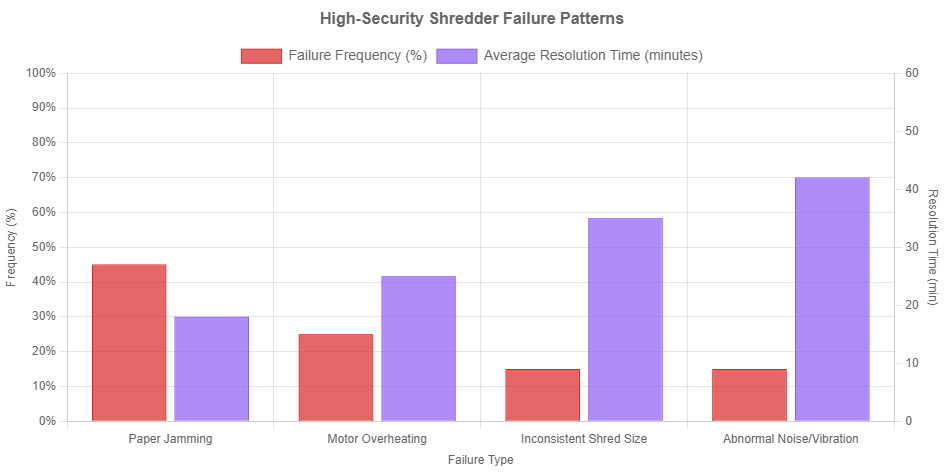

This comprehensive guide addresses the most frequent operational challenges encountered with high-security paper shredders in demanding environments. These industrial-grade machines are essential for confidential data destruction, but their complex mechanical systems can experience specific failures that disrupt workflow and compromise security protocols. We will systematically explore paper jamming causes, motor overheating issues, inconsistent shred quality, and abnormal noise patterns, providing actionable solutions backed by engineering principles and real-world case studies to ensure optimal performance and longevity of your critical data destruction equipment.

Root Causes and Solutions for Shredder Jamming

Paper jamming represents the most frequent operational disruption in high-security shredding operations, particularly in environments processing diverse document types. Unlike standard office shredders, industrial high-security units face challenging materials that test their mechanical limits. Jamming occurs when the feeding and cutting mechanisms cannot properly process the input material, causing a mechanical blockage that requires immediate attention to prevent motor damage or blade misalignment. Understanding the specific causes behind these jams is essential for both prevention and efficient resolution.

The consequences of frequent jamming extend beyond mere inconvenience. Each jam event places significant stress on the shredder's drive system, potentially leading to premature wear of gears, shafts, and cutting components. In high-security environments where document destruction must be timely and reliable, persistent jamming can create security vulnerabilities by forcing staff to bypass proper destruction protocols. A systematic approach to identifying and addressing jam causes can dramatically improve operational efficiency and reduce long-term maintenance costs.

Paper Type Mismatch and Blade Compatibility Issues

High-security shredders are engineered for specific material types, and using them outside these parameters frequently causes jams. Heavily laminated documents, cardboard, and envelopes with plastic windows present particular challenges. The adhesive qualities and varying tensile strengths of these materials can cause them to wrap around cutting shafts or create binding clusters in the cutting chamber. Each shredder model has specific limitations regarding the number of sheets, material type, and even the grain direction of paper that it can effectively process.

The cutting mechanism itself must be matched to the material. Cutting blades designed for cross-cut destruction of standard office paper may lack the necessary shear strength or clearance angles to cleanly process thicker materials. When non-compliant materials are fed into the system, they can cause immediate jams or gradually degrade cutting performance through accelerated blade dulling. Manufacturers typically provide clear specifications for acceptable material types, and adhering to these guidelines is the first defense against jam-related downtime.

Overload Protection Activation Due to Excessive Feed Rates

Industrial shredders incorporate overload protection systems that automatically shut down the machine when the mechanical load exceeds safe operating parameters. This most frequently occurs when operators attempt to feed materials too quickly into the machine, not allowing sufficient time for the cutting mechanism to complete its cycle. The internal torque sensing mechanism detects this strain and triggers a safety shutdown to prevent damage to the motor or drive train. While this protects the equipment, it manifests as what appears to be a jam condition to operators.

The solution involves both technical adjustments and operational training. Many modern shredders feature automated feed systems that regulate input timing to match the machine's processing capacity. For manual feed systems, visual or auditory indicators can help operators establish appropriate feeding rhythms. Additionally, ensuring that the shredder's gears transmission system is properly lubricated and adjusted reduces internal friction that contributes to premature overload triggering, allowing the machine to operate closer to its maximum designed capacity without safety shutdowns.

Screen Blockage from Excessively Fine Shred Particles

High-security shredders that produce very small particle sizes (such as micro-cut models) incorporate discharge screens that ensure uniform particle dimensions. These screens can become blocked when the volume of processed material exceeds the discharge capacity or when particularly fibrous materials create interlocking mats that resist free movement through the screen openings. This creates back-pressure in the cutting chamber that eventually leads to complete jamming of the mechanism.

