Screen blockages are one of the most frequent causes of downtime in industrial shredding operations. When the screen at the bottom of the shredding chamber becomes clogged, it halts production, increases energy consumption, and can lead to significant equipment damage. This guide provides a systematic approach to understanding why blockages occur and offers proven, safe techniques to clear them efficiently. By implementing the strategies outlined here, operators can minimize interruptions and maintain a smooth, productive workflow, whether processing plastics, wood, or metals.

The Critical Role of the Screen and the Cascading Impact of Blockages

The screen, or screen basket, is a fundamental component located at the discharge end of a shredder's cutting chamber. It acts as a gatekeeper, ensuring only particles that have been reduced to the desired size can exit the machine. Its perforations or gaps dictate the final particle size of the shredded material. A blockage occurs when these openings become obstructed, preventing the free flow of material. This simple malfunction triggers a chain reaction that can paralyze an entire production line, leading to operational inefficiencies and increased costs.

The Screen's Role in Controlling Output Size and Throughput

The primary function of the screen is to control the granulometry of the output material. Particles are repeatedly cut and torn by the rotors until they are small enough to pass through the screen's openings. This process ensures a consistent product size, which is often critical for downstream processes like washing, sorting, or pelletizing. A properly functioning screen maintains a steady flow of material, allowing the shredder to operate at its designed capacity. The relationship between screen aperture and throughput is direct; smaller apertures produce finer material but can limit the maximum hourly output of the machine.

When the screen is clear, the shredder operates in a state of equilibrium. Material enters at a controlled rate, is size-reduced, and exits smoothly. This balance is essential for energy efficiency and equipment longevity. The machine's motor operates within its optimal amperage range, and mechanical components are not subjected to excessive stress.

Direct Symptoms of Blockage: Rising Current, Unusual Noise, and Reduced Output

Operators can identify a developing screen blockage by monitoring several key indicators. The most reliable is the motor's current draw, displayed on the control panel amperage meter. As the screen begins to clog, the cutting chamber fills with material that cannot exit. The rotors must work against this accumulated mass, requiring more torque and causing the motor to draw higher electrical current. A sustained current reading above the motor's rated amperage is a clear warning sign.

Auditory cues are also significant. The normal, rhythmic sound of cutting is replaced by a lower, straining rumble as the chamber fills. In severe cases, knocking or banging may occur as large pieces of material are tossed around but not evacuated. Simultaneously, the flow of material from the discharge conveyor will visibly diminish or stop entirely. Recognizing these symptoms early allows for intervention before a complete blockage occurs.

The Severe Consequences of Ignoring Blockages

Neglecting the early signs of a screen blockage can lead to catastrophic equipment failure. The most immediate risk is motor overload, which can cause winding burnout, requiring expensive repairs or replacement. The increased mechanical strain transmits through the entire drive train, potentially damaging bearings, couplings, and the gearbox. This stress shortens the lifespan of these critical components significantly.

Beyond the drive system, the cutting tools themselves suffer. Blades rubbing against a packed mass of material experience accelerated wear and can overheat, losing their temper and hardness. In extreme cases, the sheer torque can cause a shredder shaft to twist or even fracture. The cumulative cost of these failures, combined with production losses, far exceeds the time invested in preventive maintenance and prompt blockage clearing.

