Industrial shredders are engineered for robust operation, but certain materials pose significant challenges that can lead to rapid wear, mechanical failure, and unplanned downtime. This guide provides operators and managers with a strategic framework for diagnosing, resolving, and preventing problems when processing high-hardness materials, like tool steel and manganese castings, or high-tangibility materials, like wire cable and sheet metal trim. Understanding the root causes of these issues and implementing targeted solutions is critical for maintaining continuous production, ensuring operator safety, and protecting your capital investment. A proactive approach, combining mechanical upgrades, operational best practices, and advanced monitoring, can transform these challenging materials from a shredder's nemesis into a manageable stream.

Defining the Problem: Why High-Hardness and Tangible Materials Are a Shredder's Adversary

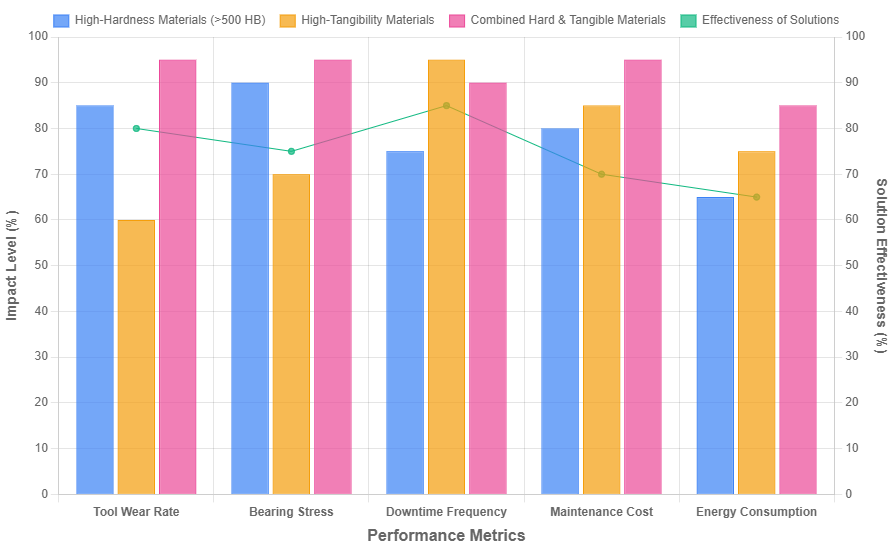

High-hardness and high-tangibility materials represent two distinct but equally destructive categories of shredding challenges. High-hardness materials, typically those with a hardness exceeding 500 HB, resist deformation and cutting, generating immense mechanical stress. High-tangibility materials, characterized by high tensile strength and ductility, do not cut cleanly but instead bend, stretch, and wrap around rotating components. These inherent properties directly oppose the fundamental shredding actions of cutting and shearing.

From a mechanical perspective, these materials trigger different failure modes. Hard materials transmit extreme shock loads through the cutting tools to the rotor shafts and bearings, accelerating fatigue and causing catastrophic failures. Tangible materials apply massive radial loads and torque as they wind around the rotor, leading to sudden jamming and motor overloads. When a material exhibits both hardness and toughness, it presents a compound challenge that tests the absolute limits of a shredder's design, requiring a comprehensive strategy to manage.

High-Hardness Material (Hardness > 500 HB): The Invisible Shockwave

The primary threat from high-hardness materials is instantaneous impact force. When a shredder tool strikes a material like a hardened steel plate, the force exerted can far exceed the yield strength of the tool material itself. Instead of a clean cut, the tool edge may experience micro-fractures, chipping, or catastrophic failure. Repeated impacts work-harden the tool's substrate, making it more brittle and susceptible to further damage in a vicious cycle.

This shockwave of force does not remain isolated at the cutting edge. It travels through the tool holder into the rotor shaft, subjecting it to bending stresses it was not designed to handle continuously. The shock loads are then transferred to the rotor bearings, drastically shortening their calculated L10 life expectancy. The entire drive train, including gears and couplings, is subjected to these pulsating loads, leading to premature wear and potential breakdowns.

