Selecting the right paper shredder for a home office environment requires careful consideration of factors that differ significantly from industrial or large office settings. This guide is specifically tailored to address the unique challenges of working from home, where noise levels, space constraints, and usage patterns demand specialized equipment. We focus on three critical pillars: acoustic performance, processing efficiency, and spatial compatibility to help you find a machine that protects your privacy without disrupting your domestic environment.

Through detailed technical parameter analysis and comparison of measured data, this guide provides a clear framework for evaluating shredder options. We move beyond marketing claims to examine the actual engineering and design features that contribute to quiet operation and reliable performance. The goal is to empower you to make an informed decision that balances professional-grade security with the comfort and practicalities of a home workspace, ensuring your shredder is an asset, not a nuisance.

Analysis of Special Requirements for Home Office Scenarios

The home office presents a unique set of constraints that are often overlooked in standard shredder specifications. Unlike a dedicated corporate office, a home workspace is multifunctional, often shared with living areas, and requires equipment that integrates seamlessly into a domestic setting. The choice of a shredder must therefore be guided by a deep understanding of these environmental and behavioral factors.

Key considerations include the proximity of the shredder to areas of relaxation or concentration, the frequency and volume of shredding tasks, and the available physical space for the unit. A shredder that is perfectly adequate for a corporate mailroom may be entirely unsuitable for a home office due to its noise output, size, or operational characteristics. This analysis lays the groundwork for identifying the specific features that will deliver the best user experience in a residential context.

Noise-Sensitive Environment Adaptation Standards (Decibel Thresholds)

Noise is the primary concern in a home environment. The ambient sound level in a quiet home is typically around 40 dB. A standard shredder can operate between 65-75 dB, which is comparable to a vacuum cleaner and is unacceptably disruptive. For a home office, a "silent" or "quiet" shredder should operate at or below 60 dB, which is about the level of a normal conversation and will not disturb other household activities or concentration.

Prolonged exposure to noise above 60 dB can also contribute to fatigue and reduced productivity. Therefore, selecting a shredder designed for low acoustic emissions is not just a matter of courtesy but also of maintaining a productive and comfortable work atmosphere. Manufacturers achieve this through specialized quiet motors, sound-dampening materials, and optimized mechanical designs that reduce vibration and gear noise, making them ideal for shared living spaces.

Small-Batch High-Frequency Usage Characteristics (Single-Session Throughput)

Home office shredding habits are characterized by frequent, small-batch operations. Instead of shredding large stacks of documents at once, a home user is more likely to shred a few sheets at a time throughout the day—a single letter, a shipping label, or a few pages of sensitive notes. This usage pattern places different demands on the machine compared to high-volume office shredders.

The shredder must be ready for instant use without a long warm-up time and must handle these small inputs efficiently. The key metric here is the recommended sheet capacity per session, not just the absolute maximum. A machine rated for 5-8 sheets is often sufficient for these tasks, as attempting to feed more than a dozen pages at once is rare in a home setting. This focused capacity often allows for a more compact and quieter design, perfectly suited to the actual use case.

Compact Space-Saving Device Design (Volume/Weight Parameters)

Real estate on a home desk or in a small office nook is precious. The physical footprint of the shredder is a critical deciding factor. Dimensions (length, width, and height) and weight determine where the unit can be placed—under a desk, on a shelf, or beside a workstation. A compact design, often with a vertical orientation, minimizes the space consumed while remaining functional.

Weight is a double-edged sword. A heavier machine may be more stable during operation, reducing vibration and noise, but it also makes it difficult to move for cleaning or storage. The ideal home office shredder finds a balance: heavy enough to stay put during use but light enough to be manageable, often between 5 and 10 kilograms (11 to 22 pounds). This ensures it can be easily integrated into a dynamic home workspace without becoming a permanent, cumbersome fixture.

Multitasking Capability (Continuous Run Time)

While home shredding is typically done in short bursts, there may be occasional needs for longer sessions, such as during tax season or a major document clear-out. The continuous run time specifies how long the shredder can operate before it requires a cool-down period to prevent the overheat protection sensor from triggering an automatic shutdown.