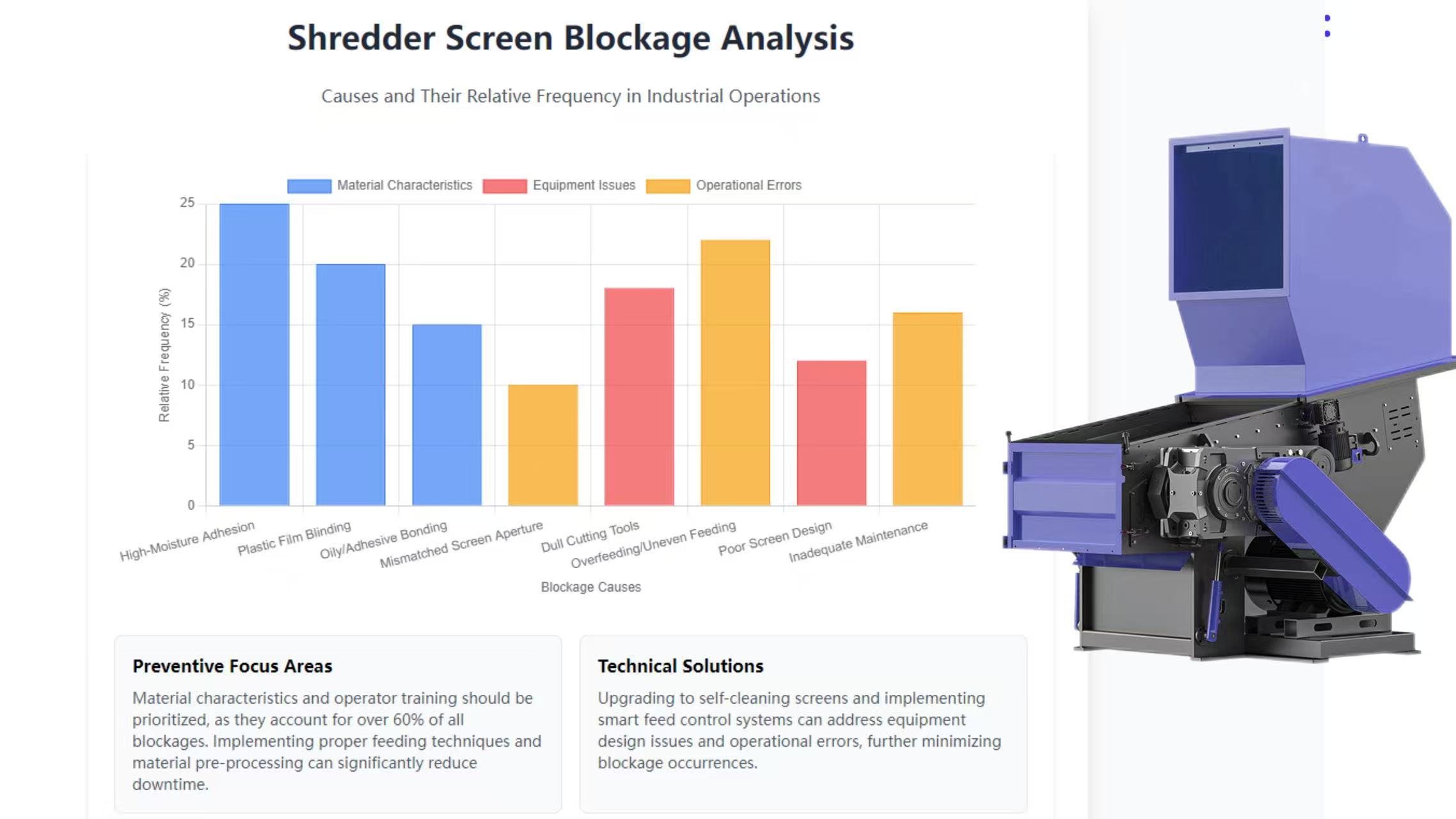

Material Characteristics as the Root Cause of Blockages

The physical and chemical properties of the feedstock are often the primary contributors to screen blockages. Different materials present unique challenges that must be understood to select the correct equipment and operating parameters. A shredder configuration that works perfectly for one material may be entirely unsuitable for another, leading to persistent clogging issues.

The Adhesion Problem of High-Moisture, High-Fiber Materials

Materials with high moisture content, such as green wood, agricultural waste, or wet paper, are prone to clogging. The water acts as a binder, causing fine particles to agglomerate into a paste-like substance that plasters itself over the screen openings. This paste effectively seals the screen, preventing any further material from passing through. The problem is exacerbated in materials with high fiber content, as the fibers interlock, creating a dense, matted layer.

