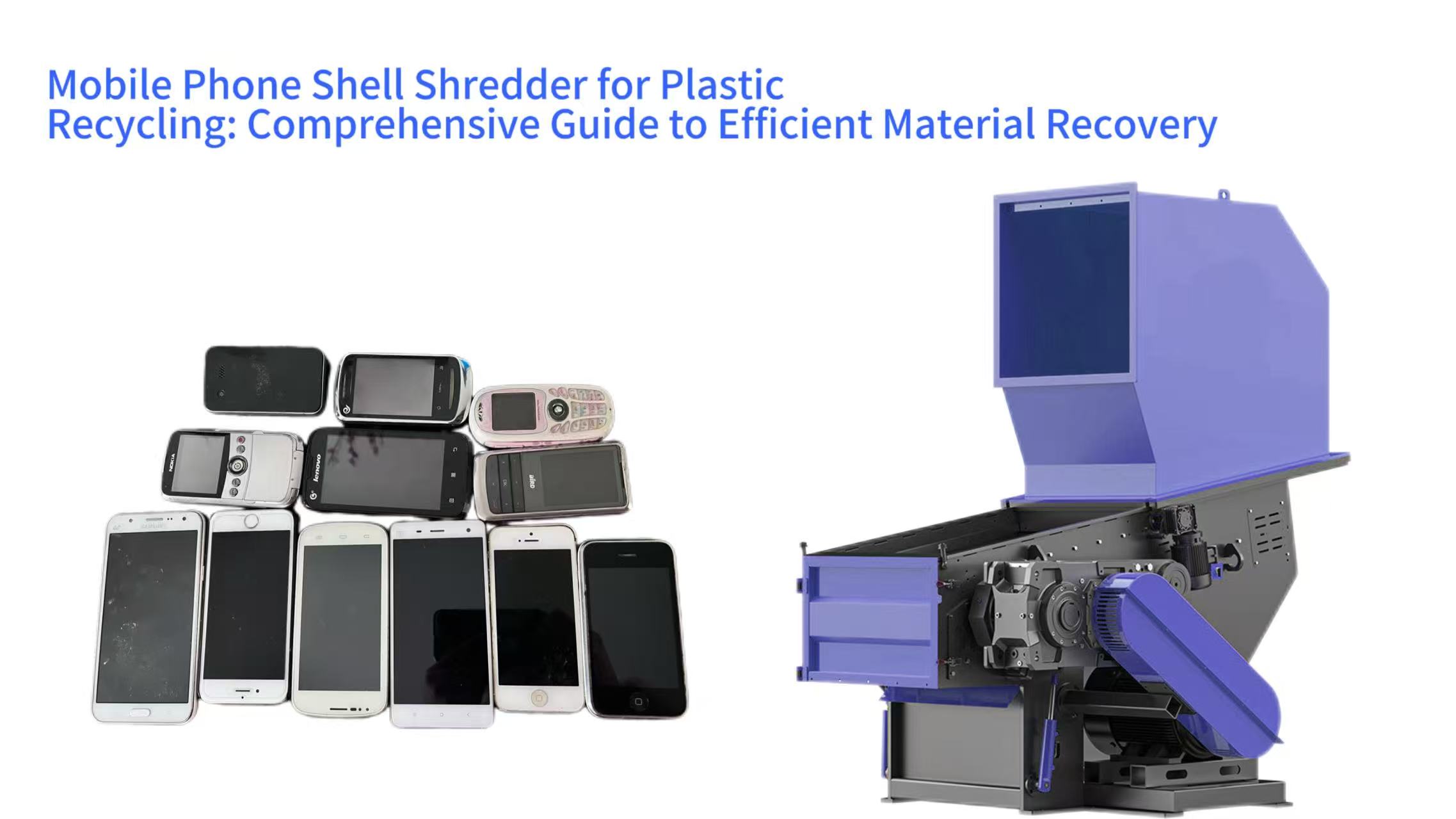

The specialized field of mobile phone shell recycling represents a critical segment within the broader electronic waste management industry, requiring tailored equipment solutions to address unique material characteristics and recovery challenges. Mobile phone shell shredders have emerged as purpose-built machines designed specifically to process the complex polymer compositions found in modern device casings. These industrial shredders employ advanced cutting technologies and material-specific processing parameters to transform discarded phone shells into uniform plastic flakes suitable for high-value recycling applications. The growing emphasis on circular economy principles within the electronics industry has accelerated the adoption of these specialized shredding systems worldwide.

