The automotive recycling industry has made remarkable progress in recovering valuable materials from end-of-life vehicles, with modern facilities achieving metal recovery rates exceeding 95%. This impressive efficiency results from sophisticated shredding technology combined with advanced separation processes that systematically dismantle and separate vehicle components. The journey from whole car to purified metal streams represents a triumph of engineering innovation and environmental responsibility.

An average vehicle contains approximately 65% steel and iron, 10% non-ferrous metals, and 25% non-metallic materials. Through optimized shredding and separation processes, modern facilities can recover nearly all metallic content while properly handling fluids, plastics, and other materials. This comprehensive approach transforms what was once considered waste into valuable raw materials for manufacturing new products, creating a circular economy that reduces mining demand and environmental impact.

Critical Pre-treatment Steps in Vehicle Dismantling

Before vehicles enter the shredder, they undergo meticulous pre-treatment to remove hazardous components and recover reusable parts. This crucial phase ensures operational safety, prevents contamination of output materials, and protects shredding equipment from damage. Proper pre-treatment significantly enhances the efficiency of subsequent processing stages and improves the quality of recovered materials.

European standards require the removal of all fluids, batteries, tires, and certain plastic components before shredding. Facilities that implement comprehensive pre-treatment protocols report 30% higher purity in their metal output and experience 40% fewer maintenance issues with their shredding equipment. The initial investment in proper dismantling infrastructure yields substantial returns through improved operational efficiency and higher-quality output materials.

Precision Fluid Extraction and Management

Modern vehicle dismantling facilities employ specialized equipment to capture engine oil, transmission fluid, coolant, and fuel with exceptional efficiency. Advanced extraction systems can recover up to 98% of fluids, minimizing environmental contamination and maximizing resource recovery. These systems incorporate containment measures that prevent spills and cross-contamination between different fluid types.

Infrared spectroscopy technology enables real-time monitoring of residual fluid levels, ensuring that components contain less than 0.5% residual fluids before shredding. This precise measurement prevents the contamination of shredded materials and reduces the fire risk during processing. The recovered fluids undergo purification for reuse or proper disposal, completing a responsible management cycle.

Structural Dismantling Methodology

Strategic dismantling of large components follows a systematic approach that prioritizes both efficiency and material preservation. Seats and interior trim are removed as modular units, allowing for efficient separation of different material types. Electrical systems are carefully extracted to preserve copper wiring integrity, while plastic body panels are separated according to resin type for optimal recycling.

This methodical approach reduces the volume of material entering the shredder by 25-30%, allowing the equipment to operate more efficiently on the remaining metal-rich content. The removed components follow specialized recycling pathways that maximize their value and minimize environmental impact. This careful separation at the dismantling stage significantly improves the overall economics of vehicle recycling operations.

Shredder Configuration and Optimization Techniques

The selection and configuration of industrial shredders directly determine metal liberation efficiency and downstream separation performance. Modern automotive recycling facilities typically employ double-shaft shredders specifically engineered for vehicle processing. These machines utilize shear-force mechanisms that effectively tear apart vehicle structures while minimizing metal deformation that could impede separation.

Optimal shredder operation requires precise adjustment of multiple parameters including rotor speed, screen size, and cutting geometry. Research demonstrates that properly optimized shredders can achieve metal liberation rates exceeding 98%, meaning nearly all metal particles are separated from attached non-metallic materials. This high liberation rate is essential for achieving the overall 95% metal recovery target that represents industry best practice.

Dynamic Blade Balancing Technology

Shredder blades face extreme operating conditions when processing vehicles, requiring advanced materials and monitoring systems. Tungsten carbide cutters have become the industry standard for automotive applications, providing exceptional wear resistance against abrasive materials. These cutting elements maintain their sharpness up to five times longer than conventional steel blades, significantly reducing maintenance requirements.

Vibration analysis systems continuously monitor blade condition, detecting imbalances before they cause equipment damage. Automatic gap adjustment mechanisms maintain optimal clearance between blades as wear occurs, ensuring consistent particle size distribution. This proactive approach to blade management reduces unplanned downtime by 60% and extends overall equipment life by approximately 40%.

Shredding Chamber Flow Optimization

The internal dynamics of the shredding chamber significantly impact processing efficiency and particle quality. Computational fluid dynamics modeling has enabled engineers to design chamber geometries that promote optimal material flow and prevent bridging or clogging. These designs incorporate strategic impact zones that maximize size reduction while minimizing energy consumption.

Integrated dust extraction systems maintain negative pressure within the chamber, containing particulate matter and preventing emissions. Proper airflow management also helps regulate operating temperature, reducing thermal stress on components. Facilities that have implemented these optimized chamber designs report 15% higher throughput rates and 20% lower energy consumption per ton processed.

