This guide provides a comprehensive analysis of industrial shredder maintenance, covering the classification of cleaning tools, the scientific selection of detergents, safety operation protocols, and long-term upkeep strategies. Proper maintenance is not just about cleanliness; it is a critical operational function that directly impacts productivity and cost-efficiency. By adhering to the principles outlined herein, businesses can significantly extend the operational lifespan of their equipment, sometimes by years, while ensuring it runs at peak performance. A well-maintained shredder is a reliable asset in any waste management, recycling, or data security operation.

Industrial shredders are complex machines designed to process a vast array of materials, from paper and plastic to metals and electronic waste. Each material presents unique challenges, leaving behind residues that can impair function. This document will delve into the specifics of tackling these challenges, offering a clear roadmap for developing a robust maintenance regimen. The goal is to empower operators and facility managers with the knowledge to make informed decisions that prevent downtime, reduce repair costs, and maintain a safe working environment.

Analysis of Industrial Shredder Cleaning Necessity

The operation of an industrial shredder generates significant amounts of particulate matter and debris. This is not merely a housekeeping issue but a fundamental aspect of preserving the machine's mechanical integrity. Without a systematic cleaning schedule, the accumulated waste can lead to a cascade of mechanical failures, safety hazards, and increased operational expenses. The necessity for cleaning is rooted in the basic principles of physics and engineering that govern all heavy machinery.

Understanding this necessity is the first step toward proactive maintenance. It transforms cleaning from a reactive chore into a strategic, scheduled activity that protects a substantial capital investment. For instance, studies on industrial equipment reliability have shown that up to 70% of bearing failures are related to lubrication issues, often caused by contamination from dust and debris, which underscores the critical role of cleanliness.

Impact of Debris Accumulation on Equipment Performance (Blade Wear/Motor Overload)

When paper屑, plastic fragments, or metal dust accumulate within the cutting chamber, they interfere with the precise alignment and movement of the cutting blades. This debris acts as an abrasive medium, accelerating the wear on the sharp edges of the tungsten carbide cutters. Even a minor layer of dust can force the blades to work harder, requiring the motor to draw more current to maintain torque. This increased electrical load, often measured in amperage, can lead to motor overheating and trigger thermal protection shutdowns.

Prolonged operation under such stressed conditions can reduce motor lifespan by as much as 30%. Furthermore, the increased friction and resistance caused by compacted debris place undue stress on the entire gearbox and transmission system. This not only leads to more frequent blade replacements but also risks catastrophic failure of more expensive components like the shredder shaft or rotor assembly, resulting in thousands of dollars in unplanned repairs and extended downtime.

Safety Hazards Induced by Dust Pollution (Electrostatic Fire/Bearing Seizure)

Dust pollution, particularly from materials like paper or certain plastics, creates a highly combustible environment. The constant friction and movement within the shredder can generate significant static electricity. If this static discharge occurs in a cloud of concentrated dust, it can ignite a fire or even cause an explosion. Industrial safety boards report that dust-related fires are a leading cause of incidents in waste processing facilities.

Beyond fire risks, fine dust particles are notorious for infiltrating sealed bearings. Once inside, these particles mix with lubricating grease, forming a gritty paste that abrades the bearing races and balls. This contamination leads to increased friction, overheating, and ultimately, bearing seizure. A seized bearing can bring the entire machine to an abrupt halt and often causes secondary damage to the shafts and housings it supports, necessitating a complex and costly repair process.

