Industrial shredders are powerful machines essential for recycling, waste management, and material size reduction. Keeping them in optimal condition is not just about preventing breakdowns; it's about ensuring safety, maximizing efficiency, and protecting your significant investment. This comprehensive guide walks through the fundamental steps of shredder maintenance, from daily cleaning and lubrication to blade replacement and troubleshooting. A well-maintained shredder can process tons of material per hour, with some industrial models handling up to 50 tons of plastic waste in a single shift. By following a structured maintenance schedule, operators can significantly extend the machine's operational life, often by several years, while ensuring it runs safely and productively.

Daily Cleaning and Inspection

Consistent daily routines form the foundation of any effective maintenance program. These simple steps, performed at the end of each shift, prevent the accumulation of material debris that can lead to premature wear, corrosion, and potential mechanical failures. A clean machine is also easier to inspect, allowing operators to quickly identify issues like loose components or leaks before they escalate into major problems. Spending just 15-20 minutes on these tasks can save hours of downtime and costly repairs in the future.

The process begins with ensuring the machine is completely powered down and isolated from its energy source. This is a critical safety step that must never be overlooked. Once safe, operators can proceed to remove dust, plastic flakes, and other residues from all external and accessible internal surfaces. This daily attention prevents small particles from interfering with moving parts and electrical systems.

Post-Operation Cleaning Procedure

After the shredder has been properly shut down, the cleaning process can begin. Using brushes, air hoses, and non-flammable cleaning agents, operators should remove all plastic dust and chips from the cutting chamber, hopper, and discharge areas. It is crucial to avoid using high-pressure water directly on the machine, as moisture can cause corrosion and damage electrical components. The goal is to leave the machine free of processing residue.

Inspecting Blade Wear and Tightness

The blades are the heart of the shredder. Visually inspect them for obvious signs of damage, such as nicks, chips, or blunt edges. Using the appropriate tools, check the tightness of all bolts and fasteners that secure the blades to the shaft. Loose blades can create uneven cutting, cause excessive vibration, and lead to catastrophic failure. Early detection of wear allows for planned replacement instead of emergency downtime.

Clearing Feed and Discharge Hopper Blockages

Inspect the infeed and discharge chutes for any material that did not clear the system. Residual material, especially flexible plastics, can harden and create significant blockages that strain the motor and drive system during the next startup. Ensuring a clear path for material flow is essential for maintaining consistent processing rates and preventing jams.

Checking Electrical Connections and Wiring

A visual inspection of the electrical cabinet for any signs of dust ingress, as well as checking for loose conduit connections, frayed wires, or overheating components, is vital. Many electrical faults begin as a simple loose connection. Keeping the electrical system clean and secure ensures reliable operation and reduces fire risk.

Regular Lubrication and Preventative Care

Lubrication is the lifeblood of any industrial machine with moving parts. Proper lubrication reduces friction, minimizes wear, dissipates heat, and protects against corrosion. For a shredder, which operates under high torque and stress, the correct application of lubricants is non-negotiable for achieving its intended service life. Manufacturers provide specific lubrication schedules and recommend types of grease and oil; adhering to these is critical.

Neglecting lubrication leads to increased energy consumption, as the motor works harder to overcome friction. It also accelerates the wear of bearings, gears, and shafts, leading to frequent breakdowns and expensive component replacements. A well-lubricated machine runs smoother, quieter, and more efficiently.