High-Tangibility Material (Tensile Strength & Ductility): The Flexible Bind

Tangible materials like wire rope or long, thin sheet metal behave like flexible bindings. Upon entering the cutting chamber, they are not immediately severed. Instead, they are grabbed by the rotor tools and begin to wrap around the shaft or other stationary components. With each rotation, another layer is added, increasing the bundle's diameter and, consequently, the mechanical advantage against the rotor.

The resulting radial force creates immense friction and resistance to rotation. This places a tremendous strain on the drive system, causing the motor to draw excessive current in an attempt to maintain speed, often tripping overload protectors or, in worst-case scenarios, causing motor burnout. The wrapped material also acts as a barrier, preventing new feedstock from entering the cutting zone and effectively stalling the shredding process until the machine is stopped and manually cleared.

The Compound Challenge: When Materials Are Both Hard and Tough

Some materials, such as certain high-grade alloy steels or titanium components, present a dual threat. They possess the hardness to resist cutting and cause tool damage, while also having the ductility to deform and wrap rather than shatter. This combination is particularly difficult for standard shredders, as the tools cannot cleanly shear the material nor effectively fragment it through impact.

Processing these compounds requires a shredder configuration that addresses both problems simultaneously. This often means utilizing tools with an extremely sharp and hard edge to initiate a cut, combined with a mechanical action that pulls the material into the cut rather than allowing it to deflect. The machine must also be built to withstand the sustained high torque and shock loads generated during the process.

Weapon Upgrade: Reinforced Shredder Configurations for High-Hardness Materials

Conquering high-hardness materials requires a shredder designed from the ground up for extreme duty. This involves upgrades across several key systems: tooling, structural components, and intelligent controls. Standard off-the-shelf machines are not suitable; instead, purpose-built configurations with enhanced materials and design features are necessary to withstand the immense forces involved. Investing in these upgrades is not merely an option but a requirement for economic processing of hard scrap.

The core philosophy is to absorb, dissipate, and manage shock loads rather than simply resisting them. This means using components that can tolerate high-impact events without failing. Furthermore, the machine must be equipped with sensors and software that can react instantaneously to protect itself from damage when an unbreakable or overly hard item is encountered, preventing a single event from causing a lengthy and expensive shutdown.

Tooling Material and Process Revolution: From Standard Tool Steel to Special Alloys

The choice of tool material is the most critical factor in shredding hard materials. Standard D2 tool steel, while good for general purpose use, may not suffice. Premium grades like H13 offer better impact resistance and toughness. The ultimate solution often involves composite tooling, where a tough alloy steel body is clad with a surface layer of extremely hard material, such as tungsten carbide, applied through welding or thermal spraying.

This combination provides the best of both worlds: the韧性 (toughness) of the base material absorbs the shock and prevents catastrophic fracture, while the ultra-hard surface layer provides exceptional resistance to abrasive wear, maintaining a sharp edge for longer. The geometry of the tools is also modified, often featuring a sharper hook angle to bite into the hard material more effectively and pull it into the shear zone, rather than bouncing off it.

Rotor Dynamics Reinforcement: Heavy-Duty Bearings and High-Inertia Design

To mitigate the effect of shock loads, the rotor assembly must be reinforced. This begins with a high-inertia design. A heavier, more massive rotor acts as a flywheel, absorbing sudden impacts and smoothing out the power demand, which protects the drive system from peak loads. The rotor shafts are manufactured from high-tensile strength steel and are of a larger diameter to resist bending under extreme torque.

The bearings supporting the rotor are upgraded to heavy-duty ratings, specifically chosen for their high capacity to handle both radial and axial loads. Their calculated operating life (L10) under expected load conditions must be verified. Often, bearing housing designs are also reinforced to ensure perfect alignment and prevent distortion under load, which is a common cause of premature bearing failure in these demanding applications.

Intelligent Response: Torque-Feedback-Based Auto-Reversal and Slow-Speed Control

Modern shredders can be equipped with sophisticated programmable logic controllers (PLCs) that act as a nervous system. By continuously monitoring the motor's current draw or, more accurately, the hydraulic pressure in shear shredders, the PLC can detect instantaneous spikes that indicate an overload condition, such as hitting an unbreakable object.