Preventing screen blockages requires both proper operation and regular maintenance. Operators should avoid processing large quantities of materials with high tensile strength fibers (such as cotton-based papers or documents with reinforced edges) in single batches. Maintenance schedules should include regular inspection and cleaning of discharge screens, with particular attention to any signs of material buildup. In some cases, modifying the screen design to include anti-clogging features or vibration-assisted discharge mechanisms can significantly reduce blockage incidents in high-volume applications.

Motor Overheating and Frequent Shutdown Issues

Thermal management represents a critical aspect of shredder reliability, particularly in high-security applications where extended operation is necessary to process large volumes of sensitive materials. Motor overheating triggers automatic shutdowns that protect the equipment from permanent damage but disrupt workflow and potentially leave sensitive materials incompletely destroyed. The thermal protection systems in industrial shredders are designed to activate at specific temperature thresholds, typically between 80°C and 100°C, depending on the motor's insulation class and design specifications.

Frequent thermal shutdowns indicate underlying issues that extend beyond simple overuse. While all electric motors generate heat during operation, properly functioning shredders dissipate this heat efficiently enough to maintain stable operating temperatures even during extended run periods. When shutdowns occur regularly during normal operation, they signal problems with heat dissipation, electrical efficiency, or mechanical loading that must be addressed to prevent cumulative damage to the motor's windings, bearings, and insulation systems.

Ventilation Blockage and Cooling System Failures

The most straightforward cause of motor overheating is inadequate cooling airflow due to obstructed ventilation pathways. Industrial shredders operate in environments where paper dust and particulate matter are abundant, and these materials can quickly accumulate on intake grilles, heat sinks, and fan blades. A layer of dust as thin as 2-3 millimeters can reduce heat transfer efficiency by up to 30%, leading to progressively worse thermal performance until overheating occurs. Regular inspection and cleaning of all ventilation openings should be part of standard maintenance protocols.

More serious cooling system failures involve malfunctioning cooling fans or failed thermal management components. Many industrial shredders incorporate temperature-activated cooling fans that only engage when needed, and these systems can develop electrical faults or mechanical failures that prevent proper operation. Additionally, some high-capacity models use forced-air cooling systems with dedicated blowers that may require specific maintenance. Testing these systems under load conditions helps identify weaknesses before they lead to thermal shutdowns during critical operations.

Consequences of Exceeding Rated Continuous Operation Time

Every industrial shredder has a specified duty cycle that defines its sustainable operational parameters. This rating, usually expressed as minutes of operation followed by required cooling periods, is determined by the motor's thermal capacity and the efficiency of the cooling system. Continuously operating beyond these specifications causes heat to accumulate in the motor windings and bearings, leading to insulation degradation, lubricant breakdown, and ultimately premature motor failure. The damage from thermal overstress is cumulative and often irreversible.

For facilities with high-volume destruction needs, selecting equipment with an appropriate duty cycle is essential. True continuous-duty shredders incorporate specially designed motors with higher thermal tolerances and more robust cooling systems. When existing equipment cannot meet operational demands, implementing operational discipline through scheduled cooling periods or deploying multiple units in rotation can prevent thermal damage. Monitoring actual run times versus manufacturer specifications helps identify when equipment is being operated beyond its design limitations.

Impact of Voltage Instability on Motor Longevity

Electrical supply quality significantly affects motor performance and thermal characteristics. Voltage fluctuations, particularly under-voltage conditions, cause motors to draw higher current to maintain torque output. This increased current flow generates additional heat through I²R losses in the windings, potentially raising operating temperatures by 10-15°C even with adequate cooling. Industrial environments often experience voltage sags during peak operational periods, exactly when shredders are most needed for document processing.

Protecting shredders from voltage-related thermal stress requires both monitoring and conditioning equipment. Installing voltage recording instruments can help identify patterns of voltage depression that correlate with overheating incidents. For facilities with unstable power quality, voltage regulation systems or uninterruptible power supplies can clean the electrical signal before it reaches sensitive motor controls. Ensuring proper wiring gauge and secure connections throughout the power delivery system minimizes voltage drop between the distribution panel and the equipment, maintaining optimal electrical conditions for motor operation.

Strategies for Adjusting Inconsistent Shred Size

Consistent particle size represents a critical aspect of high-security destruction, with standards such as DIN 66399 specifying precise dimensional requirements for different security levels. Inconsistent shred size not only potentially violates compliance requirements but also indicates mechanical issues that could lead to more serious failures. The cutting mechanism in industrial shredders represents a precision system where even minor wear or misalignment can significantly impact output quality, making regular monitoring and adjustment essential for maintaining security standards.

