This guide provides a scientific approach to choosing and applying UV-resistant coatings for scrap metal four shaft shredder housings operating in high-altitude concentrator plants. High-altitude regions present unique challenges due to intense ultraviolet radiation, extreme temperature fluctuations, and dry conditions that accelerate coating degradation. Understanding these factors helps maintain equipment integrity and operational continuity in demanding industrial settings.

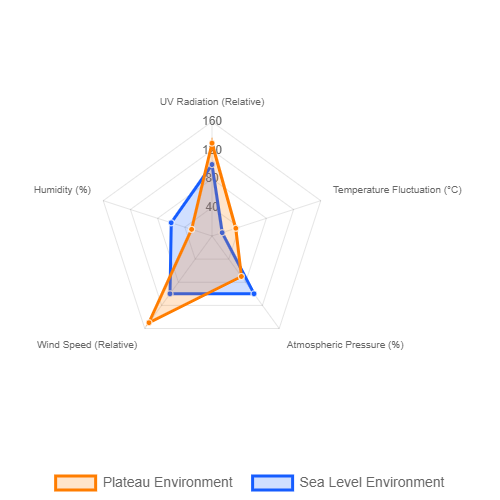

Plateau environments typically experience UV radiation levels 20-30% higher than sea-level areas, with annual doses reaching 150-200 kLy in some regions. This comprehensive coverage addresses material science principles, selection methodologies, application techniques, and long-term performance monitoring to ensure optimal protection for industrial machinery.

Environmental Challenges for Shredder Housing Coatings in Plateau Regions

High-altitude operating conditions create multiple stressors that simultaneously attack protective coatings. The combination of intense solar radiation, atmospheric conditions, and temperature variations requires specialized coating solutions beyond standard industrial applications.

Plateau concentrator plants typically operate at elevations above 3,000 meters where atmospheric filtration decreases significantly. This reduced filtration allows more harmful UV-B radiation to reach the Earth's surface, creating particularly aggressive conditions for exterior coatings on machinery such as scrap metal four shaft shredders.

Spectrum Characteristics and Degradation Mechanisms of Intense UV Radiation

Ultraviolet radiation in high-altitude environments contains higher proportions of UV-B wavelengths between 280-315 nanometers. These shorter wavelengths carry greater energy that breaks molecular bonds in polymer-based coatings. The photochemical degradation process initiates when photons with energies exceeding 300 kJ/mol strike coating surfaces.

Research indicates that UV radiation at 4,000 meters elevation can be 50% more intense than at sea level. This increased intensity accelerates the breakdown of chemical bonds in coating resins, leading to chalking, gloss loss, and eventual film failure. The degradation follows first-order kinetics, with reaction rates doubling for every 10°C increase in temperature.

Coating Stress Fatigue from Extreme Temperature Cycling

Diurnal temperature swings in plateau regions frequently exceed 30°C, creating repeated expansion and contraction cycles in metal substrates and coatings. The coefficient of thermal expansion mismatch between steel housings (approximately 12 × 10⁻⁶/°C) and typical coatings (50-100 × 10⁻⁶/°C) generates significant interfacial stresses.

These thermal cycles cause progressive damage through mechanical fatigue mechanisms. After 5,000 cycles equivalent to approximately 3-4 years of service, microcracks develop and propagate toward the substrate interface. The stress concentration at crack tips eventually leads to adhesive failure and coating delamination.

Impact of Low Atmospheric Pressure and High Winds on Coating Curing and Adhesion

At altitudes above 3,000 meters, atmospheric pressure decreases to about 70% of sea-level values. This reduction slows the evaporation rates of solvent-based coatings and affects the curing kinetics of two-component systems. The partial pressure of oxygen drops proportionally, potentially inhibiting oxidation-cure mechanisms in alkyd and oil-based coatings.

Persistent winds exceeding 8 m/s are common in exposed plateau locations. These conditions accelerate solvent evaporation from coating surfaces, potentially causing improper film formation. Wind-driven particles including mineral dust abrade newly applied coatings before full cure, compromising surface integrity and long-term performance.

Synergistic Erosion Effects from Arid Climate and Particulate Matter

Relative humidity in plateau concentrator plants often remains below 30%, causing coating polymers to become brittle through plasticizer migration and polymer embrittlement. The low moisture content reduces the molecular mobility within coating films, decreasing their ability to absorb mechanical impacts without cracking.

Airborne silica and mineral particles measuring 5-50 micrometers in diameter act as abrasive media when propelled by winds. This combination of material brittleness and mechanical abrasion produces distinctive erosion patterns characterized by directional micro-grooves and premature wear at exposed edges and corners.