Quantified Relationship Between Cleaning and Equipment Lifespan (Case Data Comparison)

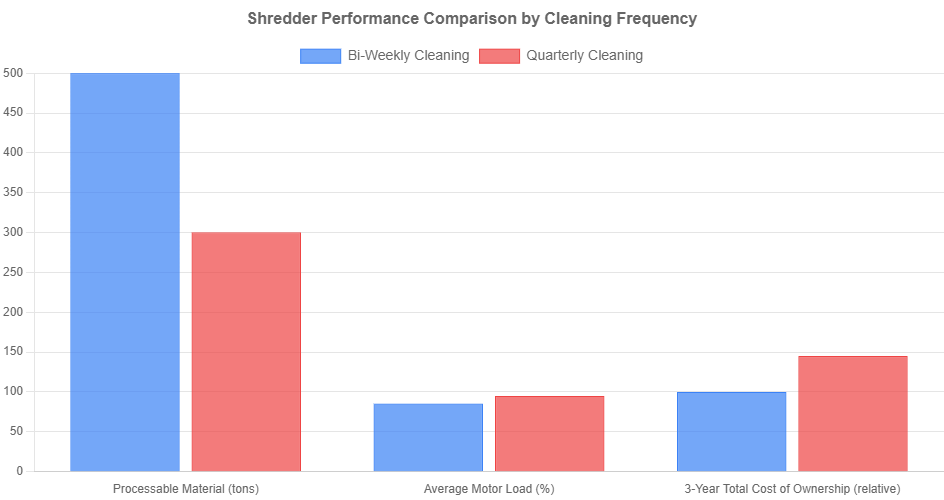

The correlation between regular cleaning and extended equipment lifespan is strongly supported by operational data. For example, a case study comparing two identical shredders in a recycling plant demonstrated a clear divergence in performance. The shredder on a bi-weekly cleaning regimen required its first major blade sharpening after processing 500 tons of material. Its motor operated at an average of 85% of its rated load.

In contrast, the shredder cleaned only quarterly showed noticeable performance degradation after 300 tons and required a full blade replacement. Its motor frequently spiked to 95% load, and after 18 months, it experienced a failure of its main drive gearbox. The total cost of ownership for the poorly maintained machine was calculated to be 45% higher over a three-year period, vividly illustrating the financial impact of a disciplined cleaning schedule.

Specialized Cleaning Needs for Different Processed Materials (Plastic/Metal/E-Waste)

Each material category processed by a shredder demands a tailored cleaning approach. Plastic shredding, especially films, often generates static-charged flakes that cling to every surface and can melt from friction heat, creating a stubborn, glue-like residue. This requires specific tools and detergents to effectively remove without spreading the problem. Metal shredding produces sharp, conductive fines that can short-circuit electrical components and are highly abrasive, demanding robust, magnetic cleaning tools.

Electronic waste, or e-waste, presents perhaps the most complex challenge. Shredding circuit boards releases fine dust containing heavy metals and brominated flame retardants, which can be hazardous. Cleaning an e-waste shredder requires methods that control and capture this hazardous dust, often involving integrated dust extraction systems and HEPA filtration to protect both the machine and the operators from exposure.

Classification and Selection Criteria for Specialized Cleaning Tools

Selecting the right tools for cleaning an industrial shredder is a science in itself. The wrong tool can be ineffective or, worse, can cause damage to sensitive components. The market offers a wide array of tools designed for specific cleaning tasks, from dislodging heavy debris to removing microscopic dust particles from delicate sensors. A strategic selection is based on the machine's design, the materials it processes, and the frequency of use.

A comprehensive toolkit is an investment in the shredder's health. It enables maintenance crews to perform thorough cleanings efficiently and safely, ensuring that no component is overlooked. The right tools can cut cleaning time in half, reduce labor costs, and provide a consistent level of cleanliness that directly translates to machine reliability and longevity.

Mechanical Cleaning Tools (Anti-Static Brushes/High-Pressure Air Pumps)

Mechanical tools are the first line of defense against debris accumulation. Anti-static brushes are essential for manually removing dust from electrical panels, motor housings, and around bearings without generating static sparks that could ignite dust. Their conductive bristles safely channel any static charge away from sensitive areas. For heavier, compacted debris, brass-bristled brushes are preferred as they are non-sparking and softer than steel, minimizing the risk of scratching machined surfaces.

