Choosing the appropriate waste plastic shredder is a critical decision that directly impacts the efficiency, cost-effectiveness, and success of any recycling operation. With numerous plastic types and shredder configurations available, selecting the wrong equipment can lead to premature wear, excessive energy consumption, and unsatisfactory output quality. This guide provides a systematic approach to matching shredder technology with specific plastic material characteristics, from common packaging films to reinforced industrial plastics. Understanding the relationship between material properties and machine capabilities ensures optimal performance and return on investment. The global plastic recycling market, valued at over $40 billion, relies heavily on proper shredder selection to process the estimated 400 million tons of plastic waste generated annually worldwide.

Understanding Different Plastic Material Properties

The foundation of selecting the right shredder begins with a thorough understanding of plastic materials and their diverse characteristics. Plastics vary significantly in their chemical composition, physical properties, and behavior under mechanical stress. These differences directly influence how they should be processed, what type of shredding mechanism is most effective, and what output quality can be expected. Without this fundamental knowledge, operators risk selecting equipment that is either underpowered for the application or unnecessarily expensive for the required task.

Plastics are primarily categorized by their response to heat, with thermoplastics and thermosets representing the two main families. Beyond this basic distinction, factors such as hardness, flexibility, impact resistance, and melt flow index play crucial roles in determining the appropriate shredding approach. Additionally, many plastics contain additives like fillers, plasticizers, or reinforcing fibers that can significantly alter their processing characteristics and present unique challenges for shredding equipment.

Differences Between Thermoplastic and Thermoset Materials

Thermoplastics, which constitute approximately 80% of all plastic production, become soft when heated and harden when cooled, allowing them to be remelted and recycled multiple times. Common examples include polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET). In contrast, thermoset plastics undergo irreversible chemical changes when heated, creating a permanent molecular structure that cannot be remelted. While thermoplastics are ideal for mechanical recycling through shredding, thermosets typically require alternative processing methods such as chemical recycling or energy recovery.

Physical and Chemical Properties of Common Plastic Types

Each plastic type possesses distinct characteristics that influence shredder selection. Low-density polyethylene (LDPE) is soft, flexible, and prone to wrapping around shafts, requiring specialized cutting systems. Polyvinyl chloride (PVC) can be either rigid or flexible but presents challenges due to its abrasive nature and potential emission of acidic gases when overheated. Engineering plastics like ABS and polycarbonate offer high impact resistance but require substantial power to shred effectively. Understanding these properties is essential for matching material characteristics with appropriate shredder technology.

Impact of Material Hardness and Toughness on Shredding Results

Material hardness, measured on scales such as Shore D or Rockwell, directly affects the wear on cutting components and the power requirements for shredding. Toughness, which represents a material's resistance to fracture, influences the cutting mechanism needed for efficient size reduction. Brittle materials like polystyrene (PS) fracture easily under impact, while tough materials like polyamide (nylon) require shearing action for effective processing. These material properties determine whether a shredder should utilize shear, tear, or impact mechanisms for optimal results.

Considerations for Plastics with Additives like Plasticizers and Fillers

Many plastics contain additives that alter their processing characteristics. Plasticizers added to PVC increase flexibility but can cause sticking to cutting components. Fillers such as calcium carbonate or glass fibers increase abrasiveness, accelerating wear on blades and internal components. Reinforcing materials like fiberglass can significantly increase material strength, requiring more powerful shredders with specialized cutting geometries. These additives must be considered when selecting both the shredder type and the construction materials for wear parts.

