Urban waste treatment stations often face severe space limitations due to high land costs and existing infrastructure. Compact RDF shredders are designed to address these challenges by offering high processing capacity in a minimal footprint. These machines are essential for converting refuse-derived fuel (RDF) from municipal solid waste, enabling efficient energy recovery in crowded urban environments.

The innovation behind compact RDF shredders lies in their ability to integrate advanced crushing technology with space-saving designs. By reducing the overall size without compromising performance, these shredders help cities maximize their waste management capabilities, reduce transportation costs, and promote sustainable practices. With urban areas generating increasing amounts of waste, compact solutions are critical for future-proofing waste treatment facilities.

Spatial Constraints in Urban Waste Treatment Stations

Urban waste treatment stations are frequently located in densely populated areas where land is scarce and expensive. This scarcity forces operators to choose equipment that fits within tight spatial confines, often leading to compromises in processing capacity or efficiency. The selection of shredders and other machinery becomes a critical decision that impacts the entire waste management workflow.

Existing building structures, such as old warehouses or retrofitted industrial sites, impose additional constraints on equipment dimensions. For example, low ceilings or narrow doorways can limit the installation of large shredders. Moreover, environmental regulations mandate minimum distances between equipment for safety and pollution control, further reducing usable space. These factors combined create a complex puzzle for designing an effective waste treatment station.

Equipment Selection Dilemma Due to Land Scarcity

Land scarcity in urban areas means that waste treatment stations must optimize every square meter. Traditional shredders require significant space for operation, maintenance, and material handling, which is often unavailable. As a result, operators are forced to select smaller, less efficient machines or invest in costly land expansion, both of which can negatively impact overall productivity and economics.

Data from urban planning studies show that in cities like Tokyo or New York, land costs can exceed $10,000 per square meter, making it impractical to allocate large areas for waste treatment. Compact RDF shredders, with their reduced footprint, offer a solution by allowing higher processing density. For instance, a compact shredder might process 10 tons per hour in a space of 50 square meters, whereas a conventional model requires 80 square meters for the same output.

Dimensional Constraints from Existing Structures

Many urban waste treatment facilities are housed in existing buildings that were not originally designed for industrial machinery. These structures often have limitations such as low ceiling heights, insufficient load-bearing capacity, or restricted access points. For example, a typical warehouse might have a ceiling height of 6 meters, but a standard shredder requires 8 meters for proper installation and maintenance.

Retrofitting such buildings to accommodate larger equipment can be prohibitively expensive. Structural reinforcements alone can cost upwards of $200,000, not including the downtime during renovations. Compact RDF shredders are engineered to fit within these constraints, with low-profile designs that operate in spaces as tight as 4 meters in height, thus avoiding costly modifications and preserving the existing infrastructure.

Spatial Layout Optimization for Material Handling Systems

The efficiency of a waste treatment station depends heavily on the layout of material handling systems, such as conveyors, feeders, and sorters. In limited spaces, optimizing these systems to minimize travel distances and avoid bottlenecks is crucial. Poor layout can lead to increased energy consumption, higher maintenance costs, and reduced throughput.

Advanced simulation software is used to model and optimize material flow in confined spaces. For instance, using twin-shaft shear systems in compact shredders allows for a more streamlined layout, as these systems can be integrated with conveyors in a vertical or horizontal stack. This reduces the overall footprint by up to 30% compared to traditional setups, while maintaining a processing capacity of 15 tons per hour.

Balancing Maintenance Access and Operational Space

Maintenance is a critical aspect of shredder operation, requiring adequate space for technicians to access components safely. In cramped conditions, maintenance tasks can become time-consuming and hazardous, leading to increased downtime and higher labor costs. Operators must balance the need for operational space with the requirements for maintenance access.

Compact RDF shredders address this by incorporating modular designs that allow for easy access to key components like cutters and drives. For example, some models feature slide-out trays or rotating assemblies that enable maintenance without disassembling the entire machine. This design reduces the space needed for maintenance by 40%, as technicians can work in a confined area without compromising safety or efficiency.