High-pressure air pumps, or blow-off guns, are invaluable for evacuating dust from hard-to-reach areas like cooling fins, gear teeth, and between hydraulic lines. It is critical that these air guns are used with a pressure regulator; excessive pressure can force dust past seals into bearings and electrical connectors, creating new problems. For optimal safety and efficiency, these tools should be part of a larger system that includes proper employee PPE and local exhaust ventilation.

Electric Cleaning Equipment (Industrial Vacuums/Ultrasonic Cleaners)

Industrial-grade vacuum systems are arguably the most important piece of cleaning equipment for any shredder operation. Unlike shop vacs, these units are designed to handle heavy volumes of abrasive and potentially hazardous materials without risking motor burnout or filter failure. They often feature automatic filter cleaning mechanisms, spark-resistant construction, and grounding cables to prevent static discharge. A powerful vacuum is indispensable for maintaining a clean waste bin collection area and for general housekeeping around the machine.

For deep cleaning of disassembled components like smaller blades, gears, and sensors, ultrasonic cleaners offer an unmatched level of precision. These devices use high-frequency sound waves to create microscopic bubbles in a cleaning solution that implode, blasting away contaminants from every surface, including tiny crevices invisible to the eye. This process restores components to a like-new condition without the abrasive damage that can result from manual scrubbing, significantly extending their service life.

Intelligent Inspection Tools (Endoscopes/Dust Concentration Monitors)

Modern maintenance relies on predictive technologies to identify issues before they cause failure. Industrial borescopes or endoscopes are flexible cameras that allow technicians to visually inspect the interior of a shredder without disassembly. They can be fed through small openings to examine the condition of hidden blades, check for cracks in the shredder shaft, or verify the integrity of internal liners, providing invaluable diagnostic information that guides the cleaning and repair process.

Dust concentration monitors are critical for environmental and safety compliance. These laser-based sensors continuously measure the level of airborne particulates in the operator's breathing zone and around the machine. If dust levels approach a dangerous threshold, the monitor can trigger an alarm or even activate the facility's enhanced dust extraction system automatically, ensuring a safe working environment and helping to prevent combustible dust explosions.

Three Principles of Tool Selection (Efficiency/Safety/Compatibility)

The selection of any cleaning tool must be governed by three core principles: efficiency, safety, and compatibility. Efficiency refers to the tool's ability to perform the task quickly and thoroughly, reducing machine downtime. A tool that cuts cleaning time by 30 minutes per shift saves hundreds of hours of labor over a year. This principle demands an evaluation of the tool's power, capacity, and ergonomics for the specific task at hand.

Safety is non-negotiable. Tools must be certified for use in their intended environment, especially regarding explosion-proof ratings (like ATEX) when working around combustible dust. Compatibility ensures the tool will not damage the shredder. For example, a solvent that is effective on grease might also degrade the plastic housing of a proximity sensor. Every tool and chemical must be vetted against the manufacturer's recommendations to avoid causing inadvertent damage during the cleaning process.

Cleaning Agent Composition Analysis and Selection Guidelines

Choosing the correct cleaning agent is as crucial as selecting the right tool. The wrong chemical can damage seals, corrode metals, degrade plastics, and leave harmful residues that contaminate the next batch of material. Cleaning agents are formulated with specific chemistries to target certain types of soils, such as oils, adhesives, or dust. Understanding their composition is key to their safe and effective use.

The evolution of cleaning chemistry has also been driven by environmental and worker safety regulations. Modern formulations prioritize biodegradability, low toxicity, and low volatile organic compound (VOC) content without sacrificing cleaning power. A strategic selection balances cleaning efficacy with environmental responsibility and operator safety, ensuring compliance with standards like RoHS and OSHA.

