In the realm of industrial shredding, the selection of an output type is a critical strategic decision that extends far beyond mere particle size. The choice between strip-cut, cross-cut, and particle-cut outputs directly dictates the destiny and value regeneration of the processed materials. This article provides a comprehensive analysis of how these three primary output methods profoundly influence the efficiency, cost, and quality of downstream recycling processes. We will explore their intrinsic connections to material science, sorting technology, and recycling economics, offering a scientific basis for selecting the optimal shredding strategy for your operations.

Decoding Shred Output Types: A Morphological Definition from Strip to Particle

Understanding the fundamental differences between shred output types is essential for making informed decisions in waste management and material recovery. These types are defined by the physical configuration of the cutting shafts and the number of times material is cut during the shredding process. The morphology of the output material plays a pivotal role in determining its handling characteristics, storage density, and suitability for subsequent recycling stages.

The specific output is a direct result of the shredder's mechanical design. Different industrial applications demand different output specifications, driving the engineering of machines capable of producing precise and consistent particle shapes. This precision is crucial for automating downstream processes and maximizing the economic value of recycled materials.

Strip-Cut: Primary Shredding into Long Strands

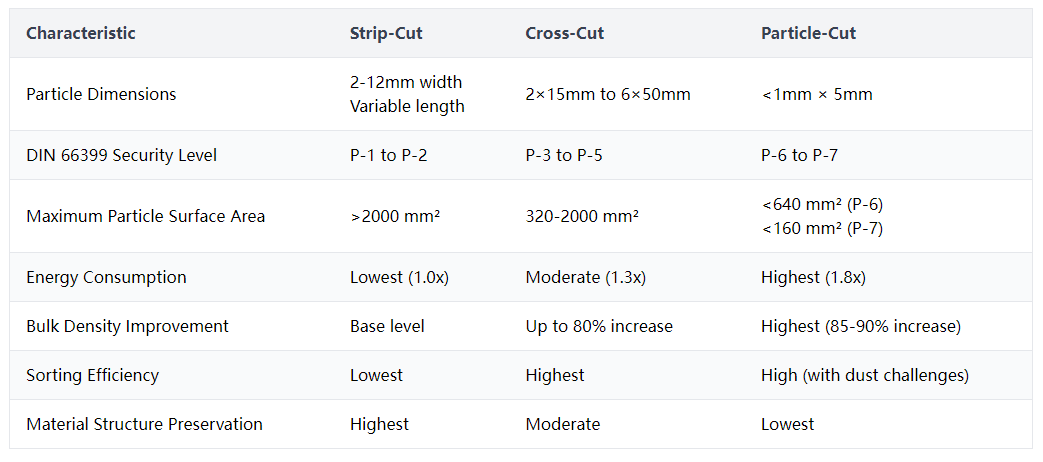

Strip-cut shredding represents the most fundamental form of size reduction. This process employs a relatively simple arrangement of parallel cutting shafts that slice material into long, narrow strands. The typical width of these strands can vary from 2 millimeters to over 12 millimeters, depending on the spacing of the cutters on the shafts. The length of the strands is inconsistent, often determined by the original size of the fed material and its inherent tensile strength.

The primary advantage of this method lies in its mechanical simplicity and high throughput. The cutting action is direct, requiring less torque and energy per ton of material processed compared to more complex cuts. This makes strip-cut a common starting point in two-stage shredding systems, where a primary shredder reduces bulk material before a secondary granulator refines it further. However, the long, fibrous nature of the output can present significant challenges in material handling and sorting systems.

Cross-Cut: The Balanced Choice for Granular Output

Cross-cut shredding, also known as confetti-cut, represents a significant evolution in shredding technology by introducing a secondary cutting plane. This is typically achieved through two sets of cutting shafts positioned perpendicularly to each other or via a single shaft system with angled blades that create a shearing action. The material is cut both longitudinally and laterally, resulting in small, granular particles that are often rectangular, diamond-shaped, or roughly circular.

The particle size is much more uniform than in strip-cut output, with typical dimensions ranging from 2x15mm to 6x50mm. This uniformity drastically improves the material's bulk density, reducing storage and transportation volumes by up to 80% compared to strip-cut output. The granular nature of cross-cut material also makes it far less prone to tangling around equipment rollers and screws in downstream recycling facilities, thereby minimizing operational downtime and maintenance requirements.

