Modern recycling operations face significant challenges when processing high-hardness alloys, requiring specialized equipment that combines durability with energy efficiency. Four shaft shredders have evolved to meet these demands through advanced material science, intelligent engineering, and optimized operational strategies. This technical overview explores how contemporary shredding technology maintains performance while reducing operational costs in demanding metal recycling applications.

The processing of high-hardness alloys represents one of the most demanding applications in industrial shredding, with material hardness often exceeding HRC 55 and tensile strengths above 1200 MPa. These extreme conditions necessitate equipment designed specifically to withstand accelerated wear while managing energy consumption effectively throughout the shredding process.

Material Characteristics and Processing Challenges of High-Hardness Alloy Scrap

High-hardness alloys possess unique physical properties that differentiate them from conventional scrap metals, creating specific challenges during size reduction processes. Understanding these material characteristics forms the foundation for developing effective shredding strategies and equipment configurations.

The metallurgical composition of these advanced materials includes work-hardening properties that significantly impact equipment performance. Nickel-based superalloys, high-manganese steels, and tool steels each present distinct processing difficulties that must be addressed through specialized engineering solutions.

Typical Categories and Mechanical Properties of High-Hardness Alloys

Common high-hardness alloys encountered in scrap processing include high-manganese steels with hardness values between HRC 55-60, nickel-based superalloys maintaining strength at elevated temperatures, and high-speed steels used in cutting tools. These materials typically demonstrate yield strengths exceeding 800 MPa and tensile strengths above 1200 MPa, creating substantial resistance during shredding operations.

The exceptional mechanical properties derive from complex microstructures featuring carbide formations, intermetallic compounds, and sophisticated heat treatment histories. These metallurgical characteristics enable the materials to maintain integrity under extreme stress but simultaneously make them particularly challenging to process using conventional shredding equipment.

Connection Between Work Hardening Effects and Tool Wear Mechanisms

High-hardness alloys frequently exhibit work hardening characteristics where plastic deformation increases material hardness by 20-30% during the shredding process. This phenomenon occurs through dislocation multiplication and strain-induced phase transformations that strengthen the material as it undergoes shear deformation.

The combination of initial high hardness and additional work hardening creates a compounding wear effect on cutting tools. This leads to both abrasive wear from hard particle interactions and fatigue wear from cyclic loading, significantly reducing tool life compared to processing conventional steel scrap materials.

Tangling and Jamming Risks Associated with High Toughness Materials

Nickel-based alloys and austenitic manganese steels demonstrate exceptional toughness with elongation at fracture often exceeding 40%. This mechanical property enables the materials to undergo substantial plastic deformation without fracturing, creating a tendency to wrap around rotating components rather than breaking into smaller pieces.

The tangling behavior presents significant operational risks including sudden overload conditions, drive system damage, and extended downtime for clearing jammed materials. These challenges require specific countermeasures in equipment design and operational protocols to maintain processing efficiency and equipment safety.

Special Characteristics of Irregularly Shaped Scrap During Feeding and Stress Application

Casting remnants, forged components, and machining stock often feature complex geometries with varying cross-sections and protrusions. These irregular shapes create uneven feeding patterns and generate fluctuating resistance forces throughout the shredding chamber of a scrap metal four shaft shredder.

The intermittent loading conditions produce impact forces that can reach 2-3 times the steady-state processing loads, creating significant dynamic stresses on structural components and cutting elements. These transient load conditions accelerate fatigue damage and require specific engineering considerations in equipment design.

Wear-Resistant Cutting System Design and Material Science Applications

Cutting tools represent the primary interface between the shredding equipment and processed materials, making their performance critical to overall system efficiency. Advanced materials and engineering approaches have dramatically improved tool life and processing capabilities for high-hardness alloys.

Modern cutting systems integrate sophisticated metallurgy, precision manufacturing, and intelligent monitoring to maximize service life while maintaining processing quality. These developments have transformed tooling from simple replaceable components to integrated systems that actively contribute to operational efficiency.

