Industrial shredding represents a critical component in modern security and recycling operations, where material reduction serves multiple objectives beyond simple size reduction. Understanding the fundamental differences between strip-cut, cross-cut, and micro-cut technologies enables organizations to make informed decisions balancing security requirements, operational efficiency, and economic considerations. This comprehensive examination explores how each shredding methodology transforms material characteristics while meeting specific industrial standards and processing objectives across various applications.

Understanding Industrial Shredding Modes: Beyond Size Reduction

Industrial shredding technologies serve diverse purposes extending far beyond basic volume reduction, with each cutting methodology producing distinct particle geometries that directly influence material security, recyclability, and downstream processing efficiency. The selection process requires careful consideration of multiple factors including material composition, security classification, and intended disposal or recovery pathways. Different shred modes create particle characteristics that either facilitate or complicate subsequent material handling, separation, and value recovery processes. This complex relationship between shred methodology and overall system performance necessitates thorough evaluation before implementing any shredding solution.

Defining Shredding Modes: From Geometric Shapes to Security Levels

Strip-cut technology produces elongated fragments typically measuring 5-20 millimeters in width, maintaining linear characteristics of the original material while providing basic size reduction. Cross-cut methodology generates rectangular or diamond-shaped particles through two-dimensional cutting action, significantly increasing reconstruction difficulty compared to strip-cut outputs. Micro-cut systems reduce materials to near-powder consistency with particle dimensions frequently measuring less than 1 millimeter, representing the highest security level available in industrial shredding applications. These geometric differences directly correspond to security classifications established in international standards such as DIN 66399 and NSA/CSS specifications.

Security Level Standards and Their Correspondence to Shredding Modes

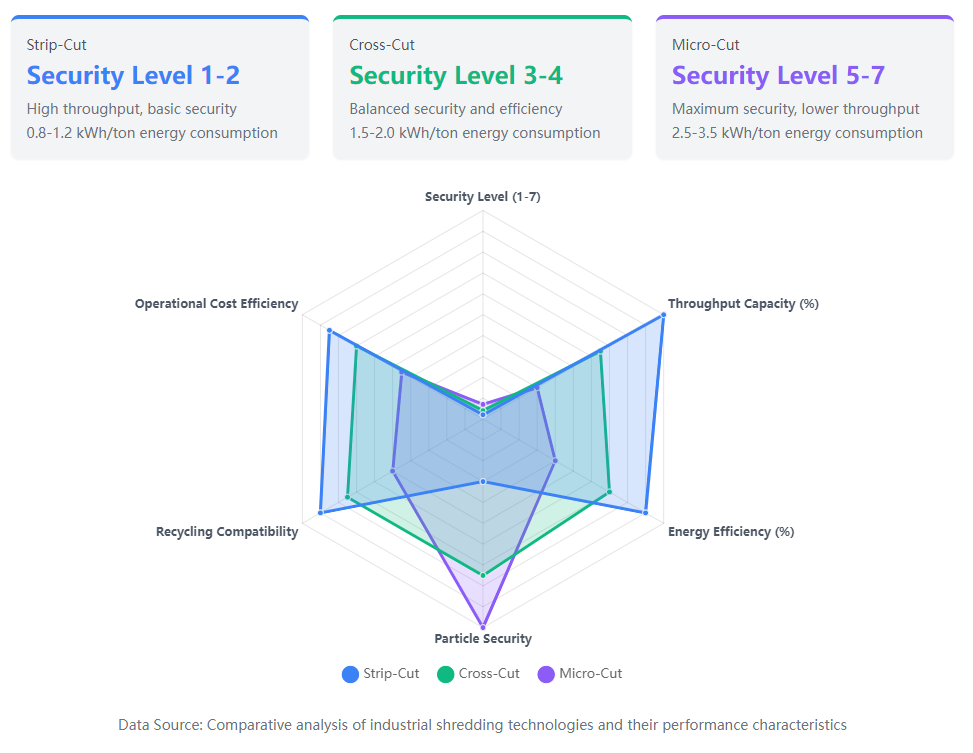

International security standards establish precise particle size requirements for different classification levels, with strip-cut shredding typically meeting basic security levels 1-2, cross-cut achieving intermediate levels 3-4, and micro-cut satisfying the most stringent levels 5-7. The DIN 66399 standard specifically addresses various material categories including paper, data media, and hardware components, with security levels determined by maximum particle dimensions and reconstruction feasibility. Organizations handling classified information frequently require security levels 4 or higher, necessitating cross-cut or micro-cut technologies to comply with regulatory mandates and protect sensitive data effectively.