Water-Based Cleaners (Mechanism of Surfactants)

Water-based cleaners are versatile and generally the safest option for both users and equipment. Their cleaning power comes from surfactants, or surface-active agents. These molecules have a hydrophilic (water-attracting) head and a hydrophobic (water-repelling) tail. The hydrophobic tails surround and break up oil and grease droplets, while the hydrophilic heads allow these droplets to be rinsed away with water. This mechanism effectively emulsifies fats, oils, and many particulates.

Many modern water-based formulas are also enhanced with builders, which soften water to improve surfactant efficiency, and corrosion inhibitors to protect ferrous and non-ferrous metals during the cleaning process. They are typically non-flammable, have a low odor, and are suitable for general cleaning of machine exteriors, floors, and non-delicate parts. However, they are not ideal for use on or near unprotected electrical components due to the risk of short-circuiting.

Solvent-Based Cleaners (Application Scenes for Hydrocarbon/Ester Solvents)

Solvent-based cleaners are powerful degreasers designed to dissolve stubborn contaminants that water-based solutions cannot. Hydrocarbon solvents are excellent at breaking down heavy oils, greases, and tar-like residues left behind from shredding certain plastics or treated woods. They evaporate quickly, leaving little to no residue, which is ideal for cleaning electrical contacts and precision mechanisms where moisture cannot be tolerated.

Ester-based solvents represent a more advanced and environmentally friendly category. They offer high solvency power with lower toxicity and better biodegradability than traditional hydrocarbons. Esters are particularly effective at removing cured adhesives, inks, and plastic melts without damaging underlying metals or most plastics. Their controlled evaporation rate allows for sufficient contact time to dissolve the contaminant without flashing off too quickly. Regardless of the type, all solvent use requires adequate ventilation and appropriate personal protective equipment to ensure operator safety.

Eco-Friendly Cleaners (Biodegradability Certification Standards)

The demand for sustainable industrial practices has propelled the development of high-performance eco-friendly cleaners. These products are defined by their rapid biodegradability, meaning they break down into harmless substances like water and carbon dioxide within a short period after disposal, typically 28 days for most organic components. This prevents long-term pollution of soil and waterways.

To validate these claims, reputable manufacturers have their products certified to recognized international standards. The most common is the OECD 301 series of tests for ready biodegradability. A cleaner certified to such a standard provides assurance that it meets stringent environmental criteria. Additionally, many eco-friendly cleaners are derived from renewable resources like plant-based alcohols and citrus extracts, further reducing their environmental footprint while maintaining powerful cleaning performance on par with traditional chemicals.

List of Prohibited Components (Strong Acids/Strong Alkalis/Chlorinated Solvents)

Certain chemicals are strictly prohibited for use on shredders due to their highly corrosive or hazardous nature. Strong acids (e.g., hydrochloric acid, sulfuric acid) and strong alkalis (e.g., sodium hydroxide, lye) are extremely aggressive. They will rapidly etch and corrode metals, degrade protective coatings, and destroy elastomer seals and hoses, leading to catastrophic component failure. Their use is never recommended for routine maintenance.

Chlorinated solvents, such as trichloroethylene and methylene chloride, are powerful degreasers but pose severe health risks to operators, including potential carcinogenic effects. They are also known to stress-crack certain plastics and can decompose under heat to form highly corrosive hydrochloric acid. Furthermore, their environmental impact is significant, as they are persistent pollutants. Modern safety and environmental regulations, including RoHS and OSHA standards, heavily restrict or outright ban the use of these substances in industrial maintenance.

Standardized Safe Cleaning Operation Procedures

Adhering to a standardized cleaning procedure is the cornerstone of safety and effectiveness. A haphazard approach risks personal injury, equipment damage, and incomplete cleaning. A formal, step-by-step protocol ensures that every cleaning session is performed consistently, thoroughly, and, most importantly, safely. This protocol should be documented, readily available to all maintenance personnel, and reinforced through regular training.

