Selecting the correct industrial shredder is a critical decision that hinges on one fundamental parameter: the target output particle size. This comprehensive guide explores how this single factor dictates the choice of machinery, impacting everything from operational efficiency and downstream processing costs to the final product's market value. We will demystify the principles of different shredding technologies, analyze the trade-offs between energy consumption and particle fineness, and provide a systematic framework for selecting equipment that maximizes your return on investment. Understanding this relationship is the first step toward optimizing any recycling, waste-to-energy, or size reduction operation.

Understanding the Importance of Target Particle Size and Industry Standards

The desired size of shredded material is not an arbitrary choice; it is a precise specification driven by the material's subsequent journey. Particle size directly influences transportation costs, as uniformly smaller particles can be packed more densely, reducing the number of hauls. In sales and recycling markets, specific size ranges often command premium prices because they are ready for immediate use in processes like melting or chemical treatment, requiring no further processing by the buyer.

Furthermore, particle size is a decisive factor in the efficiency of downstream industrial processes. For instance, in blast furnace operations, ferrous scrap must meet strict size specifications to ensure consistent melting rates and chemical composition within the molten iron. Deviations from these specifications can lead to operational delays, increased energy use, and potential damage to refractory linings. This makes the shredder a vital component in the preparation of raw materials for heavy industry.

How Particle Size Influences Downstream Processing Costs and Efficiency

Achieving a finer particle size generally enhances processing efficiency in applications like smelting. Smaller pieces have a larger cumulative surface area, which allows for faster and more uniform heat transfer and chemical reactions. This can lead to reduced cycle times and lower energy consumption in the furnace itself. However, this benefit comes at a significant cost earlier in the chain.

The energy required by the shredder to achieve these smaller sizes increases exponentially. Industry data suggests that reducing particle size by half can require up to four times the energy input. This creates a crucial economic balance where the savings in downstream processing must be carefully weighed against the increased operational expenses of the shredding operation to find the overall cost-neutral point.

Target Size Ranges for Common Waste Materials

Different materials have established target size ranges based on their recycling and recovery pathways. Prepared heavy scrap steel for oxygen furnaces typically aims for a dimension of 200mm x 200mm x 200mm. Shredded aluminum scrap, destined for remelting furnaces, is often ideal in a range of 50mm to 100mm to prevent excessive oxidation. For waste-derived fuels (RDF/SRF), a particle size below 50mm is standard to ensure efficient combustion and a high-quality, consistent fuel product.

Electronic waste presents a unique challenge, requiring shredding to small particles, often below 10mm, to liberate valuable metals from composite materials for effective separation. Automotive shredder residue (ASR), the non-metallic fraction left after metal recovery, may be shredded further to 20mm or less for use as a filler material or for thermal recovery, highlighting how particle size unlocks different valorization pathways.

Wide vs. Narrow Distribution: Selecting Particle Uniformity for the End Product

The particle size distribution (PSD) is as important as the target size itself. A narrow PSD, where most particles are very close to the same size, is critical for processes requiring consistent bulk density and predictable behavior. In smelting, a uniform charge ensures even melting and stable chemistry. In plastic recycling, uniform flakes ensure consistent melting and extrusion in the pelletizing process.

Conversely, a wider PSD can be acceptable or even beneficial for other applications. For instance, in the production of refuse-derived fuel (RDF), a mix of particle sizes can improve the compaction and structural integrity of fuel pellets. The choice between a shear shredder, which produces a uniform strip, and a hammer mill, which yields a mix of shapes and sizes, is therefore fundamentally linked to the PSD requirements of the final product.

Laboratory Sieve Analysis: Determining Existing Material Size

Establishing the current particle size distribution of a feed material is a essential first step in sizing a new shredding system. This is typically done through a standardized laboratory sieve analysis. A representative sample of the material is placed on a stack of sieves with progressively smaller mesh sizes, mounted on a mechanical shaker. The shaker operates for a fixed duration, often 15 minutes, allowing particles to settle on the sieve with an aperture just smaller than their size.