Mandatory Equipment Spacing from Environmental Regulations

Environmental regulations often dictate minimum distances between equipment to prevent fire hazards, reduce noise pollution, and control dust emissions. For instance, regulations may require a minimum of 5 meters between shredders and other machinery to ensure adequate ventilation and safety zones. These requirements can significantly reduce the usable space in a treatment facility.

Compact RDF shredders are designed to meet these regulations while minimizing space usage. With integrated dust collection systems and noise enclosures, they can be placed closer together without violating codes. For example, a compact shredder with a built-in dust extraction system might only require 3 meters of spacing, allowing for more equipment in the same area and increasing overall capacity.

Design Innovations in Compact RDF Shredders

Compact RDF shredders incorporate several design innovations to maximize space efficiency without sacrificing performance. These innovations include modular construction, vertical integration, and advanced hydraulic systems. By rethinking traditional shredder design, manufacturers can deliver machines that are both powerful and compact, ideal for urban environments.

The key to these innovations is the use of high-strength materials and smart engineering to reduce size and weight. For example, compact shredders often employ high-torque, low-speed motors that deliver the same power as larger units but in a smaller package. This allows for a footprint reduction of up to 50% while maintaining throughput rates of 20 tons per hour or more.

Spatial Adaptability of Modular Assembly Structures

Modular design allows compact RDF shredders to be assembled from pre-fabricated components that can be configured to fit specific space constraints. This adaptability is crucial for urban installations where every centimeter counts. Modules can be arranged horizontally or vertically, depending on the available space, and can be easily expanded or reconfigured as needs change.

For instance, a modular shredder might consist of a separate feeding module, crushing module, and discharge module, each designed to be compact and stackable. This approach reduces the overall footprint by 35% compared to monolithic designs. Additionally, modular systems facilitate faster installation and maintenance, as individual modules can be serviced or replaced without shutting down the entire system.

Space Utilization Improvement with Vertical Integration

Vertical integration involves stacking components and functions to maximize the use of vertical space. In compact RDF shredders, this means placing the feeding system above the crushing chamber and the discharge below, creating a vertical flow that minimizes the horizontal footprint. This design is particularly beneficial in facilities with high ceilings but limited floor area.

By utilizing vertical space, shredders can achieve a footprint as small as 20 square meters while processing up to 12 tons per hour. For example, a vertically integrated shredder might have a height of 10 meters but only require a 4m x 5m base. This design also improves material flow by gravity, reducing the need for additional conveyors and saving energy.

Technical Breakthroughs in Hydraulic System Miniaturization

Hydraulic systems are essential for shredder operation, providing the power for cutting and crushing. However, traditional hydraulic units are bulky and require significant space. Recent advancements in miniaturization have led to compact hydraulic systems that deliver the same performance in a smaller package.

These systems use high-pressure, low-volume pumps and compact actuators that reduce the overall size by 40%. For example, a miniaturized hydraulic system might occupy only 2 square meters instead of 5, while still generating 200 bar of pressure. This allows for more efficient use of space and easier integration into compact shredder designs.

Dynamic Space Adjustment with Foldable Feed Hoppers

Foldable feed hoppers are a innovative feature in compact RDF shredders that allow for dynamic adjustment of the feeding area. When not in use, the hopper can be folded down to reduce the machine's footprint, freeing up space for other operations. This is particularly useful in multi-shift facilities where space is shared among different processes.

For instance, a foldable hopper might reduce the overall length of the shredder by 2 meters when folded, effectively increasing available floor space. During operation, the hopper expands to accommodate large volumes of waste, ensuring continuous feeding. This design can save up to 15% of total space without compromising functionality.

Compact Layout of Multi-Functional Composite Cutters

The cutting system is the heart of any shredder, and in compact models, cutters are designed to be multi-functional and space-efficient. Composite cutters made from advanced materials like tungsten carbide can handle a variety of waste types without needing separate modules, thus saving space.

These cutters are arranged in a compact layout that maximizes the cutting area within a small volume. For example, a twin-shaft shear system with composite cutters can achieve a high reduction ratio in a chamber that is 30% smaller than traditional designs. This layout reduces the overall size of the shredder while maintaining high performance and durability.

