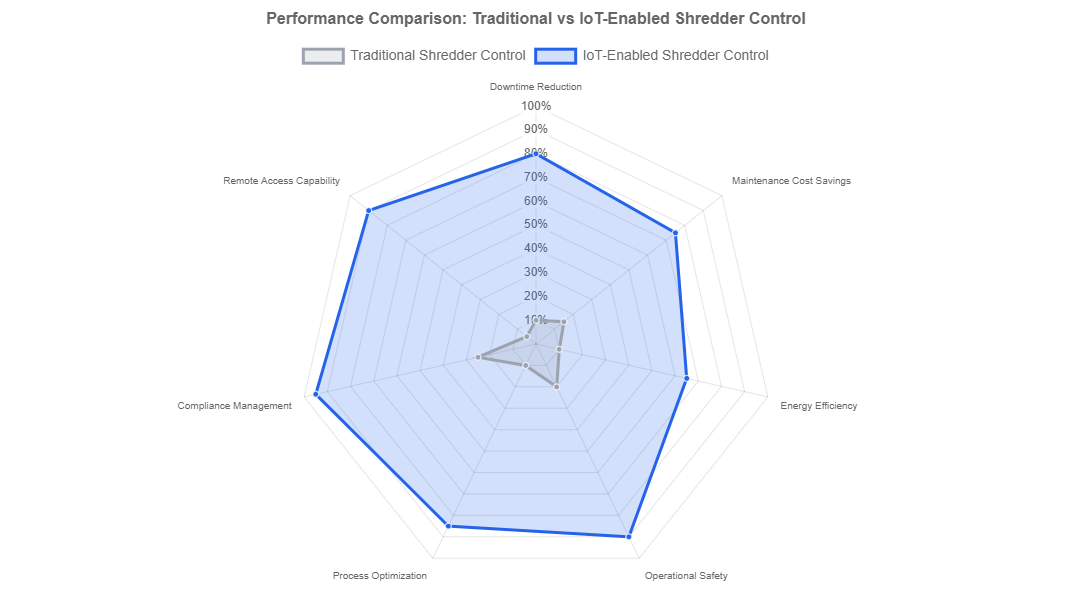

The Internet of Things (IoT) is fundamentally reshaping how industrial shredders are operated and maintained. By integrating a network of sensors, edge computing devices, and cloud platforms, these powerful machines are transforming from isolated units into intelligent, data-driven components of a larger waste management ecosystem. This technological evolution enables unprecedented levels of automation, efficiency, and predictive insight, moving operations from reactive interventions to proactive optimization.

This article delves into the core applications of IoT in shredder control, illustrating how real-time data acquisition and analysis can revolutionize six key areas: operational monitoring, predictive maintenance, energy management, remote control, data analytics, and compliance. The adoption of these smart technologies is not merely an upgrade; it is a strategic imperative for businesses aiming to build a resilient, efficient, and future-proof digital waste processing infrastructure that minimizes downtime and maximizes return on investment.

IoT Technology Infrastructure Design

The transformation of a standard shredder into a smart, connected device begins with a robust and layered IoT architecture. This framework is designed to seamlessly collect, process, and transmit data from the harsh industrial environment of the shredding floor to decision-makers anywhere in the world. A well-designed infrastructure ensures data reliability, system security, and operational scalability, forming the foundational nervous system for all advanced IoT applications.

This architecture is typically structured in three distinct tiers: the sensor layer embedded on the machine itself, the edge gateway for local data processing, and the cloud platform for holistic analysis and storage. Each layer has a specific role, working in concert to reduce latency, conserve bandwidth, and provide a comprehensive view of the shredder's health and performance. Selecting the right components and protocols for each layer is critical for building a system that is both powerful and practical.

Composition of a Shredder IoT System (Sensor Layer/Edge Gateway/Cloud Platform)

The sensor layer is the frontline of the IoT system, consisting of various physical devices attached to the shredder. These include vibration sensors on bearings and the shredder shaft, current sensors on motor windings, temperature and humidity sensors in the control panel, and laser sensors monitoring the feed opening. These sensors continuously capture raw analog data about the machine's physical state, converting it into digital signals for further processing.

