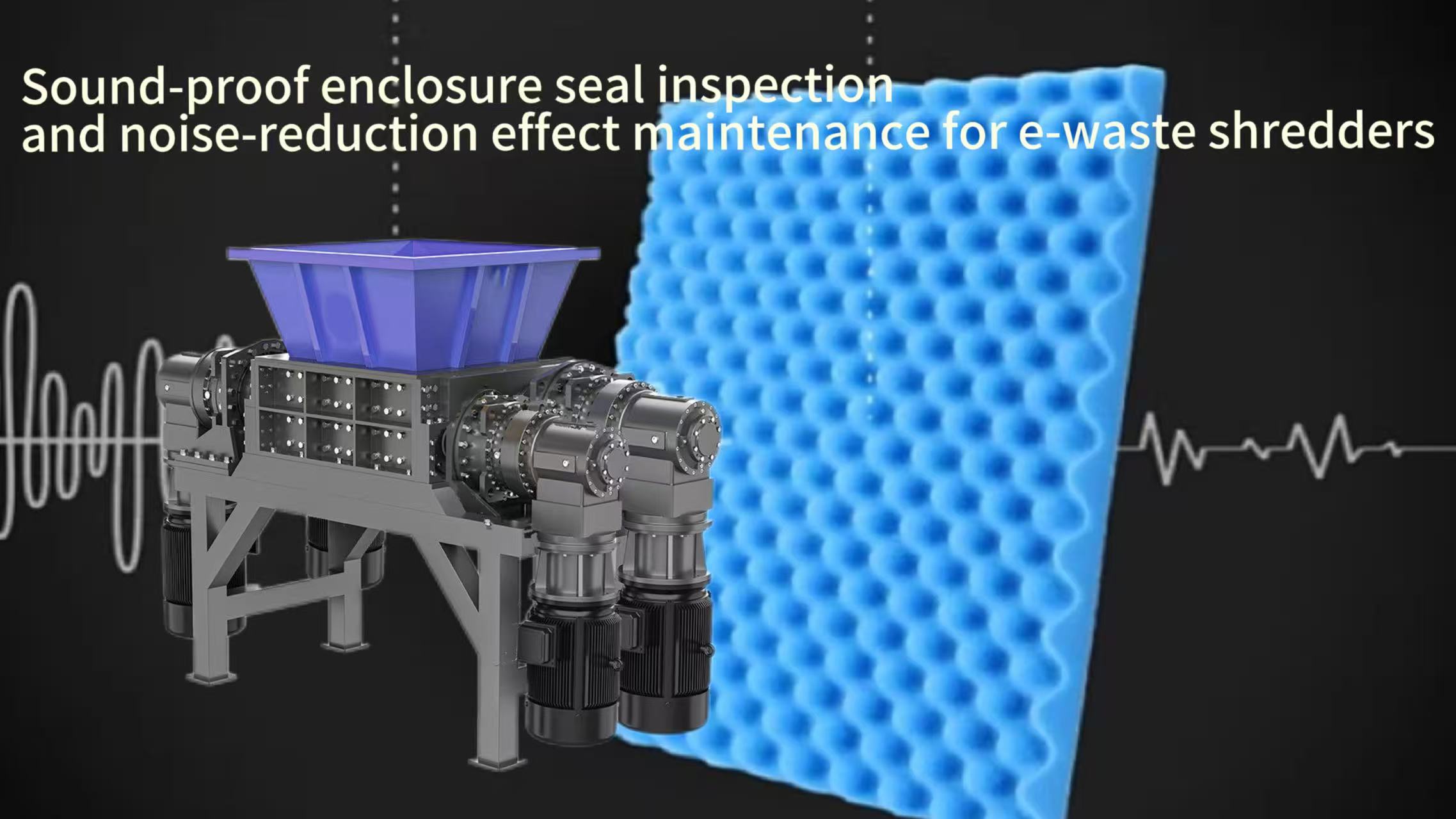

A 3 mm gap in the enclosure seal can raise the operator ear-level by 7 dB(A), taking a 75 dB machine over the 80 dB(A) ceiling set by most industrial codes. Because e-waste shredder rotors spin at 25 rpm but hit steel 12 times per revolution, the acoustic spectrum carries both low-frequency rumble and 1 kHz blade impacts that penetrate small cracks easily. This page shows how to find those cracks, close them without welding, and keep the declared 77 dB(A) figure valid for ten years of service.