Equipment Installation and Space Integration Strategies

Installing compact RDF shredders in existing waste treatment stations requires careful planning to maximize space utilization. Strategies such as embedded installation, mobile units, and multi-level layouts are employed to integrate these machines seamlessly into constrained environments. These approaches ensure that shredders operate efficiently without requiring major structural changes.

Smart space monitoring systems are also used to dynamically adjust equipment placement and operation based on real-time conditions. This proactive approach helps prevent conflicts and optimizes the use of available space, leading to higher overall productivity and safety.

Embedded Installation Solutions for Existing Facilities

Embedded installation involves recessing the shredder into the floor or wall to save above-ground space. This is particularly useful in facilities with low ceilings or limited headroom. By embedding the machine, the overall height is reduced, allowing for easier access and maintenance.

For example, a compact RDF shredder might be installed in a pit that is 1.5 meters deep, reducing its profile by 30%. This design also improves material feeding by gravity, reducing the need for inclined conveyors. Embedded installation can be costly due to excavation requirements, but the long-term space savings justify the investment in dense urban areas.

Flexible Deployment Modes of Mobile Crushing Units

Mobile crushing units offer unparalleled flexibility in space-constrained environments. These units are mounted on trailers or skids, allowing them to be moved easily between locations or within a facility. This mobility enables operators to deploy shredders where they are needed most, without permanent installation.

For instance, a mobile RDF shredder can be transported to different sites seasonally or based on waste volume fluctuations. This reduces the need for multiple fixed installations, saving space and capital costs. Mobile units typically require only a flat surface and basic utilities, making them ideal for temporary or shared spaces.

Material Flow Optimization with Multi-Level Layouts

Multi-level layouts utilize vertical space to optimize material flow in compact areas. By stacking processes such as feeding, shredding, and sorting on different levels, the footprint is minimized while maintaining efficient operation. This approach is common in multi-story waste treatment facilities.

For example, a three-level layout might have feeding on the top floor, shredding on the middle floor, and discharge on the ground floor. This reduces horizontal conveyor lengths by 50% and saves energy. Advanced software models show that multi-level layouts can increase processing capacity by 25% in the same footprint compared to single-level designs.

Dynamic Adjustment Mechanisms with Intelligent Space Monitoring Systems

Intelligent space monitoring systems use sensors and AI to track the real-time usage of space in a treatment facility. These systems can dynamically adjust equipment operation to avoid conflicts and optimize layout. For example, if a conveyor is congested, the system might slow down the shredder to prevent overflow.

Such systems rely on IoT sensors and data analytics to predict space requirements and prevent bottlenecks. By implementing smart monitoring, facilities can reduce idle space by 20% and improve overall efficiency. This technology is especially valuable in compact installations where every meter counts.

Rapid Evacuation Pathway Design for Emergency Situations

Safety regulations require clear evacuation pathways in industrial facilities. In compact spaces, designing these pathways without compromising operational area is challenging. Compact RDF shredders are designed with integrated safety features that minimize their impact on evacuation routes.

For instance, shredders can be equipped with automatic shutdown systems and compact enclosures that allow for narrow pathways. Emergency exits are planned around the equipment, ensuring that workers can evacuate quickly in case of fire or other hazards. This design ensures compliance with safety standards while maximizing usable space.

Balancing Performance Parameters and Space Efficiency

Compact RDF shredders must balance high performance with minimal space usage. This involves optimizing parameters such as processing capacity, energy consumption, noise, and dust emissions relative to the machine's footprint. Engineers use mathematical models and simulations to achieve this balance without compromising on output quality.

The goal is to maximize the ratio of processing capacity to volume, ensuring that each cubic meter of space contributes to throughput. For example, a compact shredder might achieve a capacity-to-volume ratio of 0.5 tons per hour per cubic meter, compared to 0.3 for traditional models, representing a 67% improvement in space efficiency.