An edge gateway acts as a local data hub, often mounted near the shredder. It aggregates data from all sensors, performing initial filtering, preprocessing, and time-sensitive analysis. For example, it can instantly detect an anomalous vibration pattern and trigger an immediate alarm without waiting to send data to the cloud. This reduces response time and bandwidth usage. Processed data is then packaged and securely transmitted via industrial protocols to the cloud platform, where it is stored, visualized on dashboards, and subjected to deeper, long-term analytical models.

Industrial Protocol Adaptation (MQTT/OPC UA/Modbus)

For different components within the IoT system to communicate effectively, they must speak a common language, known as a protocol. Modbus is a classic, widely adopted protocol used to connect PLC and HMI systems with sensors and actuators. It is reliable and simple, making it a common choice for basic data reading and writing operations within the industrial environment of a shredder.

Modern IoT systems increasingly favor more advanced protocols like MQTT and OPC UA. MQTT is a lightweight publish-subscribe protocol designed for efficient data transmission in low-bandwidth situations. It is ideal for sending sensor readings from the edge gateway to the cloud. OPC UA is a more robust, secure, and interoperable standard that provides a unified framework for not just data exchange but also complex information modeling, ensuring that data from a vibration sensor on one brand of shredder can be understood by a cloud platform from another vendor.

Network Security Architecture (Data Encryption/Access Control)

Connecting an industrial shredder to the internet introduces potential cybersecurity risks that must be rigorously managed. A comprehensive security architecture begins with encrypting all data both at rest (stored in the cloud) and in transit (moving between the edge and the cloud). This is typically achieved using strong encryption standards like TLS (Transport Layer Security), which prevents unauthorized interception and reading of sensitive operational data.

Access control is equally critical. Role-based access control (RBAC) systems ensure that only authorized personnel can view data or perform actions. For instance, a machine operator might have permission to view real-time status dashboards, while a maintenance manager has additional rights to access historical performance trends, and only a system administrator can change critical operational parameters. Multi-factor authentication adds an extra layer of security, requiring more than just a password to gain access to the system.

Low-Power Communication Technologies (LoRaWAN/NB-IoT)

In large recycling facilities or remote waste management sites, running Ethernet cables to every shredder can be impractical and expensive. Low-Power Wide-Area Network (LPWAN) technologies solve this challenge. LoRaWAN enables long-range communication (over 10 km in rural areas) with very low power consumption, allowing battery-powered sensors to operate for years. This is ideal for monitoring parameters like tank levels or ambient temperature around shredders spread across a large yard.

NarrowBand IoT (NB-IoT) is another LPWAN technology that operates on licensed cellular bands. It offers deeper penetration through walls and structures, making it suitable for monitoring shredders located inside buildings or underground. It provides highly reliable and secure connectivity, leveraging existing cellular infrastructure. The choice between LoRaWAN and NB-IoT depends on factors like network coverage, data transmission frequency, and infrastructure costs, but both enable the cost-effective deployment of IoT across extensive industrial sites.

Real-Time Operational Status Monitoring

The immediate benefit of an IoT system is the ability to monitor every critical aspect of a shredder's operation in real time. This moves machine management from periodic manual checks to a continuous, automated stream of actionable intelligence. Operators and managers gain a living, breathing digital twin of the physical equipment, allowing them to see precisely what is happening inside the machine at any given moment, from anywhere.

This constant vigilance helps in optimizing performance, preventing catastrophic failures, and ensuring consistent output quality. By tracking key parameters, the system can provide immediate alerts when anything deviates from normal operating ranges, enabling swift intervention before a minor issue escalates into a major problem, thereby safeguarding both the equipment and the production schedule.

Blade Wear Monitoring (Vibration Analysis Technology)

As shredder cutting blades wear down or become damaged, the machine's vibration signature changes dramatically. IoT systems use high-frequency accelerometers mounted on the bearing housings of the rotor to continuously monitor these vibrations. The data is analyzed using Fast Fourier Transform (FFT) algorithms to break down complex vibration patterns into specific frequencies and amplitudes.

By establishing a baseline vibration profile for a new, sharp set of blades, the system can detect subtle changes indicative of wear. For instance, an increase in amplitude at specific harmonic frequencies often signals that a blade has chipped or become dull. This allows maintenance to be scheduled precisely when needed—after processing a certain tonnage or when wear reaches a critical threshold—preventing unexpected breakdowns and ensuring consistent shredding quality without the need for manual, periodic inspections.