Micro-Cut / Particle-Cut: Ultimate Security Through Pulverization

Micro-cut or particle-cut shredding represents the pinnacle of size reduction and security. This process involves feeding material through multiple stages of cutting heads, each progressively reducing the particle size. A true particle-cut output is the result of three or more cutting actions, transforming documents and materials into a fine, confetti-like powder where individual particles are nearly indistinguishable.

The particle size is exceptionally small, often measuring less than 1mm x 5mm. This extreme reduction provides the highest level of security but requires significantly more complex machinery with higher power consumption. The engineering challenges include managing heat generation from intense friction and ensuring consistent feed rates to prevent jamming in the finely spaced cutting teeth. The resulting output has the highest bulk density but can sometimes be too fine for efficient air classification or screening in certain recycling processes.

The Correspondence Between Security Level and Output Type

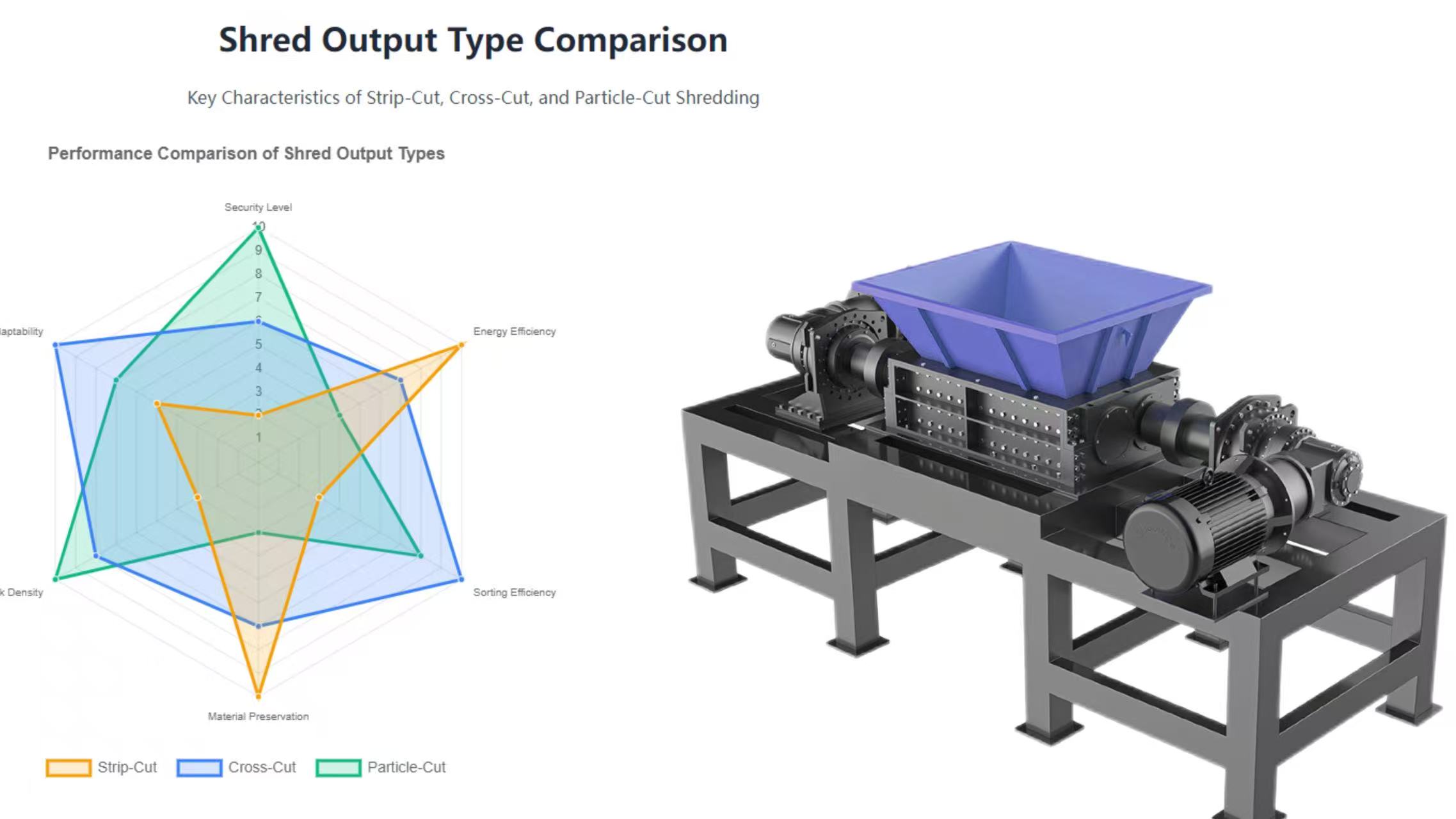

Internationally recognized standards, most notably the DIN 66399 standard, classify shredder security into distinct levels based on the resulting particle size and the information reconstruction effort required. These levels provide a clear framework for selecting equipment based on the sensitivity of the material being destroyed. The standard encompasses seven security levels, from P-1 for general office documents to P-7 for top-secret materials.

Strip-cut outputs generally correspond to the lower security levels, typically P-1 and P-2, with particle widths exceeding 12mm. Cross-cut outputs cover a broad middle range, from P-3 to P-5, with particle surfaces areas not exceeding 320 mm², 800 mm², and 2000 mm² respectively. Micro-cut outputs are mandatory for the highest security levels, P-6 and P-7, where particle surface areas must not exceed 640 mm² and 160 mm² respectively. This classification system ensures that shredding practices meet rigorous data protection and compliance requirements across various industries.

The Core Challenges of Recycling: Material Sorting and Contaminant Control

Modern recycling is a sophisticated industrial process that relies on precise engineering and advanced technology to separate and purify waste streams. It is far more complex than simple melting and remolding. The efficiency of these recycling processes is heavily dependent on the physical properties of the input material, which are directly influenced by the initial shredding stage.

The ultimate goal is to transform mixed waste into high-purity secondary raw materials that can compete with virgin resources. Achieving this requires a series of mechanical and sometimes chemical steps designed to isolate homogeneous material fractions. The morphology of the shredded material either facilitates or hinders these separation processes, making the choice of shred output a critical economic and environmental decision.

