In large-scale office environments, the demand for secure and efficient document and material destruction is growing rapidly. Traditional manually-fed shredders are no longer sufficient for meeting the high-volume, high-security processing requirements of modern businesses. This article explores the core necessity of the Auto-Feed function in industrial-grade shredders, analyzing how it fundamentally transforms workflows, enhances security protocols, reduces operational costs, and becomes an indispensable component of a contemporary corporate information security management system. We will examine the strategic value of auto-feed technology from multiple perspectives, including efficiency, security, economic benefits, and future developments.

Understanding How Auto-Feed Technology Works in Industrial Shredders

Auto-feed functionality represents a significant engineering achievement, integrating sensing, mechanical, and control technologies into a cohesive system. It transcends the basic concept of automation by creating an intelligent, self-regulating process. This system is designed to handle continuous input with minimal oversight, distinguishing it fundamentally from the repetitive and labor-intensive nature of manual feeding operations.

The core principle involves a synchronized sequence where the machine assumes control of the material intake process. This eliminates the variability and potential for error introduced by human operators. The system is engineered for reliability and consistency, ensuring that every item fed into the paper shredder is processed according to predefined parameters without constant supervision.

Core Component Composition: Feed Tray, Sensors, and Conveyance Mechanism

At the heart of the system lies the feed tray or hopper, a dedicated compartment designed with substantial capacity. Industrial models often feature hoppers that can accommodate over 500 sheets at once, which is crucial for batch processing. The design prioritizes easy and safe loading of materials, allowing operators to deposit a large stack of documents without precise alignment.

Optical sensors continuously monitor the hopper for the presence of new material. Upon detection, a signal is sent to the central microprocessor to initiate the feeding cycle. The conveyance mechanism, typically comprised of durable rubber rollers or a belt-driven system, then engages. These components are designed to grip the topmost sheets gently yet firmly, pulling them from the stack and guiding them smoothly towards the powerful cutting blades of the shredding unit.

The Workflow Cycle: The Automated Sequence from Detection to Completion

The operational cycle begins in a standby mode, where the system consumes minimal power while the sensors remain active. When documents are placed into the hopper, the optical sensors detect their presence and trigger the feeding mechanism. The rollers rotate, engaging the first sheet and pulling it inward at a controlled speed.

The feeding continues until the sensors indicate the hopper is empty. Following the shredding of the last sheet, the system may operate for a few additional seconds to ensure all material has passed completely through the cutting unit before returning to its standby state. This entire process creates a closed-loop system that drastically reduces points of human intervention, thereby enhancing both security and operational efficiency.

Intelligent Control and Adaptability: Processing Different Materials and Thicknesses

Modern auto-feed systems are governed by sophisticated microprocessors that adjust operational parameters in real-time. These processors can modulate the feed speed and torque based on the resistance detected from the material. This allows the same machine to efficiently process a single sheet of standard paper, a thick report with staples, or even mixed media like plastic cards.

A critical aspect of this intelligence is the built-in overload prevention mechanism. If an unusually thick or rigid object is detected, the system can automatically reverse the feed rollers to eject the item, preventing a jam. This self-protection feature safeguards the machine's motor and cutting components from damage, reducing downtime and maintenance costs while ensuring consistent performance across a variety of materials.

Meeting High-Volume Demands: How Auto-Feed Enhances Operational Efficiency

The primary advantage of auto-feed technology in an industrial context is its direct address of the core challenge of high-volume destruction tasks. Large offices generate immense quantities of sensitive waste, and processing this manually is a significant bottleneck. Auto-feed shredders are engineered to remove this bottleneck, transforming a tedious, constant task into a streamlined, background operation.

This efficiency is not merely about speed but about the reallocation of valuable human resources. By automating the feeding process, these machines enable a shift from continuous manual labor to efficient batch processing. This allows organizations to handle larger volumes of material without a corresponding increase in labor hours, thereby scaling their operations effectively.