The causes of inconsistent shred size range from simple wear components to complex systemic issues. Diagnosing the specific cause requires systematic examination of the cutting process from material entry through final discharge. The interaction between the cutting elements, the material being processed, and the machine's operating parameters all contribute to the final particle dimensions. Addressing shred size inconsistencies often involves multiple adjustments rather than a single repair, particularly in high-security systems where tolerances are exceptionally tight.

Cutting Performance Degradation from Blade Wear

The cutting elements in industrial shredders experience gradual wear that diminishes their cutting efficiency and precision. This wear occurs through both abrasive action from paper fibers and impact loading from occasional foreign objects or overly thick material batches. As cutting edges dull, they tear rather than cleanly shear material, producing irregular shreds with feathered edges that may fail security standards. The rate of wear depends on both material volume and type, with certain synthetic papers or laminated materials accelerating blade deterioration.

Monitoring blade condition requires both output inspection and direct examination. Security facilities should implement regular shred quality checks using sample collection and measurement against compliance standards. When output consistently fails to meet specifications, direct inspection of cutting components becomes necessary. Many industrial shredders feature modular cutting cartridges that can be rotated or replaced without complete disassembly. Establishing a preventive replacement schedule based on actual throughput volume rather than time prevents unexpected quality degradation while optimizing component lifespan.

Correction Methods for Screen Deformation and Misalignment

The discharge screen in micro-cut and high-security cross-cut shredders serves as both a sizing mechanism and a safety barrier. These screens can become deformed through impact damage or thermal stress, creating irregular openings that produce inconsistent particle sizes. Additionally, improper installation or vibration-induced loosening can cause misalignment between the cutting elements and the screen pattern, resulting in partially cut material that either jams the system or passes through as oversize particles.

Correcting screen-related issues requires precise measurement and adjustment. Specialized gauges are available to verify screen opening dimensions against manufacturer specifications. For screens with minor deformation, careful reshaping using approved methods can restore functionality without replacement. Ensuring proper mounting tension and alignment according to factory specifications prevents many sizing issues. Facilities processing mixed materials should consider implementing more frequent screen inspections, as certain plastic laminates or reinforced papers can cause accelerated wear or deformation of screen components.

Diagnosing Abnormal Noise and Vibration

Unusual acoustic and vibrational signatures represent some of the most valuable diagnostic indicators for industrial shredder condition. Unlike gradual performance degradation, changes in operational sound and vibration patterns often provide early warning of developing mechanical issues before they cause complete failure. High-security shredders incorporate numerous rotating and reciprocating components that generate characteristic vibration profiles when functioning properly, and deviations from these baseline patterns signal specific types of wear or misalignment.

Systematic noise and vibration analysis enables predictive maintenance that prevents unplanned downtime. Modern diagnostic approaches use both simple auditory techniques and advanced vibration analysis equipment to detect issues at their earliest stages. Establishing baseline acoustic and vibrational signatures when equipment is new and properly adjusted provides reference points for comparison throughout the machine's operational life. Training maintenance personnel to recognize abnormal sound patterns allows for intervention before minor issues escalate into major repairs.

Early Identification Methods for Bearing Deterioration

Bearings represent critical components in shredder drive systems, supporting high loads at substantial rotational speeds. Early bearing failure detection prevents catastrophic damage to shafts, housings, and other connected components. The initial stages of bearing deterioration produce distinctive acoustic signatures that often manifest before measurable vibration increases occur. Using an acoustic emissions sensor or even a simple mechanic's stethoscope, trained technicians can detect the high-frequency sounds generated by microscopic surface imperfections in bearing races and elements.

As bearing damage progresses, vibration patterns emerge at specific frequencies related to bearing geometry and rotational speed. Regular vibration monitoring using portable analyzers can track the development of these patterns, allowing replacement scheduling during planned maintenance windows rather than emergency responses to failure. For high-security facilities where unexpected downtime presents significant operational challenges, implementing a formal bearing monitoring program represents a valuable investment in operational reliability. Such programs typically reduce bearing-related failures by 70-80% compared to run-to-failure approaches.

Adjustment Techniques for Drive Belt Tension and Alignment

Power transmission systems in industrial shredders frequently use reinforced rubber belts that require specific tension and alignment to operate efficiently and quietly. Improper belt tension represents one of the most common sources of operational noise, producing distinctive squealing or chirping sounds during acceleration or under heavy load. Belt misalignment creates a different acoustic signature, often generating a rhythmic slapping or thumping noise as the belt tracks improperly across pulley surfaces.

Correcting belt-related noise issues requires precise measurement and adjustment. Tension should be verified using frequency-based tension gauges or deflection measurement tools rather than subjective assessment. Laser alignment tools ensure pulley systems operate with parallel shafts and proper belt tracking. The specific tension requirements vary based on belt type and configuration, making manufacturer specifications essential for proper adjustment. Facilities should incorporate belt tension and alignment checks into regular maintenance schedules, as these parameters naturally change over time through normal wear and operational vibration.