Critical Performance Indicators for UV-Resistant Coating Materials

Selecting appropriate coatings for high-altitude applications requires understanding key material properties that determine long-term performance. These quantifiable parameters provide objective criteria for comparing different coating systems and predicting their service life in demanding conditions.

Modern coating technology employs advanced additives and resin chemistry to resist environmental degradation. Performance standards established by organizations like ASTM International and ISO provide testing protocols that simulate years of exposure in accelerated laboratory conditions.

Synergistic Action of UV Absorbers and Hindered Amine Light Stabilizers

UV absorbers function by converting damaging ultraviolet radiation into harmless heat energy through reversible chemical reactions. Benzotriazole-type absorbers effectively screen wavelengths between 300-400 nanometers, with molar extinction coefficients typically exceeding 15,000 L·mol⁻¹·cm⁻¹. These compounds remain stable through thousands of UV absorption cycles before depletion.

Hindered amine light stabilizers operate through a different mechanism by neutralizing free radicals formed during photo-oxidation. The regeneration of nitroxyl radicals enables HALS molecules to protect coatings through multiple cycles. When combined, UVA and HALS provide complementary protection that can extend coating life by 3-5 times compared to unstabilized systems.

Matching Glass Transition Temperature with Plateau Temperature Conditions

The glass transition temperature (Tg) represents the point where coating polymers transition from rigid to flexible states. For plateau applications, coatings should maintain a Tg at least 20°C above maximum service temperatures, which frequently reach 60-70°C in direct sunlight. Most high-performance polyurethane and fluoropolymer coatings exhibit Tg values between 80-120°C.

Operating above the Tg causes significant reduction in coating hardness, typically measured by pencil hardness tests. This softening increases susceptibility to dirt pickup, marking, and mechanical damage. Modern acrylic-urethane hybrids maintain Tg around 90°C while retaining flexibility at temperatures as low as -40°C encountered during plateau nights.

Quantitative Standards for Adhesion Strength and Humidity Resistance

Adhesion performance is quantified through standardized testing methods including ASTM D3354 cross-cut tape test. High-performance coatings for severe environments should achieve ratings of 4B or better, indicating less than 5% removal after testing. Additional assessment using pull-off adhesion testers typically shows values exceeding 5 MPa for properly applied systems.

Resistance to humid conditions is evaluated through ISO 6270 cyclic condensation testing. Quality coatings withstand 1,000 hours of exposure without blistering, maintaining adhesion strength above 4 MPa. The incorporation of reactive diluents and adhesion promoters in modern epoxy primers enhances performance at the coating-substrate interface.

Non-Linear Relationship Between Film Thickness and UV Protection Efficacy

UV protection increases with coating thickness up to a critical point typically between 120-150 micrometers for most organic coatings. Below this threshold, insufficient pigment and additive concentration compromises protection, while excessive thickness provides diminishing returns and increases material costs without proportional benefits.

Statistical analysis of field performance data reveals that increasing dry film thickness from 80μm to 120μm can extend service life by approximately 60%. Further increasing to 150μm provides only an additional 15-20% improvement. This non-linear relationship guides economic optimization of coating systems for large industrial assets.

Systematic Selection Process for Four-Shaft Shredder Housing Coatings

Implementing a structured methodology ensures optimal coating selection based on technical requirements, environmental conditions, and economic considerations. This eight-step process transforms subjective decisions into data-driven selections with predictable outcomes.

The selection framework incorporates both laboratory testing and field validation to bridge the gap between accelerated aging data and real-world performance. This approach minimizes risk while maximizing the service life of protective coatings on critical equipment.

Step One: Baseline Assessment and Failure Mode Analysis

Initial evaluation documents the current condition of existing coatings through visual inspection and instrumental analysis. Techniques including optical microscopy, infrared spectroscopy, and adhesion testing identify dominant failure mechanisms. This assessment determines whether UV degradation, abrasion, or chemical attack represents the primary concern.

Documenting failure modes guides subsequent material selection by highlighting specific performance requirements. Historical maintenance records provide valuable data on previous coating lifetimes, helping establish performance benchmarks for new systems under consideration.

Step Two: Quantitative Operational Environment Parameter Collection

Environmental monitoring gathers specific data relevant to coating performance, including annual UV radiation dosage, temperature extremes, and pollution concentrations. Electronic dataloggers positioned at the installation site record conditions for a minimum 30-day period to capture diurnal and seasonal variations.