Sorting Technologies in Modern Recycling Facilities: Optics, Air, and Eddy Currents

Contemporary material recovery facilities (MRFs) employ a battery of advanced technologies to separate different materials. Near-Infrared (NIR) optical sorters use spectroscopy to identify material types based on their unique light reflectance signatures and then use precisely timed air jets to divert them into separate collection streams. These systems require a consistent and non-tangled feed of material to function accurately.

Air classifiers separate materials based on density and aerodynamic properties, effectively lifting light materials like films and papers while allowing heavier materials like metals and certain plastics to fall. Eddy current separators induce electrical currents in non-ferrous metals, repelling them from a conveyor belt into a collection bin. The effectiveness of all these technologies is maximized when the input material is of a uniform size and shape, free from intertwined strands that can carry contaminants into the wrong output stream.

Contaminants: The Crippling Impact of Mixed Materials on Recycling Quality

The economic value of recycled materials is almost entirely dependent on their purity. Even small percentages of foreign material can degrade the quality of an entire batch, rendering it unsuitable for high-value applications. For instance, plastic fragments in a paper pulp stream will create weak spots and discoloration in the resulting recycled paperboard. Metal shards mixed into plastic regrind can damage expensive extrusion dies during the pelletizing process.

The shredding process itself can either help or hinder the goal of purity. A poorly chosen output type can commingle materials so thoroughly that they become economically unviable to separate. The design of the shredding system must therefore be aligned with the composition of the input waste stream and the capabilities of the downstream sorting infrastructure to prevent the creation of a low-value, contaminated mixed fraction destined for landfill.

The Advantages and Limitations of Strip-Cut Output in Recycling

Strip-cut shredding occupies a specific niche in the recycling ecosystem, offering distinct advantages for certain material types while presenting significant challenges for others. Its applicability is highly dependent on the downstream processing technology available. A thorough understanding of these pros and cons is necessary for integrating strip-cut shredding into an effective material management strategy.

This method is often favored for its robustness and ability to handle large, voluminous items with minimal risk of jamming. The cutting mechanics are less complex than those of cross-cut or micro-cut systems, which can translate to lower initial capital investment and reduced maintenance costs. However, these benefits must be carefully weighed against the handling difficulties inherent in the long, fibrous output it produces.