Modern mobile phone shells incorporate sophisticated material combinations including polycarbonate, ABS plastics, thermoplastic polyurethane, and various composite materials that present distinct processing challenges. Standard industrial shredders often prove inadequate for these applications due to issues with material wrapping, inconsistent particle size distribution, and excessive wear from glass-filled compounds. The development of dedicated mobile phone shell shredders addresses these limitations through engineered cutting geometries, specialized wear protection systems, and integrated separation technologies that optimize the entire recycling workflow from initial size reduction to final material purification.

Mobile Phone Shell Plastic Recycling Process Overview

Collection & Sorting

Gather discarded shells and remove non-plastic components

Pre-Processing

Remove adhesives/coatings and sort by material type

Shredding

Process through specialized shredders to produce uniform flakes

Purification

Remove contaminants and separate plastic fractions

Recycling

Mechanical or chemical processing into reusable materials

Fundamental Principles of Mobile Phone Shell Shredding Technology

The mechanical processing of mobile phone shells through shredding technology operates on several interconnected principles that differentiate it from conventional plastic size reduction methods. These machines utilize precisely engineered cutting mechanisms that apply controlled shear and impact forces to fracture plastic components along their natural failure planes. The cutting geometry incorporates specific clearance angles and blade configurations that prevent material wrapping around rotating components, a common issue when processing the mixed polymer streams characteristic of electronic device housings. This fundamental approach ensures consistent particle size distribution while minimizing energy consumption per unit of processed material.

Material flow dynamics within the shredding chamber represent another critical principle governing machine performance and output quality. The internal architecture directs plastic components through a progressive size reduction pathway where initial coarse fragmentation precedes finer cutting actions. This staged approach prevents over-processing of softer materials while ensuring complete fracture of reinforced sections and metal inserts. The controlled residence time within the cutting zone allows for efficient liberation of different material fractions without excessive heat generation that can degrade polymer properties and compromise subsequent recycling value.

Cutting Mechanics and Blade Configuration

The cutting systems in mobile phone shell shredders employ sophisticated blade geometries specifically engineered for the mixed plastic streams encountered in electronic waste. These cutting elements typically feature differential hardness profiles with ultra-wear-resistant tips for penetrating reinforced sections and tougher core materials that withstand impact loading from metal contaminants. The cutting edges incorporate multi-stage profiles that initially grip irregularly shaped phone shells before applying primary and secondary cutting actions that progressively reduce particle size. This approach minimizes the power requirements while maximizing cutting efficiency across diverse material types.

Blade mounting systems provide precise angular adjustment capabilities that enable operators to optimize cutting clearances for different phone shell compositions. The rotational dynamics create a scissor-like action between rotating and stationary cutting elements that efficiently processes mixed material streams without requiring pre-sorting by plastic type. Advanced systems incorporate quick-change blade cartridges that reduce maintenance downtime when transitioning between different phone models or material compositions. The cutting mechanics have been refined through extensive testing to achieve optimal performance across the wide spectrum of plastics used in mobile device manufacturing.

Material-Specific Processing Parameters

The shredding of mobile phone shells requires careful adjustment of operational parameters to accommodate the diverse material properties present in modern electronic devices. Processing parameters including rotational speed, feed rate, and cutting clearances must be optimized for specific polymer types to achieve desired particle characteristics while minimizing energy consumption. Hard polycarbonate shells typically require higher cutting forces and slower rotational speeds to prevent excessive fine generation, while softer thermoplastic polyurethane components process more efficiently at increased throughput rates with modified cutting geometries.

Advanced shredding systems incorporate sensor technology that monitors operational parameters in real-time, automatically adjusting processing conditions to maintain optimal performance as material characteristics change. Acoustic monitoring detects changes in cutting efficiency that indicate blade wear or material composition variations, while power consumption tracking provides insights into processing effectiveness. These automated adjustment capabilities ensure consistent output quality despite the inherent variability of post-consumer electronic waste streams. The implementation of these intelligent systems has significantly improved the economic viability of mobile phone shell recycling operations.

Integrated Separation and Cleaning Systems

Modern mobile phone shell shredders often incorporate integrated separation systems that enhance the value of output materials by removing contaminants during the shredding process. Magnetic separation units efficiently extract ferrous metal components including screws, shields, and other internal hardware that frequently remain attached to phone shells. These systems typically employ overband magnets or magnetic head pulleys that continuously remove metal contaminants without interrupting the primary shredding operation. The early removal of metallic elements reduces wear on cutting components and improves the purity of output plastic flakes.