Solar radiation measurements typically show values between 180-220 W/m² for UV radiation in plateau regions. Temperature records often reveal daily fluctuations from -15°C to 45°C, creating significant thermal stress. Wind speed data assists in predicting abrasive wear rates from airborne particles.

Step Three: Determining Substrate Compatibility and Surface Preparation Requirements

Shredder housings commonly utilize carbon steel grades such as Q235 or SS400 with specific surface characteristics. Metallurgical analysis confirms composition and identifies potential issues including surface contaminants, existing corrosion products, or previous coating residues that might affect adhesion.

Surface preparation specifications typically mandate Sa 2.5 blast cleaning according to ISO 8501-1, producing a surface profile of 50-75 micrometers. The high-altitude environment necessitates compressed air drying systems to prevent condensation during blasting operations, which could compromise surface cleanliness.

Step Four: Technical Screening of Candidate Coating Systems

Initial selection identifies 3-4 coating technologies with proven performance in similar environments. Common candidates include aliphatic polyurethanes, fluoropolymers, and silicone-modified polyesters. Each system undergoes preliminary evaluation against established technical criteria including UV resistance, flexibility, and chemical compatibility.

Technical data sheets provide initial performance indicators, but additional testing remains necessary to confirm suitability for specific application conditions. Laboratory analysis focuses on pigment volume concentration, resin chemistry, and additive packages that determine long-term durability.

Key Control Points for Specialized Coating Application in Plateau Environments

Proper application proves equally important as material selection for achieving designed coating performance. The unique atmospheric conditions in high-altitude locations require adjustments to standard application protocols and quality control measures.

Successful coating implementation demands careful planning around weather conditions, material handling, and application techniques. These factors collectively determine the final coating properties and their ability to withstand decades of exposure to extreme environments.

Surface Preparation Standards and Altitude-Specific Adjustments

Conventional surface preparation protocols require modification for high-altitude conditions. The reduced oxygen levels slow chemical reactions during conversion coating processes, while low humidity accelerates moisture evaporation from prepared surfaces. These factors necessitate tighter time intervals between preparation and primer application.

Industry practice in plateau regions mandates coating application within 4 hours of surface preparation versus the standard 8-hour window at lower elevations. This compressed schedule prevents surface oxidation and contamination that could compromise coating adhesion. Continuous monitoring of surface cleanliness using international standards ensures proper conditioning before coating application.

Coating System Design and Film Thickness Distribution Optimization

High-performance coating systems typically employ multiple layers with specific functions. A common configuration includes a zinc-rich epoxy primer for cathodic protection, an epoxy intermediate coat for build and barrier properties, and a fluoropolymer or polyurethane topcoat for UV resistance and color retention.

Film thickness distribution receives particular attention during application, with statistical process control ensuring 90% of measurements fall within ±20% of the specified thickness. Critical areas including edges, welds, and fasteners receive additional coating through specific application techniques to compensate for inherent thin spots.

Temperature Compensation Adjustments for Coating Viscosity at High Altitudes

Coating viscosity changes significantly with temperature variations common in plateau environments. Manufacturers provide viscosity-temperature tables that guide thinner additions, with typical adjustments of 5-10% required for every 10°C temperature change from standard conditions at 25°C.

Heated application equipment maintains optimal viscosity between 30-40 seconds measured using ISO flow cups. This controlled viscosity ensures proper atomization during spray application while preventing sagging on vertical surfaces. Electronic monitoring systems track material temperature throughout application to maintain consistency.

Curing Monitoring and Extended Drying Time Strategies

Infrared thermography monitors coating cure by detecting the exothermic reactions in crosslinking polymers. The reduced oxygen partial pressure at high altitudes can slow oxidative cure mechanisms, extending tack-free times by 30-50% compared to sea-level conditions.

Application scheduling accommodates these extended cure times by allowing additional intervals between coats. For typical epoxy systems, recoat windows may extend from 16 hours to 24 hours at 3,000 meters elevation. Forced drying methods using indirect-fired heaters maintain temperatures within the optimal curing range when ambient conditions prove unfavorable.

Coating Performance Verification and Long-Term Monitoring Solutions

Post-application assessment confirms whether coating systems meet design specifications and establishes baseline data for future comparison. A structured monitoring program detects early signs of degradation before significant damage occurs, enabling proactive maintenance planning.

Advanced analytical techniques provide quantitative data on coating condition beyond visual inspection. These methods measure subtle changes in material properties that precede visible deterioration, creating opportunities for intervention before failure becomes extensive.