The mass of material retained on each sieve is then weighed precisely. This data is plotted on a graph to create a particle size distribution curve, showing the percentage of material that is finer or coarser than any given size. This analysis provides a quantitative baseline for engineers to determine the necessary size reduction ratio a shredder must achieve and to select the appropriate machine type and screen size.

Mainstream Industrial Shredder Technologies and Their Particle Output Characteristics

Industrial shredders employ distinct physical principles to break down materials, each resulting in unique particle characteristics. The primary mechanisms are shear, tear, impact, and attrition. Shear-based shredders use counter-rotating blades to scissor material apart, producing a controlled, predictable particle shape. Tear and rip mechanisms involve hooks and claws that pull material apart, often resulting in a more ragged output.

Impact shredders, like hammer mills, use high-speed rotors to violently throw material against hardened breaker plates, shattering it into smaller, often more cubicle pieces. Attrition involves grinding two surfaces together to wear material down, typically used for very fine size reduction. The choice of mechanism directly dictates the final particle's morphology, density, and size distribution, making it the most fundamental decision in the selection process.

Twin-Shaft Shear Shredders: The Preferred Choice for Controlled Fragmentation

Twin-shaft shear shredders are renowned for their ability to produce a uniform, predictable output. Their design consists of two intermeshing rotors equipped with cutting blades that rotate at low speeds but generate high torque. The material is grabbed by the hooks on the rotors and drawn between the precisely spaced blades, which shear it into strips and chips. The final particle size is primarily controlled by the size of the discharge screen.

The low rotational speed minimizes fines generation and dust, while the high torque allows for processing tough, dense materials without stalling. This combination makes twin-shaft shredders exceptionally versatile, capable of handling everything from metals and tires to electronic waste and plastics, consistently producing an output ideal for downstream sorting, transport, and processing.

High-Speed Hammer Mills: Powerhouses for Producing High-Density Granules

Hammer mills operate on the principle of impact. A central rotor spins at high velocity, with multiple pivoting or fixed hammers attached. Feed material is struck by these hammers and flung against the surrounding breaker plates or screen, undergoing repeated impacts until it is small enough to pass through the screen apertures. This violent process generates a more cubicle or spherical particle shape compared to shear shredders.

The intense impact action makes hammer mills highly effective for brittle materials and for applications requiring a very fine, high-density output. The resulting particles stack efficiently, maximizing weight per volume, which is a critical advantage for transporting recycled materials like glass or for preparing fine powders. However, this method typically consumes more energy per ton and generates more wear on consumable parts like hammers and screens.

Combined Primary and Secondary Shredding for Multi-Stage Size Control

For complex waste streams or stringent size requirements, a single shredder is often insufficient. A two-stage system, combining a primary and secondary shredder, offers superior control and efficiency. The primary shredder, often a robust, slow-speed, high-torque shear shredder, performs the initial size reduction, breaking down large, voluminous items into manageable chunks, typically in the 100-300mm range.

This pre-shredded material is then conveyed to a secondary shredder, which could be another shear shredder with a smaller screen or a hammer mill for final refinement. This staged approach allows each machine to operate at its peak efficiency, reduces wear on the secondary unit, and enables the system to achieve a precise, homogenous final particle size that would be difficult or inefficient to produce in a single pass.