Air classification systems provide additional separation capabilities that exploit differences in material density between various plastic types and contaminants. These systems generate controlled air streams that selectively transport lighter plastic fractions while allowing heavier materials to continue through the primary shredding path. Some advanced configurations incorporate electrostatic separation stages that exploit differences in surface conductivity between plastic types, enabling preliminary material categorization immediately following the shredding process. The integration of these separation technologies creates a more streamlined recycling pathway that reduces the need for downstream processing steps.

Technical Specifications and Performance Metrics

The evaluation of mobile phone shell shredders involves multiple technical parameters that collectively determine machine suitability for specific recycling applications. Throughput capacity represents a primary consideration, with industrial-scale systems typically processing between 200-2,000 kilograms per hour depending on machine size and configuration. This metric must be considered in conjunction with power consumption, which generally ranges from 15-150 kW for most commercial systems. The relationship between throughput and energy usage provides important insights into operational efficiency and determines the economic viability of recycling operations.

Particle size distribution in the output material significantly influences downstream processing efficiency and eventual material value. High-quality shredders produce consistent flake sizes between 5-20 millimeters, with minimal fines generation that can complicate washing and separation processes. The standard deviation of particle size typically falls below 2 millimeters for well-engineered systems, indicating tight control over the shredding process. This consistency enables more efficient sorting in downstream optical separation systems and improves melt uniformity during subsequent extrusion processes. Monitoring these output characteristics provides valuable feedback for optimizing shredder performance across different input materials.

Throughput Capacity and Scalability

The throughput capacity of mobile phone shell shredders varies significantly based on machine design, power allocation, and specific application requirements. Smaller systems designed for laboratory testing or pilot-scale operations typically process 50-200 kilograms per hour, while full-scale industrial installations routinely handle 1,000-2,000 kilograms hourly. This capacity scaling follows predictable patterns where increased power allocation and larger cutting chambers enable higher processing rates, though the relationship is not strictly linear due to efficiency improvements in larger systems. Understanding these scaling principles helps operations select appropriately sized equipment for current needs while planning for future expansion.

System scalability extends beyond simple throughput considerations to encompass flexibility in processing different material types and adapting to changing input characteristics. Modular shredder designs allow for subsequent upgrades including additional cutting stages, enhanced separation systems, and improved material handling components. This scalability ensures that initial equipment investments remain viable as processing requirements evolve. The most successful recycling operations implement shredding systems with 20-30% excess capacity to accommodate normal fluctuations in feed material availability and composition while maintaining consistent output quality.

Power Consumption and Energy Efficiency

Power consumption profiles for mobile phone shell shredders reveal important relationships between machine design, operational parameters, and processing efficiency. Industrial-scale systems typically operate in the 30-75 kW range for standard applications, with specialized high-capacity configurations reaching 150 kW for particularly challenging material streams. The specific energy consumption, measured in kilowatt-hours per kilogram of processed material, provides a more meaningful efficiency metric that typically falls between 0.08-0.15 kWh/kg for well-optimized systems. This efficiency measurement enables direct comparison between different shredder technologies and configurations.

Energy management systems have become increasingly sophisticated in modern shredders, incorporating power factor correction, soft-start capabilities, and load-sensing hydraulic systems that minimize energy waste during operation. Variable frequency drives allow motors to operate at optimal speeds for specific material types, reducing energy consumption by 15-25% compared to fixed-speed systems. Heat recovery systems capture and repurpose thermal energy generated during the shredding process, further improving overall system efficiency. These energy optimization features have become standard in newer equipment designs as recycling operations seek to minimize operating costs and environmental impact.

Output Quality and Material Characteristics

The quality of shredded output from mobile phone shell processing directly influences subsequent recycling steps and ultimately determines the economic value of recovered materials. High-quality output features consistent particle size distribution with minimal variation, typically exhibiting 80-90% of material within a 5-millimeter size range. The physical characteristics of these flakes including aspect ratio, surface texture, and bulk density significantly impact behavior in downstream processes including washing, separation, and extrusion. Optimal shredding produces flakes with moderate aspect ratios between 2:1 and 4:1 that facilitate efficient washing and drying operations.

Material contamination levels represent another critical quality metric, with high-performance shredders achieving non-plastic contamination below 2% in output streams. This purity level enables direct processing in many recycling applications without additional cleaning steps. The degree of polymer mixing in output materials depends on shredder configuration and the effectiveness of integrated separation systems. Advanced systems can maintain material separation at 85-95% effectiveness when processing mixed phone shell streams, significantly enhancing the value of recovered plastics by reducing the need for complex separation in downstream operations.