Correlation Models Between Laboratory Accelerated Aging and Field Performance

Accelerated weathering tests using QUV apparatus with UV-B lamps provide preliminary performance data. Statistical analysis correlates laboratory exposure hours with field service years, establishing that 1,000 hours of QUV testing approximately equals 1.5-2 years of plateau exposure for most coating systems.

These correlation models incorporate acceleration factors based on spectral power distribution, temperature, and moisture cycles. Validation through parallel field exposure confirms prediction accuracy within ±15% for most coating chemistries. This relationship enables reasonable service life projections during material selection phases.

Regular Tracking of Gloss and Color Changes Through Instrumental Measurement

Gloss retention measurements using 60° geometry provide quantitative data on surface degradation. High-performance coatings typically maintain at least 80% of initial gloss after 5 years of severe exposure. Measurements conducted quarterly establish degradation trends, with values below 50% indicating significant surface erosion.

Color change evaluation employs spectrophotometers to measure ΔE values according to CIELAB methodology. Industrial standards typically consider ΔE values below 5 as acceptable for most applications, while values exceeding 8 indicate significant color shift requiring investigation into coating performance.

Electrochemical Impedance Spectroscopy Assessment of Protective Properties

EIS measures coating resistance to ionic penetration by applying small alternating currents across a range of frequencies. High-performance coatings demonstrate impedance values exceeding 1×10⁹ Ω·cm² at low frequency (0.01 Hz) after 12 months of field exposure, indicating intact barrier properties.

Regular EIS testing detects early-stage deterioration before visible signs appear. A one-order-of-magnitude decrease in impedance typically precedes blister formation or corrosion initiation by 6-12 months, providing advanced warning for maintenance planning.

Data-Driven Models for Protection Efficacy and Maintenance Decision-Making

Statistical analysis of monitoring data enables prediction of remaining service life using Weibull distribution models. These models incorporate environmental parameters, coating properties, and performance measurements to forecast degradation trajectories with confidence intervals.

Maintenance triggers establish intervention points based on technical condition rather than fixed time intervals. Typical models recommend recoating when gloss retention falls below 50% or impedance drops below 1×10⁸ Ω·cm², ensuring action before significant substrate damage occurs.

Economic Analysis and Return on Investment for Coating Systems

Lifecycle cost analysis provides comprehensive economic evaluation beyond initial purchase price. This methodology accounts for installation expenses, maintenance requirements, and operational impacts to determine true cost of ownership over the equipment's service life.

Financial modeling demonstrates how premium coating systems deliver value through extended maintenance intervals, reduced downtime, and improved operational reliability. These benefits often justify higher initial investments through significant long-term savings.

Comparative Analysis of Initial Investment Versus Traditional Coating Solutions

High-performance UV-resistant coatings typically command 30-50% higher initial costs compared to standard industrial coatings. This premium reflects advanced resin technology, specialized additives, and more rigorous manufacturing controls that enhance durability in severe environments.

The economic justification emerges when considering complete lifecycle costs. Extended service intervals of 7-10 years for premium systems versus 3-5 years for conventional coatings reduce application frequency, lowering long-term expenses despite higher initial investment.

Cost Modeling for Preventive and Corrective Maintenance Approaches

Preventive maintenance following planned intervals typically costs 5 times less than emergency repairs following coating failure. The cost differential results from planned execution during scheduled downtime versus unplanned equipment stoppages that disrupt production schedules.

Comprehensive cost models account for direct expenses including materials and labor, plus indirect costs from production losses. For typical shredding operations, a single day of unplanned downtime can exceed the total cost of a preventive recoating project, making proactive maintenance economically advantageous.

Indirect Impacts of Coating Performance on Shredder Operational Reliability

Effective housing protection prevents secondary damage to internal components including electrical systems, bearings, and cutting mechanisms. Statistical data from concentrator operations shows that properly maintained exterior coatings reduce unscheduled maintenance events by 25-35% annually.

The protective function extends beyond cosmetic preservation to maintaining critical dimensional stability of housing components. Properly coated structures better resist distortion from thermal gradients, ensuring precise alignment of shredder shafts and cutting elements for optimal performance.

Investment Payback Period and Comprehensive Benefit Calculation Models

Financial analysis typically shows payback periods of 2-3 years for premium coating systems in severe environments. This calculation incorporates direct savings from reduced maintenance frequency and indirect benefits from improved operational reliability and extended equipment life.

Return on investment calculations frequently demonstrate annualized returns exceeding 25% for upgraded coating systems. These compelling financial metrics justify capital allocation decisions, particularly when considering the strategic importance of continuous operation in concentrator plants.