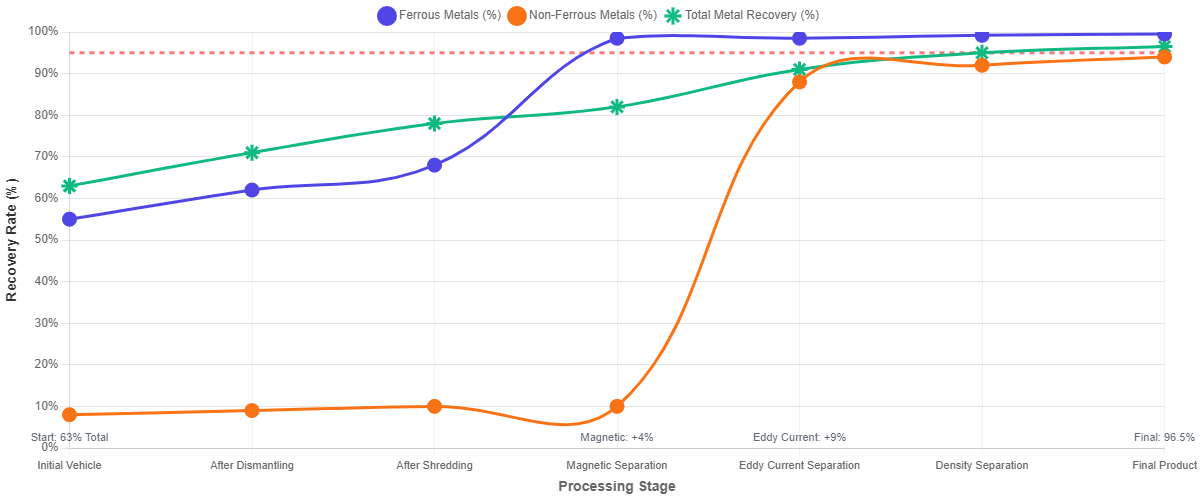

Magnetic and Eddy Current Separation Systems

The separation phase represents the critical juncture where metals are isolated from the shredded material stream. Magnetic separation efficiently captures ferrous metals, while eddy current systems recover non-ferrous materials. The synergistic operation of these technologies enables comprehensive metal recovery that meets modern recycling targets.

Advanced facilities employ multiple stages of separation to maximize recovery rates. Initial magnetic separation captures approximately 90% of ferrous metals, with subsequent stages recovering remaining materials. Eddy current systems then separate aluminum, copper, and other non-ferrous metals from the non-metallic fraction. This multi-stage approach achieves the high recovery rates that make modern vehicle recycling economically viable and environmentally beneficial.

Magnetic Separation Equipment Configuration

Modern recycling facilities utilize overband magnetic separators with precisely calibrated magnetic fields that extract ferrous materials from moving conveyor streams. The strength and configuration of these magnetic systems are tailored to the specific characteristics of shredded vehicle materials. Proper adjustment ensures maximum recovery while minimizing the carryover of non-metallic contaminants.

The positioning of magnetic elements relative to the material stream significantly impacts separation efficiency. Optimal installation typically places magnets 100-150mm above the conveyor surface, creating a magnetic field strength of 600-1000 Gauss at the product level. This configuration achieves ferrous metal recovery rates exceeding 99%, with purity levels that meet specifications for steel mill feedstock.

Eddy Current Separation Optimization

Eddy current separators utilize rapidly alternating magnetic fields to induce electrical currents in non-ferrous metals, creating repulsive forces that eject them from the material stream. Modern systems feature eccentric rotor designs that create optimal field patterns for different metal types. The frequency of the magnetic field can be adjusted to target specific metals, improving separation precision.

Advanced control systems monitor separation efficiency in real-time, making automatic adjustments to maintain optimal performance. High-speed cameras track particle trajectories, providing data that fine-tunes operational parameters. These systems typically achieve 90-95% recovery rates for non-ferrous metals, with purity levels that command premium prices in metals markets.

Density Separation Technologies

Following magnetic and eddy current separation, density-based methods further refine material streams and recover additional metals. These technologies exploit differences in mass and aerodynamic properties to separate materials that similar-sized but different densities. The strategic application of density separation enhances overall recovery rates and product purity.

Air classifiers, hydrocyclones, and sink-float systems each serve specific roles in the density separation process. Air separation effectively removes light materials such as foam and fabric, while water-based systems separate heavier non-metallics from metals. This multi-technology approach ensures that virtually all metal content is recovered, regardless of size or shape characteristics.