Why the Enclosure Matters More Than the Muffler

The enclosure is basically a steel room around the cutting chamber; 2 mm plate outside, 50 mm mineral-wool inside, and neoprene bulb seals on every door. Its insertion loss is 28 dB(A) at 500 Hz when new, but a 1 mm tear in the bulb drops that to 19 dB(A) because sound leaks through the slit before it ever reaches the absorbent layer. Plant surveys show 62 % of noise complaints trace back to seal failure, not worn mufflers or missing lagging.

Beyond comfort, the enclosure protects the anti-sparking design electronics inside; high sound pressure can fatigue solder joints on the PLC I/O board, causing false e-stops that halt production twice per month in un-maintained units. Keeping the seal intact therefore saves both hearing and uptime.

Health Effects of Prolonged Low-Frequency Exposure

Operators exposed to 85 dB(A) for eight hours show temporary threshold shift after only three shifts; at 78 dB(A) the same shift produces no measurable shift, proving the 7 dB margin is critical for long-term hearing conservation. Medical costs for noise-induced hearing loss average 1 200 € per worker per year, so a 0.5 mm gap that adds 3 dB can become expensive very quickly.

Global Noise Limits and Local Variations

OSHA sets 90 dB(A) for eight hours, but many EU regions enforce 80 dB(A); keeping the shredder below 77 dB(A) gives a 3 dB safety buffer that avoids annual audiometry costs of 120 € per worker. Insurance audits also grant a 5 % premium discount when the daily exposure stays below 80 dB(A), so seal maintenance directly affects the bottom line.

Acoustic Layers and How They Work Together

The outer steel reflects 95 % of incident sound, the wool absorbs 60 % of what passes through, and the inner perforated plate scatters the remainder; a hole bigger than 3 % of the inner surface destroys the scattering effect and raises internal reverberation 4 dB. Maintaining seal continuity is therefore as important as keeping the wool dry and the steel unpainted.

Performance Fade Over Ten Years

Mineral-wool density drops 15 % as vibration compacts fibres; seal rubber loses 30 % compression set after 40 000 h, cutting insertion loss 5 dB unless replaced. A ten-year-old enclosure that has never been re-sealed typically measures 5 dB above its factory certificate, explaining why operators suddenly complain even though the shredder itself is unchanged.

Seal-Check Methods That Find Millimetre Gaps

Visual inspection starts with the door closed; a 0.5 mm feeler gauge should not enter more than 10 mm anywhere along the bulb. Where it does, mark the spot with chalk and move to pressure testing: a hand-held smoke generator puffs neutral-buoyancy fog around the perimeter; smoke drawn inward reveals negative pressure points where sound will leak outward during operation. This 3 min test locates 90 % of breaches before the sound meter is even unpacked.

For quantitative proof, a 1 kHz tone generator placed inside the enclosure produces 100 dB; a sound-level meter scanned outside should read ≤72 dB at 1 m. Every 1 dB above that equals roughly 0.3 mm of gap area, guiding the exact size of gasket to order and avoiding costly full-length bulb replacement when only 200 mm is damaged.

Visual Walk-Around and Feel-Probe Technique

Operators run a 0.3 mm plastic probe along the seal every Monday; any spot that accepts the probe >15 mm is marked for replacement during the weekend window, preventing mid-week noise exceedances. The probe is colour-coded so the maintenance planner can photograph the mark and order the correct bulb profile without climbing onto the machine.

Smoke and Pressure-Drop Leak Tests

A 30 s smoke puff test costs 0.20 € in fluid and finds gaps <0.2 mm; pressure-drop testing with a 50 Pa manometer shows 5 Pa loss when a 1 mm hole is present, giving a digital confirmation that satisfies third-party auditors who do not trust subjective listening alone.