Selecting Shredder Type Based on Material Characteristics

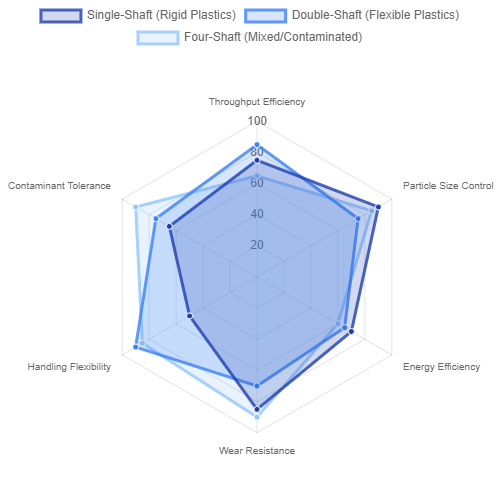

With an understanding of plastic properties, the next step involves matching these characteristics to appropriate shredder technologies. Different shredder designs employ distinct cutting actions and mechanisms optimized for specific material types and applications. The selection process involves evaluating factors such as shaft configuration, cutting chamber design, drive power, and cutting element geometry to ensure efficient processing of the target material. Proper matching of machine to material ensures optimal throughput, particle size consistency, and operational economy.

Industrial shredders for plastics primarily utilize shear-based cutting action, where material is cut between counter-rotating or rotating and stationary blades. The configuration of these cutting elements, the number of shafts, and the overall machine design vary significantly based on the intended application. From single-shaft grinders for preliminary size reduction to sophisticated four-shaft systems for fine homogenization, each design offers distinct advantages for specific material types and desired output characteristics.

Application Scenarios for Single-Shaft vs. Double-Shaft Shredders

Single-shaft shredders, featuring a rotating rotor with mounted blades working against a stationary bed knife, excel at processing bulky, thick-walled materials and provide good control over output particle size. Double-shaft shredders utilize two intermeshing rotors that provide a self-feeding tearing and shearing action, making them ideal for mixed material streams, films, and fibers that might wrap around single shafts. The choice between these configurations depends on material characteristics, desired throughput, and output size requirements.

Features of Shredders Designed for Soft Plastics like Films and Bags

Soft, flexible plastics present unique challenges due to their tendency to wrap around rotating components rather than being cut. Shredders designed for these soft materials incorporate specialized features such as anti-wrapping rotors, hook-shaped cutting blades that pull material into the cutting zone, and integrated systems that prevent material from bypassing the cutting elements. Many also include feeding mechanisms that maintain tension on the material to ensure clean cutting rather than tearing.

Design Considerations for Hard Plastic Applications like Pipes and Sheets

Rigid plastics such as pipes, profiles, and thick sheets require shredders with high torque capabilities and robust construction. Machines designed for these hard materials typically feature low rotational speeds and high torque delivery to fracture materials through shear forces rather than impact. Reinforced cutting chambers, heavy-duty bearings, and powerful hydraulic or electric drive systems ensure reliable operation under the substantial stresses generated when processing dense, rigid materials.

Processing Solutions for Materials Containing Metal Contaminants

Plastic waste streams often contain metal contaminants that can damage standard shredders. Systems designed for these challenging applications incorporate protective features such as automatic reversal systems that detect jams and clear them, hardened cutting components resistant to occasional metal contact, and integrated separation systems using magnets or eddy current separators to remove metallic contaminants either before or after the shredding process.

Considering Shredder Capacity and Efficiency Requirements

Capacity planning is essential for ensuring that the selected shredder meets production requirements without unnecessary oversizing or problematic undersizing. Capacity considerations extend beyond simple throughput measurements to include factors such as material density, feed consistency, desired output size, and operational hours. Proper capacity matching ensures economic operation while providing flexibility for future production increases or material changes.

Shredder efficiency encompasses not only throughput rates but also energy consumption, maintenance requirements, and operational reliability. Efficient systems minimize energy use per ton of processed material, reduce downtime through robust design and easy maintenance access, and provide consistent output quality regardless of variations in input material. These factors collectively determine the operational economy and environmental footprint of the shredding operation.

Small Shredders for Household or Laboratory Applications

Small-scale shredders, typically with motors under 10 horsepower, serve applications requiring limited throughput such as laboratory sample preparation, small-batch recycling, or specialized manufacturing processes. These compact units often feature simple direct-drive systems, basic safety controls, and capacities ranging from 10 to 100 kilograms per hour. While limited in capability, they offer an economical entry point for applications not justifying industrial-scale equipment.