Instead of waiting for a mechanical fuse to break or an operator to react, the control system can be programmed to automatically respond. This response typically involves instantly reversing the rotor direction for a brief period to dislodge the jammed material, or dropping the rotor speed to a crawl to gently work through the obstruction. This intelligent automation protects the machine from damage and significantly reduces downtime associated with manual clearing operations. For the most extreme challenges, exploring hard material shredding solutions is often the most effective path forward.

Untangling the Knot: Mechanical and Systemic Strategies for Tangible Materials

Defeating tangible materials requires a shift in strategy from pure cutting to a combination of cutting, pulling, and tearing. The goal is to prevent the material from ever establishing a secure wrap around the rotor. This is achieved through specialized tool designs that aggressively grab and process material, assisted by auxiliary systems that manage the feed and discharge processes. A holistic system view is essential, as the solution often extends beyond the shredder itself to include pre- and post-processing steps.

The design of the cutting chamber plays a pivotal role. Open, accessible chamber designs with minimal areas for material to snag are preferable. Furthermore, the discharge system must be designed to handle the output without clogging, as long, stringy materials can easily cause downstream blockages even after they have been processed, negating the shredder's success.

Tool Morphology Optimization: Hook, Eagle's Beak, and Scissor-Shear Designs

Standard straight-edge tools are ineffective against tanglers. The solution lies in tools with aggressive hook shapes or pronounced "eagle's beak" geometries. These designs do not merely wait for material to enter the shear point; they actively reach out, grab it, and pull it down into the cutting zone. This pulling and tearing action is far more effective at processing long, fibrous materials than a standard shear cut.

Some systems employ a true scissor-shear action, where counter-rotating tools intermesh very closely, shearing the material in a clean, snapping motion that leaves no long tails to wrap. The key principle is to reduce the material's length quickly upon entry, transforming long, flexible pieces into short, manageable fragments before they have a chance to interact with the rotor body itself.

Integrated Auxiliary Devices: Compactors, Pushers, and Smart Dust Control

A major cause of wrapping is irregular feeding, which allows light, fluffy tanglers to float into the chamber and make contact with the rotor in an uncontrolled manner. Hydraulic pusher rams or feed rollers solve this problem. They apply constant, firm pressure to the feedstock, compressing it and forcing it into the cutting tools at a controlled rate. This ensures a positive feed and prevents material from riding on top of the rotor.

For materials like wire insulation or certain plastics, dust and static electricity can cause thin strands to cling together and to equipment surfaces. Integrated spray systems can introduce a fine mist to suppress dust and reduce static, preventing this agglomeration and promoting a cleaner material flow. This is a simple yet highly effective systemic solution to a common feeding problem.

Screen Anti-Blocking Technology: Screenless Designs and Quick-Change Systems

The discharge screen is a common failure point for tangible materials. Long, stringy outputs can rapidly lace across the screen apertures, blocking the discharge flow and causing a backup inside the chamber. For the most challenging materials, a primary shredder with a screenless discharge is the preferred option. This allows for continuous ejection of material regardless of its size or shape, relying on a secondary shredder to achieve the final particle size.

When a screen is necessary, quick-change and easy-clean designs are mandatory. Slide-out screen racks, large clean-out doors, and tools like screen pokers (air-powered rams that punch through clogs) are essential for maintaining uptime. The ability to rapidly remove and clean a blocked screen in minutes, rather than hours, is a critical feature for operations handling consistent volumes of tangible waste. A solid waste shredder often incorporates many of these features to handle diverse and challenging material streams.

The Art of Operation: Feeding Techniques and Process Optimization for Challenging Materials

Even the most robustly configured shredder can be defeated by poor operating practices. Scientific feeding is the first and most cost-effective line of defense against challenging materials. Operators must be trained to understand how different materials behave in the shredder and must be empowered with strategies to manage difficult feeds. This human element is often the difference between smooth operation and constant mechanical issues.

Process optimization involves managing the feed composition, sequence, and rate to create a stable and efficient operation. This may involve pre-processing steps, careful monitoring of the feedstock on the conveyor, and making real-time adjustments to the shredder's operation based on sound and power consumption. A well-trained operator can hear and see the signs of an impending problem and take corrective action before a jam or overload occurs.