The procedure must be treated with the same importance as an operational manual. It outlines not just the steps to take, but the rationale behind them, fostering a culture of safety and precision. By standardizing the process, businesses can ensure that regardless of which technician performs the task, the outcome will be the same: a clean, safe, and fully operational shredder ready for production.

Pre-Treatment Phase (Power Disconnection/Cooling/Protective Gear)

The pre-treatment phase is the most critical for safety. The first and non-negotiable step is a full Lockout-Tagout (LOTO) procedure. This involves physically shutting off and locking the main power disconnect to the shredder, placing a tag with the cleaner's name and reason for the lockout. This prevents any accidental energization of the machine during cleaning. Verifying a zero-energy state with a voltage tester is a mandatory final check.

Next, the machine must be allowed to cool completely. Shredders generate immense heat through friction, and internal components like bearings, the hydraulic system, and the motor can remain dangerously hot for hours after shutdown. Attempting to clean a hot machine can cause burns or cause cleaning agents to evaporate too quickly or produce hazardous fumes. During this cooling period, technicians must don appropriate personal protective equipment (PPE): safety glasses, cut-resistant gloves, steel-toed boots, respiratory protection for dust, and hearing protection if necessary.

Core Component Cleaning (Blade Set/Feed Opening/Dust Collection Box)

Cleaning the core components requires methodical care. The blade set is the heart of the shredder. After ensuring the machine is powerless, technicians should carefully remove accumulated debris from the cutting chamber using non-sparking scrapers and brushes. For a cutting blades set, a specialized cleaner that dissolves paper dust and ink without causing corrosion should be applied, followed by a careful wipe-down and a light application of a recommended lubricant to prevent rust.

The feed opening and hopper are next, as built-up material here can cause jams and reduce capacity. These areas can be scrubbed with a brush and a general-purpose, non-abrasive cleaner. Finally, the dust collection box or bin must be completely emptied and cleaned. This is a primary source of dust and fire hazard. It should be vacuumed out, and its interior walls wiped down to remove all fine particles. Any filters associated with the collection system should be inspected and replaced or cleaned according to the manufacturer's instructions.

Electrical System Maintenance (Circuit Board/Sensor Cleaning)

The electrical system demands the most delicate touch. Control panels, PLCs, sensors, and circuit boards are highly sensitive to moisture and physical damage. Compressed air should be used first to blow dust out of the panel and off components. The air must be dry and regulated to a low pressure to avoid damaging fragile parts. For more stubborn grime, a specialized electronic-grade contact cleaner, which is non-conductive, non-corrosive, and fast-drying, should be sprayed onto a soft, lint-free cloth—not directly onto the component—for gentle wiping.

Particular attention should be paid to sensors, such as an overheat protection sensor, as a layer of dust can insulate them and cause inaccurate readings. Their lenses should be cleaned with isopropyl alcohol to ensure they function correctly. Throughout this process, technicians must be mindful not to dislodge or bend any wiring connections. Any work on electrical systems should ideally be performed by a qualified electrician.

Post-Cleaning Inspection (Dynamic Balance Test/Leakage Current Check)

A cleaning cycle is not complete without verification. Before reassembling any guards or panels, a visual inspection should confirm that all tools and rags have been removed from the machine—a common cause of startup damage. For shredders with high-speed rotors, a dynamic balance test may be necessary if major components were removed or adjusted. Imbalance can cause severe vibration, leading to premature bearing failure and structural damage.

Finally, an electrical safety check is imperative. After reassembly and before restoring full power, a leakage current test should be performed to ensure that no moisture or cleaner has compromised the insulation of electrical components. Once power is restored, the machine should be started under no load to verify smooth operation, proper system pressures, and the absence of unusual noises. Only after passing these checks should the shredder be returned to full production service.

Cleaning Solutions for Special Working Conditions

Not all shredders operate in clean, climate-controlled environments. Many are subjected to extreme conditions that present unique cleaning and maintenance challenges. A one-size-fits-all approach is insufficient. Specialized protocols are required to combat issues like rust, chemical contamination, biological growth, and temperature extremes. Adapting the maintenance strategy to the operating environment is key to ensuring reliability.