For most home models, a continuous run time of 3 to 5 minutes is standard. Higher-end models may extend this to 10-20 minutes. This is determined by the motor's duty cycle and the effectiveness of its cooling system. Understanding this metric prevents frustration; a user who needs to shred a large bin of old files should choose a model with a longer run time to complete the task efficiently without frequent interruptions for cooling.

Core Performance Indicator Analysis

Beyond the home-specific requirements, the fundamental performance of a shredder is defined by a set of objective technical指标 (indicators). These specifications determine the machine's capability, security level, and suitability for different types of materials. Understanding these metrics is essential for cutting through marketing jargon and identifying a machine that truly meets your needs.

These core specs interact with each other; a machine with a very small feed opening may be more compact and quieter but will limit the types of documents you can destroy. Conversely, a high-speed shredder might save time but could be louder. Evaluating these parameters together provides a holistic view of the shredder's performance profile and helps you prioritize based on your specific document destruction habits.

Shredding Speed (Meters per Minute vs. Sheets per Minute)

Shredding speed can be advertised in two ways: meters per minute (how long a strip of paper it can cut in 60 seconds) or sheets per minute (how many standard sheets it can process). Meters per minute is a more consistent measure of the motor's and cutting blades' raw power, often ranging from 2 to 5 meters per minute for home units.

Sheets per minute is more practical for understanding daily use but depends on the assumed sheet size and weight. A speed of 10-15 feet per minute (approx. 3-4.5 meters per minute) is generally adequate for home use, allowing a few sheets to be processed in seconds. Ultra-high speed is less critical in a home environment than consistent, reliable feeding and quiet operation. A moderate speed often correlates with lower noise levels and reduced vibration.

Shredding Particle Size (Strip-Cut / Cross-Cut / Micro-Cut)

The size of the shredded particles determines the security level of the destruction. Strip-cut shredders slice paper into long, vertical strips. This is the fastest and least secure method, as documents can be reassembled with patience. Cross-cut (or confetti-cut) shredders cut paper both vertically and horizontally into small diamonds or rectangles, offering a medium security level suitable for most personal documents.

Micro-cut shredders pulverize paper into tiny, unreadable particles, similar to confetti. This provides the highest level of security, mandated for sensitive financial or personal data. The trade-off is that micro-cutting is slower, puts more strain on the motor, and reduces the overall sheet capacity per pass. For a home office, a cross-cut shredder often represents the best balance of security, speed, and machine durability.

Cutting Blade Material (Hardened Steel vs. Carbon Steel)

The longevity and sharpness of a shredder are directly tied to the quality of its cutting blades. For home use, blades are typically made from hardened steel. This material is treated to enhance its hardness and wear resistance, allowing it to maintain a sharp edge through thousands of cutting operations on standard paper, staples, and paper clips.

Higher-end models may feature blades with a higher carbon content or special coatings for added durability. While industrial shredders might use tungsten carbide cutters for extreme durability, this is overkill for home applications. The key for a home user is that the blade material is sufficient to handle occasional small metal objects like staples without dulling quickly, ensuring a long functional life for the machine.

Feed Opening Width (220mm vs. 330mm)

The width of the feed opening dictates the maximum size of document the shredder can accept without folding. A standard letter-sized document (8.5 inches or 216mm wide) fits comfortably into a 220mm (approx. 9-inch) opening. This is the most common size for home office shredders and is sufficient for the vast majority of personal mail, invoices, and documents.

A wider opening, such as 330mm (13 inches), is necessary for destroying larger documents like legal-sized papers (8.5" x 14") or folded brochures without pre-folding them. While offering more flexibility, a wider throat often means a larger and sometimes louder machine. Most home users will find a 220mm opening perfectly adequate, reserving the larger size for those who frequently handle oversized documents as part of their work.

Silent Technology Implementation Path

Achieving quiet operation in a shredder is not a matter of chance but the result of deliberate engineering choices aimed at noise reduction at the source. Several technologies work in concert to dampen sound, from the type of motor used to the physical design of the machine's components. Understanding these paths helps identify which models are genuinely designed for silence rather than simply marketed as such.

True quiet shredders employ a multi-faceted approach. They manage noise generated by the motor, reduce vibration that can transmit sound to the surface the shredder sits on, and design airflow pathways to minimize whistling or aerodynamic noise. This systematic reduction across all noise generation points results in a machine that can operate discreetly in the background of a home office or even a living area.