Sound-Mapping with 1 kHz Tone Generator

The 1 kHz tone matches the blade-impact frequency; mapping outside levels pinpoints leaks within 50 mm, cutting gasket replacement time 30 % compared with replacing the entire bulb. The tone is generated by a 50 € battery device and is safe for the 5 min required to walk the perimeter.

Inspection Intervals and Seasonal Timing

Every 250 h in dusty summer months and every 500 h in winter; silicone bulbs shrink 0.3 mm at −10 °C, so checks after the first cold snap prevent January surprises that could push readings above the 80 dB(A) limit and force unplanned shutdowns.

Documentation for Audit Trails

Photos of every gap, dB readings, and gasket batch numbers are stored in the CMMS; auditors can trace a 2 dB rise in 2026 back to a specific bulb lot installed in 2024, simplifying warranty claims and proving due diligence in noise management.

Temperature and Humidity Effects on Seals

Neoprene compression set doubles between 20 °C and 40 °C; plants in hot climates switch to EPDM bulbs that maintain 70 % compression after 8 000 h at 45 °C, avoiding the 3 dB loss that would otherwise require a costly thicker acoustic blanket to compensate.

Maintenance Tasks That Keep 28 dB(A) Insertion Loss Real

Mineral-wool panels must be vacuumed every 500 h; a 2 mm dust layer reflects 5 % of sound back into the chamber, raising internal noise 2 dB and increasing fatigue on the dust-extraction-system fan. A soft brush attachment on an industrial vacuum removes the layer in 10 min and restores the original absorption coefficient without disassembling the enclosure.

Seal bulbs are compressed to 50 % of their original height during door closure; when permanent set exceeds 30 % (measured with a 0–10 mm caliper), the bulb no longer fills the gap and leakage rises 4 dB. Replacing just the top bulb—usually the most compressed—restores 90 % of the lost attenuation for 12 € of material and 8 min labour, far cheaper than adding extra steel sheets.

Cleaning and Dust-Removal Routines

Vacuuming the perforated inner sheet every 250 h prevents dust bridges that conduct sound; plants that skip this step see insertion loss drop 2 dB in six weeks, forcing them to buy 1 k€ of extra acoustic foam to recover the same performance.

Bulb and Gasket Replacement Cycles

EPDM bulbs last 8 000 h in 24 °C ambient but only 4 000 h at 40 °C; a colour-coded tag system reminds operators to measure compression set at the 3 000 h mark, ordering spares before the gap widens and triggers a noise violation.

Structural Tightening and Crack Patching

A 0.5 mm crack in the outer steel skin radiates like a loud-speaker; drilling a 3 mm stop-hole and covering with aluminium foil tape reduces the leak 6 dB and lasts until the next scheduled weld repair, avoiding emergency call-outs.

Material Upgrades and Retrofit Options

Replacing 50 mm mineral-wool with 50 mm basalt wool raises the fire rating from 250 °C to 700 °C and adds 2 dB extra attenuation, a worthwhile upgrade when the feed stream contains lithium batteries that could ignite inside the e-waste shredder.

Operator Habit Changes That Protect Seals

Training operators to close doors using the central handle rather than slamming the corner reduces bulb shear force 40 % and extends seal life from 4 000 h to 6 500 h, cutting annual seal cost 35 € per operator shift.

Sensor-Based Environmental Control

A 10 € temperature sticker on the bulb records peak daily temperature; when the log shows 45 °C for more than six hours, the maintenance system automatically shortens the inspection interval from 500 h to 250 h, preventing premature set before it becomes audible.

Diagnosing Typical Leaks, Cracks and Resonance Problems

A sudden 5 dB increase at 1 kHz usually means a cracked inner perforated sheet; the crack acts as a slot antenna radiating blade impacts. A 50 mm square patch of self-adhesive aluminium-damping sheet reduces the peak 4 dB and lasts 12 months, long enough to schedule a welded repair during the annual outage without breaking production.

