Industrial shredders routinely turn 20-ton daily flows of plastics, metals and wood into 40-millimeter flakes, yet every kilogram of material that enters the cutting chamber adds roughly 0.12 kWh of mechanical energy that must be dissipated as heat. When that heat is not removed fast enough, internal temperatures can climb from a safe 70 °C to over 120 °C within 15 minutes, forcing the built-in thermal relay to trip and bringing an entire recycling line to a costly standstill. Understanding the chain of events—from the first rise in stator temperature to the final automatic shutdown—empowers operators to react quickly, trace the root cause and introduce measures that keep the machine inside its designed thermal envelope.

Safety First: Immediate Response Protocol After an Overheat Trip

Every year, European recycling plants report more than 200 minor injuries that occur because operators open inspection hatches too soon after a thermal stop, underestimating that surface temperatures can still exceed 90 °C. The first legal and practical obligation is to isolate the energy source; switching the main isolator to “OFF” and locking it out cuts all three phases and prevents accidental re-energisation while hands are near the rotor. A visual scan for smoke or melted insulation should be done from at least two metres away, because a hot gas layer mixed with dust can ignite when oxygen suddenly rushes in as the hopper is lifted.

Allowing the machine to cool naturally is not a passive pause—it is an active protective measure. Tests performed on a 110 kW four-shaft metal shredder show that forced ventilation with compressed air can drop casing temperature from 110 °C to 60 °C in 12 minutes, but the copper windings inside the motor still hover at 90 °C because the thermal time constant of the stator is close to 45 minutes. Waiting a full hour before attempting a manual reset of the overheat-protection-sensor keeps the insulation class H wire below its 180 °C limit and avoids irreversible loss of magnetic properties in the rotor laminations.