Managing these materials often requires pre-processing, such as air drying or using a shredder designed with larger screen apertures and aggressive, hook-shaped tools that pull materials apart rather than just cutting them. The internal geometry of the cutting chamber is also crucial, as it must promote constant material turnover to prevent the formation of stagnant, wet pockets.

The "Blinding" Phenomenon with Soft, Ductile Plastics

Soft and ductile plastics, particularly films and flexible packaging, present a unique challenge known as screen blinding. Unlike brittle materials that shatter, these plastics deform and stretch during the shredding process. Instead of breaking into clean pieces, they can form long, stringy strands or thin sheets that lay flat over the screen surface. These sheets cover the holes, blocking the path for other particles.

This is a common issue when processing materials like LDPE film using a shredder designed for rigid objects. The solution often involves using a plastic film shredder with a specialized cutting geometry, such as scissors-like shear action between two shafts, which is more effective at slicing through ductile materials than a single-shaft crusher. Additionally, screen designs with slotted openings instead of round holes can sometimes mitigate this issue.

Bonding Clogs from Oily or Adhesive-Laden Materials

Feedstock contaminated with oils, greases, or adhesives can cause severe blockages. These substances act as powerful glues, cementing shredded particles together and onto the screen surface. For instance, metal turnings from machining operations are often coated with cutting fluids, and plastic containers may still have adhesive labels. The heat generated inside the shredding chamber can soften these adhesives, making the problem worse.

Processing such materials requires shredders equipped with easy-to-clean surfaces and sometimes specialized screen coatings that reduce adhesion. In severe cases, a pre-cleaning stage might be necessary to remove the contaminants before shredding. The choice of cutting tool geometry can also help; ripping and tearing actions may be more effective than fine cutting for breaking up bonded masses.

The Classic Error of Mismatched Material Size and Screen Aperture

A fundamental rule of shredding is that the infeed particle size must be compatible with the machine's capacity and the screen's aperture. Feeding excessively large items into a shredder equipped with a fine screen is a direct recipe for blockage. The machine may struggle to reduce the large pieces quickly enough, causing them to recirculate endlessly in the chamber without ever becoming small enough to exit.

This recirculation leads to a rapid buildup of material, overheating, and eventual shutdown. The correct approach is to use a two-stage shredding process: a primary shredder with a large screen or no screen at all to achieve a coarse reduction, followed by a secondary granulator with a finer screen to produce the final product size. This staged approach is far more efficient and reliable than attempting to achieve a fine grind in a single pass from large feedstock.

Equipment Configuration and Operational Errors Leading to Blockages

Beyond material characteristics, blockages frequently stem from equipment setup and operator practices. Even the most robust shredder will underperform if improperly configured or operated. Attention to detail in maintenance and procedure is essential for uninterrupted operation.

Dull Cutting Tools: The Root Cause of Incomplete Size Reduction

Sharp cutting tools are the heart of efficient shredding. Worn or dull blades do not cut cleanly; they crush, tear, and mangle the material. This inefficient action produces an excess of poorly defined, fibrous particles that are more likely to interlock and bridge across screen openings. A shredder with sharp blades produces clean, free-flowing fragments, while a shredder with dull blades generates a problematic fluff that readily causes blockages.

Establishing a regular blade inspection and sharpening schedule is not merely a maintenance task; it is a core operational requirement. The frequency of sharpening depends on the abrasiveness of the material being processed. Materials filled with sand, glass, or minerals will dull blades much faster than clean plastics. Monitoring motor amperage can serve as an indirect indicator of blade sharpness, as dull blades require more energy to achieve the same level of size reduction.

Overfeeding or Uneven Feeding: Exceeding Machine Capacity

Consistent, controlled feeding is critical for stable shredder operation. Overfeeding the machine, either by dumping a large volume at once or running the infeed conveyor too fast, overwhelms the cutting chamber. The rotors cannot process the material as quickly as it enters, leading to a backlog that packs against the screen. This packed mass restricts the movement of the rotors and blocks the discharge path.