These specialized solutions often involve targeted chemicals, modified procedures, or additional protective measures. By anticipating the challenges posed by the environment, maintenance teams can proactively prevent the unique forms of degradation that occur, ensuring the shredder remains a dependable asset regardless of where it is installed.

Anti-Rust Treatment in High-Humidity Environments (Vapor Corrosion Inhibitor Application)

In coastal areas or humid climates, the constant presence of moisture in the air leads to rapid oxidation and rust on unprotected ferrous metal surfaces. This is especially damaging to the precision-machined surfaces of shredder shafts and the cutting chamber. Standard lubricants can wash away, leaving metal vulnerable. To combat this, Vapor Corrosion Inhibitors (VCIs) are employed.

VCIs are a class of chemicals that release a protective vapor which condenses on all metal surfaces within an enclosed space, forming a microscopic protective layer that prevents moisture and oxygen from reacting with the metal. They can be applied as sprays, emitters, or impregnated into packaging materials. For a shredder, after a thorough cleaning and drying, a VCI spray can be applied to internal components. This provides protection even when the machine is not in operation, significantly slowing the corrosion process and preserving the integrity of critical components.

Chemical Contamination Residue Removal (pH Value Control Technology)

Shredders processing industrial waste may encounter materials contaminated with strong acids or alkalis. These chemicals can leave corrosive residues on metal surfaces that attack the metal over time. Neutralizing these residues is essential. This is achieved through pH value control technology, which involves applying a mild neutralizing agent to the affected area.

For instance, a surface contaminated with an acidic residue (low pH) can be treated with a mild alkaline solution, such as a diluted baking soda and water mixture. Conversely, a basic residue (high pH) requires a mild acidic solution, like a diluted vinegar rinse. The area is then tested with pH indicator paper to confirm it has been returned to a neutral state (pH 7) before being rinsed thoroughly with clean water and dried completely. This process prevents ongoing, hidden corrosion that could lead to component failure.

Microbial Growth Prevention and Control (Bacteriostat Selection Criteria)

In environments where organic material is shredded (e.g., food waste, paper pulp) and combined with moisture and warmth, microbial growth like bacteria, mold, and mildew can flourish. This biofilm is not just unhygienic; it can be acidic, promoting corrosion, and can clog filters and small passages. Controlling this requires the use of bacteriostatic agents, which inhibit the growth and reproduction of microorganisms.

When selecting a bacteriostat, key criteria include its efficacy against a broad spectrum of microbes, its compatibility with machine materials, its environmental safety, and its residual activity. Quaternary ammonium compounds are commonly used for this purpose as they are effective, stable, and can be formulated into cleaning solutions. After a standard cleaning, a quat-based solution can be applied to interior surfaces and allowed to air dry, leaving an invisible film that prevents microbial colonization for an extended period, thus maintaining a cleaner and more hygienic system.

Adaptation Solutions for Extreme Temperature Environments (-40℃~80℃)

Shredders operating in extreme temperatures, such as unheated warehouses in winter or hot foundries in summer, face unique material challenges. In cold environments, standard lubricants can thicken and become ineffective, elastomer seals can become brittle and crack, and condensation can form, leading to ice and internal rust. In hot environments, lubricants can thin out and lose their protective properties, and electrical components can overheat.

The cleaning and maintenance regimen must adapt. In cold climates, cleaning must be done more quickly to prevent water-based cleaners from freezing, and specialized low-temperature, synthetic lubricants must be used. All moisture must be meticulously removed after cleaning. In hot climates, cleaning may need to be more frequent to remove dust that impedes cooling. Heat-resistant lubricants are essential, and electrical connections must be checked more often for thermal degradation. In both cases, selecting cleaning agents and tools rated for the operational temperature range is critical to ensure they perform as intended without causing damage.