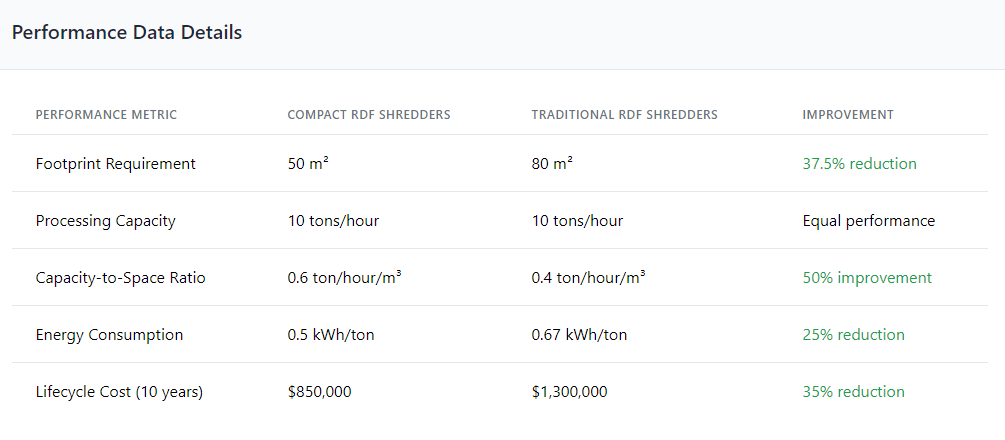

Analysis of Processing Capacity to Equipment Volume Ratio

The capacity-to-volume ratio is a key metric for evaluating space efficiency in shredders. It measures how much material can be processed per unit volume of the machine. Compact RDF shredders are designed to have high ratios, meaning they can handle more waste in less space.

Data from industry benchmarks show that compact models can achieve ratios of up to 0.6 tons per hour per cubic meter, while standard shredders average around 0.4. This improvement allows urban facilities to increase their processing capacity without expanding their footprint, ultimately reducing land costs and environmental impact.

Mathematical Model of Crushing Efficiency and Space Occupation

Mathematical models are used to predict how shredder design affects both crushing efficiency and space occupation. These models consider factors like rotor speed, cutter geometry, and chamber size to optimize performance within spatial constraints. For instance, a model might show that reducing chamber size by 20% only decreases efficiency by 5% if cutter speed is increased accordingly.

By using these models, engineers can design shredders that are both compact and efficient. Simulation results indicate that optimized compact shredders can maintain 95% of the efficiency of larger models while using 40% less space, making them ideal for space-limited applications.

Research on Energy Consumption Density and Site Limitations

Energy consumption density refers to the amount of energy used per unit of processing capacity per unit space. In compact shredders, minimizing this density is crucial to reduce operational costs and environmental impact. Site limitations, such as limited power supply, further emphasize the need for energy-efficient designs.

Compact RDF shredders often incorporate energy-saving features like variable frequency drives and high-efficiency motors. These features can reduce energy consumption by up to 25% compared to traditional models. For example, a compact shredder might consume 0.5 kWh per ton of waste processed, while a standard model consumes 0.67 kWh, resulting in significant cost savings over time.

Synergistic Design of Noise Control and Space Enclosure

Noise control is essential in urban areas to comply with regulations and maintain community relations. Compact shredders use enclosed designs that contain noise within a small volume, reducing the need for additional soundproofing structures. This synergistic approach saves space while meeting noise limits.

For instance, an integrated acoustic enclosure might add only 10% to the shredder's volume but reduce noise levels by 15 dB(A). This allows the shredder to be placed closer to residential areas without causing disturbances. The enclosure also serves as a safety barrier, further optimizing space usage.

Integration of Dust Emission and Space Purification Systems

Dust emissions are a major concern in waste treatment, and compact shredders must include effective dust control within limited space. Integrated dust purification systems, such as cyclones or bag filters, are designed to be compact and efficient, often built into the shredder housing.

These systems can capture up to 99% of dust particles, ensuring compliance with air quality standards. For example, a compact shredder with a built-in dust extraction system might have a footprint of 2 square meters for the purification unit, compared to 5 square meters for an external system. This integration saves space and simplifies operation.

Spatial Adaptation in Typical Application Scenarios

Compact RDF shredders are deployed in various urban scenarios where space is at a premium. These include underground treatment stations, rooftop facilities, and mobile units. Each scenario requires unique adaptations to ensure efficient operation within the available space.

