Industrial shredders are powerful machines designed to process tough materials, but they face a silent adversary: metal dust. This byproduct of shredding operations might seem harmless, but it significantly impacts equipment performance and longevity. Understanding these effects is crucial for maintaining optimal operation and avoiding costly downtime. Proper dust management transforms from a maintenance task into a critical operational strategy.

Metal dust particles, often finer than 20 micrometers, behave almost like a liquid, infiltrating the smallest gaps in machinery. A study on industrial equipment wear found that contaminated lubrication can increase wear rates by up to 70%. This is particularly relevant for shredders processing materials like aluminum or copper, where dust accumulation can exceed 500 grams per cubic meter of air in poorly ventilated spaces. Recognizing this invisible threat is the first step toward effective mitigation.

Understanding Metal Dust Impacts on Shredder Performance

The continuous generation of metal dust during shredding operations creates a cascade of mechanical challenges. These microscopic particles act as an abrasive medium, accelerating wear on moving components and interfering with critical systems. The cumulative effect of this exposure gradually degrades performance and can lead to catastrophic failure if left unaddressed.

Research indicates that equipment operating in high-dust environments requires maintenance interventions 40% more frequently than those in controlled conditions. The financial implications extend beyond repair costs, including production losses and potential safety hazards. Implementing comprehensive dust management protocols becomes essential for sustainable operation.

How Metal Dust Wears Down Shredder Blades

Shredder blades constantly encounter abrasive metal particles that accelerate wear through micro-abrasion. This process gradually removes material from cutting edges, reducing their effectiveness and requiring more power to achieve the same shredding results. The wear pattern is often uneven, creating imbalances that further stress the entire drive system.

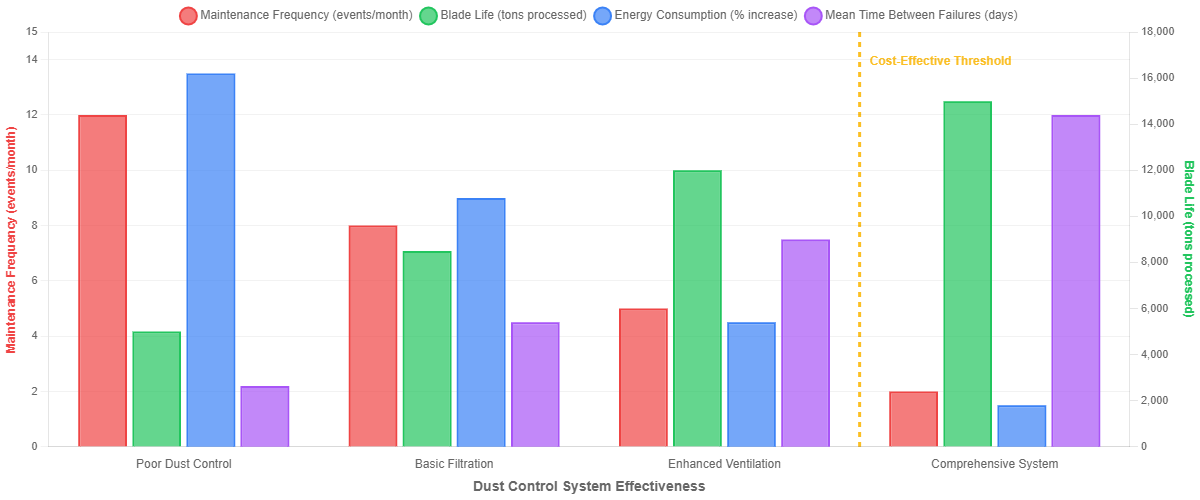

Studies of tungsten carbide cutters show that proper dust control can extend blade life by up to 300%. Without protection, blade replacement becomes necessary after processing approximately 5,000 tons of material, compared to 15,000 tons in optimized conditions. Regular inspection of cutting components is essential for maintaining shredding efficiency.

Dust Accumulation and Thermal Management Issues

Metal dust coatings on surfaces act as insulation, reducing the effectiveness of heat dissipation systems. This is particularly problematic for shredder motors and hydraulic systems that generate significant operational heat. Elevated operating temperatures accelerate lubricant degradation and can cause thermal expansion of precision components.