Advantage: Lower Energy Consumption and a Simpler Shredding Process

The mechanical action of a strip-cut shredder is fundamentally straightforward. Material is drawn between two parallel rotating shafts equipped with cutting discs that shear it into strips. This direct cutting action requires less instantaneous torque and energy compared to the multi-directional shearing and tearing involved in cross-cutting. Studies on power consumption have shown that strip-cut shredding can consume up to 30% less energy per ton of material processed than an equivalent cross-cut operation.

The simplicity of the cutting mechanism also contributes to operational reliability. With fewer moving parts and a less demanding cutting action, strip-cut systems often experience lower wear rates on their cutting blades and bearings. This can lead to longer intervals between maintenance shutdowns and reduced spending on replacement parts, contributing to a lower overall cost of ownership for applications where its output characteristics are acceptable.

Advantage: Superior Material Structure Preservation for Specific Applications

For some recycling pathways, preserving the longitudinal fiber structure of a material is highly desirable. In the paper recycling industry, longer fibers are more valuable as they contribute to the strength and quality of the resulting recycled pulp. A gentle strip-cut process can do less damage to these valuable cellulose fibers compared to a aggressive cross-cut or micro-cut action that shortens them significantly.

Similarly, for certain plastics and textiles, a strip-cut output can be easier to wash and decontaminate. The larger surface area and open structure of the strands allow for more effective removal of labels, adhesives, and surface impurities in wash lines. This preserved structure can make the material more suitable for open-loop recycling applications where mechanical properties are critical, such as turning plastic bottles into polyester fibers for clothing.

Limitation: Proneness to Tangling and Sorting Difficulties

The most significant drawback of strip-cut output is its tendency to tangle and form large, matted clumps. In automated recycling facilities, these long strands readily wrap around the shafts of conveyors, the rotors of air classifiers, and the discs of optical sorters. This wrapping action causes frequent operational stoppages for manual clearing, reducing overall plant throughput and increasing labor costs. A single tangled mass can disrupt the entire sorting process for several minutes.

Beyond causing jams, the irregular shape and size of strip-cut material make it extremely difficult to sort efficiently. It does not flow evenly on conveyor belts, leading to poor presentation to optical sorters. It is also resistant to screening and size-based separation methods. This often results in lower purity rates in the output fractions and higher levels of cross-contamination, ultimately diminishing the market value of the recycled commodities produced.

Limitation: Inherent Security Risks for Data-Bearing Materials

While the focus here is on recycling, it is impossible to ignore the security implications of strip-cut shredding. The long, readable strips it produces offer minimal protection against information reconstruction. For any document containing confidential personal, financial, or corporate data, strip-cut destruction is considered grossly inadequate.

Modern data protection regulations, such as GDPR and HIPAA, effectively mandate much higher security levels that strip-cut shredding cannot provide. Therefore, its use is generally restricted to non-sensitive materials or to the pre-shredding stage of a two-stage system where a secondary granulator will further reduce the particle size to a secure level before the material enters the recycling stream.

Cross-Cut and Micro-Cut: Analyzing Recycling Adaptability with High Security

Cross-cut and micro-cut shredding have become the industry standard for applications balancing security needs with recycling efficiency. Their granular output morphology is inherently better suited to the automated, equipment-intensive nature of modern material recovery facilities. The uniform particle size they create introduces a level of predictability and control that is essential for high-volume, high-quality recycling operations.

These methods transform waste into a flowable, bulk material that behaves predictably on conveyors and in sorting machinery. This predictability allows recycling operators to fine-tune their equipment for maximum recovery and purity. The choice between cross-cut and the more extreme micro-cut often comes down to a trade-off between the desired security level, energy consumption, and the potential impact on the quality of the recycled material itself.

Enhanced Sorting Efficiency from Particle Uniformity

The consistent geometry of cross-cut and micro-cut particles is a major advantage in material sorting. Uniform particles spread evenly on conveyor belts, ensuring optimal presentation to the sensors of NIR optical sorters. This leads to higher identification accuracy and more precise ejection of target materials, directly increasing the purity of the output streams. A well-calibrated optical sorter can achieve purity rates exceeding 98% when processing uniformly sized material.