Liberating Human Resources: From Continuous Operation to Batch Processing

Manual shredding requires an employee to stand at the machine, feeding sheets one after another. This is an unproductive use of time for potentially hours each week. An auto-feed shredder redefines this workflow. An employee can load hundreds of sheets into the hopper, activate the cycle, and immediately return to other, more valuable tasks.

The productivity gain is substantial. For instance, an employee who previously spent five hours per week on shredding can now complete the same task in less than thirty minutes of cumulative loading time. This reclamation of over four hours of productive labor per week per employee translates into a significant boost in overall organizational efficiency and a reduction in operational costs.

Enabling Uninterrupted Continuous Shredding Capability

The large-capacity hopper is a key feature that supports extended operation. Unlike manual feeding, which requires pauses to add more material, an auto-feed system can run continuously until the entire batch is destroyed. This is particularly vital for centralized destruction events, such as clearing out archived files or conducting regular departmental purges.

This continuous operation capability means a single machine can process a week's worth of accumulated documents in one focused session. It ensures that destruction schedules are met reliably without causing disruptions to other office activities, making it an ideal solution for implementing a consistent and reliable information lifecycle management policy.

Quantifying Efficiency Gains: A Comparative Analysis of Volume and Time Savings

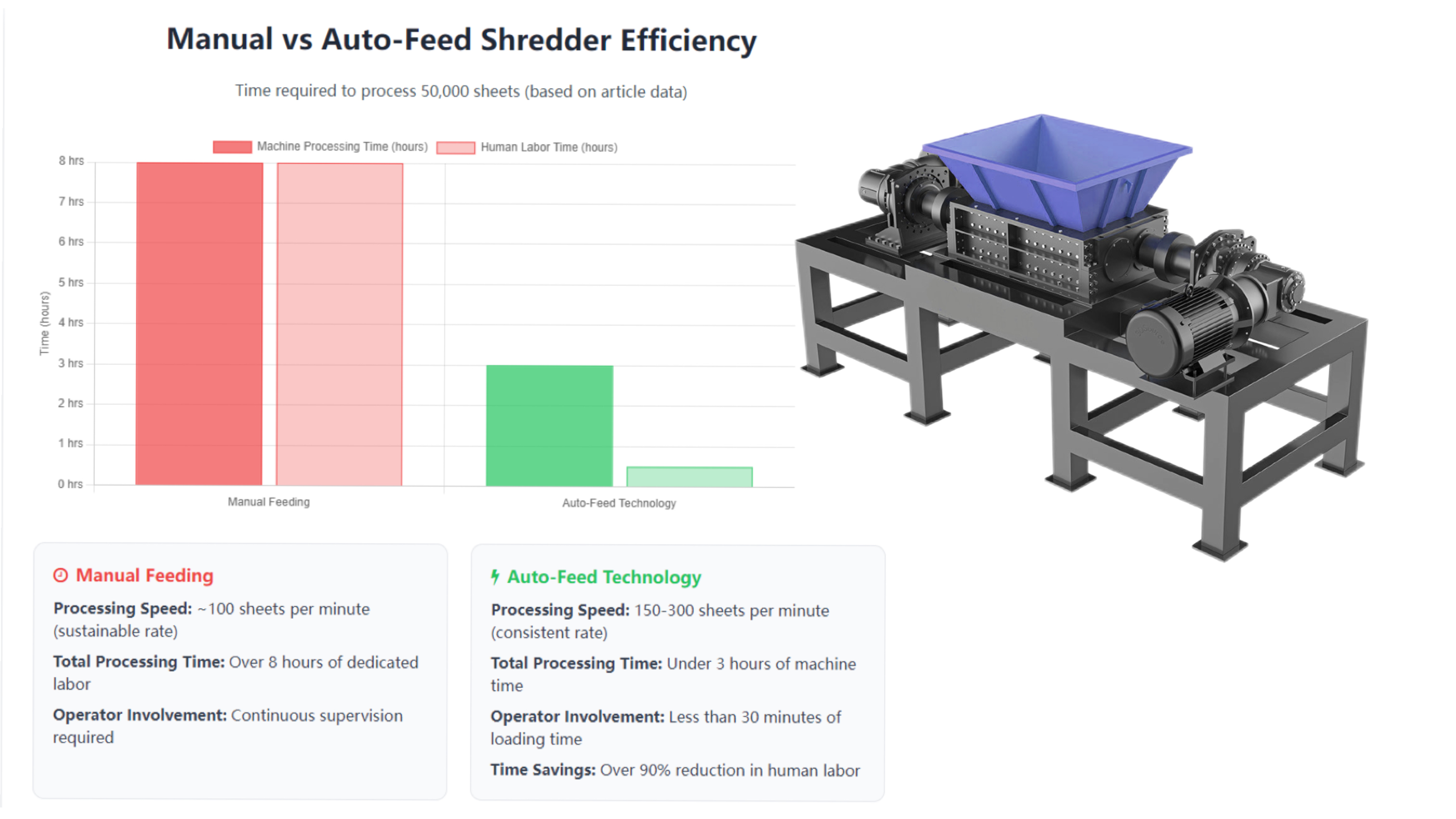

The efficiency difference between manual and auto-feed systems can be quantified. A typical office employee operating a manual shredder might process approximately 100 sheets per minute, but this rate is unsustainable over long periods due to fatigue. In contrast, an industrial auto-feed shredder can maintain a consistent feed rate of 150 to 300 sheets per minute for hours.

This translates to a machine processing between 9,000 and 18,000 sheets per hour. For an office that destroys 50,000 sheets per week, a manual process could take over 8 hours of dedicated labor. An auto-feed system could complete this task in under 3 hours of machine time, with less than 30 minutes of human labor required for loading, representing a time saving of over 90% for the employee.

Beyond Efficiency: The Security and Compliance Advantages of Auto-Feed