The "Cocktail" Mix: Co-Processing Problematic Materials with Easy-to-Shred Waste

One of the most effective operational techniques is never to feed a homogeneous load of a challenging material. Instead, problematic items like wire bundles or thick steel should be mixed with easy-to-shred material like light gauge sheet metal, plastic, or wood. The easy-to-shred material acts as a carrier and a cutting medium, helping to pull the difficult material into the cutting zone and providing a continuous flow that prevents tanglers from isolating and wrapping.

This method helps to balance the load on the drive system, preventing the extreme spikes in power consumption that occur when processing a pure stream of hard or tough material. It leads to a more stable operation, more consistent throughput, and reduced mechanical stress on the entire machine. This is a simple yet powerful technique that requires no capital investment, only disciplined operational management.

Pre-Cutting and Size Control: The Strict Ban on Oversized Feedstock

A fundamental rule for protecting a shredder is to enforce strict size control on incoming feedstock. Long, flexible items like conveyor belts, cables, or sheet metal coils must be pre-cut into manageable lengths using shears, saws, or torches before they ever reach the shredder feed conveyor. A good rule of thumb is that no single dimension of any feed item should exceed the physical dimensions of the shredder's feed opening.

This pre-processing step dramatically reduces the potential for bridging in the hopper and wrapping around the rotor. It allows the shredder to process the material in bites it was designed to handle, rather than being overwhelmed by a single, large, problematic item. Enforcing this rule at the receiving area is a crucial responsibility of both operators and management.

Operator Alertness Training: Recognizing "Danger" Materials and Protocols

Operators should be trained to become expert "look-outs." They must be able to visually identify materials on the feed conveyor that are likely to cause problems, such as wire rope, entire engine blocks, or large forged tools. Upon identifying such material, they must know the predefined protocol, which may involve diverting it to a separate pile for pre-processing, adjusting the feed rate, or initiating a specific shredder operating mode designed for tough feeds.

This training should also include recognizing auditory and visual cues from the shredder itself. A change in sound pitch, a sudden vibration, or a flicker on the ammeter can be the first sign of a problem. Teaching operators to respond to these cues—for example, by momentarily reversing the feed conveyor or activating a rotor reversal cycle—can prevent a minor issue from escalating into a major jam or breakdown. For specific material streams like tires, a dedicated tire shredder is designed with features like bead wire separators and reinforced cutting systems to handle their unique challenges.

Battle-Ready Status: Targeted Preventive Maintenance and Health Monitoring

Processing challenging materials accelerates the wear and tear on a shredder, making a standard maintenance schedule obsolete. A targeted, condition-based preventive maintenance (PM) program is essential. This program must be more frequent and more rigorous, focusing on the components most affected by the extreme operating conditions. The goal is to replace wear parts on a planned schedule before they fail, thereby avoiding unplanned downtime and secondary damage to other components.

This enhanced PM regimen should be based on actual operating data, such as tons processed or engine motor hours, rather than calendar time. A shredder processing high-hardness material may require tool inspection every 500 tons, while one processing abrasive material might need bearing checks every 1,000 hours. This data-driven approach ensures maintenance is performed when it is actually needed.

Shortened Inspection Cycles and Dynamic Tool Replacement: Tonnage-Based Schedules

The wear on cutting tools is directly proportional to the amount and type of material processed. Therefore, tool inspection and replacement schedules must be based on the tonnage of material shredded, especially when that material is abrasive or hard. Operators should maintain a log of throughput, and tools should be rotated or replaced once a predetermined tonnage threshold is reached.

Regular visual inspections are also crucial. Tools should be checked for signs of chipping, cracking, or excessive wear at the hook and cutting edge. Using a template to check tool dimensions can help quantify wear and determine the optimal time for rotation or replacement. Keeping a full set of spare tools on hand is mandatory to minimize downtime during these scheduled changes. For processing highly abrasive e-waste, tools with tungsten carbide cutters are often used for their superior wear resistance.

Advanced Diagnosis of Bearings and Drive Systems: Vibration and Oil Analysis

Traditional maintenance often relies on reactive measures—fixing things after they break. Predictive maintenance uses technology to forecast failures. Vibration analysis is a key technique for monitoring the health of rotating components like bearings and gears. Sensors mounted on bearing housings collect vibration data, which can be analyzed to detect imbalances, misalignments, or the early stages of bearing wear long before failure.