Temperature monitoring has shown that dust layers as thin as 3 millimeters can increase operating temperatures by 15°C above design specifications. This thermal stress reduces component lifespan and increases energy consumption by up to 8%. Maintaining clean cooling system surfaces is crucial for thermal management.

Electrical Short Circuit Risks from Dust Infiltration

Conductive metal dust poses particular danger to electrical components and control systems. When dust accumulates on circuit boards or in connection points, it can create unintended electrical paths that bypass safety systems. This can lead to equipment malfunction, data errors, or even electrical fires.

Industrial safety reports indicate that approximately 18% of electrical failures in processing equipment originate from dust contamination. Control panels equipped with proper sealing and positive pressure systems demonstrate 90% fewer dust-related incidents. Regular cleaning of electrical enclosures is essential for preventing these failures.

The Domino Effect of Metal Particles in Bearings

Bearings are particularly vulnerable to metal dust infiltration through microscopic gaps in seals. Once inside, hard particles create surface imperfections that generate additional friction and heat. This leads to premature lubricant breakdown and eventually causes bearing seizure if undetected.

Vibration analysis studies show that bearings contaminated with metal dust exhibit failure patterns 60% sooner than protected counterparts. Advanced sealing technologies and dedicated lubrication system can extend bearing life by maintaining proper cleanliness levels within rotating assemblies.

Daily Maintenance Protocols for Metal Dust Environments

Effective daily maintenance routines form the first line of defense against metal dust accumulation. These procedures focus on early detection and removal of dust before it can cause significant damage. Consistent implementation prevents the compounding effects of dust-related wear and maintains operational efficiency.

Operations that implement structured daily maintenance protocols report 45% fewer unplanned downtime events related to dust issues. The investment in routine cleaning yields substantial returns through extended component life and reduced emergency repairs. Establishing clear accountability and documentation procedures ensures consistency across shifts.

15-Minute Pre-Shift Inspection Checklist

A comprehensive visual inspection at shift changeover provides critical baseline assessment of equipment condition. This includes examining visible surfaces for dust accumulation, checking filter indicators, and verifying proper operation of dust extraction system. Early identification of issues prevents minor problems from escalating into major failures.

Facilities that implemented standardized pre-shift inspections reduced dust-related maintenance costs by 32% within six months. The inspection process should include documentation of findings to track trends over time and identify developing issues before they impact production.

Specialized Tools for Effective Dust Removal

Conventional cleaning methods often redistribute dust rather than removing it from the environment. Industrial vacuum systems with HEPA filtration capture particles down to 0.3 micrometers, preventing their recirculation. Non-sparking tools are essential for safe cleaning in areas where combustible dust may accumulate.

Research demonstrates that proper tool selection improves cleaning efficiency by 70% compared to basic methods. The investment in specialized equipment typically pays for itself within one year through reduced maintenance requirements and improved equipment reliability.

Emergency Shutdown Cleaning Procedures

Unplanned shutdowns require specific protocols for safe and efficient cleaning before restarting equipment. This involves isolating energy sources, verifying atmospheric conditions, and methodically removing dust from all surfaces. Proper sequencing ensures no contamination remains to cause immediate failure upon restart.

Documented emergency cleaning procedures reduce restart time by approximately 40% while improving safety outcomes. Training maintenance personnel in these specific protocols ensures consistent application during high-stress situations when proper procedures are most critical.

Visual Detection Methods for Residual Dust

Visual inspection techniques enhanced by lighting and magnification can identify dangerous dust accumulation before it causes problems. Certain dust types become visible under specific lighting conditions, allowing early intervention. Standardized assessment criteria ensure consistent evaluation across different inspectors.

Facilities using enhanced visual inspection methods detect problematic accumulation 50% earlier than those relying on casual observation. Training operators in recognition techniques transforms them into first-line defenders against dust-related issues.

Preventive Maintenance Scheduling for High-Dust Applications

Strategic maintenance planning accounts for the accelerated wear rates in dusty environments through adjusted intervals and specialized procedures. This proactive approach schedules interventions before failures occur, maximizing equipment availability while controlling maintenance costs. Data-driven decision making optimizes the balance between preventive maintenance and production requirements.