While efficiency is a major benefit, the role of auto-feed technology in enhancing security and ensuring compliance is perhaps even more critical for modern organizations. In an era of strict data protection regulations, the destruction process itself must be secure and auditable. Auto-feed shredders provide a technological solution to human-centric security vulnerabilities.

These systems introduce a layer of control and consistency that is impossible to achieve with manual operation. They standardize the destruction process, minimizing human factors that could lead to errors, omissions, or security breaches. This makes the auto-feed function not just a convenience tool but a powerful instrument for risk management and regulatory adherence.

Eliminating Human Error and Visual Exposure Risks

A significant security risk in manual shredding is the unavoidable visual exposure of sensitive information. Operators tasked with feeding documents one by one inevitably see confidential data, from financial reports to personal employee information. This exposure creates a potential vector for information leakage, whether intentional or accidental.

Auto-feed technology mitigates this risk entirely. The design allows an operator to load a stack of documents into the hopper without needing to view the contents of each page. The operator can turn away from the machine immediately after initiation, ensuring no sensitive information is read or memorized. This process aligns perfectly with strict data confidentiality principles required by standards like GDPR or HIPAA.

Ensuring Process Integrity and Auditability

Security is as much about process as it is about technology. Auto-feed shredders create a "load-and-go" closed system. Once documents are placed in the hopper and the cycle starts, the entire stack is processed without any further handling until it emerges as shreds in the collection bin. This eliminates the risk of documents being accidentally dropped, misplaced, or intentionally removed during the feeding process.

This closed-loop process provides a clear and demonstrable chain of custody for sensitive materials from the point of disposal to destruction. For compliance officers and auditors, this offers tangible proof that destruction procedures are followed correctly. Many advanced models can even be equipped with software that logs usage times and volumes, creating digital audit trails for compliance reporting.

Standardized Output and Consistency Assurance

The security level of shredding is defined by the particle size of the output. Manual feeding is inconsistent; feeding too fast can overload the machine and cause imperfect shredding, while feeding too slowly is inefficient. Auto-feed systems maintain a precise, constant speed that matches the optimal capacity of the cutting blades.

