Large-scale recycling centers represent the backbone of the global electronic waste processing industry, handling thousands of tons of obsolete computers, smartphones, and appliances annually. The selection of a high-throughput e-waste shredder is the most critical capital investment decision for these facilities, as this single machine dictates the entire plant's capacity, efficiency, and profitability. Unlike standard industrial shredders, a high-volume e-waste system must be engineered to handle extreme abrasion from fiberglass and ceramics, variable material densities, and the relentless demand of 24/7 operation. The right shredder acts as the heart of the plant, pumping a consistent, well-liberated stream of material to downstream sorting and separation systems.

Choosing the wrong equipment can lead to catastrophic bottlenecks. A recent industry report highlighted that under-capacity shredding is a primary cause of inefficiency, with some facilities losing over 15% of potential revenue due to inadequate material liberation and excessive downtime. The selection process involves a complex balance of throughput requirements, particle size needs for downstream separation, total cost of ownership, and future scalability. This guide provides a comprehensive framework for evaluating and selecting the optimal high-throughput shredding solution, ensuring that large recycling centers can meet the growing challenges of the e-waste stream efficiently and profitably.

Evaluation of Core Factors in High-Throughput Equipment Selection

Selecting a high-volume shredder is a multi-faceted engineering and economic decision that extends far beyond simply choosing the largest available machine. The process requires a deep understanding of the facility's specific feedstock, operational goals, and financial constraints. A thorough evaluation must consider not only the machine's headline specifications, such as tons-per-hour capacity, but also its integration capabilities with existing material handling systems, its resilience to abrasive wear, and the total cost of operation over its expected lifespan. This holistic approach ensures that the selected shredder becomes a reliable asset rather than a source of constant operational challenges.

The first step often involves a detailed analysis of the incoming e-waste stream. A facility processing a high volume of large domestic appliances, like refrigerators and washing machines, will have vastly different requirements compared to a plant specializing in small IT equipment and printed circuit boards. The former necessitates a powerful primary shredder with a massive hydraulic ram feeder to compact and push large items into the cutting chamber, while the latter might prioritize a system that can produce a finer, more consistent output size ideal for subsequent separation of precious metals. This initial assessment directly informs the choice of shredder type, size, and configuration.

Balancing Strategy Between Throughput and Precision

In e-waste processing, throughput and precision exist in a constant state of tension. A shredder can be configured to maximize hourly tonnage, but this often comes at the expense of particle size consistency. Conversely, aiming for a perfectly uniform output can reduce the overall processing rate. The key is to find the optimal balance that meets the specific needs of the downstream separation processes. For instance, an eddy current separator for recovering non-ferrous metals requires a specific particle size range to function at peak efficiency; particles that are too large may not be ejected cleanly, while excessive fines may be lost entirely.

Advanced shredders address this challenge through intelligent design. Models like a four-shaft e-waste shredder utilize a shearing and tearing action between slowly rotating shafts equipped with staggered cutters. This design provides a much more controlled particle size reduction compared to a high-speed hammer mill, resulting in a higher percentage of optimally sized material without sacrificing overall throughput. By producing a consistent output, these shredders can improve downstream separation efficiency by up to 25%, significantly increasing the yield and purity of recovered metals and plastics.

Analysis of Equipment Energy Consumption and Operating Costs

The purchase price of an industrial shredder is only a fraction of its total lifetime cost. Energy consumption represents one of the largest and most variable operational expenses. High-throughput shredders are powerful machines, with some models featuring motors exceeding 1,000 horsepower. However, not all shredders are equally efficient. Modern systems equipped with PLC-based control systems can optimize motor load and torque based on the material being processed, reducing energy draw during lighter loads and preventing overloads that trip breakers and cause downtime.

Beyond electricity, operating costs include routine maintenance, wear parts replacement, and potential downtime. A shredder processing abrasive e-waste will consume tungsten carbide cutters and other wear parts. Selecting a machine with easy access for maintenance, a reliable automatic lubrication system, and a readily available supply of spare parts can drastically reduce maintenance time and associated labor costs. A comprehensive operating cost analysis often reveals that a slightly more expensive, but more robust and efficient machine, offers a far better return on investment over a five-to-ten-year period.

The Importance of Dust and Water Protection Ratings in Large Recycling Environments

An e-waste recycling plant is an exceptionally harsh operating environment. The shredding process generates large quantities of abrasive and often conductive dust from printed circuit boards, plastics, and glass. This dust can infiltrate electrical panels, bearings, and motor housings, leading to premature failure, electrical shorts, and fire hazards. Therefore, the Ingress Protection (IP) rating of a shredder's critical components is not a minor specification but a fundamental requirement for reliable operation.