Feed Opening Blockage Early Warning (Laser Distance Sensors)

Blockages at the feed opening or in the hopper are a common cause of shredder downtime. IoT solutions combat this using non-contact laser distance sensors positioned above the feed throat. These sensors constantly measure the distance to the top of the material pile. Under normal conditions, the distance fluctuates as material is fed and processed.

If the measured distance remains constant for a preset period while the shredder is running, it indicates that material has stopped flowing—a clear sign of a bridging or blockage event. The system can then instantly send an alert to an operator's dashboard or mobile device and can even be programmed to automatically reverse the feed mechanism for a few seconds to attempt to clear the obstruction, preventing a full stall and protecting the motor from overload.

Real-Time Motor Load Tracking (Current Sensors)

The electric motor is the heart of the shredder, and its load is a direct indicator of the effort required to process the material. Clamp-on or integrated current transformers continuously measure the amperage draw of the main drive motor. This real-time data is streamed to the IoT platform and displayed on a dashboard, often as a percentage of the motor's full-load amperage rating.

Monitoring this load provides invaluable insights. A sudden, sharp spike in current may indicate an attempt to shred an unprocessable object (like a metal bar in a paper shredder), triggering an immediate emergency stop. A gradual but steady increase over time can signal growing resistance due to blade wear or bearing issues. Furthermore, operators can use this data to optimize feed rates, ensuring they are running the machine at its most efficient capacity without risking overload.

Environmental Parameter Collection (Temperature/Humidity/Dust Concentration)

The environment around a shredder significantly impacts its operation and longevity. IoT sensors deployed around the machine monitor ambient temperature and humidity. High temperatures can affect motor cooling and hydraulic fluid viscosity, while high humidity can promote rust on critical components, especially in metal shredding applications where corrosion is a constant threat.

Perhaps most critically, laser-based dust monitors measure the concentration of airborne particulates. In applications like e-waste shredding, where dust may contain hazardous materials, or in any application where combustible dust is a risk, this monitoring is essential for safety. If dust levels exceed safe thresholds, the system can automatically activate enhanced dust extraction systems and alert personnel, helping to ensure a safe working environment and prevent potential fire hazards.

Predictive Maintenance System Construction

Predictive maintenance represents a paradigm shift from traditional time-based or reactive maintenance models. By leveraging IoT data, maintenance is performed only when evidence of actual need is detected, thereby avoiding unnecessary maintenance tasks and preventing unexpected failures. This approach transforms maintenance from a cost center into a strategic value-add function that maximizes equipment availability and lifespan.

An IoT-driven predictive maintenance system for a shredder uses historical and real-time data to model the machine's health. It identifies subtle trends and patterns that precede failures, allowing maintenance to be planned weeks or even months in advance. This scheduling can be aligned with production calendars to minimize disruption, ensure parts are available, and ultimately drive down the total cost of ownership of the equipment.

Fault Mode Identification (Machine Learning Algorithms)

The core of predictive maintenance lies in advanced algorithms capable of identifying the early signs of specific failure modes. Machine learning models are trained on vast datasets of historical operational data, including vibration spectra, temperature readings, and power consumption patterns from both normal operation and periods preceding known failures.

Once trained, these models continuously analyze incoming real-time data. For example, they can learn that a specific combination of a slight temperature increase in a bearing housing and a specific high-frequency vibration pattern is a reliable predictor of impending bearing failure, with a 95% confidence level. This allows the system to flag issues long before they would be noticeable to a human operator, providing a crucial window for planned intervention.

Dynamic Maintenance Cycle Adjustment (Usage Intensity Analysis)

Fixed maintenance schedules are inherently inefficient. A shredder processing soft plastics eight hours a day requires less frequent maintenance than one processing tough metals for 24 hours. IoT systems automatically adjust maintenance recommendations based on actual usage intensity. They track metrics like total motor operating hours, tonnage processed, and average motor load.

The software algorithms synthesize this data to calculate a dynamic "health index" or "remaining useful life" estimate for key components like blades, bearings, and hydraulic fluids. Instead of a calendar-based reminder, the system generates a work order when the health index of a component drops below a predefined threshold. This ensures that maintenance resources are used exactly when and where they are needed, optimizing both maintenance spend and machine reliability.

Spare Parts Demand Prediction (Inventory Management System Integration)

One of the biggest challenges of maintenance is having the right part available at the right time. IoT predictive systems solve this by integrating directly with enterprise inventory management (ERP) systems. When the algorithm predicts that a specific component, such as a set of tungsten carbide cutters, will need replacement in three weeks, it can automatically generate a purchase requisition or reserve the part from existing stock.