Modern shredders often feature automated feeding systems linked to the main motor's power consumption. These systems adjust the feed rate to maintain a constant, optimal load. For manual feeding operations, training is essential. Operators must learn to feed material at a steady, manageable rate and to recognize the sound and sight of a machine operating under balanced conditions, stopping the feed immediately if signs of distress appear.

Screen Design Flaws: Low Open Area and Poor Hole Geometry

The design and quality of the screen mesh itself are critical factors. The term "open area" refers to the total percentage of the screen surface that consists of holes or slots. A screen with a low open area has less space for material to pass through, making it inherently more prone to clogging. Furthermore, the shape of the openings matters. Round holes can be更容易 blocked by near-round particles, while slotted openings often provide better flow characteristics for certain materials.

Thin or poorly manufactured screens can also deform under load, changing the critical gap between the rotor tips and the screen surface. This can lead to material being trapped rather than cut. Investing in high-quality, thick screens with a high open area and an appropriate hole pattern is a fundamental step in preventing chronic blockage issues. Some advanced screens feature anti-blinding technologies, such as rubber balls bouncing against the underside to dislodge stuck particles.

Rapid Unclogging Techniques: Safe and Effective Emergency Procedures

When a blockage occurs, a methodical and safe approach to clearing it is paramount. Rushing the process or using incorrect tools can lead to equipment damage or personal injury. The following procedures prioritize safety while ensuring the quickest possible return to operation.

Safety First: The Lockout-Tagout (LOTO) Procedure

Before any physical contact with the shredder is made, the machine must be made safe. The Lockout-Tagout procedure is a non-negotiable safety standard. This involves completely shutting down the shredder, disconnecting it from all power sources (electrical, hydraulic, pneumatic), and using a personal lock and tag to prevent accidental re-energization. The keys to the locks must be in the possession of the personnel working on the machine. This simple, rigorous procedure is the most effective way to prevent catastrophic accidents during maintenance and unclogging operations.

Verifying zero energy state is a critical final step before proceeding. This may involve attempting to start the machine from the local control station (after ensuring no one is in a dangerous position) to confirm it is truly inactive. Only after these steps are completed should any manual intervention begin.

Correct Use of the Jog Reverse Function

Many modern shredders are equipped with a jog or reverse function controlled by the Programmable Logic Controller (PLC). This feature allows the operator to rotate the main rotor slowly in the reverse direction for a short distance. The purpose is to break the mechanical lock created by the jammed material. By reversing the rotation, the tightly wedged mass can be loosened, often allowing it to fall away from the screen or reorient itself within the chamber.

This function should be used in short, controlled bursts. The operator should engage the reverse jog for a second or two, then return to the neutral position. This process can be repeated several times. It is crucial to avoid prolonged reverse operation, as it can damage the drive system. If the reverse jog does not dislodge the blockage after a few attempts, manual clearing will be necessary.

Manual Clearing Techniques Using Specialized Tools

If automated methods fail, manual clearing is required. Personnel must use long-handled tools specifically designed for this purpose, such as pry bars, hooks, or rakes. The goal is to break up the clogged material from a safe distance, typically through the discharge opening. Working from the discharge side is generally safer than reaching into the feed hopper.

The material should be broken apart carefully and pulled out in chunks. Forceful stabbing or prying against the screen or rotors should be avoided, as this can damage these precision components. For particularly stubborn blockages, it may be necessary to remove the screen from the machine for a thorough cleaning. This task should only be performed by trained technicians following the manufacturer's guidelines.

Long-Term Prevention Strategies: Optimizing Configuration and Building Habits

Reactive unclogging is a temporary solution. A sustainable approach involves implementing strategies that prevent blockages from occurring in the first place. This requires a combination of technical upgrades, disciplined maintenance, and skilled operation.

Optimal Screen Selection: Maximizing Open Area and Anti-Stick Coatings

The selection of the correct screen is a strategic decision. For materials prone to clogging, choosing a screen with the maximum possible open area is the first line of defense. Additionally, specialized screen coatings can be highly effective. Non-stick coatings, such as those based on polytetrafluoroethylene (PTFE), create a slippery surface that prevents adhesive materials from bonding. For abrasive applications, wear-resistant hard-facing coatings extend the screen's life and maintain the integrity of the openings.