Impact of Shredding Modes on Downstream Processing Operations

The geometric characteristics of shredded materials significantly influence subsequent processing stages, with strip-cut fragments facilitating efficient air separation and magnetic recovery due to their elongated shape and predictable behavior. Cross-cut particles demonstrate superior flow characteristics and bulk density properties that enhance transportation efficiency and storage optimization. Micro-cut materials present challenges in certain separation processes but offer advantages in chemical recovery applications where increased surface area accelerates reaction rates and improves extraction efficiency.

Capacity, Energy Consumption and Operational Cost Considerations

Processing capacity varies substantially between shredding methodologies, with strip-cut systems typically achieving throughput rates 40-60% higher than cross-cut configurations and 200-300% greater than micro-cut installations. Energy requirements follow an inverse relationship, with micro-cut technology consuming approximately 2.5-3.5 kilowatt-hours per ton of processed material compared to 0.8-1.2 kilowatt-hours for strip-cut operations. Operational expenses extend beyond energy consumption to include cutting element replacement, maintenance intervals, and system availability, with micro-cut systems requiring more frequent component replacement and specialized maintenance procedures.

Strip-Cut Shredding Mode: Balancing Efficiency and Basic Security

Strip-cut shredding represents the most efficient methodology for volume reduction applications where maximum security is not the primary operational objective. This technology employs parallel cutting elements to transform materials into narrow strips while preserving material integrity for subsequent separation and recovery processes. The relatively simple mechanical design contributes to higher reliability, lower maintenance requirements, and reduced operational complexity compared to more advanced shredding technologies. Organizations prioritizing processing capacity and operational economics frequently select strip-cut systems for general-purpose applications with moderate security requirements.

Working Principles and Output Characteristics of Strip-Cut Shredders

Strip-cut shredders utilize counter-rotating shafts equipped with cutting discs that engage material fed through precision-controlled intake mechanisms, producing continuous strips with widths determined by cutter spacing and configuration. Typical industrial systems generate strips measuring between 5-25 millimeters in width, with length determined by original material dimensions and feed orientation. The cutting action occurs through a shearing mechanism between precisely aligned cutting elements, requiring robust construction to withstand the significant forces generated during operation. Output materials retain sufficient structural integrity to enable efficient handling through pneumatic, magnetic, and mechanical separation systems.

Materials and Industrial Applications Suitable for Strip-Cut ProcessingStrip-cut technology demonstrates particular effectiveness with cardboard, plastic containers, metal sheets, and general office waste where security concerns remain secondary to volume reduction objectives. The recycling industry extensively employs strip-cut shredders as primary reduction equipment in material recovery facilities, where initial size reduction facilitates subsequent sorting and processing operations. Manufacturing operations utilize strip-cut systems for reducing production scrap and preparing materials for reuse in various industrial processes. The agricultural sector applies this technology for processing biomass and organic materials where particle geometry influences composting efficiency and biological processing rates.

Security Limitations in Data Destruction Applications

The elongated particle geometry produced by strip-cut systems presents significant security vulnerabilities for sensitive information, with document reconstruction remaining technically feasible through manual reassembly or automated pattern recognition technologies. Testing conducted by security agencies indicates that determined adversaries can reconstruct strip-cut documents with approximately 70-85% accuracy depending on particle dimensions and material characteristics. Data storage devices shredded through strip-cut methodology frequently retain recoverable information sectors, particularly when modern storage technologies employ advanced data distribution algorithms across physical media. These security limitations restrict strip-cut applications to unclassified materials or situations where additional destruction methods follow the initial shredding process.