This integration ensures that critical spare parts are procured in advance, eliminating costly downtime waiting for parts to arrive. It also allows for better inventory control, reducing the capital tied up in unnecessary spare parts while preventing stock-outs. The system can even track the usage rates of consumables, like hydraulic oil or filters, and automatically reorder them based on actual consumption rather than guesswork.

Automatic Maintenance Task Dispatch (ERP System Integration)

Closing the loop on predictive maintenance requires seamless execution. Upon identifying a required maintenance action and confirming part availability, the IoT platform can automatically create a work order in the company's computerized maintenance management system (CMMS) or ERP. This work order contains all relevant details: the diagnosed issue, the required parts, the predicted time for completion, and even links to instructional videos or manuals.

The system can then automatically assign the task to the most appropriate technician based on their skills, current workload, and proximity to the machine. Notifications are sent directly to the technician's mobile device. This end-to-end automation ensures that critical maintenance tasks are never overlooked in a busy schedule, are completed efficiently, and are properly documented for future analysis and compliance auditing.

Energy Management Optimization Solutions

Industrial shredders are significant consumers of energy, and their efficiency has a direct impact on operational costs and environmental footprint. IoT technology provides the tools to measure, analyze, and optimize energy consumption with a level of precision previously unavailable. This goes beyond simply reducing bills; it involves understanding the energy profile of every process and making data-driven decisions to improve it.

By monitoring power consumption in real-time and correlating it with operational data like load and throughput, businesses can identify energy waste, optimize machine settings for efficiency, and automate energy-saving strategies. This holistic approach to energy management can lead to substantial cost savings and is a key component of corporate sustainability initiatives.

Real-Time Power Consumption Monitoring (Electricity Metering Modules)

The first step to optimization is measurement. Smart electricity metering modules, integrated into the shredder's power supply, provide real-time data on voltage, current, power factor, and active energy consumption (kWh). This data is fed into the IoT platform, which calculates key performance indicators like specific energy consumption—the energy used per ton of material processed.

This granular data reveals inefficiencies that would otherwise remain hidden. For example, the system might identify that the shredder consumes a disproportionate amount of energy during its startup phase or when running under a partial load. Operators can use this insight to adjust practices, such as minimizing stop-start cycles and ensuring the machine is fed consistently to operate near its optimal load capacity, thereby maximizing energy efficiency.

Load-Adaptive Adjustment (Variable Frequency Drive Technology)

Many traditional shredders run at a constant speed regardless of the load, which is highly inefficient. IoT systems can be integrated with Variable Frequency Drives (VFDs) to create a load-adaptive control system. Sensors monitoring the motor load and the feed rate provide real-time data to the VFD, which then intelligently adjusts the motor's speed and torque.

When the system detects a lighter load or a temporary decrease in feed material, it can automatically command the VFD to reduce the motor speed, significantly cutting energy consumption. Conversely, when a heavy load is detected, it can ramp up power to maintain performance. This dynamic adjustment ensures the motor only uses the energy required for the task at hand, typically reducing energy use by 20-30% compared to fixed-speed operation.

Peak-Valley Electricity Price Strategy Execution (Time Control Algorithms)

In many regions, electricity costs vary depending on the time of day, with peak hours being significantly more expensive. IoT systems can be programmed with algorithms that are aware of this tariff structure. The system can analyze the production schedule and the queue of material waiting to be processed.

For non-urgent shredding tasks, the system can automatically schedule the shredder to operate during off-peak, low-cost hours. It can even prepare the machine by pre-shredding a small amount of material during peak hours to ensure a smooth start when rates drop. This strategy requires no manual intervention and can lead to substantial reductions in energy costs without impacting overall production targets.

Carbon Footprint Tracking (Emission Calculation Models)

As businesses face increasing pressure to report and reduce their carbon emissions, IoT systems provide a automated solution for tracking the carbon footprint of shredding operations. The platform uses the real-time energy consumption data and multiplies it by the specific emission factor of the local electricity grid (e.g., kg of CO2 per kWh).

This provides an accurate, ongoing calculation of the greenhouse gas emissions attributable to the shredder. These metrics can be integrated into corporate sustainability reports, demonstrating a commitment to environmental responsibility. Furthermore, by quantifying the carbon savings achieved through energy optimization measures (like using a VFD), companies can accurately measure the environmental return on investment of their technology upgrades.