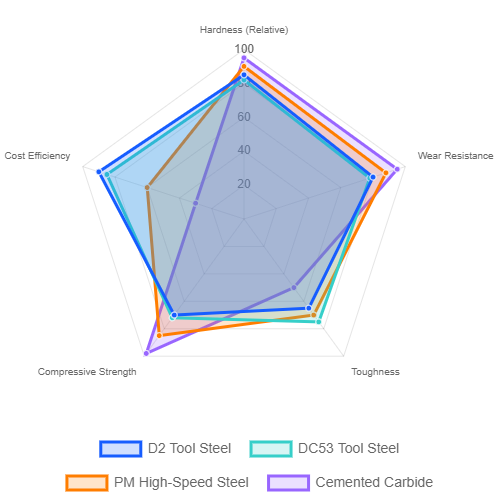

Selection Matrix for Tool Base Materials and Application Scenarios

Tool steel selection follows a systematic approach balancing hardness, toughness, and cost considerations for specific application requirements. D2 tool steel provides excellent wear resistance with hardness up to HRC 62, while DC53 offers improved toughness for applications involving impact loading. Powder metallurgy high-speed steels deliver superior performance in extreme conditions but at significantly higher cost.

Cemented carbide tools represent the premium solution for processing the hardest alloys, with hardness values reaching HRA 92-94 and compressive strength exceeding 6000 MPa. The tungsten carbide-cobalt compositions provide exceptional wear resistance but require careful engineering to manage their relatively lower toughness compared to tool steel alternatives.

Advanced Surface Treatment Technologies and Wear Resistance Improvements

Physical vapor deposition coatings including TiAlN (titanium aluminum nitride) create surface layers with hardness values between HV 3000-3500, significantly enhancing wear resistance. These thin film coatings typically measure 2-5 micrometers thick and reduce friction coefficients while providing thermal barrier properties that protect the underlying tool material.

Modern coating technologies can extend tool life by 3-5 times compared to uncoated equivalents when processing high-hardness alloys. The combination of optimized substrate properties and specialized surface engineering creates synergistic effects that dramatically improve performance in the most demanding shredding applications.

Tool Geometry Optimization and Shearing Efficiency Enhancement

Advanced cutting tool designs incorporate variable rake angles, multi-level step configurations, and specialized edge preparations that reduce peak torque requirements by 20-30%. These geometrical innovations distribute cutting forces more evenly across the tool profile and minimize stress concentrations that initiate premature failure.

Computational fluid dynamics and finite element analysis guide the development of tool geometries that efficiently manage the chip formation process. Optimized designs control material flow during shearing, reducing energy consumption while maintaining consistent particle size distribution in the output material.

Modular Tooling System Designs and Rapid Replacement Solutions

Patented quick-change systems utilizing precision locking mechanisms enable single tool replacement within 15 minutes, reducing downtime by approximately 70% compared to conventional bolted systems. These designs maintain precise positioning accuracy while eliminating the need for time-consuming alignment procedures during tool changes.

The modular approach allows operators to replace individual damaged tools without disassembling entire shafts or adjacent components. This targeted maintenance strategy significantly reduces spare parts inventory requirements and minimizes equipment downtime during tool replacement operations.

Energy-Efficient Drive and Transmission System Configurations

Drive system optimization represents a critical opportunity for reducing operational costs while maintaining processing capacity for high-hardness alloys. Modern shredders incorporate sophisticated power transmission technologies that maximize energy conversion efficiency throughout the operating range.

The integration of advanced motor technologies, intelligent control systems, and optimized mechanical components creates synergistic effects that significantly reduce specific energy consumption. These developments have transformed energy management in industrial shredding operations.

High-Torque Density Permanent Magnet Synchronous Motors and Efficiency Advantages

Permanent magnet synchronous motors achieve efficiency levels of 94-96% across a broad operating range, outperforming traditional asynchronous motors by 8-12% at partial loads. The constant high efficiency results from reduced rotor losses and improved power factor characteristics that minimize reactive power requirements.