Operational Considerations and Maintenance Requirements

The successful operation of mobile phone shell shredders requires careful attention to numerous factors that influence equipment performance, maintenance requirements, and operational costs. Proper feeding techniques ensure consistent material flow into the cutting chamber, preventing bridging and uneven loading that can accelerate wear patterns. Operational monitoring encompasses multiple parameters including motor current, bearing temperatures, and cutting chamber pressures that provide early indication of developing issues. Establishing comprehensive operational protocols significantly extends equipment service life while maintaining consistent output quality throughout production cycles.

Preventive maintenance programs represent a critical component of shredder operational management, incorporating scheduled inspections, component replacements, and system calibrations that prevent unplanned downtime. These programs typically include daily visual inspections, weekly measurement of critical wear components, and monthly comprehensive evaluations of all systems. Maintenance frequency correlates directly with operational intensity and material characteristics, with systems processing glass-filled plastics requiring more frequent attention than those handling unfilled polymers. Detailed maintenance records facilitate predictive analysis that optimizes replacement part scheduling and identifies design improvements for future equipment selections.

Routine Operational Procedures

Standard operational procedures for mobile phone shell shredders encompass systematic approaches to machine startup, operation, and shutdown that ensure optimal performance and equipment protection. Startup sequences typically include comprehensive system checks, gradual ramp-up to operating speed, and initial processing of lighter materials before transitioning to full-capacity operation. During normal operation, continuous monitoring of power consumption, noise levels, and vibration patterns provides early detection of developing issues that might compromise performance or equipment integrity. These monitoring practices enable proactive intervention before minor issues escalate into major failures.

Material handling procedures significantly influence shredder performance by ensuring consistent feed rates and appropriate material preparation. Pre-sorting of phone shells by major material categories enables parameter optimization that improves processing efficiency and output quality. Feeding systems should maintain consistent material flow without overloading the cutting chamber, as irregular feeding patterns cause uneven wear and inconsistent particle size distribution. Operational documentation should include detailed procedures for different material types, enabling consistent performance across shift changes and operator variations. These standardized approaches maximize equipment utilization while minimizing operational variances.

Cutting System Maintenance

The cutting systems in mobile phone shell shredders require meticulous maintenance to sustain performance levels and extend component service life. Regular inspection protocols should document cutting edge condition, clearance measurements, and wear patterns that indicate potential alignment issues. Blade sharpening intervals typically range from 200-800 operational hours depending on material processed, with glass-filled compounds necessitating more frequent attention. Proper sharpening techniques maintain original cutting geometries while removing minimal material, thus extending total component life. Cutting tip replacement follows predictable patterns based on material volume processed, enabling proactive inventory management of critical wear components.

Cutting chamber maintenance encompasses multiple components beyond the primary cutting elements, including wear liners, screen systems, and discharge arrangements. Liner replacement schedules vary based on material abrasiveness, with standard applications requiring attention every 1,000-2,000 operational hours. Screen systems demand regular inspection for wear and blockage, with cleaning protocols that prevent material buildup in critical areas. Comprehensive maintenance records facilitate analysis of wear patterns that inform design improvements and operational adjustments. The systematic approach to cutting system maintenance represents one of the most significant factors in determining long-term operational costs and equipment reliability.

Drive System and Bearing Maintenance

The drive systems in mobile phone shell shredders require specialized maintenance approaches that address the high-torque, variable-load conditions characteristic of size reduction applications. Regular vibration analysis provides early detection of bearing wear or misalignment issues before they progress to catastrophic failure. Lubrication schedules must account for operational intensity and environmental conditions, with advanced systems incorporating automatic lubrication that ensures consistent protection during extended operation. Gearbox maintenance includes regular oil analysis that detects developing issues through particulate monitoring and viscosity changes, enabling proactive intervention before major damage occurs.

Bearing maintenance represents a critical aspect of drive system care, with replacement intervals typically ranging from 4,000-8,000 operational hours depending on application severity. Proper installation techniques including precise clearance setting and appropriate mounting forces significantly extend bearing life. Monitoring bearing temperatures during operation provides valuable insights into lubrication effectiveness and load distribution. Drive coupling inspection should occur during regular maintenance intervals, with alignment checks ensuring optimal power transmission and vibration control. The comprehensive maintenance of drive systems prevents unexpected downtime and maintains processing efficiency throughout equipment service life.