This uniformity also enables highly efficient size-based screening. Vibrating screens and trommels can be used to remove undersized contaminants (like dirt and glass fines) or to separate different material fractions based on their size before they reach more expensive sorting technologies. This pre-sorting step reduces the load on downstream equipment and improves the overall efficiency of the recycling plant. The free-flowing nature of the material also prevents bridging in hoppers and ensures consistent feed rates, which are critical for stable operation.

The Impact of Altered Density and Surface Area on Washing and Melting

The reduction in particle size significantly increases the total surface area of the material. This can be a double-edged sword in recycling. On one hand, a larger surface area can enhance the effectiveness of washing and cleaning processes. Detergents and solvents can more easily access and remove contaminants from the material's surface, leading to a cleaner recycled product. This is particularly beneficial for plastics recovered from post-consumer waste streams.

On the other hand, this increased surface area can make the material more susceptible to oxidation and thermal degradation during the melting process in plastics recycling or smelting in metal recycling. It can also mean that moisture and other volatile contaminants are more readily absorbed and harder to remove completely. For micro-cut materials, the extreme fineness can sometimes lead to the formation of dense, impermeable mats that resist water penetration and airflow in wash cycles, ironically making them harder to clean than larger particles.

The Challenge of Micro-Cut: Downgrading and Dust Handling

There is a point at which shredding material too finely can be detrimental to its recycling potential. For fiber-based materials like paper and cardboard, micro-cutting severely shortens the cellulose fibers. These shortened fibers lack the binding strength of longer fibers, resulting in recycled paper products with inferior structural integrity. This often forces the material to be "downcycled" into lower-value products like egg cartons or paperboard, rather than being recycled back into high-quality office paper.

Furthermore, micro-cut particles approach the size and behavior of dust. This creates significant housekeeping and industrial hygiene challenges, including dust explosion risks and respiratory hazards for workers. Air handling systems must be more robust to capture this fine particulate matter. In some cases, the cost of managing this dust can outweigh the value of the recovered material, making the process economically marginal and potentially leading to the landfilling of what could have been a valuable resource if shredded to a less extreme size.

Beyond Paper: Special Considerations for Metal, Plastic, and E-Waste Output

The principles of shredding output selection apply across a vast spectrum of materials, each with its own unique set of requirements for downstream processing. The optimal particle morphology for metal shredding differs from that of plastic shredding or e-waste processing. Understanding these material-specific needs is crucial for designing an efficient recovery chain.

Industrial shredders are engineered with specific cutting geometries and power trains to handle the distinct tensile strength, abrasiveness, and elasticity of different materials. The output is not just about size; it's about creating a particle that will behave in a predictable and beneficial way during the subsequent stages of liberation, separation, and purification that are unique to each material type.

Metal Shredding: Density and Volume Compression Ratios

In metal recycling, the primary goal of shredding is to reduce the volume of bulky scrap and to liberate different metals attached to each other. The output, often referred to as "frag," is a mixture of metal pieces, non-ferrous metals, and non-metallic residues. The density of this frag is a critical economic factor, as it directly impacts transportation costs to smelters and the efficiency of furnace charging.

While both chunkier and finer metal shreds have their place, a denser output is generally preferred. This often leads to the use of shear-type shredders that produce a compact, blocky particle. After shredding, the metal frag is frequently passed through a metal shredder's overband magnet to remove ferrous material and then through an eddy current separator to recover non-ferrous metals like aluminum and copper. The efficiency of these separation processes is highly dependent on the particle size and the degree of liberation achieved by the shredder.

Plastic Shredding: Granule Morphology for Extruder Feeding and Homogenization

The recycling of plastics almost always involves re-melting and re-pelletizing the material. The shredding stage is therefore a prelude to extrusion. For this process to be efficient and to produce high-quality pellets, the feed to the extruder must be consistent in size and shape. Uniform flakes or granules melt at a consistent rate, preventing unmelted particles from causing defects in the new pellet or damaging the extruder screw.

An ideal plastic shred output is a clean, uniformly sized flake that is free of dust and long, stringy "angel hair" that can wrap around equipment. The size is typically optimized to ensure efficient washing and drying; too large, and contaminants are trapped inside; too small, and material is lost in the water stream or becomes difficult to handle. The choice between a cross-cut and a granulator-style output is often determined by the type of plastic and the contamination level of the feed stock.