Similarly, oil analysis can provide a deep insight into the health of gearboxes and hydraulic systems. By periodically taking oil samples and analyzing them for metal particulates, viscosity changes, or the presence of water, maintenance teams can detect internal wear and take corrective action before a component fails catastrophically. This allows for repairs to be planned during scheduled downtime, avoiding costly unplanned outages.

Establishing Equipment Health Records: Logging Post-Processing Status and Actions

Maintaining detailed equipment health records is a powerful tool for predicting future maintenance needs. After each significant processing run of challenging material, a log entry should be made. This entry should note the type and volume of material processed, any unusual sounds or vibrations observed, and any maintenance actions taken (e.g., "rotated tools," "cleaned screen," "checked bearing X for play").

Over time, this record becomes a valuable historical database. It can reveal patterns, such as a specific bearing needing replacement every 5,000 tons of hard steel, allowing for predictive parts ordering and planned downtime. This proactive approach to maintenance planning is a hallmark of a world-class operation, ensuring maximum equipment availability and reliability. For complex systems, ensuring the control panel PLC/HMI is correctly logging operational data is key to this process.

The Ultimate Solution: When a Traditional Shredder Is Not Enough

It is crucial to recognize that a single, universal shredder has inherent limitations. For some extreme materials, the cost of modifying and maintaining a standard shredder to handle them may exceed the value of the recovered material or the cost of alternative processing methods. In these cases, the most economical and efficient solution is to invest in a dedicated technology designed specifically for that material stream.

A thorough cost-benefit analysis is required. This analysis must weigh the continuous costs of increased maintenance, downtime, and energy consumption associated with forcing an ill-suited machine to process difficult materials against the capital investment (CAPEX) of a dedicated solution. Often, the productivity gains and operational savings of the right tool for the job result in a rapid return on investment.

Introduction of Dedicated Equipment: Metal Breakers, Alligator Shears, Cable Strippers

For extremely hard and large items like entire engine blocks or large castings, a dedicated metal shredder or gravity-drop hammer mill (metal breaker) is the appropriate choice. These machines use massive falling weights or rotating hammers to smash material through impact and shock, a principle better suited to fracturing hard, brittle metals than shear-based shredding.

For long, tangible metals like rebar or cable, an alligator shear is the ideal pre-processing tool. It cleanly snips the material into short, manageable lengths that can then be safely fed into a shredder. For recovering copper from cable, a dedicated cable stripping machine is far more efficient than shredding, as it cleanly removes the insulation without chopping the valuable copper into fine pieces that are harder to separate. For preparing waste for energy recovery, a specialized RDF shredder is designed to produce a precise, high-quality fuel fraction.

Two-Stage Shredding Systems: Division of Labor and Specialization

A two-stage system is often the ultimate solution for complex, mixed material streams. The primary shredder, or "grinder," is a robust, often screenless, slow-speed, high-torque machine designed for one job: size reduction and liberation. Its goal is to break down everything in the stream into small-enough pieces for the secondary shredder to handle.

The secondary shredder then refines the output from the primary stage to the exact target particle size. Because the primary has already done the heavy lifting of breaking apart the toughest items, the secondary shredder can be optimized for efficiency and precise sizing. This division of labor allows each machine to operate at peak efficiency, dramatically increasing total system throughput and reliability while reducing overall energy consumption and wear.

The Cost-Benefit Decision: Weighing Repair Costs, Downtime, and New Investment

The decision to upgrade, supplement, or replace existing equipment is ultimately a financial one. Management must calculate the true cost of persisting with an inadequate solution. This includes direct costs like frequent wear part replacement and high energy bills, as well as indirect costs like production downtime, lost revenue from processing delays, and labor hours spent on constant clearing and repairs.

This total cost of ownership (TCO) is then compared to the capital cost, operating cost, and projected benefits of a new, dedicated system. Often, the analysis reveals that the ongoing losses and expenses far outweigh the one-time investment in the right technology. Making the business case for capital investment based on a solid TCO analysis is the final, crucial step in solving the challenge of processing high-hardness and high-tangibility materials. For tough plastics, a plastic shredder with hardened steel shafts and specialized cutting geometry is often the right choice, while a wood shredder with a disc chipper is designed for fibrous organic material.