The Core Parameter Trade-off: Capacity, Energy Consumption, and Target Size

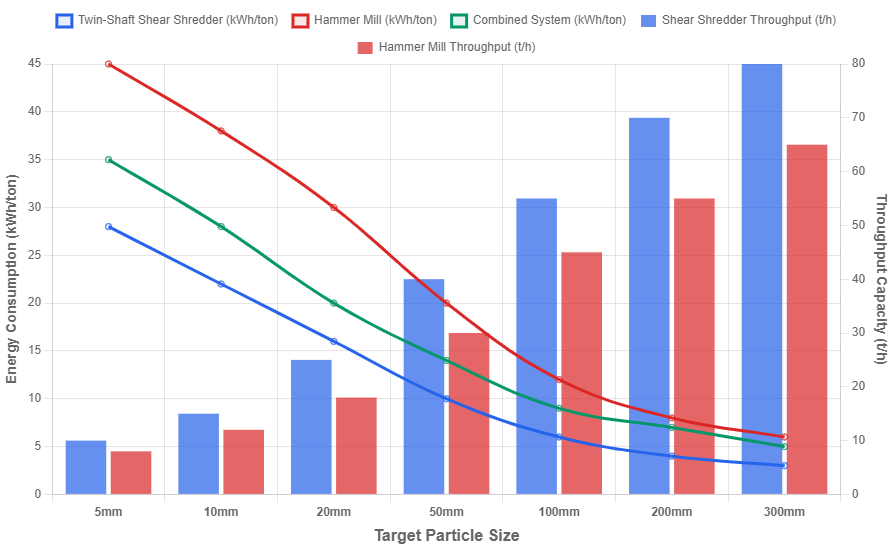

The relationship between particle size, throughput capacity, and energy consumption is a fundamental engineering triangle in shredding. Pursuing a smaller target particle size invariably forces a compromise on the other two fronts. To achieve finer output, a machine must either process material more slowly, allowing for more size reduction actions per particle, or expend significantly more energy to maintain the same throughput rate.

This is not a linear relationship. Empirical data, often based on Bond's Law of comminution, suggests that the energy required is inversely proportional to the square root of the particle diameter. This means that halving the particle size requires approximately four times the energy. This exponential increase makes the economic assessment of target size crucial, as the cost of electricity can quickly erode the value added by creating a finer product.

Screen Selection: The Key to Controlling Maximum Discharge Size

The discharge screen, or grate, is the primary mechanical component dictating the maximum size of the output particle. Material remains within the cutting chamber until it is reduced enough to pass through the apertures of this screen. The screen's aperture size, shape (round, square, or slotted), and open area percentage are therefore critical design choices.

A smaller aperture guarantees a finer top-size but restricts material flow, potentially reducing throughput and increasing energy consumption as material is recirculated and re-shredded. A larger open area improves flow but may compromise the structural integrity of the screen. Selecting the optimal screen is a balance between the required particle size specification and the need to maintain acceptable machine productivity and energy efficiency.

Energy Intensity (kWh/ton) Calculation: The Cost of Finer Particles

Energy intensity is a key performance indicator (KPI) for any shredding operation, calculated by dividing the total energy consumed (in kilowatt-hours) by the total tonnage of material processed. Monitoring this metric is essential for understanding the operational cost of achieving a specific particle size. As the target size decreases, the energy intensity curve rises steeply.

Plant operators can use this data to perform a simple return on investment (ROI) analysis. The additional revenue or downstream cost savings generated by a finer product must be greater than the additional cost of the electricity required to produce it. This calculation provides a clear, financial rationale for selecting the most economically viable target particle size, rather than simply the smallest technically achievable one.

The Subtle Influence of Tooling Geometry and Rotor Speed on Particle Morphology

Beyond the basic mechanism, the precise design of the cutting elements significantly influences the output. The geometry of the shredder tools—including their thickness, hook angle, and cutting edge sharpness—affects how they engage and fracture the material. A sharper, more aggressive hook angle will tend to bite and tear material, while a blunter angle may rely more on shear or crushing.

Rotor speed is another critical variable. Lower speeds favor a tearing and shearing action, producing a coarse, ragged particle. Higher speeds can induce more impact and fracturing, leading to a finer, more fragmented output. Modern shredders often feature variable frequency drives (VFDs) that allow operators to adjust rotor speed, providing a degree of control over the particle size and shape to adapt to different material types or changing output requirements.

A Systematic Methodology: Working Backwards from Your Requirements

The most effective approach to shredder selection is a reverse-engineering process that starts with the final product specification. Instead of choosing a machine and seeing what it produces, the process begins by definitively establishing the required particle size, throughput, and material characteristics for the end market. This product-focused methodology ensures the selected equipment is perfectly aligned with business objectives.