E-Waste Recycling: Precious Metal Liberation and Sorting

Shredding electronic waste is a delicate balance. The goal is to physically liberate the valuable components—such as gold-bearing CPUs, memory chips, and other precious metal-plated parts—from the bulk material like plastic casings and aluminum heat sinks without destroying those valuable components in the process. The shredding must be aggressive enough to break the devices apart but controlled enough to avoid reducing the precious components to a fine powder that is impossible to separate.

The output from an e-waste shredder is a complex mixture of materials. Subsequent sorting steps are highly sophisticated, employing shredders with tungsten carbide cutters to handle abrasive circuit boards, as well as a series of magnets, eddy current separators, and advanced optical sorters. The particle size and shape directly influence the yield of precious metals; an optimal shred will create a mixture where valuable metals are fully exposed and can be efficiently separated from the non-valuable substrate material.

Formulating Strategy: Selecting the Optimal Shredding Method for Your Recycling Goal

Choosing the right shred output type is a strategic decision that requires a holistic view of the entire material lifecycle, from point of generation to final re-manufacturing. There is no one-size-fits-all answer; the optimal choice depends on a careful balance of security mandates, material type, downstream infrastructure, and economic objectives. A methodical approach to this decision can maximize return on investment and ensure environmental compliance.

This decision-making process should be collaborative, involving not only the waste generator but also logistics providers, shredding operators, and most importantly, the end-market recyclers who will ultimately process the material. Their technical requirements and economic models are the final arbiters of what constitutes a "good" shred. The most sophisticated shredding operation fails if it produces an output that recyclers cannot or will not accept.

Priority Setting: Security Compliance vs. Maximizing Recycling Value

The foremost consideration must always be regulatory and security compliance. For data-bearing materials, the required security level (e.g., DIN 66399 P-4, P-5, etc.) is non-negotiable and will dictate the minimum shred fineness. Once the security threshold is met, the focus can shift to optimizing the output for recycling efficiency. In many cases, a cross-cut output (e.g., P-4) provides an excellent balance, offering high security while still producing a particle that is readily recyclable.

For non-sensitive materials, the decision is purely driven by economics and material flow. The goal is to produce an output that commands the highest price from recyclers, which is a function of its purity, bulk density, and ease of handling. This often leans towards a coarse cross-cut or a well-defined granulate that preserves material quality and minimizes downstream processing costs for the recycling partner.

Communication and Collaboration with Downstream Recycling Partners

Proactive engagement with recycling facilities is perhaps the most critical step in the strategy formulation process. Different MRFs and specialized recyclers have equipment calibrated for specific input size ranges and material forms. A shredder output that is perfectly suited for one facility might cause significant problems at another.

It is essential to understand the recycler's preferences and technical specifications. Some may have strict limits on the percentage of fines (dust) in a load, while others may require a minimum particle size to ensure efficient sorting. Establishing a direct dialogue ensures that the shredding process is aligned with market demand, creating a stable and valuable outlet for the processed material and avoiding costly rejection of loads at the recycling gate.

Investing in Flexible Shredding Systems with Adjustable Output

For organizations processing a wide variety of material streams, the most future-proof solution is to invest in a shredding system with adjustable output capabilities. Some advanced industrial shredders feature interchangeable cutting screens or adjustable screen meshes that allow the operator to change the output size based on the specific material being processed.

This flexibility allows a single machine to produce a coarse strip-cut for breaking down bulky plastic items, a standard cross-cut for general office waste, and a finer granulate for specific high-security or high-density requirements. While these systems often require a higher initial investment, they provide unparalleled operational adaptability, protecting the investment against changing material mixes, evolving security regulations, and fluctuating end-market demands.

Lifecycle Thinking: A Holistic Cost Assessment from Destruction to Rebirth

The final decision should be guided by a total lifecycle cost analysis that looks beyond the shredder's purchase price. This analysis must include operational costs (energy, labor, maintenance), logistical costs (transportation volume, frequency of collection), and revenue potential (value of recycled commodities).

A finer shred may have higher energy costs but lower transportation costs due to higher bulk density. A shredder that produces a high-quality, recyclable output may have a higher capital cost but generate significant revenue from material sales, offsetting the initial investment. Conversely, a cheap shredder that produces a low-value, contaminated output can incur hidden costs through high disposal fees for rejected material. The most sustainable and economical choice is the one that minimizes the total cost from the point of waste generation to its final transformation into a new product.