Value Recovery Advantages in Subsequent Processing Operations

The uniform geometric characteristics of strip-cut materials enhance performance in various separation technologies, with elongated metallic fragments demonstrating improved eddy current separation efficiency and ferrous materials exhibiting superior magnetic recovery rates. Paper and fiber materials processed through strip-cut systems maintain fiber length integrity that preserves material value in recycling applications where fiber length directly correlates with end-product quality and market value. Plastic materials shredded through strip-cut methodology experience minimal thermal degradation and polymer chain damage, maintaining material properties essential for high-value recycling applications and closed-loop manufacturing processes.

Cross-Cut Shredding Mode: Enhanced Security and Versatility

Cross-cut shredding technology represents the predominant choice for security-conscious organizations requiring balanced performance across multiple operational parameters. This methodology introduces secondary cutting orientation that transforms materials into discrete particles with controlled dimensions in both length and width directions. The resulting particle geometry significantly increases reconstruction difficulty while maintaining reasonable processing rates and operational costs. Modern cross-cut systems incorporate advanced control technologies that optimize cutting parameters based on material characteristics, ensuring consistent particle geometry across varying feed conditions.

Implementation of Two-Dimensional Cutting in Cross-Cut Systems

Cross-cut shredders employ sophisticated cutting mechanisms that combine initial size reduction with secondary cutting actions, frequently utilizing helically arranged cutting elements that progressively engage materials at varying angles. Advanced systems incorporate independent primary and secondary cutting stages that optimize energy consumption while ensuring precise particle dimension control. The cutting geometry creates particles with aspect ratios typically ranging from 1:1 to 1:3, with industrial systems commonly producing particles measuring 2x10 millimeters to 6x40 millimeters depending on security requirements and material characteristics. This controlled particle geometry ensures predictable material behavior in subsequent handling and processing operations.

Security Enhancement Through Geometric Particle Control

The two-dimensional particle confinement inherent in cross-cut technology elevates security levels substantially, with reconstruction requiring identification and orientation of individual particles across multiple dimensions simultaneously. Security testing demonstrates that cross-cut particles measuring 2x15 millimeters or smaller render document reconstruction economically impractical, with successful recovery rates dropping below 5% even with sophisticated automated reassembly technologies. Data storage devices processed through cross-cut systems experience physical destruction that exceeds manufacturer-specified destruction thresholds, ensuring complete data irretrievability when properly configured. These security characteristics make cross-cut technology suitable for confidential and sensitive information across government, financial, and corporate applications.

Processing Efficiency with Mixed Material Streams

Cross-cut shredders demonstrate particular effectiveness with heterogeneous material streams commonly encountered in electronic waste, composite materials, and industrial byproducts where component liberation precedes separation and recovery. The controlled particle size distribution enhances separation efficiency in downstream processes including screening, air classification, and sensor-based sorting technologies. Electronic components shredded through cross-cut methodology experience optimal liberation of precious metals from substrate materials, increasing recovery rates in subsequent hydrometallurgical or pyrometallurgical processes. Composite materials benefit from the particle geometry that maximizes surface area for chemical processing while maintaining manageable handling characteristics.

Material Handling Advantages in Resource Recovery Applications

The consistent particle dimensions produced by cross-cut systems facilitate efficient material transport through pneumatic and mechanical conveying systems, with bulk density increases of 30-50% compared to strip-cut materials enhancing transportation economics. Storage characteristics improve significantly due to reduced particle interlocking and more predictable flow properties, minimizing bridging and hang-up incidents in storage silos and transfer points. The homogeneous particle size distribution enables precise metering and feeding in subsequent processing operations, contributing to stable operation and consistent product quality in recycling and energy recovery applications.

Micro-Cut Shredding Mode: Maximum Security Implementation

Micro-cut shredding represents the pinnacle of security destruction technology, reducing materials to particle sizes that eliminate any possibility of reconstruction through physical means. This technology employs multi-stage reduction processes that progressively transform materials into near-powder consistency through combinations of cutting, shearing, and grinding actions. The extreme security level comes with operational trade-offs including reduced throughput capacity, increased energy consumption, and elevated maintenance requirements. Organizations handling classified information, proprietary technology, and sensitive intellectual property typically implement micro-cut technology to meet stringent security mandates.