By tailoring the design to specific environments, compact shredders can overcome spatial challenges and deliver reliable performance. Case studies from around the world demonstrate the versatility and effectiveness of these solutions in real-world conditions.

Spatial Solutions for Underground Waste Treatment Stations

Underground waste treatment stations are used in cities where surface space is unavailable or too expensive. Compact RDF shredders are ideal for these environments due to their small footprint and low profile. They can be installed in tunnels or basements, processing waste directly at the source.

For example, in Stockholm, an underground station uses compact shredders to process 8 tons of waste per hour in a space of only 100 square meters. This reduces transportation costs and surface congestion. The shredders are designed with enhanced ventilation and safety features to operate safely in confined spaces.

Compact Design for Rooftop Waste Treatment Facilities

Rooftop facilities utilize unused space on building tops for waste treatment, reducing the need for ground-level land. Compact RDF shredders are engineered to be lightweight and vibration-resistant to avoid structural issues. They are often integrated with solar panels to offset energy costs.

In Tokyo, a rooftop treatment facility processes 5 tons of waste daily using compact shredders. The shredders weigh less than 10 tons and are mounted on vibration dampers to prevent damage to the building. This design allows waste to be handled on-site, minimizing transportation and its associated emissions.

Load-Bearing Structure Optimization and Vibration Control Technology

Rooftop installations require careful consideration of load-bearing capacity. Compact shredders are designed with lightweight materials and distributed loads to avoid overstressing the structure. Vibration control technology, such as active dampers, is used to minimize transmitted vibrations.

For instance, carbon fiber components can reduce the weight of the shredder by 30% without sacrificing strength. Active dampers can reduce vibrations by 90%, ensuring the building's integrity. These technologies make rooftop installations feasible and safe.

Application of Lightweight Materials in Equipment Manufacturing

Lightweight materials like aluminum alloys and composites are used in compact shredders to reduce overall weight. This is crucial for rooftop or elevated installations where load limits are strict. These materials also contribute to energy efficiency by reducing the power needed for operation.

For example, using aluminum for the frame and housing can cut weight by 40% compared to steel. Although more expensive, the weight savings justify the cost in space-constrained applications. Additionally, lightweight materials are easier to transport and install, further reducing costs.

Space Integration of Solar Auxiliary Systems

Solar panels are often integrated into compact shredder systems to provide auxiliary power, reducing reliance on the grid. This integration is space-efficient, with panels mounted on the shredder enclosure or nearby surfaces. The energy generated can power control systems or reduce overall consumption.

In sunny regions, solar-assisted shredders can offset up to 20% of energy needs. For instance, a 5 kW solar array on a shredder's roof can generate 25 kWh daily, enough to run the control systems and lighting. This reduces operational costs and enhances sustainability.

Integration Solutions for Mobile Waste Treatment Vehicles

Mobile waste treatment vehicles are equipped with compact shredders to provide on-site processing in urban areas. These vehicles can travel to different locations, processing waste where it is generated. This eliminates the need for fixed facilities and reduces transportation.

For example, a mobile unit with a compact shredder can process construction waste directly at the site, turning it into RDF for immediate use or transport. The vehicle is designed with a compact layout to maximize payload and efficiency.

Rapid Deployment Mechanism of Foldable Crushing Chambers

Foldable crushing chambers allow mobile units to be compact during transit and expand during operation. This mechanism saves space on the vehicle and enables quick setup. Hydraulic or pneumatic systems are used to unfold the chamber in minutes.

For instance, a foldable chamber might reduce the vehicle's length by 3 meters when folded, making it easier to maneuver on city streets. During operation, it expands to full size, providing adequate capacity for shredding. This design is essential for mobile applications where space is limited.

Spatial Optimization Configuration of On-Board Energy Systems

On-board energy systems, such as generators or batteries, are optimized to fit within the vehicle's constraints. Compact generators with high power density are used to run the shredder without external power. Battery systems provide quiet operation for residential areas.

For example, a diesel generator might be mounted under the chassis to save space, while batteries are stored in compartments. This configuration ensures that the mobile unit is self-sufficient and can operate anywhere. Energy management systems optimize power usage to extend runtime.