Maintenance Cycle and Effectiveness Evaluation System

Determining how often to clean a shredder and how to measure the success of that cleaning is vital for optimizing maintenance resources. An arbitrary schedule can lead to over-maintenance (wasting time and money) or under-maintenance (risking failure). A data-driven approach, based on the machine's actual usage and condition, creates a rational and cost-effective maintenance cycle.

An evaluation system transforms maintenance from a subjective task into an objective, measurable process. By tracking key performance indicators before and after cleaning, businesses can quantify the return on investment of their maintenance activities, justify expenditures, and continuously refine their procedures for maximum efficiency and equipment uptime.

Basis for Setting Cleaning Frequency (Usage Duration/Processing Volume)

The primary factors dictating cleaning frequency are the shredder's operational hours and the total volume of material processed. A shredder running two 8-hour shifts per day processing dense plastic will require more frequent cleaning than one running a single shift processing paper. Manufacturers often provide baseline recommendations, but these must be adjusted based on real-world use.

A more precise method involves monitoring the motor's amperage draw. As debris accumulates, the motor works harder, and the amperage reading will trend upward. By establishing a baseline amperage for a clean machine, operators can set a threshold—for example, a 10% increase in load—that triggers a cleaning cycle. This condition-based approach ensures cleaning happens exactly when it is needed, maximizing the interval between cleanings without risking damage from overloading.

Quantitative Indicators for Cleaning Effectiveness (Residue Rate/Noise Level)

The effectiveness of cleaning must be measured objectively. The residue rate is a key metric. This can be checked by running a small amount of clean, uniform material (like a few sheets of paper) through the machine after cleaning and inspecting the output collection area for any cross-contamination from previous materials or excessive dust. A low residue rate indicates a thorough cleaning of the cutting chamber and discharge pathways.

Noise level is another excellent indicator. A clean shredder typically operates with a consistent, smooth hum. Increased vibration and noise often point to imbalance, misalignment, or debris trapped in the cutting mechanism. Using a sound level meter to record dB levels before and after cleaning can provide a quantitative measure of improvement. A significant reduction in noise post-cleaning is a strong sign that mechanical components have been freed from obstructions and are running true.

Equipment Condition Monitoring Methods (Vibration Analysis/Temperature Monitoring)

Advanced condition monitoring techniques can predict maintenance needs and verify cleaning effectiveness. Vibration analysis involves placing sensors on key bearing points and the machine frame to measure vibration frequencies and amplitudes. A clean, well-aligned shredder will show a characteristic vibration signature. Changes in this signature can indicate issues like bearing wear, imbalance, or blade damage that might be related to or exacerbated by contamination.

Infrared temperature monitoring is equally valuable. Using a thermal camera, technicians can scan the shredder after a cleaning and subsequent run-up. Hotspots on bearings, the motor, or the hydraulic system can indicate excessive friction caused by inadequate lubrication (often due to contaminated grease) or misalignment. Establishing a normal temperature profile allows for easy identification of anomalies, enabling repairs before a failure occurs and confirming that the cleaning process has not inadvertently created a new problem.

Maintenance Cost Optimization Strategy (Preventive Maintenance Model)

The ultimate goal of any maintenance program is to minimize the total cost of ownership. A reactive, run-to-failure model is the most expensive due to unplanned downtime, higher repair costs, and shorter equipment life. A preventive maintenance (PM) model, based on scheduled cleanings and inspections, is far more cost-effective. It plans for downtime and addresses small issues before they become large ones.

The most advanced strategy is a predictive maintenance (PdM) model, which uses the condition monitoring data (vibration, temperature, amperage) to predict exactly when maintenance will be needed. This model further optimizes the maintenance schedule, ensuring that no unnecessary maintenance is performed while virtually eliminating unexpected failures. By investing in a structured PM or PdM program centered on thorough cleaning, facilities can achieve the lowest possible lifetime operating cost for their shredders, ensuring maximum availability and return on investment.

