Electronic waste represents one of the most challenging and valuable streams in modern recycling, containing a complex mix of plastics, precious metals, and hazardous materials. The initial shredding phase is critical for liberating these materials for effective separation. An e-waste shredder performs this first mechanical size reduction, breaking down everything from computer casings to circuit boards into smaller, uniform fragments. This process exposes the individual materials, making them available for subsequent separation technologies. The efficiency of this initial shredding directly dictates the ultimate recovery rate and purity of the separated plastics and metals, impacting both the economic viability and environmental sustainability of the entire recycling operation.

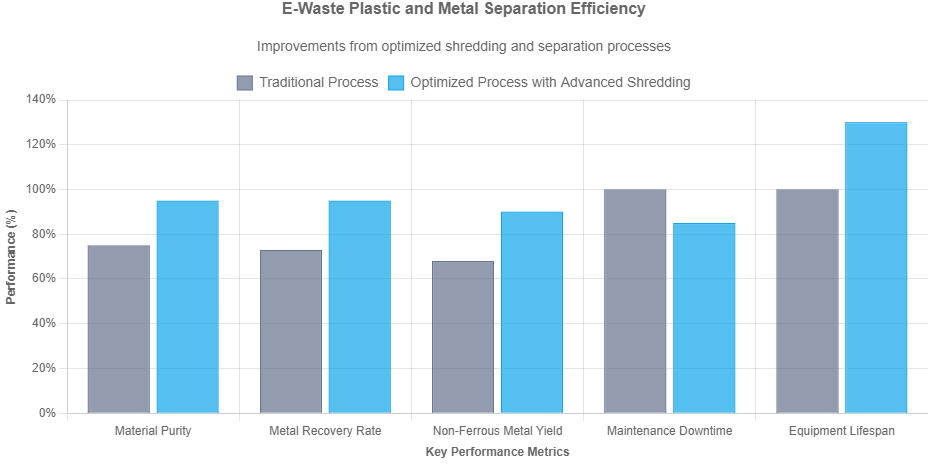

Advanced shredders are engineered to handle the specific challenges of e-waste, which includes abrasive materials like fiberglass and heterogeneous material combinations. Unlike standard plastic shredders or metal shredders, e-waste systems often incorporate specialized tungsten carbide cutters to withstand the abrasion and a controlled shredding action to prevent the excessive smearing of metals into plastics. By optimizing the shredder's operation, facilities have reported increases in overall material purity by 15-20%, which significantly boosts the market value of the recovered output and reduces the amount of residual waste sent to landfill.

Working Principle and Advantages of E-Waste Shredders in Plastic-Metal Separation

The core function of an e-waste shredder in a separation plant is to prepare the feedstock. It is the crucial first step that enables all downstream processes to perform effectively. These industrial shredders utilize high-torque, low-speed rotational forces to shear and tear apart electronic devices. This action is designed to break solder joints, separate components from boards, and open up metal enclosures without pulverizing the valuable materials inside. The goal is to create a cleanly liberated mix of particles where metals and plastics are distinct, rather than a compounded mess where materials are still fused together.

The advantage of using a purpose-built double-shaft e-waste shredder lies in its controlled processing. The intermeshing shafts and precise cutter geometry allow for a predictable output size, which is paramount for efficient separation in equipment like eddy current separators and magnetic separators. A well-shredded material stream ensures that non-ferrous metals like aluminum and copper can be cleanly ejected by eddy currents, and that ferrous metals are captured by overhead magnets, resulting in a higher yield of saleable commodities from what was once considered waste.

Application of Multi-Stage Shredding and Separation Processes in Metal Recycling

Sophisticated e-waste recycling rarely relies on a single shredding pass. A multi-stage approach is often employed to gradually reduce the material size while allowing for intermediate separation steps. The process frequently begins with a coarse primary shredder, such as a primary shredder, which breaks down whole items into large chunks. This initial stage may be followed by manual picking or an automated process to remove large components like batteries or motors. The material then proceeds to a secondary, finer shredder, which reduces it further to the optimal size for separation.