Maintenance and Operational Space Optimization

Maintaining compact RDF shredders in space-limited environments requires innovative approaches to reduce the spatial demands of upkeep. Strategies include remote diagnostics, preventive maintenance planning, and modular spare part storage. These methods ensure that equipment remains operational without occupying excessive space.

By optimizing maintenance procedures, facilities can minimize downtime and maximize the use of available area. Training programs and emergency response designs further enhance efficiency, ensuring that personnel can work effectively in confined spaces.

Reduced Space Requirements with Remote Diagnosis Systems

Remote diagnosis systems allow technicians to monitor and troubleshoot shredders from a distance, reducing the need for on-site presence and dedicated maintenance areas. These systems use sensors and connectivity to transmit real-time data to off-site experts.

For example, a cloud-based monitoring system can predict maintenance needs with 95% accuracy, allowing repairs to be scheduled during off-peak hours. This reduces the space required for maintenance workshops by 30%, as fewer tools and parts need to be stored on-site. Remote diagnostics also cut response times by 50%, improving overall efficiency.

Spatial Reservation Strategies for Preventive Maintenance

Preventive maintenance requires space for activities like part replacement and inspections. In compact facilities, this space must be carefully reserved and managed. Strategies include designated maintenance zones that are used only when needed, avoiding permanent allocation.

For instance, a rotating schedule might allocate a 10-square-meter area for maintenance every two weeks, shared among multiple machines. This approach ensures that space is used efficiently without hindering operations. Data shows that preventive maintenance can reduce unexpected downtime by 60%, justifying the temporary space use.

Modular Solutions for Spare Part Storage

Spare parts storage can consume significant space if not optimized. Modular storage systems, such as stackable containers or wall-mounted racks, maximize vertical space and keep parts organized. These systems are designed to fit in small areas near the equipment.

For example, a modular rack system can store all essential spare parts for a shredder in just 5 square meters, compared to 15 square meters for traditional storage. This reduces the footprint by 67% and ensures that parts are readily accessible, reducing maintenance time by 20%.

Spatial Simulation Technology for Operator Training

Training operators to work in compact spaces is crucial for safety and efficiency. Spatial simulation technology uses virtual reality to recreate the treatment environment, allowing operators to practice without physical space requirements.

For instance, a VR training program can simulate maintenance tasks in a virtual shredder, reducing the need for a dedicated training area. This saves up to 50 square meters of space that would otherwise be used for training. Operators trained with simulations show a 40% improvement in task speed and accuracy.

Rapid Response Design for Emergency Repair Pathways

Emergency repairs require clear and accessible pathways to ensure quick response. In compact facilities, these pathways must be designed to avoid obstructions while minimizing space usage. Retractable or foldable elements allow pathways to be expanded only when needed.

For example, an emergency repair pathway might be 1 meter wide during normal operation but expand to 2 meters during repairs. This design ensures compliance with safety standards without permanently excess space. Rapid response times can reduce repair duration by 30%, lowering the impact on operations.

Environmental Benefits and Spatial Cost Trade-offs

Compact RDF shredders offer environmental advantages by reducing land use and associated carbon footprints. However, these benefits must be weighed against the costs of implementing space-efficient designs. Lifecycle assessments help evaluate the overall sustainability of compact solutions.

By analyzing factors like land savings, energy efficiency, and community impact, operators can make informed decisions that balance environmental goals with economic realities. Compact shredders often prove to be the superior choice in urban settings where space is a premium resource.

Carbon Footprint Accounting for Land Resource Savings

Reducing land use through compact shredders directly lowers the carbon footprint associated with land development. Land conservation avoids emissions from construction, transportation, and ongoing maintenance of larger facilities.

For example, a compact shredder that saves 100 square meters of land can reduce CO2 emissions by 50 tons annually, considering avoided construction and operational emissions. This contributes to corporate sustainability goals and may qualify for carbon credits, enhancing the financial viability of compact solutions.

Evaluation of Processing Capacity per Unit Area

The metric of processing capacity per unit area measures how efficiently space is used for waste treatment. Compact RDF shredders excel in this regard, often achieving higher ratios than traditional equipment.