The compact design of permanent magnet motors provides higher torque density within equivalent frame sizes, enabling more powerful drives without increasing physical dimensions. This characteristic allows equipment designers to optimize space utilization while maintaining high performance standards.

Hydraulic Coupling and Intelligent Control System Synergy for Energy Savings

Fluid couplings provide smooth acceleration during startup, reducing inrush current demands by up to 60% compared to direct-on-line starting methods. This soft-start capability extends equipment life while minimizing power quality issues associated with high-current starting conditions.

Intelligent control systems monitor operational parameters and automatically adjust coupling fill levels to match torque requirements precisely. This dynamic adjustment eliminates energy waste from oversizing while providing immediate overload protection that prevents damage to mechanical components.

Planetary Gear Reducers and Torque Distribution Optimization

Planetary gear systems utilizing full-complement cylindrical roller bearings demonstrate load capacity improvements of 30% compared to conventional designs while maintaining efficiency above 96%. The multiple power paths within planetary systems distribute loads evenly across multiple gear meshes, reducing stress concentrations and extending service life.

The compact coaxial design of planetary reducers minimizes space requirements while providing high reduction ratios in a single stage. This configuration simplifies mechanical layouts and reduces the number of components in the power transmission path, improving overall system reliability.

Intelligent Load Response and Power Adaptive Adjustment Systems

Advanced control algorithms continuously monitor motor current, torque output, and processing rates to optimize energy consumption in real-time. These systems automatically adjust operational parameters including rotor speed, feed rate, and tool gap settings to match material characteristics.

The adaptive control approach prevents energy waste from operating at maximum capacity when processing lighter materials while ensuring sufficient power availability for challenging feedstocks. This dynamic optimization typically reduces specific energy consumption by 12-18% compared to fixed-parameter operation.

Structural Reinforcement and Vibration Control Technologies

The extreme forces generated during high-hardness alloy processing demand robust structural designs that maintain integrity under cyclic loading conditions. Advanced engineering approaches ensure equipment longevity while minimizing vibration transmission to surrounding structures.

Modern shredder frames incorporate sophisticated analysis techniques and specialized components to manage the dynamic loads encountered during operation. These developments have significantly improved equipment reliability in the most demanding applications.

Finite Element Analysis and High-Stiffness Structural Optimization

Computer-aided engineering techniques including finite element analysis identify stress concentration areas and guide reinforcement strategies. Topology optimization algorithms generate ideal material distribution patterns that maximize stiffness while minimizing weight, typically achieving 40% or greater stiffness improvements compared to conventional designs.

The strategic placement of reinforcing ribs, gussets, and structural members follows computational guidance to ensure optimal load paths throughout the frame. This engineering approach creates structures capable of withstanding the extreme forces generated during high-hardness alloy processing.

Bearing Selection and Preload Adjustment for Impact Load Conditions

Double-row tapered roller bearings provide optimal performance under the combined radial and axial loads encountered in shredding applications. Proper preload adjustment ensures precise rotor positioning while distributing loads evenly across bearing elements, typically extending service life by 50% compared to standard configurations.

Advanced bearing materials including vacuum-degassed steel and specialized heat treatments enhance fatigue resistance under the high-impact conditions of alloy processing. These material improvements significantly increase bearing life in applications characterized by shock loading and vibration.

Dynamic Balance Standards and Vibration Control Specifications

Precision balancing of rotating assemblies to G6.3 standards ensures smooth operation at working speeds, with vibration velocity maintained below 4.5 mm/s. This balance quality prevents resonant vibrations that could damage structural components or degrade cutting performance over time.

Vibration monitoring systems track changes in machine dynamics that might indicate developing issues with shredder shafts or bearing condition. Continuous monitoring enables proactive maintenance interventions before vibration levels reach damaging magnitudes.