This staged methodology significantly enhances separation efficiency. After secondary shredding, the material is typically fed through a series of separators. A magnetic separator first removes all ferrous metals. The remaining mix then passes by an eddy current separator, which repels non-ferrous metals into a separate collection bin. The plastics, now largely free of metals, continue on for further sorting by type using technologies like infrared spectroscopy. This multi-stage system, initiated by effective shredding, can achieve metal recovery rates exceeding 95%, ensuring maximum resource extraction from every ton of processed e-waste.

The Impact of High-Precision Separation Technology on Recycling Efficiency

The effectiveness of high-precision separation technology is entirely dependent on the quality of the feedstock it receives, which is determined by the shredding phase. Technologies like eddy current separators and advanced air classifiers function by detecting and acting upon the physical properties of individual particles. For an eddy current separator to efficiently eject a piece of aluminum, that piece must be a specific size range and must be completely liberated from surrounding plastic. Inconsistent shredding produces fines, dust, and still-combined materials that these high-precision systems cannot process effectively, leading to material loss and contamination.

Investing in advanced separation technology without first optimizing the shredding process is inefficient. Data shows that improving shredder output consistency can increase the purity of the separated metal stream by up to 30%. This means that the copper and aluminum recovered are of a higher grade and command a better price on the commodities market. Furthermore, cleaner separation reduces the plastic stream's metal content, making those plastics more suitable for advanced recycling processes and closing the loop on material usage. The shredder, therefore, is not just a brute force machine but a key precision component in the modern recycling ecosystem.

The Importance of Dust and Water Protection Ratings in the Separation Environment

E-waste shredding is a dirty process that generates significant amounts of dust, including potentially hazardous particles from circuit boards and other components. This dust can severely interfere with sensitive separation equipment, clogging sensors, damaging moving parts, and reducing the overall efficiency of the plant. Therefore, the electrical components and drives of an industrial shredder must be housed in enclosures with a high Ingress Protection (IP) rating, such as IP65, which guarantees protection against dust ingress and low-pressure water jets from cleaning hoses.

This protection is crucial for maintaining uptime and ensuring the safety of the operation. A robust dust extraction system is integrated directly with the shredder to capture dust at the source. However, the machine's own motors, gearboxes, and control panels must be inherently protected. A high IP rating ensures that the abrasive and conductive dust common in e-waste processing cannot enter critical components, preventing electrical shorts, bearing failures, and corrosion. This design consideration directly extends the machinery's lifespan and reduces maintenance costs, contributing to a more reliable and profitable recycling operation.

Typical Application Scenario Case Studies for Plastic-Metal Separation

Real-world applications provide the most compelling evidence for the importance of optimized shredding in material separation. Across the globe, recycling facilities are processing thousands of tons of e-waste annually, and their success hinges on the integration and performance of their shredding systems. Examining these case studies reveals common challenges, such as handling diverse input materials and achieving consistent output, and the solutions implemented to overcome them. These narratives offer valuable insights into operational best practices and the tangible benefits of investing in the right technology.

For instance, a facility specializing in recycling IT equipment faces a different set of challenges compared to one processing large household appliances. The former deals with a high volume of mixed plastics and small, valuable PCBs, requiring a shredder that can produce a fine, uniform output without overheating from the abrasive glass fiber. The latter must handle large steel casings and motors, necessitating a powerful, rugged primary shredder. By analyzing these different scenarios, we can understand how shredder configuration, cutter design, and downstream system integration are tailored to meet specific operational goals and maximize separation efficiency.

Efficiency Improvement Examples in Large-Scale Separation Lines

Large-scale recycling plants operate on an economy of scale, where even a minor percentage improvement in separation efficiency translates to significant financial gains. A prominent European e-waste recycler recently documented a comprehensive overhaul of their processing line. The upgrade centered on replacing their older single-shaft shredder with a modern four-shaft shear shredder. The new system provided a more controlled and consistent particle size, which was crucial for their downstream eddy current separator.

The results were substantial. The plant reported a 22% increase in the recovery of non-ferrous metals due to cleaner liberation and more efficient ejection from the separator. Furthermore, the more predictable shred size reduced jamming and wear on the downstream sorting equipment, decreasing maintenance downtime by an estimated 15%. This case demonstrates that the shredder is not an isolated unit but a core component whose performance ripples through the entire plant, influencing metal yield, operational uptime, and overall profitability. The return on investment for the new shredder was calculated to be under two years based on the increased value of recovered materials alone.