This requires a deep understanding of the material's journey after it leaves the shredder. Will it be automatically sorted by optical sensors that require a specific size range? Will it be melted in a furnace that has strict charging specifications? Or will it be compressed into fuel pellets that demand a certain bulk density? Answering these questions defines the target, and the shredder is then selected as the tool to hit that target most efficiently.

Step One: Defining Your Final Application and Value Optimization Point

The initial phase involves a rigorous questioning process to pinpoint the value driver for the shredded material. Key questions include: What is the maximum acceptable particle size for the next processing step? Is a narrow particle size distribution more valuable than a mixed one? What is the cost penalty of oversized material? What is the premium paid for a perfectly sized product? How does particle size affect transportation and handling costs?

The answers create a financial model for particle size. This model identifies the "value optimization point," which is the target size that delivers the highest net value when all costs and revenues are considered. This point is rarely the absolute smallest size achievable; it is almost always an economic compromise that maximizes profitability, guiding all subsequent technology choices.

Laboratory Testing Guide for Material Properties (Bond Work Index, Drop Weight Test)

Predicting how a material will behave in a shredder requires quantifying its mechanical properties. Laboratory tests provide this data. The Bond Work Index is a standard measure of a material's resistance to crushing and grinding. It measures the energy (in kWh/ton) required to reduce a material from a theoretically infinite feed size to 80% passing 100 micrometers.

Other tests, like the Drop Weight Test or JK Rotary Breakage Test, provide insights into how a material fractures upon impact, generating parameters that can be used in advanced comminution models. These tests, while an upfront investment, dramatically reduce the risk of selecting an underpowered or inappropriate machine by providing empirical data on the energy requirements and breakage patterns of the specific feedstock.

Leveraging Manufacturer Test Centers for Pilot-Scale Trials

While laboratory tests provide valuable data, there is no substitute for processing a representative sample of the actual material in a full-scale or pilot-scale shredder. Most reputable equipment manufacturers operate test centers where potential customers can conduct trials. This allows for the collection of real-world data on throughput, particle size distribution, energy consumption, and potential wear rates.

To prepare for a successful test, provide the manufacturer with a large enough sample (often several tons) that accurately represents the full range of materials the shredder will encounter. This includes variations in size, composition, and contamination. The results from a well-executed pilot test are the most reliable indicator of machine performance and are critical for finalizing equipment sizing and configuration.

Looking Beyond Size: Other Critical Factors in the Selection Process

While achieving the target particle size is paramount, it cannot be the sole criterion for selection. The chosen machine must also deliver the required performance reliably over many years. This necessitates a holistic view that considers mechanical robustness, maintenance accessibility, and integration capabilities. A machine that produces the perfect size but is frequently offline for repairs will ultimately be less profitable than a slightly less precise but far more reliable alternative.

The total cost of ownership (TCO) is a far more important metric than the initial purchase price. TCO encompasses not only the capital investment (CAPEX) but also the long-term operational expenditures (OPEX), including energy consumption, wear part replacement costs, maintenance labor, and lost production time during downtime. A slightly more expensive machine built with superior materials and designed for easy maintenance will often yield a significantly lower TCO.

Designing for Capacity Redundancy: Building in Room for Future Growth

A common strategic error is selecting a shredder that exactly meets current capacity requirements with no room for expansion. Operational demands almost always increase over time due to business growth, new material streams, or increased shift patterns. A more prudent approach is to select a machine with a rated capacity 20-25% higher than current needs.

This capacity redundancy, or "upsizing," provides a buffer for peak loads and ensures the system will not become a bottleneck as the business grows. It also allows the shredder to operate at a lower percentage of its maximum capacity, reducing mechanical stress, wear rates, and energy intensity, thereby extending its operational life and improving reliability.

The Impact of Wear Part Design and Easy Replacement on Long-Term Operational Costs

The design of wear parts like cutters, screens, and anvils, and the ease with which they can be accessed and replaced, is a major differentiator between equipment manufacturers. Machines designed with quick-change tooling systems, where cutters can be replaced in a matter of hours instead of days, drastically reduce downtime and associated labor costs.