For large-scale recycling centers, a minimum rating of IP54 is standard, indicating protection against dust ingress and water splashes. However, for critical components like the main drive motor and PLC control cabinet, an IP65 rating is highly recommended. This rating guarantees complete protection against dust and low-pressure water jets, allowing the equipment to be safely hosed down during cleaning. This level of protection is essential for meeting facility hygiene standards, preventing cross-contamination between material batches, and ensuring the long-term reliability of the electrical systems that control the shredding process.

Performance Optimization Solutions for High-Throughput Equipment

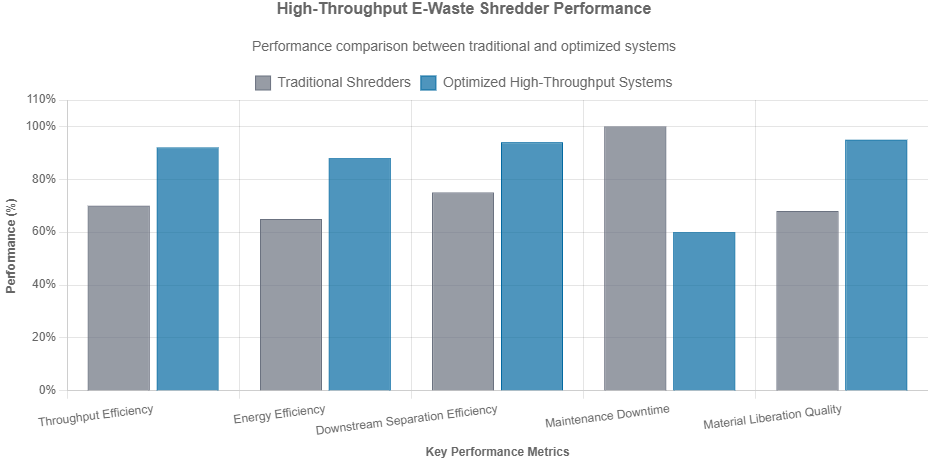

Once a high-throughput shredder is installed, the focus shifts to optimization—extracting the maximum possible performance, efficiency, and value from the capital investment. Optimization is a continuous process that involves fine-tuning the machine's operation, integrating it seamlessly with upstream and downstream equipment, and implementing a proactive maintenance strategy. In a sector where profit margins are directly tied to material throughput and recovery rates, even small percentage gains in efficiency can translate to significant annual financial benefits.

Optimization strategies can be mechanical, operational, and digital. Mechanically, this involves selecting the optimal cutter configuration and screen size for the specific material mix being processed. Operationally, it includes training staff to recognize and respond to changes in machine sound and performance, indicating potential issues. Digitally, it leverages the data generated by modern shredders equipped with sensors and PLC controls to predict maintenance needs and optimize energy consumption. Together, these strategies create a highly tuned, efficient operation that maximizes uptime and output.

The Impact of Modular Design on Equipment Upgrades

The rapid evolution of electronic waste, with constantly changing product designs and material compositions, demands recycling equipment that can adapt. A shredder with a modular design offers significant advantages in this dynamic environment. Modularity allows specific components or entire subsystems to be upgraded or reconfigured without replacing the entire machine. For example, a facility might initially operate a double-shaft shredder but later require a finer output. A modular system could allow for the integration of a secondary fine-shredding module or a different cutting rotor assembly to meet this new requirement.

This approach future-proofs the investment and protects against technological obsolescence. It also simplifies maintenance and reduces downtime. If a specific module, such as the hydraulic power pack or a drive unit, requires service, it can be disconnected and replaced quickly with a spare, getting the line operational again in hours instead of days. This capability is invaluable in a high-volume setting where downtime costs can exceed thousands of dollars per hour. Modular designs represent a shift from viewing the shredder as a static asset to treating it as a scalable and adaptable platform.

The Role of Intelligent Control Systems in Efficiency Improvement

Modern high-throughput shredders are increasingly defined by their software and control systems as much as their mechanical components. An intelligent PLC-based control system acts as the brain of the operation, continuously monitoring a vast array of parameters including motor amperage, hydraulic pressure, bearing temperatures, and vibration levels. These systems do much more than just start and stop the machine; they optimize its performance in real-time. For instance, the PLC can automatically reverse the rotor direction to clear a jam or adjust the feed rate based on motor load to prevent overloads and maximize throughput.

The data collected by these systems is a goldmine for predictive maintenance. By analyzing trends in motor current and vibration, the system can alert operators to abnormal conditions days or weeks before a component fails. This allows maintenance to be scheduled during planned downtime, avoiding catastrophic failures that cause extended unplanned outages. Furthermore, these control systems can be integrated into the plant's wider network, providing real-time performance data to managers and enabling remote diagnostics by technical support teams, which drastically reduces response times for troubleshooting and support.