Scheduled Replacement of Lubricants and Grease

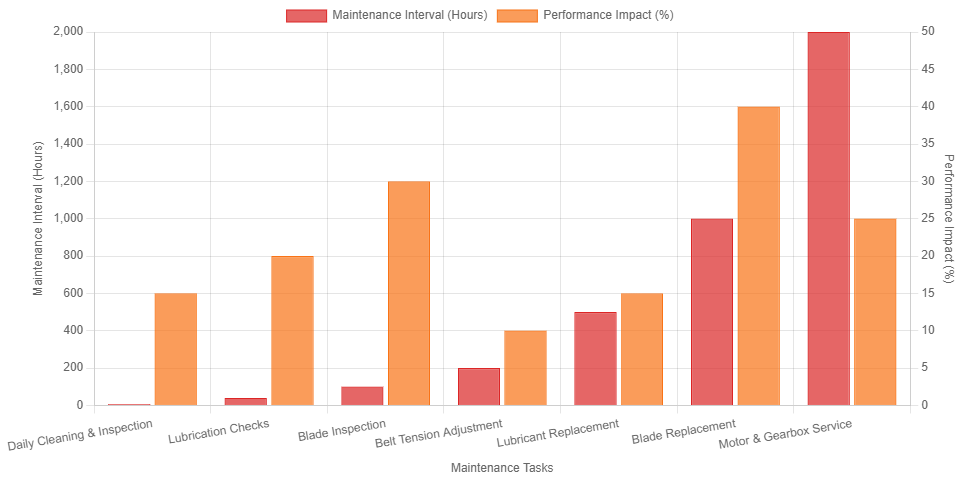

Over time, lubricants break down and become contaminated with microscopic wear particles and moisture. Following the manufacturer's specified intervals, old oil and grease should be completely purged and replaced with fresh, high-quality products. For many shredder bearings, this might be every 500 operating hours, while gearbox oil changes might be scheduled annually or every 2,000 hours.

Lubricating Key Components like Bearings and Gears

Centralized lubrication systems or manual grease guns are used to deliver grease to bearings on the rotor shaft and other pivot points. Gears within the drive train require a specific grade of gear oil to be maintained at the proper level. Each point must be lubricated according to its specific requirement—over-greasing can be as harmful as under-greasing.

Inspecting and Adjusting Drive Belt Tension

Drive belts transmit power from the motor to the shredder rotor. They should be inspected for cracks, glazing, or signs of wear. Proper tension is crucial; a belt that is too loose will slip and burn out, while one that is too tight will overload bearings. Tension should be checked periodically with a tension gauge and adjusted to the manufacturer's specifications.

Maintaining the Motor and Gear Reducer

The motor and gear reducer are the powerhouse of the shredder. Maintenance includes checking for unusual noises or vibrations, ensuring cooling fins are clean, and verifying that oil levels in the gear reducer are correct. These components are expensive to repair or replace, so proactive care is a high priority.

Blade Replacement and Adjustment

Blades are consumable items in a shredder, and their sharpness directly impacts power consumption and product quality. Dull blades require more energy to pull material into the cutting chamber and produce irregularly shaped flakes. Knowing when and how to change them is a key skill for any shredder operator. A typical set of blades on a mid-sized plastic shredder may process between 50 to 200 tons of material before requiring sharpening or replacement, depending on the plastic type.

The replacement process requires strict safety protocols, including lockout-tagout of all power sources. The goal is to install new or sharpened blades and set the precise clearance between the rotary and stationary blades. This clearance is critical for efficient cutting and preventing the blades from striking each other, which can cause severe damage.

Identifying Signs and Degree of Blade Wear

Visible indicators of wear include rounded cutting edges, deep grooves, or chipped sections on the blades. Operational signs include a noticeable drop in throughput, an increase in motor amperage, and the production of larger, unevenly torn particles instead of cleanly cut fragments.

Preparing Tools and Materials for Blade Changeout

Before starting, gather all necessary tools: the correct wrenches, torque wrench, hydraulic pulling tools for removing the rotor, new blades or sharpened sets, and new seals or gaskets if required. Having everything on hand streamlines the process and minimizes downtime.

Following Correct Steps for Replacement and Gap Setting

The process involves disassembling parts of the cutting chamber to access the rotor. Old blades are removed, the shaft and mounting surfaces are cleaned, and new blades are installed and torqued to specification. The gap between the rotary and stationary blades is then carefully set using feeler gauges to the manufacturer's recommended tolerance, often between 0.3mm to 0.5mm.

Testing the Performance and Stability of New Blades

After reassembly, the shredder should be started without material to check for any unusual sounds. Then, a small amount of easy-to-process material is fed through. The machine's power consumption and output particle size should be monitored to verify that the new blades are performing correctly before resuming full-capacity operation.

Troubleshooting and Repair

Even with excellent maintenance, issues can arise. Effective troubleshooting involves a systematic approach to diagnose and resolve problems quickly. Understanding common symptoms and their likely causes is the first step to getting the machine back online. Keeping a log of past issues and solutions can be an invaluable resource for diagnosing recurring problems.

Operators should be trained to recognize early warning signs, such as changes in sound, vibration, or product output. Addressing a small issue immediately can prevent it from developing into a major failure that halts production for an extended period.