Advantages of Medium-Sized Shredders for Small and Medium Enterprises

Medium-capacity shredders, with power ratings between 20 and 100 horsepower, represent the workhorses of many small to medium recycling operations. These systems typically process between 500 and 2,000 kilograms per hour, offering a balance between investment cost and production capability. They often incorporate more advanced features such as hydraulic pusher plates for consistent feeding, programmable logic controllers for automated operation, and comprehensive safety systems suitable for commercial environments.

Large Industrial Shredders for High-Volume Plastic Waste Processing

Large industrial shredders represent the pinnacle of processing capability, with power systems exceeding 200 horsepower and throughput capacities measuring multiple tons per hour. These heavy-duty systems feature robust construction with thick steel plate frames, sophisticated hydraulic or electric drive systems, and advanced control systems that optimize performance based on material characteristics. They are essential for municipal recycling facilities, large-scale manufacturing operations, and dedicated recycling plants processing significant volumes of plastic waste.

Impact of Continuous vs. Batch Operation Modes on Throughput

The operational mode significantly influences overall system capacity. Continuous operation shredders feature integrated conveying systems that automatically remove processed material, allowing uninterrupted operation and maximizing throughput. Batch systems require periodic stopping to discharge material, reducing overall capacity but offering advantages for applications requiring careful material handling or where contamination between different material batches must be avoided. The choice between these operational modes depends on specific processing requirements and material characteristics.

Evaluating Shredder Durability and Maintenance Costs

Durability assessment extends beyond initial equipment quality to consider long-term performance under operational conditions. Factors influencing durability include design robustness, material selection for wear components, manufacturing quality, and operational parameters. A comprehensive durability evaluation considers not only the expected service life but also the maintenance requirements and associated costs throughout that lifespan.

Maintenance costs represent a significant portion of the total cost of ownership for shredding equipment. These costs include routine maintenance such as blade sharpening or replacement, preventive maintenance including bearing and drive component servicing, and unexpected repairs resulting from operational incidents or component failures. Understanding and planning for these costs ensures accurate financial forecasting and prevents unexpected operational disruptions.

Analysis of Blade Materials and Wear Resistance

Cutting blades represent the primary wear components in any shredding system, with material selection directly influencing maintenance intervals and operational costs. Standard carbon steel blades offer economical performance for non-abrasive materials but require frequent replacement when processing reinforced or filled plastics. Tungsten carbide tipped blades provide exceptional wear resistance, often lasting 10-20 times longer than standard steel in abrasive applications, though at a significantly higher initial cost. The optimal selection balances initial investment against long-term maintenance requirements based on specific material characteristics.

Assessment of Motor Power and Energy Efficiency

Motor selection influences both operational capability and energy consumption. Efficient systems utilize high-efficiency electric motors or hydraulic systems matched to specific application requirements, avoiding both undersizing that leads to premature failure and oversizing that wastes energy. Modern variable frequency drives optimize energy usage by adjusting motor speed based on processing demands, potentially reducing energy consumption by 20-30% compared to fixed-speed systems. Energy efficiency represents an increasingly important consideration given rising energy costs and environmental concerns.

Convenience and Cost of Replacing Wear Parts

The design accessibility for wear part replacement significantly impacts maintenance costs and equipment availability. Systems featuring quick-change blade cartridges, accessible bearing assemblies, and modular design components reduce downtime during maintenance operations. Standardization of wear parts across equipment models can reduce inventory costs and simplify procurement. These design considerations should be evaluated alongside initial equipment cost to understand the total cost of ownership.

Manufacturer Warranty Coverage and After-Sales Service Support

Comprehensive warranty terms and responsive after-sales support provide valuable protection against unexpected repair costs and operational disruptions. Leading manufacturers typically offer 12-24 month warranties on equipment and provide technical support, spare parts availability, and service technician access. The quality and responsiveness of this support network can significantly influence equipment uptime and should be carefully evaluated during the selection process.

Compliance with Environmental and Safety Standards

Regulatory compliance represents a critical consideration in shredder selection, with requirements varying by jurisdiction and application. Environmental regulations may address noise emissions, dust generation, and potential emissions from processed materials. Safety standards govern equipment design, protective systems, and operational procedures to protect personnel from injury. Compliance ensures legal operation while demonstrating environmental responsibility and commitment to workplace safety.