Intelligent Control and Process Parameter Optimization Strategies

Modern control systems transform shredders from simple mechanical processors to intelligent manufacturing systems that continuously optimize performance. These advanced control strategies balance multiple operational objectives including throughput, energy efficiency, and equipment protection.

The integration of sensor networks, computational algorithms, and automated adjustment capabilities creates systems that adapt to varying material conditions in real-time. This adaptive approach maximizes productivity while minimizing operational costs across diverse processing scenarios.

Adaptive Control Algorithms Based on Material Identification

Vision systems utilizing hyperspectral imaging and laser profiling technologies automatically classify incoming materials by alloy type and geometry. This classification enables the control system to recall pre-optimized parameter sets for specific material categories, ensuring optimal processing conditions from the start of each batch.

The automated parameter selection adjusts multiple variables including rotor speed, feed rate, and tool gap settings to match material characteristics. This optimization typically improves processing efficiency by 15-25% compared to fixed-parameter operation across mixed material streams.

Intelligent Torque Distribution and Four-Shaft Synchronization Control

Master-slave control architectures maintain precise speed and torque relationships between the four shredder shafts, ensuring balanced loading across all cutting elements. Advanced algorithms continuously adjust individual shaft outputs to maintain torque differentials below 5%, preventing localized overload conditions.

The synchronized operation eliminates uneven wear patterns that develop when shafts operate at different loading conditions. This balanced approach extends maintenance intervals and ensures consistent product quality throughout the equipment service life.

Jamming Prevention and Automatic Reversal Control Logic

Dual-signal detection systems monitoring both motor current and hydraulic pressure provide reliable jam detection within 200 milliseconds of overload initiation. This rapid response prevents material compaction that could require extended downtime for manual clearing operations.

Automated reversal sequences clear jams by briefly operating the feed system in reverse while maintaining cutter rotation in the forward direction. This coordinated action typically resolves jam conditions within 2-3 reversal cycles without operator intervention, minimizing processing interruptions.

Maintenance Systems and Lifecycle Cost Management Approaches

Proactive maintenance strategies ensure long-term equipment reliability while optimizing total cost of ownership throughout the equipment service life. These systematic approaches balance preventive maintenance activities with operational requirements to maximize equipment availability.

Modern maintenance programs integrate condition monitoring technologies, inventory optimization, and specialized procedures to support equipment operating in demanding conditions. These comprehensive approaches have transformed maintenance from reactive interventions to strategic asset management.

Condition-Based Preventive Maintenance Program Development

Integrated monitoring systems collect vibration data, oil analysis results, thermal imaging, and performance metrics to establish comprehensive equipment health assessments. This multi-parameter approach provides early warning of developing issues before they progress to equipment failure.

Maintenance scheduling follows actual equipment condition rather than fixed time intervals, optimizing resource allocation while preventing unexpected downtime. This approach typically reduces maintenance costs by 25-35% while improving equipment availability compared to calendar-based maintenance programs.

Replacement Cycle Optimization and Inventory Management Models

Statistical analysis of component wear rates enables precise prediction of replacement requirements based on actual operating conditions. These predictive models consider material processing volumes, alloy characteristics, and operational parameters to forecast spare part needs with 95% confidence levels.

Inventory optimization algorithms balance carrying costs against downtime expenses to establish optimal spare parts stocking levels. This analytical approach typically reduces inventory investment by 20-30% while maintaining target equipment availability standards.

Lifecycle Cost Modeling and Optimization Decision Frameworks

Comprehensive cost analysis considers acquisition expenses, energy consumption, maintenance requirements, and operational losses over a 15-year equipment life. This holistic perspective reveals the true cost of ownership beyond initial purchase price, enabling informed decision-making.

The lifecycle approach typically demonstrates that equipment selection based solely on initial cost fails to account for 60-70% of total ownership expenses. This understanding guides investment decisions toward solutions that optimize long-term operational efficiency rather than minimizing short-term capital expenditure.