Analysis of maintenance records shows that properly scheduled preventive maintenance reduces total maintenance hours by 25% compared to reactive approaches. The cost savings come from fewer emergency repairs, reduced parts inventory, and extended equipment life. Implementing a scheduled program requires initial investment but delivers long-term benefits.

Maintenance Milestones Based on Operating Hours

Equipment operating in high-dust environments requires more frequent maintenance than manufacturer recommendations for clean conditions. Establishing specific service intervals based on actual operating hours accounts for the increased wear rates. Critical components need inspection and service at predetermined milestones to prevent unexpected failures.

Operations tracking maintenance against runtime report 30% better compliance with service intervals compared to calendar-based scheduling. Digital tracking systems automatically generate work orders when equipment reaches specified hour thresholds, ensuring timely intervention regardless of production pressures.

Vibration Analysis for Predictive Maintenance

Advanced vibration monitoring detects developing problems in rotating components long before they become critical. Changes in vibration signatures indicate issues like bearing wear, imbalance, or misalignment—all accelerated by dust contamination. Regular monitoring establishes baseline patterns and identifies deviations that warrant investigation.

Facilities implementing vibration analysis programs prevent approximately 80% of bearing failures through early detection. The technology pays for itself by avoiding single catastrophic failure that could cause extended downtime and secondary damage to other components.

Implementing Oil Spectroscopy Analysis

Regular lubricant analysis provides insights into equipment condition by identifying wear metals, contaminants, and lubricant degradation. In dusty environments, increasing particle counts indicate sealing failures or filter problems before they cause significant damage. Trend analysis reveals developing issues that require attention.

Oil analysis programs typically identify problems with 100-200 hours of lead time before failure becomes imminent. This advanced warning allows scheduling of repairs during planned downtime rather than experiencing unexpected failures during production periods.

Lifecycle Management for Wear Components

High-dust environments accelerate wear on components like filters, seals, and blades. Tracking service life and replacement history allows predictive planning for component changes before failure occurs. Maintaining inventory of critical wear parts ensures availability when needed without excessive capital tied up in spare parts.

Operations implementing lifecycle management reduce emergency parts purchases by 65% through better planning. Historical data also informs decisions about component upgrades or material improvements that might extend service life in specific operating conditions.

Lubrication Management in Dusty Environments

Proper lubrication practices become particularly challenging in environments contaminated with metal dust. Conventional lubricants can actually capture and retain abrasive particles, creating a grinding compound that accelerates wear. Specialized approaches are required to maintain effective lubrication while excluding contaminants.

Studies show that up to 70% of bearing failures relate to lubrication issues, with contamination being the primary factor in dusty environments. Implementing comprehensive lubrication management extends component life by 200-300% while reducing lubricant consumption through better control and contamination management.

Selecting Dust-Resistant Lubricants

Specialized lubricants formulated for contaminated environments contain additives that help exclude particles and maintain protective films despite contamination. These lubricants often have higher viscosity indices and better adherence properties than standard products. Proper selection depends on specific operating conditions and equipment requirements.

Testing has demonstrated that dust-resistant lubricants can extend relubrication intervals by 40% while reducing wear rates by approximately 60%. The premium cost for specialized lubricants is typically offset by reduced consumption and extended component life.

Retrofitting Automatic Lubrication Systems

Automatic lubrication systems provide precise, measured lubricant delivery at regular intervals without manual intervention. This ensures consistent lubrication while minimizing human exposure to hazardous environments. Closed systems also prevent contamination during the lubrication process itself.

Facilities that implemented automatic systems reported 90% reduction in lubrication-related failures and 50% reduction in lubricant consumption. The initial investment typically pays back within 18 months through reduced labor costs, extended component life, and avoided failures.

Design Principles for Dust Seals on Lubrication Points

Effective sealing of lubrication points prevents contaminant ingress while retaining lubricant. Multi-stage seals with labyrinth paths and positive exclusion features provide significantly better protection than simple lip seals. Regular inspection and replacement of worn seals maintains protection throughout component life.