Modern shredding systems incorporate numerous features designed to address regulatory requirements and industry best practices. These include integrated dust collection systems, noise reduction enclosures, comprehensive safety interlocks, and emission control systems. Understanding applicable regulations and selecting equipment designed for compliance prevents costly modifications or operational restrictions after equipment installation.

Noise Control and Dust Emission Standards

Industrial shredding operations typically generate noise levels exceeding 85 decibels, requiring hearing protection and often triggering regulatory limits. Equipment featuring soundproof enclosures, vibration isolation mounts, and acoustic damping materials can reduce noise emissions by 15-25 decibels. Dust control represents another critical consideration, with integrated collection systems capturing particulate matter at the source to maintain airborne dust levels below regulatory thresholds and protect worker health.

Electrical Safety Design and Protective Measures

Electrical safety systems protect operators from shock hazards while preventing equipment damage from electrical faults. These include properly grounded systems, emergency stop circuits that remove power from all drives, electrical enclosure integrity preventing moisture or dust ingress, and comprehensive overload protection for motors and drives. Third-party certification from organizations like UL or CE provides independent verification of electrical safety compliance.

Emergency Stop and Fault Alarm Systems

Modern shredders incorporate multiple safety systems designed to protect operators and equipment. Emergency stop buttons at strategic locations allow immediate shutdown in hazardous situations. Fault monitoring systems detect abnormal conditions such as overloads, overheating, or mechanical jams, triggering alarms or automatic shutdown before damage occurs. These systems enhance operational safety while protecting the significant investment in shredding equipment.

Certifications and Permits Required by Local Environmental Regulations

Regulatory requirements vary significantly by location and application, with some jurisdictions requiring specific certifications or permits for shredding operations. These may include air quality permits for operations generating dust or emissions, wastewater discharge permits for systems incorporating wash lines, or special handling permits for processing certain plastic types. Understanding these requirements during equipment selection ensures compliance and prevents operational delays.

User Reviews and Case Study Analysis

Practical experience from current users provides invaluable insights beyond manufacturer specifications and claims. User reviews offer real-world perspectives on equipment performance, reliability, maintenance requirements, and manufacturer support. Case studies demonstrate application-specific solutions and document performance metrics under actual operating conditions. This information helps validate technical specifications and identifies potential issues before equipment acquisition.

When evaluating user feedback, it's important to consider the context of each application, including material characteristics, operational hours, and maintenance practices. Patterns of comments across multiple users provide more reliable indicators than individual experiences. Documented case studies from reputable sources offer particularly valuable information, typically including detailed operational data and verified performance metrics.

Success Stories from Prominent Users in the Industry

Case studies from established recycling operations demonstrate equipment capabilities under demanding conditions. These success stories typically document throughput achievements, maintenance records, energy consumption data, and return on investment calculations. They provide realistic performance expectations and often highlight innovative applications or processing solutions that might be applicable to similar operations.

Common Problems and Solutions from User Feedback

User reviews frequently identify recurring issues and effective solutions. Common themes include wear part longevity, maintenance accessibility, operational nuances, and manufacturer responsiveness to problems. This collective experience helps prospective buyers anticipate potential challenges and evaluate how different equipment designs address these issues. It also provides practical insights that might not be apparent from equipment specifications alone.

Performance Comparison Across Different Industries

Shredding equipment performance can vary significantly across different applications and industries. Equipment processing clean industrial scrap typically demonstrates different performance characteristics than systems handling post-consumer packaging with contamination. Understanding these application-specific differences helps set realistic expectations and guides the selection of equipment proven in similar applications.

Long-Term Performance Stability Assessment

Long-term user feedback provides crucial information about equipment durability and performance consistency over extended operational periods. Factors such as maintenance cost trends, availability of spare parts, technical support quality, and performance degradation over time significantly influence the total cost of ownership. This longitudinal perspective complements short-term performance data to provide a comprehensive view of equipment value.