This results in a uniform shred particle size every time, ensuring the specified security level (e.g., P-5, P-7) is consistently achieved. This consistent output is crucial for meeting the requirements of data destruction certifications and provides certainty that all materials have been destroyed to a standard that makes reconstruction impossible.

Economic Analysis: Evaluating the ROI of Auto-Feed Functionality

Investing in an industrial auto-feed shredder represents a strategic capital expenditure rather than a simple cost. The justification for this investment is found in a comprehensive Return on Investment (ROI) analysis that extends beyond the purchase price to encompass long-term savings in labor, operational efficiency, and risk mitigation. The higher initial investment is typically offset by measurable financial benefits over a surprisingly short period.

The economic argument is built on converting saved time into saved money, reducing indirect costs associated with operational delays, and minimizing future maintenance expenses. A holistic view of the Total Cost of Ownership (TCO) reveals that auto-feed technology offers compelling financial advantages for medium to large organizations.

The Long-Term Calculation of Labor Cost Savings

The most immediate and calculable savings come from reduced labor requirements. By quantifying the hours previously dedicated to shredding and applying the average hourly wage plus associated employment costs, the annual labor savings become clear. For example, if an employee earning $25 per hour (including benefits) saves 4 hours per week, the weekly saving is $100.

This amounts to over $5,000 in annual labor cost savings per machine. An industrial auto-feed shredder might carry a $5,000 premium over a comparable manual model. In this scenario, the investment would pay for itself in labor savings alone in less than twelve months. Every year thereafter represents a pure financial gain, making it a highly attractive investment.

Reducing Operational Disruption and Opportunity Cost

Beyond direct wages, there is a significant opportunity cost associated with tying up employees in low-value, repetitive tasks. The time employees spend manually feeding a shredder is time they are not spending on their primary, value-adding responsibilities such as customer service, analysis, or creative work.

Freeing up this time allows the organization to achieve more with its existing workforce, effectively increasing its capacity without hiring new staff. This reduction in operational disruption enhances overall departmental productivity and agility, contributing positively to the organization's bottom line in ways that are sometimes difficult to measure but are undoubtedly real.

Lowering Maintenance and Repair Costs from Overload and Misoperation

Manual feeding is a leading cause of shredder jams and motor strain. Feeding too many sheets at once or inserting non-conforming materials can lead to immediate breakdowns requiring technical service. Auto-feed systems are designed with intelligent safeguards that prevent these situations.

The controlled, consistent feed rate reduces wear and tear on the cutting blades and motor, extending the operational lifespan of the machine. Furthermore, built-in overload protection and automatic reverse functions prevent jams, drastically reducing downtime and the frequency and cost of service calls. This results in lower long-term maintenance costs and greater machine availability.

Integration and Future-Proofing: Auto-Feed in the Modern Office Ecosystem

Modern office equipment is increasingly expected to function as an integrated component of a larger digital and operational ecosystem, not as a standalone island. Auto-feed shredders are at the forefront of this trend, offering features that facilitate seamless integration into centralized waste management protocols and IT infrastructure.

This integration capability future-proofs the investment, ensuring the machine remains a valuable asset as office workflows evolve and security requirements become more stringent. The technology provides a platform for connectivity and data management that elevates the humble shredder from a simple destruction tool to a smart office appliance.

Seamless Integration with Centralized Destruction Strategies and Workflows

Large organizations often implement centralized destruction policies, where sensitive waste from various departments is collected and destroyed in a controlled, secure location. The high-volume capacity and automated nature of auto-feed shredders make them the ideal endpoint for this workflow.

They can be integrated into the physical layout of a records management room or a secure disposal center, acting as the final step in the information lifecycle. This supports a standardized, company-wide approach to data security, ensuring all materials are destroyed to the same high standard, regardless of their origin within the organization.

Support for a Wider Range of Material Types

Contemporary offices dispose of more than just paper. Sensitive information can be stored on CDs, DVDs, credit cards, ID badges, and thick binders. Advanced auto-feed shredders are engineered to handle this variety of media. They feature reinforced cutting units and specialized feed paths designed to destroy these diverse materials effectively.