The screen's thickness, or gauge, also impacts performance. A thicker screen is more rigid and less likely to deform under load, maintaining the precise clearance between the rotor tips and the screen surface. This consistent gap is essential for efficient cutting and preventing material from being smeared into the openings.

Establishing a Scientific Blade Inspection and Sharpening Schedule

Blade maintenance should be proactive, not reactive. A preventive schedule based on operating hours or the volume of material processed is essential. Regularly scheduled inspections allow for the detection of wear before it impacts performance. Sharpening should be performed by skilled technicians using equipment that preserves the original geometry and heat treatment of the blades.

Keeping a log of blade performance, including sharpening dates and the types of materials processed, helps refine the maintenance schedule. For operations processing highly abrasive materials, investing in premium-grade blades made from tungsten carbide or other advanced materials can significantly extend service intervals and improve overall shredding efficiency, reducing the risk of blockages caused by dull tools.

Operator Training for Consistent and Appropriate Feeding Practices

The human element is a critical factor in preventing blockages. Comprehensive operator training should extend beyond basic machine controls to include an understanding of the shredding process. Operators should be trained to "listen" to the machine—the sound of a freely operating shredder is distinct from one that is laboring under an excessive load.

They should also be taught to monitor the amperage gauge continuously, understanding the correlation between feed rate and motor load. The goal is to feed material at a consistent rate that keeps the motor operating within its ideal amperage range, typically around 80-90% of its full load rating. This practice maximizes throughput while providing a safety margin to handle occasional tough items without tripping the overload protection. Training should also cover the specific characteristics of different materials and how feed rates might need to be adjusted accordingly.

Innovative Solutions and Technological Upgrades for Clog-Free Production

For operations where blockages remain a persistent challenge despite optimization, technological advancements offer more permanent solutions. Upgrading to newer shredder designs or incorporating smart systems can virtually eliminate downtime related to screen clogging.

The Applicability and Limitations of Screenless Shredder Technology

Some shredder designs, particularly certain primary shredders for waste processing, operate without a screen. These machines rely solely on the geometry and spacing of the cutting tools to control the approximate size of the output material. The primary advantage is the complete elimination of screen-related blockages. The material exits by gravity as soon as it is small enough to fall through the grinding chamber.

The limitation of this technology is the lack of precise control over the final particle size. The output is generally less homogeneous compared to that from a screened granulator. Screenless shredders are ideal for coarse size reduction where a specific, narrow particle size distribution is not critical, such as in the initial breakdown of municipal solid waste or large plastic parts before further refining.

Smart Shredders: Automatic Feed Control Based on Current Feedback

The pinnacle of operational efficiency is achieved with intelligent shredding systems. These systems use sensors to monitor the main motor's current consumption in real-time. This data is fed to a PLC, which automatically adjusts the speed of the infeed conveyor or pusher ram. If the motor load increases towards a set limit, the feed rate is slowed down. If the load decreases, the feed rate is increased.

This closed-loop system maintains a constant, optimal load on the shredder, maximizing throughput while preventing overfeeding—the leading cause of blockages. It also protects the machine from damage caused by shock loads from overly large or dense objects. This automation not only prevents blockages but also reduces operator dependency and ensures consistent, optimal performance around the clock.

The Application of Rotary or Vibrating Screen Systems

An innovative solution to screen blinding is the use of self-cleaning screen systems. Instead of a static screen, a rotary screen drum can be employed. As the shredded material is processed, the drum rotates slowly. Any material that tends to stick is lifted by the rotation and then dropped off by gravity, or cleaned by internal scrapers, preventing a permanent buildup.

Alternatively, some systems incorporate vibratory mechanisms attached to the screen. These vibrations, which can be intermittent or continuous, shake loose any particles that are beginning to adhere to the screen surface. These technologies are particularly beneficial for wet, sticky, or fibrous materials that are notoriously difficult to handle with conventional static screens, offering a significant upgrade in reliability.