Remote Control and Automation

IoT connectivity dissolves the physical barrier between the operator and the machine, enabling secure remote control and advanced automation from virtually any location. This capability enhances operational flexibility, improves safety by reducing the need for personnel to be near powerful machinery, and allows for centralized management of distributed assets.

Automation goes beyond simple remote commands; it involves creating intelligent systems where the shredder can respond automatically to changing conditions, coordinate with other machines, and execute complex sequences without human input. This level of control maximizes throughput, ensures consistent operation, and allows human experts to focus on higher-level supervision and exception handling.

Mobile Device Control (iOS/Android Applications)

Dedicated mobile applications for iOS and Android devices put the control of an industrial shredder in the palm of an operator's hand. Through a secure VPN connection to the IoT platform, these apps provide a real-time dashboard displaying all critical parameters: motor load, bearing temperature, current status, and alarm notifications. They are not just for monitoring; they also enable control functions.

Authorized personnel can use the app to start and stop the shredder, adjust feed rates, and acknowledge alarms from anywhere on the facility floor or even off-site. This mobility increases responsiveness, as the nearest qualified person can address an issue immediately without having to travel to a fixed control panel, significantly reducing response times and improving overall operational agility.

Automatic Start-Stop Strategies (Material Detection Linkage)

Fully automating the shredder's operation cycle eliminates human error and optimizes efficiency. This is achieved by integrating the shredder's control system with material handling sensors. For instance, a photoelectric sensor or a weight sensor on the infeed conveyor can detect the presence of material ready to be processed.

The IoT system can be programmed to automatically start the shredder and its associated conveyors and dust collection systems when material is detected and automatically initiate a shutdown sequence after a preset period of inactivity. This ensures the machine only runs when there is work to be done, reducing energy consumption, minimizing wear and tear, and freeing up operators for other tasks. It also prevents the machine from running empty, which can cause unnecessary damage.

Multi-Machine Cooperative Operation (Cluster Management Protocols)

In large recycling plants, shredders often work in tandem with other equipment like overband magnets, air separators, and sorting systems. IoT enables these machines to communicate with each other as a coordinated cluster. A cluster management protocol allows them to share data and status updates in real-time.

For example, if a downstream sorting machine experiences a jam or shutdown, it can instantly send a signal to the primary shredder to pause feeding, preventing a backlog and potential overflow. Conversely, if the shredder is stopped for maintenance, it can notify upstream equipment to halt material delivery. This synchronized operation creates a smooth, efficient material flow through the entire plant, maximizing overall system throughput and preventing bottlenecks.

Remote Intervention in Abnormal States (Emergency Stop Mechanism)

Safety is paramount, and IoT enhances it with powerful remote intervention capabilities. If the system's algorithms or a remote operator identifies a dangerous condition—such as a severe overload, a rapidly rising temperature, or unauthorized access—an emergency stop command can be issued immediately from the cloud platform or a mobile device.

This command is transmitted securely and triggers the shredder's safety-rated motor thermal protection and braking systems to bring the machine to a safe stop. This remote e-stop function provides a critical layer of safety, allowing for immediate response to hazardous situations even if no one is physically present near the machine, protecting both personnel and equipment from harm.

Deep Data Value Mining

The true power of an IoT system is unlocked not just by collecting data, but by transforming it into actionable intelligence and strategic insight. The vast amounts of operational data generated by a connected shredder become a valuable asset for continuous improvement, process optimization, and informed decision-making at the management level.

Advanced analytics techniques are applied to this historical and real-time data to uncover patterns, correlations, and trends that are invisible to the naked eye. This deep data mining moves beyond basic monitoring to answer strategic questions about efficiency, quality, and future capacity, turning the shredder from a cost center into a source of competitive advantage.

Processing Efficiency Analysis (OEE Calculation Model)

Overall Equipment Effectiveness (OEE) is the gold standard for measuring manufacturing productivity. IoT systems automatically calculate OEE for the shredder by quantifying three factors: Availability (downtime losses), Performance (speed losses), and Quality (quality losses). The system tracks every minute of operation, classifying it into running, stopped, or producing defective output states.

By analyzing OEE trends, management can identify the root causes of inefficiency. For instance, a low Availability score might point to frequent jams requiring an upgrade to the anti-jamming mechanism. A low Performance score might indicate the machine is often run below its optimal speed. This data-driven approach targets improvements where they will have the greatest impact on overall output and profitability.