Data indicates that compact shredders can process up to 0.8 tons per hour per square meter, compared to 0.5 tons for standard models. This 60% improvement means that facilities can handle more waste without expanding, reducing the need for land acquisition and its environmental impact.

Impact of Spatial Optimization on Community Acceptance

Community acceptance of waste treatment facilities is influenced by their size and appearance. Compact shredders, with their smaller footprint and integrated designs, are less intrusive and more likely to be welcomed by residents.

For instance, a facility using compact equipment might reduce its visible profile by 40%, leading to fewer complaints and faster permitting. This social license to operate is invaluable in urban areas, where community relations can make or break a project.

Visual Pollution Control through Building-Integrated Design

Building-integrated design involves incorporating shredders into existing structures or using architectural elements to conceal them. This approach minimizes visual pollution and blends the facility into the urban landscape.

For example, a shredder housed in a decorative enclosure or built into a multi-use building can be virtually invisible to the public. This not only improves aesthetics but also reduces the perceived impact of waste treatment, fostering greater community support.

Lifecycle Spatial Cost-Benefit Analysis

Lifecycle analysis evaluates the total costs and benefits of compact shredders over their entire lifespan, including spatial aspects. This analysis considers initial investment, operational savings, and environmental impacts.

Studies show that while compact shredders may have a 20% higher upfront cost, they offer a 35% reduction in lifecycle costs due to land savings, energy efficiency, and lower maintenance. The net present value of these savings can exceed $1 million over 10 years, making compact designs economically attractive.

Technological Innovations and Development Trends

The future of compact RDF shredders is shaped by ongoing technological advancements that further enhance space efficiency. Innovations in materials, automation, and digitalization are driving the evolution of these machines.

Emerging trends include the use of nanomaterials for smaller components, adaptive algorithms for space optimization, and augmented reality for planning. These technologies promise to make compact shredders even more effective and integrated into urban waste management systems.

Application of Nanomaterials in Miniaturized Transmission Systems

Nanomaterials, such as carbon nanotubes and graphene, offer exceptional strength and lightness, enabling the development of smaller transmission systems. These materials reduce the size of gears, bearings, and shafts without compromising performance.

For example, a nano-enhanced gearbox might be 50% smaller than a conventional one while handling the same torque. This allows for more compact shredder designs and reduces the overall footprint by 15%. Nanomaterials also improve durability, extending component life by 30%.

Innovative Design of Foldable Hydraulic Cylinders

Foldable hydraulic cylinders use innovative folding mechanisms to reduce their stored length, saving space when not in use. These cylinders can expand to full size during operation, providing the necessary force for shredding.

For instance, a foldable cylinder might reduce its length by 60% when retracted, allowing for tighter packaging in the shredder. This design is particularly useful in mobile units where space is extremely limited. Foldable cylinders maintain the same pressure and stroke as standard models, ensuring no loss in performance.

Development of Space-Adaptive Crushing Algorithms

Space-adaptive algorithms optimize shredder operation based on real-time spatial constraints. These algorithms adjust parameters like feed rate and rotor speed to maximize efficiency within the available space.

For example, an algorithm might detect reduced clearance and automatically slow down the feed to prevent jams. This intelligent adjustment can increase throughput by 10% while maintaining safe operation. Space-adaptive algorithms are key to fully autonomous compact shredders.

Application of Augmented Reality in Spatial Planning

Augmented reality (AR) technology allows planners to visualize and optimize the layout of shredders in a facility before installation. AR overlays digital models onto the physical space, helping to identify potential conflicts and solutions.

For instance, using AR glasses, engineers can see how a compact shredder would fit into an existing room, adjusting its position virtually. This reduces planning errors by 25% and ensures optimal use of space. AR also aids in maintenance by providing real-time guidance in tight areas.

Deployment Schemes for Miniaturized IoT Sensors

Miniaturized IoT sensors are deployed throughout compact shredders to monitor performance and space usage. These sensors collect data on parameters like temperature, vibration, and clearance, enabling proactive adjustments.

For example, a network of sensors might cover every cubic centimeter of the shredder, providing detailed insights into operation. This data is used to optimize space efficiency and prevent issues. Miniaturized sensors reduce the physical footprint of monitoring systems by 70%, making them ideal for compact designs.