Applications in Plastic Recycling Value Chain

Mobile phone shell shredders serve multiple functions within the comprehensive plastic recycling value chain, transforming mixed post-consumer materials into consistent feedstocks for various recycling processes. The initial size reduction provided by these machines represents the first critical step in most plastic recovery operations, creating uniform particles that facilitate subsequent separation and cleaning stages. The liberated plastic flakes undergo sophisticated sorting processes that separate materials by polymer type, color, and specific characteristics. This sorted material then proceeds to washing, further size reduction, and eventual extrusion into pellets suitable for manufacturing new products.

The quality of shredded material significantly influences downstream processing efficiency and final product characteristics. Well-processed flakes with consistent size distribution and minimal contamination enable more effective separation in sink-float systems that exploit density differences between polymer types. The surface characteristics of shredded particles impact washing efficiency, with optimal shredding creating sufficient surface area for contaminant removal without generating excessive fines that complicate water treatment. These relationships underscore the importance of shredder selection and operation in determining overall recycling process economics and output quality.

Mechanical Recycling Applications

Mechanical recycling represents the most common application for shredded mobile phone shell plastics, transforming processed materials into new products through conventional manufacturing techniques. The shredded flakes undergo extensive washing and separation to remove contaminants before being compounded with additives and converted into pellets. These recycled pellets find applications in various products including new electronic device housings, automotive components, and consumer goods. The quality requirements for these applications dictate specific shredding parameters that preserve polymer properties while achieving necessary contamination levels.

The economic viability of mechanical recycling depends heavily on shredding efficiency and the resulting material quality. High-purity shredded streams command significant price premiums compared to mixed materials, creating strong incentives for optimal shredder operation. Material losses during shredding typically range from 2-8% depending on machine configuration and operational practices, with advanced systems achieving the lower end of this range. The preservation of polymer molecular weight during shredding represents another critical factor, as excessive thermal or mechanical degradation reduces material value and limits application potential. These considerations make shredder selection and operation fundamental to successful mechanical recycling operations.

Chemical Recycling Pathways

Chemical recycling technologies provide alternative pathways for shredded mobile phone shell plastics that cannot be effectively processed through mechanical methods. These advanced processes depolymerize plastic materials into their constituent monomers or convert them into basic chemical feedstocks. Shredding represents a critical preparation step for these applications, creating uniform particle sizes that facilitate efficient heat transfer and chemical reaction. The specific size requirements vary by technology, with most chemical recycling processes optimal with particles between 3-10 millimeters.

The contamination tolerance of chemical recycling processes often exceeds that of mechanical methods, enabling more flexible sorting requirements before shredding. However, certain elements including halogens and specific fillers can interfere with chemical processes, necessitating careful control of input materials. Shredding systems dedicated to chemical recycling applications typically incorporate different operational parameters that prioritize throughput over precise particle size control. The growing importance of chemical recycling within circular economy initiatives has driven development of shredding systems specifically optimized for these emerging applications.

Environmental and Economic Considerations

The implementation of mobile phone shell shredders within recycling operations involves significant environmental and economic considerations that influence system design and operational practices. Environmental compliance requires careful management of several factors including noise emissions, dust generation, and potential chemical releases from processed materials. Modern shredding systems incorporate comprehensive containment and treatment technologies that address these concerns while maintaining operational efficiency. The economic analysis of shredding operations must consider capital investment, operating costs, maintenance requirements, and revenue from processed materials to determine overall viability.

Lifecycle assessment methodologies provide valuable insights into the environmental footprint of shredding operations, considering energy consumption, wear part production, and eventual equipment disposal. These analyses typically indicate that the environmental benefits of recovered plastics significantly outweigh the impacts of shredding operations, with net positive outcomes across most impact categories. The economic assessment reveals similar positive outcomes, with well-operated systems achieving payback periods of 18-36 months depending on scale and material values. Both environmental and economic analyses underscore the importance of proper system selection, operational practices, and maintenance protocols in maximizing positive outcomes.

Regulatory Compliance Requirements

Mobile phone shell shredding operations must comply with numerous regulatory requirements that vary by jurisdiction but typically address worker safety, environmental protection, and material handling practices. Noise regulations often limit operational sound levels to 85 decibels or lower at property boundaries, necessitating acoustic enclosures and vibration isolation systems. Air quality standards regulate particulate emissions from shredding operations, requiring sophisticated dust collection systems that capture and contain fine particles. These regulatory frameworks continue evolving as understanding of environmental and health impacts advances, requiring ongoing compliance monitoring and system adjustments.