Technical Implementation and Equipment Configuration

Micro-cut shredders incorporate sophisticated multi-stage reduction systems that typically combine primary coarse reduction with secondary fine grinding stages, frequently employing specialized cutting geometries and precision tolerances to achieve target particle sizes. Advanced systems utilize cascaded reduction chambers with progressively finer cutting elements, with final stage clearances frequently measuring less than 0.5 millimeters to ensure consistent particle size control. The mechanical complexity necessitates robust construction with specialized materials including tungsten carbide cutting elements and hardened alloy steel components to withstand the extreme forces and abrasive conditions encountered during operation.

Compliance with Stringent Data Protection Regulations

Micro-cut technology satisfies the most rigorous security standards including DIN 66399 Level P7/E7/T7 specifications requiring maximum particle dimensions of 1.0 millimeters for paper and 0.5 millimeters for data media. Government agencies including the National Security Agency specify micro-cut destruction for classified materials, with particle size requirements varying based on classification level and material type. International standards organizations have established testing protocols to verify compliance, including reconstruction attempts using advanced imaging and pattern recognition technologies to ensure destruction effectiveness. Organizations subject to privacy regulations including GDPR, HIPAA, and FACTA frequently implement micro-cut destruction to eliminate any possibility of information recovery from discarded materials.

Effectiveness with Specialized Materials and Components

Micro-cut technology demonstrates particular effectiveness with integrated circuits, proprietary components, and advanced alloys where complete destruction prevents reverse engineering and protects intellectual property. The extreme reduction ratio facilitates subsequent processing in precious metal recovery operations by increasing surface area and liberating valuable materials from composite structures. Aerospace and defense applications utilize micro-cut destruction for sensitive components and materials to prevent technological disclosure and maintain competitive advantages. The pharmaceutical industry employs similar technology for controlled substance destruction and compliance with regulatory requirements for material accountability.

Operational Economics and Maintenance Considerations

The superior security capabilities of micro-cut technology entail significant operational compromises, with throughput rates typically measuring 25-40% of comparable cross-cut systems and 15-25% of strip-cut capacity. Energy consumption increases substantially due to the multiple reduction stages and finer cutting actions, with power requirements frequently exceeding 3.0 kilowatt-hours per ton of processed material. Maintenance intervals shorten considerably due to accelerated wear on cutting components, with specialized cutting elements requiring replacement after processing 200-400 tons of material depending on composition and contamination levels. These operational factors necessitate careful economic analysis to justify implementation based on security requirements rather than processing efficiency.

Decision Framework: Selecting Optimal Shredding Methodology

The selection process for industrial shredding technology requires systematic evaluation of multiple operational parameters extending beyond simple security classification or throughput requirements. Organizations must develop comprehensive understanding of material characteristics, processing objectives, and economic constraints to identify the optimal balance between competing priorities. This structured approach ensures that selected technology aligns with both immediate operational needs and strategic business objectives while providing appropriate flexibility for evolving requirements.

Material Classification and Security Requirement Assessment

The selection process initiates with detailed material characterization, documenting physical properties including hardness, toughness, abrasiveness, and thermal sensitivity alongside security classification and regulatory obligations. Organizations must establish clear security protocols defining destruction standards for different material categories, with particular attention to data-bearing media and proprietary information. Material volume projections and composition variability influence equipment sizing and configuration decisions, with heterogeneous streams frequently requiring different approaches than homogeneous materials. This foundational analysis establishes the parameters within which technology selection occurs.

Final Product Specifications and Value Recovery Objectives

The intended disposition pathway for shredded materials significantly influences technology selection, with landfill disposal requiring different particle characteristics than material recovery or energy production applications. Organizations pursuing resource recovery must align particle geometry with subsequent processing technologies, ensuring optimal performance in separation, cleaning, and preparation operations. Value optimization frequently involves balancing particle size reduction against material quality preservation, with excessive destruction potentially diminishing material value in certain recycling applications. Energy recovery applications prioritize particle size consistency and calorific value preservation, influencing the selection of shredding technology and operating parameters.