Air Classification System Operation

Air classifiers create controlled upward airflow that carries light materials while allowing heavier metals to fall through. Modern systems precisely regulate air velocity to match the density characteristics of the processed materials. This precision ensures effective separation while minimizing metal loss to the light fraction.

Temperature control within air classification systems maintains consistent air density, ensuring stable separation performance regardless of ambient conditions. Advanced systems incorporate moisture detection and control to prevent material clumping that could impair separation efficiency. These operational refinements typically improve metal recovery by 3-5% compared to basic air classification systems.

Hydrocyclone Technology Application

Water-based separation systems utilize centrifugal forces in hydrocyclones to separate materials by density differences. These systems are particularly effective for recovering fine metals that air classification might miss. The controlled density of the water medium can be adjusted to target specific separation points, optimizing recovery for different metal types.

Modern hydrocyclone systems incorporate water recycling and filtration that minimizes fresh water consumption. Closed-loop systems typically consume less than 5% of the water required by traditional wet separation methods. This environmental consideration, combined with high recovery efficiency, makes hydrocyclone technology an increasingly popular choice for automotive shredding operations.

Intelligent Monitoring and Process Optimization

Modern vehicle recycling facilities employ sophisticated monitoring systems that track performance metrics throughout the shredding and separation process. These systems collect real-time data on equipment operation, material flow, and separation efficiency. Advanced analytics transform this data into actionable insights that drive continuous improvement.

Current monitoring technology can detect composition changes in the incoming material stream, allowing automatic adjustment of processing parameters. This adaptive capability maintains optimal performance despite variations in vehicle types and conditions. Facilities implementing comprehensive monitoring systems report 15-20% improvements in metal recovery rates and significant reductions in operational costs.

Sensor Network Implementation

Strategic placement of sensors throughout the processing line provides comprehensive operational visibility. Pressure sensors monitor shredder loading, while metal detectors quantify metal content at various process stages. Optical sensors analyze material composition, providing real-time feedback on separation efficiency.

Data from these diverse sensors is integrated through centralized control systems that correlate information across the entire process. This holistic view enables operators to identify bottlenecks, optimize equipment settings, and predict maintenance needs. The implementation of comprehensive sensor networks typically reduces operational costs by 12-18% while improving metal recovery by 5-8%.

Data Analytics for Performance Improvement

Advanced analytics platforms process operational data to identify patterns and relationships that human operators might miss. Machine learning algorithms continuously refine process parameters based on historical performance data. These systems can predict equipment maintenance needs with 85% accuracy, reducing unplanned downtime by approximately 40%.

Performance dashboards provide real-time visibility into key metrics including recovery rates, energy consumption, and production costs. This transparency enables rapid response to process deviations and supports data-driven decision making. Facilities utilizing advanced analytics typically achieve 95% metal recovery rates consistently, with some operations reaching 97% under optimal conditions.

Industry Applications and Economic Analysis

The automotive shredding industry has evolved into a sophisticated sector that combines advanced technology with sound economic principles. Modern facilities process 150-500 vehicles per day, recovering approximately 1.5 tons of metal from each vehicle. This scale of operation generates significant economic value while providing substantial environmental benefits.

The economic viability of automotive shredding operations depends on multiple factors including metal prices, transportation costs, and regulatory requirements. Well-managed facilities typically achieve payback periods of 3-5 years on capital investments, with operating margins that support continued innovation and improvement. The combination of economic sustainability and environmental responsibility makes automotive shredding an essential component of modern materials management.

Implementation Pathways for New Facilities

Establishing a new vehicle shredding operation requires careful planning and significant capital investment. The process typically begins with comprehensive market analysis to determine optimal facility size and location. Equipment selection must balance processing capacity with flexibility to handle varying vehicle types and conditions.

Modern turnkey shredding facilities require investments of $15-40 million depending on capacity and technology level. This investment includes pre-treatment equipment, shredders, separation systems, and environmental controls. Properly planned facilities typically achieve profitability within 24-36 months of operation, with strong returns throughout the equipment's 15-20 year operational lifespan.

Regulatory Compliance and Certification

The automotive recycling industry operates within a complex regulatory framework designed to ensure environmental protection and resource conservation. The European Union's End-of-Life Vehicle Directive establishes ambitious targets for reuse, recycling, and recovery of vehicle materials. Compliance with these regulations requires meticulous documentation and verification of recycling rates.

Certification programs provide independent verification of environmental performance and operational standards. Facilities that achieve certification often qualify for preferential treatment in materials markets and may access government incentives for environmental performance. The comprehensive documentation required for certification also provides valuable operational data that supports continuous improvement efforts.