Motor Noise Reduction Design (Advantages of DC Motors)

The motor is the primary source of noise in a shredder. Many quiet home models utilize DC (Direct Current) motors instead of the more traditional AC (Alternating Current) motors. DC motors are inherently quieter because they operate with a more consistent torque and do not produce the characteristic 50/60 Hz hum associated with AC motors.

Furthermore, DC motors offer superior starting torque and speed control. They can ramp up to operating speed smoothly rather than with a jarring jerk, which reduces the initial noise spike when shredding begins. This controllability also allows the motor to operate at the minimum power required for the task, further reducing noise and energy consumption compared to a less efficient AC motor running at a constant, high speed.

Soundproofing Material Application (Sound-Dampening Foam/Vibration Absorbing Feet)

Engineers use sound-dampening materials to line the interior housing of the shredder. Specialized acoustic foam absorbs sound waves generated by the motor and cutting mechanism, preventing them from echoing inside the unit and escaping to the environment. This is a critical step in containing operational noise.

Vibration is another key transmission path for noise. Anti-vibration rubber feet are placed between the shredder's chassis and its external casing. These feet act as isolators, preventing the mechanical vibrations from the motor and gears from being transferred to the desk or floor, which would act as a large sounding board, amplifying the noise. Some high-end models even incorporate internal shock mounts for the motor assembly itself for further isolation.

Aerodynamic Optimization (Air Intake Design)

Motors and gearboxes generate heat and require airflow for cooling. However, poorly designed air intakes and exhaust vents can create whistling sounds as air moves through them. In quiet shredders, these pathways are carefully engineered with smooth, rounded contours and baffles to allow air to flow freely while minimizing turbulent noise.

The fans used for cooling are also designed for low acoustic emissions. They may have specially shaped blades that move air efficiently at lower RPMs, reducing the whooshing sound associated with cooling fans. This attention to aerodynamic detail ensures that the cooling system, a necessary component, does not become a secondary source of noise, maintaining the overall quiet performance of the machine.

Operational State Intelligent Adjustment (Load Sensing)

Advanced shredders incorporate sensors that detect the load on the motor. When only a single sheet is fed, the system can intelligently reduce the motor's power and speed, just enough to cleanly shred the paper. This light-load operation is significantly quieter than running the motor at full power unnecessarily.

Conversely, when the sensor detects a thicker stack or a more resistant material (like a card), it can briefly increase power to ensure a clean cut without jamming. This smart power management, often controlled by a microprocessor, ensures optimal performance and minimal noise for every shredding task. It represents a shift from a simple on/off operation to an adaptive, intelligent system that tailors its operation to the immediate need.

Energy Efficiency and Safety Standards

For an appliance that may sit plugged in for long periods, energy efficiency is an important consideration for both environmental and economic reasons. Modern shredders are designed to consume minimal power in standby mode and to operate efficiently during use. Coupled with robust safety features, these standards ensure the device is both economical to run and safe for use in a home, potentially around children.

Safety mechanisms are crucial for preventing accidents and protecting the shredder from damage due to misuse or malfunction. These features are designed to intervene automatically, requiring no action from the user to prevent overheating, electrical faults, or physical accidents. A thorough understanding of these standards provides peace of mind that the device will operate reliably and safely for years to come.

Energy Rating Certification (ERP Directive Compliance)

The European Union's Energy-Related Products (ERP) Directive sets standards for the energy efficiency of electronic appliances, including shredders. Compliance with this directive indicates that the shredder has been designed to limit its energy consumption, particularly in standby mode. A shredder with a good ERP rating will draw less than 1 watt of power when not in use, which is negligible on an electricity bill.

This is achieved through efficient power supply designs and smart circuitry that powers down non-essential components when the machine is idle. Choosing an ERP-compliant model is a responsible choice that reduces your carbon footprint and operational costs over the lifetime of the product. Many manufacturers now advertise this compliance as a key feature for environmentally conscious consumers.