This versatility ensures that an organization can maintain a consistent and secure destruction policy for all its sensitive waste streams using a single device. It eliminates the need for separate machines for paper and hard media, saving space, capital, and simplifying the operational process for employees.

Technology Upgrade Potential: Connectivity and Data Management

The future of industrial equipment lies in connectivity and the Internet of Things (IoT). Modern auto-feed shredders are platforms for this technological evolution. They can be equipped with network connectivity to transmit usage data to facility management systems.

This enables remote monitoring of machine status, predictive maintenance alerts based on actual usage, and automated generation of destruction audit reports. This data can be integrated into broader security information and event management (SIEM) systems, providing administrators with a complete view of their physical and digital security posture.

Decision Guide: Does Your Enterprise Need an Auto-Feed Shredder?

The decision to invest in an auto-feed industrial shredder should be based on a careful assessment of your organization's specific needs, volumes, and security requirements. While the benefits are clear, they must be weighed against the initial investment to determine the right fit. A structured evaluation framework can guide this critical procurement decision.

This decision is not one-size-fits-all. Factors such as daily shredding volume, the sensitivity of handled information, available staffing, and existing workflows all play a crucial role. A thorough analysis will determine whether the efficiency, security, and economic advantages justify the investment for your particular operational context.

Key Evaluation Metrics: Daily/Weekly Volume, Security Level, HR Configuration

Organizations should begin by quantifying their current destruction needs. A clear threshold is often a daily volume exceeding 2,000 sheets. If weekly shredding tasks require more than 10-15 hours of dedicated staff time, automation becomes a compelling solution. Security requirements are another critical factor; if your organization handles data requiring P-5 (3.9mm particle) security or higher, the consistency provided by an auto-feed system is virtually mandatory.

The configuration of human resources is also key. Offices where administrative staff are already stretched thin cannot afford to allocate hours to manual shredding. In such environments, the labor liberation offered by an auto-feed machine provides immediate and appreciable relief, improving morale and allowing a focus on core duties.

Scenario-Based Needs Analysis for Different Office Sizes

A small office with five employees generating a few hundred sheets per week may find a heavy-duty manual shredder sufficient. A medium-sized enterprise headquarters with 50-100 employees, however, likely generates enough material to make an auto-feed model a wise investment. For large institutions like banks, insurance companies, or government agencies, where daily volumes can reach tens of thousands of sheets and security is paramount, an industrial auto-feed system transitions from being an option to an essential infrastructure component.

These organizations benefit not only from the efficiency but also from the robust audit trails and impeccable security credentials that these advanced systems provide, which are necessary for regulatory compliance and protecting against data breaches.

Weighing Total Cost of Ownership (TCO) Against Functional Premium

The smartest procurement decision looks beyond the initial sticker price. The Total Cost of Ownership (TCO) includes the purchase price, expected maintenance costs over five to seven years, consumption costs like energy and bags, and the significant cost of the labor required to operate the machine. An auto-feed shredder may have a higher purchase price but a significantly lower TCO due to massive savings in labor and reduced maintenance.

Furthermore, the TCO calculation should include the mitigation of risk costs. The financial and reputational damage from a single data breach caused by improper disposal can dwarf the entire cost of a high-security shredding system. Investing in auto-feed technology is, in this light, a form of insurance against catastrophic loss.

Key Comparison Points for Mainstream Auto-Feed Shredder Specifications

When comparing models, focus on several critical technical specifications. The hopper capacity determines how much material can be loaded at once; look for capacities of 500 sheets or more. The feed rate, measured in feet per minute, determines processing speed. The supported media types are crucial; ensure the model can handle paper, staples, clips, CDs, and cards.

The security level rating (e.g., P-4, P-5, P-7) certifies the particle size of the output. Finally, examine the bin capacity to ensure it aligns with your volume, reducing the frequency of emptying. Paying attention to these specifications will ensure the selected machine meets your operational demands both now and in the foreseeable future.