torque shredders excel in applications involving mixed municipal solid waste with significant proportions of bulky items, textiles, and potential contaminants. Their robust construction and tearing action handle the unpredictable nature of these waste streams effectively. Facilities with limited pre-sorting capabilities often benefit most from this technology.

Operations prioritizing fuel quality consistency over maximum throughput typically achieve better results with high-torque systems. The controlled tearing action produces more uniform particle shapes with higher bulk density, improving combustion characteristics in energy recovery systems. This can translate to better energy recovery efficiency and higher tipping fees.

Optimal Application Scenarios for Low-Torque/High-Speed Models

High-speed shredders prove most effective when processing pre-sorted commercial and industrial waste streams with relatively consistent composition. Their rapid impact action efficiently processes materials like plastics, wood, and paper that have been separated from significant contaminants. Facilities with reliable material supply agreements often maximize value with this approach.

Applications requiring fine size reduction for subsequent processing stages benefit from the high-speed technology's ability to produce controlled particle size distributions. The higher throughput capacity makes these systems suitable for centralized processing facilities serving multiple collection points. The technology particularly suits operations with stable, high-volume feed streams.

Key Questions for Equipment Suppliers: A Procurement Checklist

Engaging with potential suppliers requires asking targeted questions that reveal true operational characteristics rather than relying solely on specification sheets. Inquiries should cover energy consumption under various loading conditions, maintenance requirements, and performance guarantees. References from similar installations provide valuable verification.

Requesting a demonstration using representative waste materials offers the most reliable assessment of suitability. Performance should be measured against key metrics like specific energy consumption, throughput rate, and particle size distribution. Contractual performance guarantees with penalty clauses protect against underperformance while ensuring supplier commitment to promised outcomes.