Overheat Protection Mechanism (Auto Shut-off Function)

Shredder motors generate heat during operation. If used continuously beyond their designed duty cycle, they can overheat, potentially causing damage to the motor's windings or surrounding components. All quality shredders include an overheat protection sensor, usually a thermal fuse or a thermistor, that monitors the motor's temperature.

If the temperature exceeds a safe threshold, the protection circuit will automatically切断电源 (cut power) to the motor, forcing a cool-down period. The shredder will be inoperable until the motor has cooled sufficiently, at which point it will reset itself. This feature is essential for protecting your investment and preventing fire hazards, ensuring the shredder's longevity by preventing catastrophic motor burnout.

Safety Lock Design (Child Proofing)

Many modern shredders feature a safety switch or a locking mechanism that prevents accidental operation. This is often a keylock that disables the power button or the feed function. This is a critical feature for households with young children, preventing them from turning on the shredder and potentially injuring themselves by inserting fingers or toys into the feed opening.

Even without children, a safety lock provides security against accidental activation, which could lead to the destruction of important documents or cause a jam if an object is inadvertently fed through. It is a simple but highly effective mechanical safety measure that adds a layer of protection and control over the device's operation.

Paper Jam Handling (Auto Reverse Function)

Paper jams are an inevitable occurrence, often caused by overfeeding, feeding wrinkled paper, or attempting to shred materials beyond the machine's capacity. A key feature for user-friendliness is an automatic reverse function. When the shredder's sensors detect a jam or a significant increase in motor load, it will automatically briefly reverse the direction of the cutting blades.

This action often dislodges the jammed material, allowing it to be removed easily from the feed throat. This prevents the user from having to manually reach into the cutting mechanism, which can be dangerous. Some models may also include a manual reverse button for greater control. This feature greatly reduces the frustration and downtime associated with jam clearance, making the shredding process much smoother.

Smart Function Adaptability

The integration of smart technology into home office shredders is a growing trend, adding convenience, improving user experience, and providing greater control over the device's operation. These intelligent features automate routine tasks, provide valuable status updates, and can even integrate the shredder into a broader smart home ecosystem, making document management seamless and efficient.

From sensors that initiate shredding to notifications that prevent overflows, smart functions transform the shredder from a dumb mechanical device into an interactive tool. While not essential for basic operation, these features can significantly enhance the daily user experience, reducing the mental load required to manage the device and ensuring it operates optimally with minimal oversight.

Auto Start-Stop Sensors (Optical/Touch Sensing)

The most common and useful smart feature is an automatic start/stop function. An optical sensor is placed just inside the feed opening. When a document breaks the sensor's beam, the shredder automatically powers up and begins feeding. Once the document has passed through and the beam is restored, the shredder automatically turns off after a brief delay.

This "hands-free" operation eliminates the need to fumble for a power switch and ensures the shredder is only running when actively destroying paper, which saves energy and reduces wear on the motor. It also contributes to safety, as the blades are only in motion when paper is present, minimizing the risk of accidental contact during loading.

Bin Full Alert System (LED/App Notification)

Forgetting to empty the shredder bin can lead to paper scraps backing up into the cutting mechanism, causing a jam. A bin-full alert system prevents this. A simple mechanical lever or an optical sensor inside the waste bin collection area detects when the shredded paper pile reaches a certain height.

This triggers a warning indicator, usually a red LED light on the control panel. More advanced models may integrate with a smartphone app via Bluetooth, sending a push notification to the user's phone as a reminder to empty the bin. This proactive alert system helps maintain the shredder's performance and prevents messy and frustrating jams caused by an overfull collection bag.

Shred Bag Capacity Monitoring (Weight Sensor)

Going a step beyond a simple "full/not full" sensor, some high-end models incorporate a weight sensor in the base of the unit where the waste bin sits. This sensor can estimate the actual weight of the shredded material inside the bag. This data can be used to provide a more precise capacity reading, such as a percentage full, on a display or within an app.

This allows for better planning; a user can see that the bin is 80% full and know they can finish a current shredding task before needing to empty it. It also provides a more accurate measurement than a simple height sensor, as different shred types (strip vs. micro-cut) have vastly different densities for the same volume.