Material Type Identification (Spectral Analysis Technology)

Advanced shredding facilities are beginning to integrate material recognition technologies into their IoT platforms. Near-infrared (NIR) spectrometers or laser-induced breakdown spectroscopy (LIBS) sensors can be mounted at the infeed conveyor to analyze the chemical composition of incoming material before it enters the shredder.

This technology can distinguish between different types of plastics, identify alloys in scrap metal, or detect the presence of hazardous materials. The IoT system can then use this information to automatically adjust shredder settings (like speed and torque) for optimal processing of that specific material. It can also sort material by triggering air jets to divert different streams, or simply tag the data for later analysis, creating a detailed log of exactly what materials were processed and when.

Production Capacity Prediction (Time Series Analysis)

Predictive analytics models use historical time-series data—such as daily throughput, motor load, and downtime events—to forecast future production capacity. These models can account for seasonal variations, maintenance schedules, and planned upgrades. By analyzing past performance, they can accurately predict how much material the shredder is likely to process in the next week, month, or quarter.

This forecasting is invaluable for supply chain and sales planning. It allows management to confidently commit to processing volumes with customers, schedule raw material purchases, and allocate human resources. It can also predict when the current shredding capacity will be exceeded, providing a clear data-backed justification for capital investment in additional equipment before a bottleneck actually occurs.

Maintenance Knowledge Base Construction (Case Database)

Every maintenance event, alarm, and operational parameter recorded by the IoT system contributes to a growing maintenance knowledge base. This database becomes a powerful institutional memory tool. It allows technicians to search for past occurrences of a specific vibration pattern or error code to see how it was resolved previously, complete with notes, photos, and videos uploaded by the prior crew.

Over time, this curated knowledge base, built on real-world data, becomes the most valuable troubleshooting resource. It reduces the mean time to repair (MTTR) by guiding technicians to a solution faster, helps train new personnel, and continuously improves the predictive algorithms by providing them with more labeled examples of failures and their precursors. This transforms reactive problem-solving into a proactive, knowledge-driven process.

Safety and Compliance Assurance

In an industry governed by stringent safety protocols and environmental regulations, IoT technology provides a robust framework for ensuring continuous compliance and enhancing operational safety. Automated data logging, access controls, and audit trails replace error-prone manual records, creating an immutable digital history of the machine's operation and all interactions with it.

This capability is crucial for demonstrating due diligence to regulators, certifying bodies, and auditors. It not only helps avoid costly fines and penalties but also builds a culture of safety and transparency, protecting the company's reputation and providing peace of mind that operations are meeting the highest standards of safety and environmental responsibility.

Data Privacy Protection (GDPR Compliance Solutions)

For shredders involved in data destruction, the IoT system itself must handle data responsibly. If the system processes any personal data from its operators or from the materials being shredded (e.g., scanning document types), it must comply with regulations like the General Data Protection Regulation (GDPR). This involves implementing principles of data minimization, where only necessary data is collected, and ensuring strong encryption for data both in transit and at rest.

The system must also be able to honor "the right to be forgotten," providing functionalities to erase an individual's personal data from logs upon request. Clear protocols must be in place for managing data breaches, including notifying authorities within the mandated 72-hour window. This rigorous approach to data privacy ensures that the tool for security (the shredder) does not itself become a vulnerability.

Operational Authority Management (Two-Factor Authentication)

Preventing unauthorized access to a powerful industrial shredder is a critical safety function. IoT platforms enforce strict operational authority through role-based access control (RBAC) coupled with two-factor authentication (2FA). 2FA requires users to provide two different forms of identification to log in, typically something they know (a password) and something they have (a code from an authenticator app on their phone).

This ensures that even if a password is compromised, an attacker cannot gain control of the machine. Different permission levels can be set; for example, a operator may only be able to view status and start/stop the machine, while a maintenance engineer has permission to adjust parameters, and a system administrator can manage user accounts. This granular control prevents accidental or malicious changes to critical machine settings.

Audit Log Tracking (Blockchain Notarization)

For industries with strict compliance requirements, such as medical or financial document destruction, providing an immutable audit trail is essential. IoT systems can integrate with blockchain technology to create a tamper-proof record of every operation. Every start, stop, maintenance action, and security override is hashed and recorded on a distributed ledger.