Advanced sealing technologies can extend bearing life in contaminated environments by 400% compared to basic seals. The investment in superior sealing represents a small fraction of the cost avoided through extended component life and reduced downtime.

Dust Control Systems Integration

Effective dust management requires integrated systems that capture particles at the source before they can disperse into the equipment environment. These systems combine capture, conveyance, and collection technologies tailored to specific dust characteristics and production processes. Proper integration ensures optimal performance without interfering with production operations.

Modern dust control systems can capture over 99% of particulate matter when properly designed and maintained. The captured material often has value as recycled content, potentially offsetting system operating costs. Integration with material handling systems creates a closed-loop approach to dust management.

Calculating Airflow Requirements for Negative Pressure Systems

Proper system design begins with accurate calculation of required airflow rates based on hood design, capture velocity needs, and conveyance requirements. Undersized systems fail to control dust effectively, while oversized systems waste energy and may interfere with material processing. Engineering calculations balance performance with operating costs.

Properly sized systems maintain capture velocities of 100-150 feet per minute at hood inlets, sufficient to overcome competing air currents in most industrial environments. Regular measurement and adjustment ensures continued performance as system conditions change over time.

Electrostatic Suppression Deployment Strategies

Electrostatic systems charge dust particles, causing them to adhere to surfaces rather than remaining airborne. This approach is particularly effective for fine particles that are difficult to capture with conventional methods. Strategic placement of suppression bars near dust generation points provides control at the source.

Field tests show electrostatic suppression can reduce airborne dust concentrations by 70-80% when properly applied. The technology works particularly well when combined with other control methods as part of a comprehensive dust management strategy.

Explosion Protection Classification and Equipment Selection

Certain metal dusts present explosion hazards under specific conditions. Equipment selection must account for these risks through proper classification and protection methods. This includes explosion venting, suppression systems, and prevention through inertization where appropriate.

Safety standards require specific equipment ratings for different dust explosion classifications. Proper implementation reduces risk while maintaining operational efficiency. Regular inspection and maintenance ensures these critical safety systems remain functional when needed.

Case Studies & Performance Benchmarking

Real-world examples demonstrate the practical application and benefits of comprehensive dust management strategies. These case studies provide measurable results that validate the return on investment for dust control initiatives. Benchmarking against industry standards helps identify improvement opportunities and best practices.

Organizations that systematically study and implement best practices achieve 20-30% better performance in dust-related maintenance metrics than industry averages. The sharing of successful strategies accelerates improvement across the industry while highlighting innovative approaches to common challenges.

Automotive Recycling Industry Application Example

Vehicle shredding operations face particularly challenging dust conditions from mixed materials including metals, plastics, and composites. One facility implemented comprehensive dust control including source capture, ventilation upgrades, and automated cleaning systems. The project reduced airborne dust by 92% while increasing equipment availability by 15%.

The investment of $2.5 million in dust control technology paid back in 2.3 years through reduced maintenance costs, improved equipment utilization, and recovered material value. The project also significantly improved working conditions and regulatory compliance.

Cost Comparison: Preventive Maintenance vs. Reactive Repairs

Detailed analysis of maintenance records reveals the substantial cost difference between planned and unplanned maintenance events. Reactive repairs typically cost 3-5 times more than equivalent preventive maintenance due to emergency premiums, secondary damage, and production losses. The business case for preventive programs becomes clear through these comparisons.

One metal processing facility documented savings of $1.2 million annually after implementing comprehensive preventive maintenance focused on dust control. The program required additional staffing but reduced total maintenance costs while improving equipment reliability and production output.

Documented OEE Improvement Metrics

Overall Equipment Effectiveness (OEE) provides a comprehensive measure of equipment performance incorporating availability, performance, and quality metrics. Dust control initiatives typically improve all three factors, resulting in substantial OEE gains. Documentation of these improvements validates the investment in dust management technology.

Several facilities have reported OEE improvements of 12-18% following implementation of comprehensive dust management programs. These gains came from reduced downtime, faster operating speeds, and improved product quality. The financial impact of these improvements typically exceeds the direct maintenance savings.