Cross-Device Interoperability (Smart Home Integration)

The frontier of smart shredders involves integration with broader smart home platforms like Amazon Alexa, Google Assistant, or Apple HomeKit. While shredding itself is not an action typically triggered by voice, integration can allow for status checks ("Alexa, is the shredder bin full?") or the receipt of notifications through a central home hub.

This level of integration is still emerging but points to a future where the shredder is just another connected device in a seamless home office ecosystem. It could, for instance, be programmed to only operate during "office hours" defined in a smart home routine or to send an alert to a family-shared notification channel when maintenance is required.

Maintenance Cost and Usability

The long-term ownership cost of a shredder extends beyond its initial purchase price. Factors such as the availability and cost of replacement parts, the ease of routine maintenance, and the manufacturer's support policy all contribute to the total cost of ownership. A slightly more expensive model with a longer warranty and lower-cost consumables may be cheaper over five years than a bargain model that requires expensive servicing.

Usability is equally important. A shredder that is difficult to clean, requires complex lubrication procedures, or has a poorly designed waste bin will become a source of frustration over time. Evaluating these maintenance and usability factors upfront ensures that the shredder remains a helpful tool rather than a burdensome appliance.

Blade Unit Replaceability (Modular Design)

The cutting blades are the consumable heart of the shredder. Over time, even the best blades will dull. A user-replaceable blade cartridge system is a significant advantage. Instead of requiring a complex disassembly or a professional service call, the user can simply unlock the old cartridge and snap in a new one.

This modular design makes maintenance quick, clean, and safe. When evaluating models, it's wise to check the availability and price of these replacement cartridges. A model with a unique, expensive cartridge might become costly to maintain, whereas a model that uses a common, reasonably priced cartridge will have lower long-term operating expenses.

Cleaning Convenience (Removable Waste Bin)

The waste bin must be easy to access and remove for emptying. A well-designed bin has a handle, is made from a smooth material that doesn't catch shredded paper, and is easy to align when reinserting. Some models feature a "lift-out" bin, while others may have a slide-out drawer design.

The best designs also include features to minimize mess, such as a lid or a cover that contains the paper dust when carrying the bin to the trash. A poorly designed bin that is difficult to remove or that spills its contents during handling will make the routine task of emptying the shredder an unpleasant chore, reducing the likelihood that it will be done regularly.

Consumables Cost (Shred Bags/Lubrication Oil)

While many shredders use a standard plastic bag liner, some require proprietary disposable bags. These can add a recurring cost to ownership. It's advisable to choose a model that can use generic bags or, even better, no bag at all, allowing you to empty the contents directly into your recycling bin.

Shredder lubrication is another consumable. Most manufacturers recommend periodically feeding a lubricant sheet or a small amount of oil to keep the blades clean and cutting smoothly. The cost and frequency of this maintenance should be considered. Some modern blades are coated or designed to be run without lubrication, which can eliminate this ongoing cost and maintenance step entirely.

Brand After-Sales Service Network (Warranty Policy)

The length and terms of the warranty are strong indicators of the manufacturer's confidence in their product. A standard warranty for a home shredder is typically 1-2 years. Some brands offer longer warranties, even lifetime warranties on the cutting heads. A longer warranty provides peace of mind against premature failure.

Equally important is the ease of accessing service. Does the brand have a clear process for warranty claims? Are there authorized service centers, or is the policy based on replacement? Researching a brand's reputation for customer service can prevent significant hassle down the road. A reliable after-sales service network ensures that if a problem does occur, it can be resolved quickly and efficiently.

Typical Product Comparison Review

To translate the technical specifications and features into practical advice, it is helpful to examine real-world examples across different market segments. The following reviews highlight models that are representative of their category, illustrating how the principles discussed in this guide are implemented by various manufacturers. This comparison is based on aggregated technical specs, professional reviews, and user feedback.

Each model exemplifies a different approach to balancing performance, noise, and price. By understanding the strengths and trade-offs of these representative products, you can better evaluate other models on the market and identify which combination of features best aligns with your specific home office needs and budget constraints.