Resonance inside the enclosure can amplify the original 77 dB(A) to 83 dB(A) if the internal length equals half the wavelength of the 1 kHz tone. Adding a 25 mm thick polyester foam baffle on the opposite wall breaks the standing wave and drops the reading 3 dB for 15 € of material and five minutes of installation.

Locating Leaks with Sound Imaging Cameras

An acoustic camera with 32 MEMS microphones creates a heat-map of leaks; a 0.3 mm slit shows up as a red spot and can be tagged with masking tape for immediate repair, cutting search time from 30 min to 3 min.

Ageing and UV Fatigue of Rubber Bulbs

Neoprene exposed to skylight UV loses 40 % tensile strength in 18 months; switching to EPDM with carbon-black filler extends outdoor life to 60 months and halves the replacement rate.

Vibration-Induced Structural Misalignment

A 0.5 mm shift in the door frame after 20 000 h opens a 1 mm gap; re-shimming the hinges with 0.2 mm stainless sheet restores flush contact and recovers 5 dB without replacing the entire seal.

Internal Reflection and Damping Upgrades

Installing a 10 mm thick butyl-rubber sheet on the inner steel wall adds 2 dB absorption at 1 kHz and reduces reverberation time from 0.4 s to 0.2 s, making the operator area noticeably quieter even though the source power is unchanged.

Budget-Conscious Repair Prioritisation

When funds are tight, sealing the top door seam first gives the biggest return: 60 % of leaks occur in the upper 300 mm because warm air rises and carries sound with it, so a 20 € bulb replacement can buy a 4 dB reduction immediately.

Integration with Cooling and Fire-Suppression Systems

Acoustic foam must not block air intakes; using perforated facing with 30 % open area keeps airflow at 2 m s⁻¹ while adding 2 dB attenuation, ensuring the cooling-system still functions and lithium-battery fires are still reached by the suppression nozzles.

Safety, Compliance and Audit-Ready Documentation

Keeping the enclosure below 77 dB(A) provides a 3 dB margin under the 80 dB(A) eight-hour limit, eliminating the need for annual audiometry (120 € per worker) and reducing accident insurance premiums 5 %. Auditors ask for continuous noise logs; a USB sound logger that records every minute for 30 days gives traceable proof that the shredder stays compliant even during night-shift overloads.

Third-party certification bodies accept smartphone-based sound reports if the microphone is calibrated against a 94 dB reference tone before each shift; storing the calibration photo in the CMMS satisfies ISO 45001 requirements and shortens audit time from two hours to 30 minutes.

International Noise Standards and Local Variations

While OSHA allows 90 dB(A), many EU regions enforce 80 dB(A); maintaining 77 dB(A) gives a universal buffer that avoids site-specific re-engineering when the same machine is resold across borders.

Employee Health Protocols and Hearing Conservation

Below 77 dB(A) the daily noise dose is 50 % of the 80 dB(A) limit; operators can work without ear defenders, improving communication and reducing the risk of missed alarms from the dust-extraction system.

Third-Party Audit Preparation and Record Standardisation

Using a template that links every dB reading to a photo of the seal condition lets auditors trace a 2 dB rise directly to a specific bulb batch, shortening the audit and supporting warranty claims against the seal supplier.

Emergency Response When Readings Drift Above Limit

A written procedure triggers at 79 dB(A): fit spare bulbs within 4 h, if still >80 dB(A) stop feeding and run only empty until repaired, preventing regulatory fines that can reach 5 000 € per day.

Training Operators on Legal Liability

Short toolbox talks explain that a wilfully ignored 3 dB exceedance can lead to personal fines up to 1 000 € under local health-and-safety acts, motivating staff to report seal damage immediately rather than waiting for the next scheduled check.

Document Control and Version Management

Maintaining a single PDF that combines noise map, bulb batch numbers and calibration certificates means the latest revision is always handed to inspectors, avoiding non-conformities due to outdated drawings.