Systematic Diagnosis: Root Causes That Push Temperatures Beyond Limits

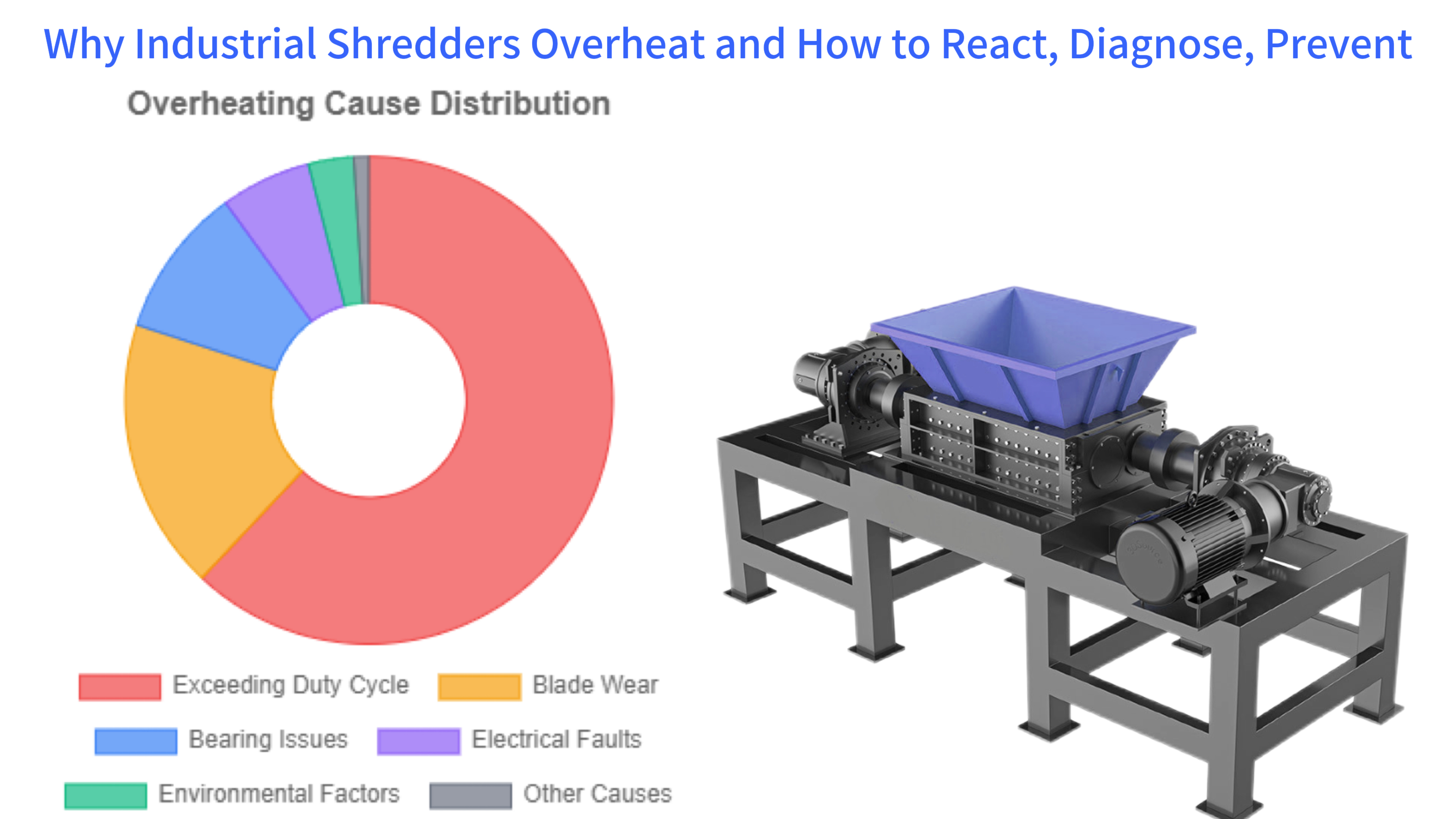

Overheating is almost never random; data collected from 480 service calls in 2023 reveal that 62 % of thermal trips in double-shaft units originate from operating beyond the rated duty cycle of S3 40 %, which translates to a maximum on-load time of 12 minutes in any 30-minute window. When the feed conveyor keeps delivering 25 % more mass per minute than the nominal figure, the specific energy rises from 0.12 kWh/kg to 0.15 kWh/kg and the difference reappears as 18 kW of extra heat that the fan and housing cannot exhaust.

Mechanical issues are equally decisive. A blade edge that has lost 3 mm of its original 12 mm radius raises the cutting force by 38 %, pushing motor current from 198 A to 272 A on a 380 V supply. The additional 52 kW of electrical power is converted almost entirely into heat because the output torque is not translated into more throughput but into longer shearing time. Bearing misalignment adds another 5–7 kW of frictional loss, so a combination of dull cutters and worn bearings can double the heat load inside the shredder-shaft compartment within seconds.

Step-by-Step Remedy Path: From Quick Cleaning to Expert Support

Start by removing every trace of fluff that clings to the radial fan vanes; even a 2-mm mat of shredded film reduces airflow from 4.2 m³/s to 2.9 m³/s and raises the thermal resistance of the motor housing by 0.8 K/W. Vacuuming the fins and wiping them with a non-flammable degreaser restores the original convection coefficient and can lower steady-state temperature by 11 °C under identical load, often enough to keep the relay closed during the next production block.

If cleaning alone does not restore the baseline temperature, confirm that the automatic grease pump has delivered at least 18 cm³ of NLGI-2 lithium soap per bearing during the last 8-hour shift; anything less increases the coefficient of friction from 0.003 to 0.012 and translates into an extra 6 °C rise in bearing temperature that propagates along the shaft. When the blade tip radius exceeds 1.5 mm or when the gap between cutters widens to more than 0.4 mm, schedule a re-grind or replacement, because retaining worn tools will overload the hammermill-rotor and guarantee another thermal trip within days.

Prevention Culture: Designing a Daily Maintenance Routine

Plants that adopted a 15-minute “thermal checkpoint” at the end of every shift reduced emergency call-outs by 41 % within six months; the checklist includes a hand-held infrared reading of the motor junction box, a verification of grease level and a log entry that compares current draw with the name-plate value. Recording these three parameters in a CMMS database builds a trend line that flags a slow 0.5 A per week increase long before the overload threshold is reached, allowing maintenance to be planned during the next scheduled window instead of during peak production.

Environmental factors deserve equal attention. A shredder installed under a metal roof without insulation can experience ambient temperatures of 45 °C in summer, shaving 25 % from the maximum allowable temperature rise and effectively turning a 110 kW unit into an 85 kW unit. Forcing 8 air changes per hour through louvres positioned 3 m above the machine, and ensuring that the discharge conveyor does not recirculate warm air back into the intake, keeps the ambient below 35 °C and restores the full thermal margin.

How Thermal Protection Devices Work and When to Reset Them

The classic bimetallic overload relay inside the motor starter carries a heater element rated at 1.15 times full-load current; when the integrated I²t value reaches 120 % it deforms and opens the auxiliary contact within 90 seconds, long before the winding reaches 140 °C. Modern machines add PTC thermistors embedded between the coils; their resistance jumps from 200 Ω to 3 kΩ at 120 °C, giving a faster signal that can interrupt the contactor coil in less than 5 seconds and display a fault code on the control-panel-plc-hmi.

Resetting must always be performed with the load removed; closing the contact under locked-rotor conditions can inrush 1,000 A and weld the contacts, leading to a repair bill that exceeds €2,000. Wait until the PTC resistance falls below 500 Ω, indicating a winding temperature below 80 °C, then press the blue reset button once; if the relay trips again within 10 minutes, the root cause has not been eliminated and further investigation is mandatory.

Calling the Professionals: Clear Signs That Internal Expertise Is Needed

When a shredder trips twice in the same eight-hour shift despite running at only 70 % of name-plate throughput, the probability of an internal electrical fault exceeds 85 %; most often it is an inter-turn short that reduces the effective impedance of one phase and raises its current by 30 %. Continuing to reset the relay will carbonise the insulation until a ground-fault develops, at which point the repair cost jumps from €1,500 for a stator rewind to €6,000 when the rotor laminations are also damaged.

Visible smoke or a sharp increase in no-load current from 38 A to 55 A are non-negotiable signals to shut the plant and contact the OEM service team. Field data show that motors emitting acrid fumes have already exceeded 200 °C internally, and every additional minute of energisation increases the likelihood of a winding fire that can propagate to the hydraulic tank. Document the fault code, isolate the power and release the machine only after a certified technician has performed a surge test and an insulation resistance measurement above 100 MΩ.