Entry-Level Silent Model (Fellowes Powershred 79Ci)

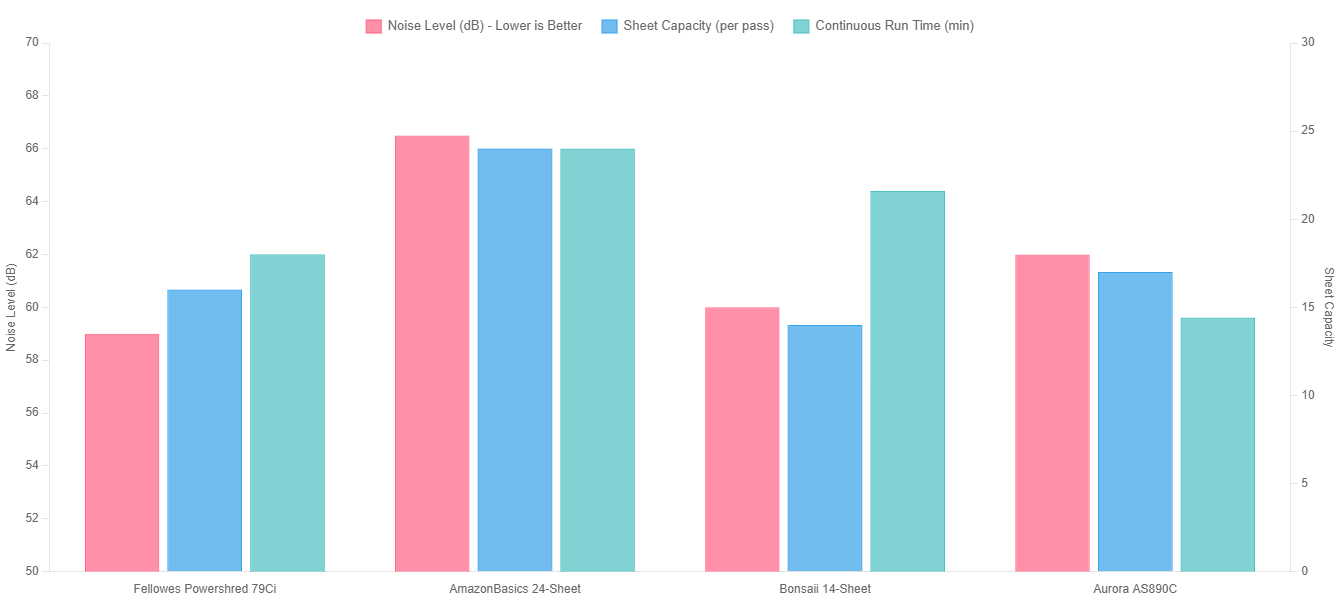

The Fellowes 79Ci is a benchmark in the entry-level quiet shredder category. It utilizes a proprietary SilentShred technology that combines sound-dampening insulation with a specially designed cutter head to achieve noise levels around 58-60 dB, making it one of the quietest in its class. It offers a respectable 16-sheet capacity for cross-cut shredding and a 15-minute continuous run time.

Its security level is P-4, reducing documents into 5/32" x 1-3/8" particles, which is sufficient for most personal documents. It features a 9-inch throat width, automatic start/stop, and a LED indicator for bin full and overload warnings. Its main trade-off is a shorter warranty period compared to more expensive models, but it represents excellent value for users seeking quiet operation on a budget.

Mid-Range High-Efficiency Model (AmazonBasics 24-Sheet)

The AmazonBasics 24-Sheet shredder prioritizes capacity and speed over absolute silence. It is designed for the home user who occasionally needs to process larger stacks of paper quickly. It boasts a 24-sheet capacity for cross-cut shredding and a wider throat to handle more complex documents. Its run time is substantial for a home unit, allowing for longer shredding sessions.

It includes standard features like auto start/stop, overload protection, and a transparent waste bin with a full indicator. While not marketed as an ultra-silent model, its noise level is still reasonable for a home office, typically around 65-68 dB. This model is ideal for those who value throughput and capacity and are less sensitive to moderate operational noise.

High-End Smart Model (Bonsaii 14-Sheet Cross-Cut)

Bonsaii models often stand out for their combination of smart features and robust build quality. A model like their 14-sheet cross-cut shredder often includes advanced smart sensors for jam prevention and bin-full detection. Some variants offer connectivity features, allowing status monitoring via a smartphone app, which is rare in the home shredder market.