Industry Certifications and Standard Compliance

Adherence to international industry standards and certifications is not merely about legal compliance; it is a framework for ensuring safety, quality, and environmental responsibility. For industrial shredders, which are powerful and potentially hazardous machines, selecting cleaning tools, chemicals, and procedures that meet these standards is paramount. It protects the company from liability, ensures operator safety, and aligns with global sustainability goals.

These standards are developed by experts to address specific risks and operational challenges. Understanding their requirements allows businesses to make informed choices about the products they use and the practices they implement, creating a safer, more reliable, and more responsible operation.

CE Marking Guide for Cleaning Equipment Selection

The CE mark is a mandatory conformity mark for products placed on the market in the European Economic Area. It indicates that a piece of equipment, such as an industrial vacuum or ultrasonic cleaner, meets the EU's health, safety, and environmental protection requirements. For cleaning equipment used with shredders, this often involves compliance with the Machinery Directive (2006/42/EC) and the Low Voltage Directive (2014/35/EU).

Selecting CE-marked equipment ensures that the device has been assessed for risks like electrical safety, mechanical stability, and noise emissions. It provides assurance that the equipment has been designed and built to a high safety standard. For a facility, using CE-marked tools simplifies regulatory compliance and demonstrates a commitment to providing a safe working environment for employees, reducing the risk of accidents and associated liabilities.

RoHS Directive Restrictions on Cleaning Agents

The Restriction of Hazardous Substances (RoHS) Directive is a critical piece of EU legislation that restricts the use of specific hazardous materials found in electrical and electronic equipment. While it directly applies to the shredder itself, its principles are essential when selecting cleaning agents for these machines. Chemicals containing restricted substances like lead, mercury, or certain brominated flame retardants could potentially contaminate the shredder's electrical systems during cleaning.

Therefore, it is a best practice to choose cleaning agents that are RoHS-compliant, meaning they are formulated without these restricted substances. This is especially important when cleaning e-waste shredders, as it prevents the introduction of additional contaminants into the valuable material stream being processed for recycling. Using RoHS-compliant cleaners supports the overall goal of reducing the environmental impact of electronic products throughout their lifecycle.

OSHA Occupational Health and Safety Specifications

The Occupational Safety and Health Administration (OSHA) in the United States sets and enforces standards to ensure safe and healthful working conditions. Several OSHA standards directly impact shredder cleaning operations. The Lockout/Tagout (LOTO) standard (29 CFR 1910.147) is the most critical, mandating specific practices for disabling machinery during maintenance to prevent accidental startup.

Furthermore, standards for hazardous communication (HAZCOM, 29 CFR 1910.1200) require that employees are trained on the safe handling of cleaning chemicals, with access to Safety Data Sheets (SDS) for every product used. Regulations for respiratory protection (29 CFR 1910.134) and exposure to airborne contaminants also apply. Compliance with OSHA standards is not optional; it is a legal requirement that protects workers from serious hazards and protects employers from significant fines and legal action.

ISO 4406:2021 Cleanliness Level Standard

ISO 4406:2021 is an international standard that defines a coding system for representing the level of particulate contamination in a fluid, typically hydraulic oil or lubricants. While it directly applies to liquids, its philosophy is central to shredder maintenance: quantifying cleanliness. For a shredder's hydraulic system, maintaining a specific ISO cleanliness code (e.g., 18/16/13) is vital for reliability. Dirty oil is a leading cause of hydraulic component failure.

This standard provides a methodology for taking oil samples, analyzing them with a particle counter, and assigning a code based on the number of particles of different sizes present. By tracking this code over time, maintenance teams can determine the effectiveness of filtration systems and schedule oil changes based on actual condition rather than a fixed timeline. Adhering to a target ISO cleanliness code for lubricants is a best practice that dramatically extends the life of bearings, gears, and hydraulic pumps within the shredder.