This provides a notarized, timestamped log that can be presented to auditors as irrefutable evidence of compliant operation. It proves that a specific batch of sensitive material was destroyed at a certain time, by a certain authorized operator, and that the machine was functioning within its specified parameters throughout the process. This level of verifiable assurance is becoming a standard requirement in many regulated sectors.

Industry Standard Conformity (ISO 50001/IEC 62443)

Adherence to international standards is simplified with IoT data. For energy management, the ISO 50001 standard requires a plan-do-check-act cycle for continuous improvement. The IoT system automatically provides the "check" component by supplying the detailed energy data needed to measure progress against targets, making certification and audits far smoother.

On the cybersecurity front, the IEC 62443 standard for industrial communication networks provides a framework for securing industrial automation and control systems. An IoT platform designed for shredders can be certified to these standards, demonstrating that it has built-in security features like segmenting the network, providing secure remote access, and offering robust vulnerability management. Using certified components is the most effective way to build a secure and compliant industrial IoT infrastructure.

Typical Industry Application Cases

The principles of IoT-enabled shredding are universally applicable, but their implementation delivers specific, transformative benefits in different industries. Each sector faces unique challenges regarding material type, security requirements, and regulatory compliance. IoT technology provides tailored solutions that address these specific pain points, delivering value that goes far beyond simple operational monitoring.

From ensuring the complete destruction of confidential data to optimizing the recovery of valuable materials from complex waste streams, connected shredders are becoming the cornerstone of modern, intelligent waste management and resource recovery operations across the globe. The following cases illustrate how this technology is applied in real-world scenarios.

Document Destruction Centers (Confidential Document Processing)

In document destruction, the chain of custody and verification of destruction are as important as the shredding itself. IoT systems provide an automated, unbreakable audit trail. Each bin of documents can be tagged with an RFID chip. When the bin is loaded into the paper shredder, the RFID is scanned, linking that specific batch to the shredding event.

The IoT system records the exact time, duration, and all machine parameters during the destruction process. Upon completion, it automatically generates a Certificate of Destruction, digitally signed and stored on the blockchain, providing the client with undeniable proof that their sensitive information has been securely destroyed in compliance with data protection laws like GDPR and HIPAA. This automated process eliminates paperwork, reduces human error, and enhances customer trust.

Metal Recycling Enterprises (Alloy Composition Analysis)

For scrap metal yards, the value of the output material is directly tied to its purity and composition. IoT systems integrated with LIBS (Laser-Induced Breakdown Spectroscopy) sensors can analyze the composition of incoming scrap metal before it is fed into the metal shredder. This analysis can identify and quantify the percentages of valuable elements like nickel, chromium, or copper in an alloy.

This data allows for intelligent sorting and optimized shredding strategies. High-value alloys can be processed separately to prevent contamination. Furthermore, the precise composition data for each output batch can be provided to buyers, commanding a higher price due to its certified quality. The IoT system tracks the value of each processed batch, providing a clear financial picture of the operation's profitability and enabling data-driven decisions about which scrap materials to accept.

Medical Waste Treatment (Traceability System Integration)

The handling of medical waste requires strict traceability from point of generation to final disposal or treatment. IoT shredders are integrated into this ecosystem. Waste bags are tagged with barcodes or RFID tags at hospitals. When these bags are loaded into a specialized medical waste shredder with integrated sterilizer, the tags are scanned.

The IoT system logs the destruction of that specific waste batch, recording the time, temperature during sterilization (ensuring pathogen kill), and confirming that the waste was rendered unrecognizable and safe. This data is fed into a central tracking system, providing regulators and generators with full visibility and proof of compliant treatment. This end-to-end traceability is critical for managing biohazard risks and meeting strict medical waste regulations.

E-Commerce Packaging Recycling (RFID Tag Identification)

The e-commerce boom has created a massive stream of cardboard boxes and packaging materials, often with plastic films and labels. IoT-driven shredders in recycling facilities can be equipped with RFID readers to identify specific types of packaging. Many large retailers are beginning to tag their boxes and pallets for inventory management.

As these materials enter the recycling plant, the shredder's IoT system can read these tags, identifying the source and type of material. This allows for automated sorting and efficient processing of homogeneous material streams. The system can also provide valuable data back to the retailers on the volume and efficiency of their packaging recycling, supporting their corporate sustainability reports and enabling a more circular economy for packaging materials.