The longevity of these parts, determined by the grade of steel used (e.g., D2, D-3, H-13 tool steel) and the quality of heat treatment, directly impacts the frequency of replacement and inventory costs. Investing in a machine with a robust, service-friendly design for its wear components is one of the most effective ways to minimize long-term operating expenses and maximize equipment availability.

Noise and Dust Emissions: Essential Considerations for Environmental Compliance

Industrial shredding operations are often subject to strict environmental and workplace safety regulations concerning noise pollution and airborne dust. Neglecting these factors can lead to regulatory fines, operational shutdowns, and health risks for operators. Modern shredder designs incorporate features to mitigate these issues directly at the source.

Acoustic enclosures lined with sound-dampening materials can reduce operational noise levels by 20-30 decibels. Integrated dust extraction ports allow for connection to baghouse filter systems, capturing airborne particles before they escape into the facility. Selecting a machine with these integrated environmental controls is not just a regulatory necessity; it is a commitment to sustainable and responsible operation, ensuring long-term social and operational license to operate.

Operational and Maintenance Best Practices for Consistent Target Output

Selecting the right shredder is only half the battle; consistent operation and disciplined maintenance are required to maintain the target particle size over the machine's lifespan. Output specifications can drift due to wear, improper operation, or changes in feed material. Implementing standard operating procedures (SOPs) and a proactive maintenance schedule is essential for quality control.

Key operational parameters must be continuously monitored. These include motor amperage (which indicates load), hydraulic pressure (for shear shredders), rotor speed, and feed rate. Deviations from established baselines can signal issues like dull tools, a clogged screen, or an inconsistent feed composition. Training operators to recognize and respond to these signs is the first line of defense against off-spec production.

Tool Wear Monitoring and Replacement Cycles: The Core of Maintaining Cutting Precision

The condition of the cutting tools is the single most important factor affecting particle size and shape. As tools wear, their edges become rounded and their hooks diminish, leading to a less efficient cutting action. Instead of shearing, the machine may begin to tear or crush the material, resulting in larger, more irregular particles and increased fines generation.

A preventive maintenance schedule based on operating hours or tonnage processed should be established. This schedule should include regular inspections, rotating tools to expose fresh edges, and ultimately replacing full sets to maintain cutting balance. Utilizing tooling with multiple cutting edges can maximize their service life and reduce the cost per ton of processed material.

Screen Inspection and Replacement: The Final Defense Against Off-Spec Particles

The discharge screen is the final arbiter of particle size. Over time, screens are subject to abrasion, which can enlarge apertures, and impact, which can cause cracks or broken bars. A worn screen will allow oversized particles to pass through, compromising product quality. A cracked screen can lead to a catastrophic failure if a large, unshreddable object is ejected.

Regular visual inspections of the screen are mandatory. This often involves stopping the machine and entering the cutting chamber—a procedure that must be performed under strict lock-out-tag-out (LOTO) safety protocols. Screens should be replaced when wear has increased the aperture size beyond acceptable tolerances or when any structural damage is detected. Keeping a spare screen on hand minimizes downtime for this critical maintenance task.

Feed Consistency Control: Uniform Infeed as a Prerequisite for Stable Output

A consistent, well-regulated feed is perhaps the simplest yet most overlooked factor in achieving stable particle size. Fluctuations in feed rate, density, or composition force the shredder to constantly adjust, leading to an inconsistent output. An overloaded shredder may choke, causing premature wear and motor overloads, while an underfed one operates inefficiently.

The solution is a controlled feed system, such as a vibratory feeder, belt conveyor with a pre-compaction unit, or a hydraulic pusher ram. These systems meter material into the shredder hopper at a steady rate, ensuring the cutting chamber is optimally filled at all times. For heterogeneous material streams, a uniform feeder helps blend the load, preventing pockets of a single, difficult-to-process material from disrupting the operation.