Diagnosing Reasons for a Shredder Failing to Start

This is often an electrical issue. The first step is to check the main power supply. Then, verify that all safety interlocks (e.g., hopper lid closed, discharge door secured) are engaged. The control panel may display an error code that points to a specific fault, such as a thermal overload from the motor or a faulty sensor.

Resolving Abnormal Noise or Vibration During Operation

Unusual noises often point to a mechanical problem. A consistent grinding sound may indicate a failing bearing, while a rhythmic knocking could be a sign of a loose or striking blade. Vibration can be caused by an unbalanced rotor, often due to uneven blade wear or material lodged in the cutting chamber. Immediate shutdown and inspection are required.

Addressing Feed Hopper Jams or Poor Discharge Flow

Jamming at the infeed can be caused by feeding overly large or irregularly shaped items that exceed the machine's design capacity. Poor discharge flow often results from a clogged screen or a worn-out conveyor mechanism. Clearing these blockages requires the machine to be completely stopped and isolated.

Repairing Faults in the Electrical System or Control Panel

Electrical repairs should only be conducted by qualified electricians. Common issues include blown fuses, failed contactors, or damaged wiring. The programmable logic controller (PLC) can also provide diagnostic information to pinpoint the exact component causing the fault.

Safe Operation and Protective Measures

Safety is the highest priority when operating or maintaining heavy industrial machinery like shredders. The immense forces involved can cause severe injury if proper procedures are not followed. A strong safety culture, reinforced by continuous training and clear protocols, is essential for protecting personnel.

This involves not only using the machine correctly but also creating a safe environment around it. This includes adequate lighting, clear signage, and keeping the area free of slip and trip hazards. Emergency stop buttons must be easily accessible and regularly tested to ensure they function correctly.

Adhering to Safe Operational Procedures

Operators must be thoroughly trained on the specific model of shredder they are using. This includes understanding the maximum material capacity, the correct feeding techniques to avoid hand injuries, and the meaning of all warning lights and alarms. No one should ever operate a shredder without formal training.

Utilizing Personal Protective Equipment (PPE)

Mandatory PPE for operating and maintaining shredders includes safety glasses with side shields to protect eyes from flying fragments, hearing protection due to high noise levels, heavy-duty gloves for handling sharp materials, and steel-toed boots. During maintenance, a lockout tagout kit is the most critical safety tool.

Powering Down and Tagging Out Before Maintenance

Lockout-Tagout (LOTO) is a non-negotiable safety procedure. Before any maintenance or clearing of a jam, the machine must be completely shut down, all power sources isolated and locked, and a tag placed on the lock explaining who is working on the machine and why. This prevents accidental startup.

Regularly Inspecting and Testing Safety Devices

All safety features, such as emergency stop cables, safety light curtains, and hopper interlocks, must be tested regularly to confirm they are functioning correctly. A malfunctioning safety device provides a false sense of security and creates a major hazard.

Long-Term Storage and Preservation

If a shredder needs to be taken out of service for an extended period, proper preservation is essential to prevent damage from corrosion and ensure it can be quickly recommissioned. A machine stored incorrectly can suffer more damage than one that is in active use. The preparation process is methodical and designed to protect all critical components from the elements.

The key enemies during storage are moisture, dust, and temperature fluctuations. The goal of preservation is to create a stable, dry, and clean environment for the equipment. A well-preserved shredder can be stored for years and returned to service with minimal effort and cost.

Thoroughly Cleaning and Drying the Machine

The shredder must be given a deep clean, far more thorough than the daily routine. Every part of the machine, inside and out, should be freed from all grease, dust, and plastic residue. After cleaning, it must be completely dried to ensure no moisture remains that could cause internal rust during storage.

Applying Anti-Corrosion Treatment and Protective Oils

All exposed metal surfaces, especially the precision-machined shafts and blades, should be coated with a protective anti-rust spray or a thin layer of oil. Hydraulic cylinder rods should be retracted to protect the polished surfaces. This coating acts as a barrier against humidity.

Storing in a Dry, Ventilated Indoor Environment

The ideal storage location is a clean, dry, and temperature-controlled warehouse. If outdoor storage is unavoidable, the machine must be covered with a breathable, waterproof tarp and placed on blocks to keep it off the damp ground. The environment should be as stable as possible.

Periodically Starting the Shredder to Check Status

Even in storage, the machine should not be completely forgotten. Every few months, if possible, the shredder should be briefly started and run through its functions. This circulates lubricants, prevents seals from setting, and helps identify any issues that may have developed during storage.