It typically operates at a quiet level (around 60 dB) thanks to a well-insulated housing and a quality motor. The security level is often high (P-4 or similar), and it includes a heavy-duty cutting head designed for longevity. The trade-off for these premium features is a higher initial purchase price, but it is justified by the enhanced convenience, connectivity, and durable construction aimed at serious home office users.

Best Value Proposition (Aurora AS890C)

The Aurora AS890C is frequently highlighted for providing a strong set of features at a highly competitive price point. It offers a good balance of a 17-sheet cross-cut capacity, a quiet operating profile (approximately 62 dB), and a sturdy build. It includes essential quality-of-life features like auto start/stop, overload protection, and a bin-full light.

Where it excels is in its value equation: it delivers core performance and reliability that meets or exceeds the needs of most home users without the premium cost associated with the top brands. It may lack some of the advanced smart features or ultra-quiet technology of more expensive models, but for users seeking a dependable, capable, and quiet shredder without unnecessary extras, it often represents the most cost-effective solution.

Installation and Usage Precautions

Proper installation and adherence to usage guidelines are crucial for ensuring the longevity, safety, and performance of your shredder. Even the best-designed machine can underperform or fail prematurely if used incorrectly or placed in an unsuitable environment. These final guidelines cover the practical aspects of integrating the shredder into your home office and maintaining it properly over time.

From choosing the right location to understanding what not to shred, these precautions help you avoid common pitfalls that lead to jams, breakdowns, or safety hazards. Following these recommendations will ensure that your shredder remains a reliable and valuable tool for protecting your privacy for many years.

Optimal Placement Location (Away from Work Area)

The ideal location for a shredder is on a stable, level, and hard surface like the floor or a dedicated stand. Placing it on a carpet can block air intakes and cause overheating. While it might be tempting to keep it on your desk for convenience, the operational vibration and noise can be disruptive. A better location is under the desk or in a corner a few feet away.

Ensure there is ample space around the unit, especially behind it, for proper ventilation to prevent the motor from overheating. The location should also be easily accessible for feeding documents and for removing and emptying the waste bin. Avoid humid areas like near a kitchen or bathroom, as moisture can cause paper to clump and jam the mechanism.

Regular Maintenance Cycle (Monthly/Quarterly)

Regular maintenance is simple but essential. The primary task is emptying the waste bin before it becomes overfull. Depending on usage, this could be weekly or monthly. Secondly, lubricating the blades is critical to prevent paper dust from building up and causing jams or motor strain. This should be done every 1-2 months, or after every 30 minutes of total runtime, using manufacturer-recommended lubricant sheets or oil.

Every few months, it's a good practice to unplug the shredder and use a can of compressed air to gently blow out any accumulated dust from the cutting blades and the feed opening. A soft, dry cloth can be used to wipe down the exterior. This simple routine prevents most common issues and keeps the shredder running smoothly.

Abnormal Noise Diagnosis Guide (Bearing/Belt Inspection)

A change in the shredder's sound can indicate a problem. A new grinding or grating noise often suggests that a foreign object like a staple or paperclip is caught in the blades. A high-pitched whining or squealing noise could indicate that a bearing is wearing out or that the drive belt (if applicable) is loose or damaged.

If the motor hums but the blades don't turn, a gear may be stripped, or a jam may be preventing movement. In most cases, the first step is to turn the shredder off and unplug it. For a jam, use the manual reverse function if available. For persistent strange noises or mechanical failures, it's best to stop using the shredder and consult the warranty or a professional repair service to avoid causing further damage.

Shredding Material Prohibited List (Credit Cards/CDs)

It is crucial to understand your shredder's limitations. Most home office shredders are designed primarily for paper. While many can handle staples and small paper clips, other materials can cause immediate damage. Never shred credit cards, CDs, or DVDs unless your model is explicitly advertised as capable of doing so. These materials can quickly dull or damage paper-cutting blades.

Also avoid shredding laminated papers, cardboard beyond the specified capacity, adhesive labels, or any material that is not explicitly approved in the user manual. These can leave sticky residues on the blades, leading to poor performance and increased jams. Feeding inappropriate materials is a leading cause of premature shredder failure and will often void the manufacturer's warranty.