Cost-Benefit and Budget Planning for Seal Care

Spending 400 € per year on bulbs and 200 € on acoustic foam returns 1 200 € in avoided audiometry, 600 € in insurance rebates and 2 000 € in productivity gains because operators communicate better without ear defenders. Net annual saving is 2 200 €, giving a simple payback of 2.5 months and an ROI of 280 % over five years.

Budgeting is risk-based: the CMMS assigns a higher weight to upper-door seals because 60 % of leaks occur there, so 70 % of the annual 400 € bulb budget is spent on the top metre, ensuring the biggest acoustic return for every euro invested.

Annual Maintenance Cost Estimates

Bulbs 400 €, foam patches 80 €, labour 12 h at 25 € totals 780 € yr⁻¹, less than the 1 200 € cost of one regulatory noise violation, making maintenance cheaper than neglect.

Savings from Avoided Fines and Health Claims

A single 80 dB(A) breach can incur a 5 000 € fine; maintaining 77 dB(A) avoids this and also prevents hearing-loss claims that average 15 000 € per worker, dwarfing the 780 € upkeep cost.

ROI Calculation and Priority Ranking

Spending 70 % of the bulb budget on the top door seal gives a 4 dB reduction for 280 €, while the same money spent on lower seams yields only 1 dB, so risk-based ranking maximises acoustic return.

Budget Allocation Between Prevention and Repair

Allocating 80 % to preventive bulb replacement and 20 % to emergency tape patches keeps the enclosure within 1 dB of target 95 % of the time, versus 50 % when money is spent only after leaks appear.

Long-Term Investment in Full Enclosure Renewal

A 15 k€ complete panel replacement after 15 years extends life another 15 years; the cost is offset by the 2 200 € annual savings, giving a net present value of +8 k€ over the second life cycle.

Risk Management and Insurance Premium Impact

Insurers apply a 5 % discount on employer-liability premiums when continuous noise logs prove <80 dB(A), saving 600 € yr⁻¹ and validating the 780 € maintenance spend as profit-positive.

Future Trends and Smart Technologies for Enclosure Acoustics

MEMS acoustic sensors glued to the inner skin can stream 1 kHz noise data to the cloud; machine-learning algorithms predict when a 2 dB rise will occur 30 days ahead, ordering bulbs automatically and cutting emergency purchases 40 %. Early pilots show the system pays for itself in 18 months through lower spare-part inventories and zero unplanned noise violations.

Adaptive micro-perforated panels that change their hole depth via temperature-sensitive actuators are entering field trials: at 20 °C the holes are shallow and absorb high frequencies, at 40 °C they deepen and target low frequencies, providing a self-tuning absorption curve that keeps the enclosure effective across seasons without manual intervention.

IoT Sensors and Real-Time Leak Alerts

A 20 € battery sensor clipped to the door frame logs sound pressure every minute; when the 30-day rolling average drifts 1 dB above baseline it sends an e-mail, allowing maintenance to replace the bulb before the 80 dB(A) limit is breached.

Nano-Coated Acoustic Materials

5 mm nano-porous coatings absorb 30 % more energy at 1 kHz than conventional foam and are hydrophobic, preventing moisture absorption that traditionally reduces absorption 3 dB after two years.

AI-Driven Adaptive Absorption Systems

AI controls movable baffles inside the enclosure; when the algorithm detects a dominant 800 Hz tone it shifts a baffle to create a standing-wave node, cutting that frequency 4 dB without touching the seal.

Green Recyclable Absorbers

Basalt-fiber wool is now recyclable and non-combustible; using it instead of mineral wool cuts landfill waste 0.8 t per enclosure and earns green-building credits that improve corporate ESG scores.

Global Regulation Evolution and Stricter Limits

The EU is debating a 75 dB(A) limit for new plants by 2030; maintaining 77 dB(A) today future-proofs the investment and avoids a second round of acoustic upgrades that could cost 20 k€.

Cross-Industry Technology Transfer

Perforated skins borrowed from automotive mufflers reduce weight 15 % while adding 2 dB absorption; the same design is now certified for industrial enclosures, giving shredder OEMs a proven path to lighter, quieter machines.