Material handling regulations specifically address the processing of electronic waste, incorporating requirements for hazardous component removal, material tracking, and reporting. Many jurisdictions mandate specific documentation regarding material flows through recycling facilities, including detailed records of processing methods and output destinations. International standards including ISO 14001 provide frameworks for environmental management systems that help operations maintain compliance while improving overall environmental performance. The complexity of regulatory requirements makes compliance management a significant operational consideration that influences equipment selection, facility design, and daily operational practices.

Economic Analysis and Return Metrics

The economic analysis of mobile phone shell shredding operations encompasses multiple factors that collectively determine financial viability and investment attractiveness. Capital investment requirements range from $50,000 for basic systems to over $500,000 for comprehensive installations with integrated separation and material handling. Operating costs typically include energy consumption, wear part replacement, labor, and maintenance, totaling $15-40 per operating hour depending on system scale and material characteristics. These costs must be evaluated against potential revenue from processed materials, which varies significantly based on output quality and market conditions.

Return on investment calculations for shredding systems typically indicate payback periods between 18-36 months for well-managed operations processing consistent material streams. The sensitivity analysis reveals that material throughput and output value represent the most significant variables influencing financial returns, followed by maintenance costs and energy efficiency. Operations processing higher-value engineering plastics typically achieve shorter payback periods despite higher initial investment, while those handling mixed commodity plastics require careful cost management to maintain profitability. These economic considerations should inform equipment selection, operational practices, and business model development for recycling operations.

Future Developments and Technology Trends

The continuing evolution of mobile phone shell shredding technology reflects broader trends in the recycling industry including increased automation, improved energy efficiency, and enhanced material recovery. Development efforts focus on several key areas including cutting system design, operational intelligence, and integration with downstream processes. These advancements aim to address current limitations while expanding processing capabilities to accommodate new materials and product designs. The ongoing miniaturization and material complexity of mobile devices ensures that shredding technology must continuously evolve to maintain effective processing capabilities.

Digitalization represents a significant trend influencing shredder development, with increased sensor integration, data analytics, and connectivity enabling new operational paradigms. Smart shredding systems incorporate comprehensive monitoring capabilities that track component wear, energy consumption, and output quality in real-time. These data streams support predictive maintenance approaches that minimize unplanned downtime while optimizing replacement part scheduling. The integration of shredding operations within broader industrial internet of things frameworks facilitates coordinated optimization across multiple process stages, improving overall system efficiency and material recovery rates.

Intelligent System Integration

The integration of artificial intelligence and machine learning technologies represents the next evolutionary stage in mobile phone shell shredding systems. These intelligent systems analyze operational data to identify patterns and correlations that inform process optimization and predictive maintenance. Visual recognition systems can automatically identify material types and adjust processing parameters accordingly, improving output consistency while reducing operator intervention. These capabilities become increasingly valuable as material streams grow more complex and variable, enabling effective processing despite changing input characteristics.

Connectivity advancements facilitate remote monitoring and operation of shredding systems, enabling expert support regardless of physical location. Cloud-based analytics platforms aggregate data from multiple installations, identifying best practices and common failure modes that inform system improvements. Digital twin technology creates virtual replicas of physical systems that enable simulation and optimization without disrupting actual operations. These digitalization trends are transforming shredder operation from experience-based art to data-driven science, improving consistency while reducing skill requirements for effective operation.

Advanced Material Recovery Enhancements

Future developments in mobile phone shell shredding technology will likely focus on enhanced material recovery through improved liberation and separation capabilities. Advanced cutting system designs aim to achieve more selective fragmentation that preserves material integrity while enabling cleaner separation. Integrated sensor-based sorting technologies may incorporate spectroscopic analysis that identifies material composition during shredding, enabling dynamic adjustment of processing parameters. These enhancements could significantly improve material purity in output streams, increasing value while reducing downstream processing requirements.

Multi-stage shredding configurations represent another development direction, incorporating sequential processing steps that progressively liberate different material fractions. These systems might include initial coarse shredding followed by targeted processing of specific components and final size reduction optimized for subsequent recycling steps. The development of specialized cutting elements for specific material combinations could further improve processing efficiency and output quality. These material-specific approaches represent a departure from universal processing methods, acknowledging the unique characteristics of different phone shell compositions and their optimal processing pathways.