Security and Operational Efficiency Optimization

Organizations must establish clear priorities between security requirements and processing economics, recognizing that enhanced security typically entails compromises in throughput capacity, energy efficiency, and operational costs. Quantitative analysis should evaluate total cost of ownership across the equipment lifecycle, incorporating capital investment, operational expenses, maintenance requirements, and personnel costs. Security investments must demonstrate appropriate return through risk reduction, regulatory compliance, and liability mitigation, with justification based on potential consequences of security breaches rather than simple cost comparison. This balanced approach ensures that security measures remain proportionate to actual risks while maintaining operational viability.

System Flexibility and Future Adaptation Capability

Equipment selection should incorporate consideration of evolving operational requirements, with modular systems providing adaptation capability as material streams, security protocols, or processing objectives change over time. Organizations anticipating material composition changes should prioritize equipment with adjustment capabilities for particle size control and cutting parameters. Facilities planning expansion or process modifications benefit from systems with scalability features including variable drive systems, modular cutting elements, and control system programmability. This forward-looking perspective ensures that capital investments maintain relevance and utility throughout their operational lifespan despite changing business conditions.

Advanced Solutions: Integrated Systems and Emerging Technologies

Modern industrial shredding operations increasingly employ sophisticated systems that combine multiple technologies and innovative approaches to optimize overall performance across security, efficiency, and economic parameters. These advanced solutions frequently incorporate intelligent controls, adaptive processing, and integrated material handling to create comprehensive destruction systems rather than standalone shredding equipment. The continuing evolution of shredding technology focuses on enhancing security while simultaneously improving operational efficiency and reducing environmental impact.

Multi-Stage Shredding Systems for Optimized Performance

Sophisticated installations frequently employ sequential shredding stages that combine different technologies to achieve optimal balance between processing efficiency and security level requirements. Common configurations incorporate primary strip-cut or cross-cut reduction followed by secondary micro-cut finishing, enabling high-volume initial processing with final security assurance. These systems typically achieve throughput rates 60-80% higher than single-stage micro-cut systems while maintaining equivalent security levels through careful integration and control optimization. The intermediate separation of components and contaminants between stages frequently enhances overall system performance and reduces operating costs.

Intelligent Sensing and Adaptive Control Technologies

Modern shredding systems incorporate advanced sensing technologies including metal detection, visual recognition, and material composition analysis to optimize processing parameters based on feed material characteristics. These intelligent systems automatically adjust cutting speeds, feed rates, and operational modes to maximize efficiency while ensuring consistent output quality and security level maintenance. Control systems continuously monitor equipment condition and performance metrics, implementing predictive maintenance protocols that minimize unplanned downtime and extend component service life. The integration of these technologies transforms shredding operations from simple destruction processes to sophisticated material management systems.

Shredding and Separation Technology Integration

Optimal system performance requires careful coordination between shredding operations and subsequent separation processes, with particle characteristics engineered to enhance efficiency in sorting, cleaning, and recovery operations. Electronic waste shredding systems frequently incorporate integrated separation technologies that immediately follow size reduction, maximizing recovery rates through timely component liberation and segregation. The particle geometry produced by different shredding methodologies directly influences performance in downstream processes including air classification, screening, and sensor-based sorting technologies. This integrated approach ensures that shredding operations support rather than hinder overall system objectives for material recovery and value optimization.

Emerging Trends in Security Destruction Technology

The continuing evolution of shredding technology focuses on enhancing security while reducing environmental impact through improved energy efficiency, reduced emissions, and enhanced material recovery capabilities. Advanced cutting geometries and materials science innovations extend component service life while maintaining precise particle size control under increasingly demanding operating conditions. Control system advancements incorporate artificial intelligence and machine learning algorithms that optimize operational parameters in real-time based on material characteristics and system performance feedback. These developments ensure that shredding technology continues to advance in capability while addressing the evolving security and sustainability requirements of modern industrial operations.