E-waste shredders have revolutionized precious metal recovery through advanced shredding and separation technologies that maximize resource extraction from electronic waste. These industrial systems enable efficient liberation of gold, silver, palladium, and other valuable metals from complex electronic components through precisely controlled size reduction processes. Modern shredders integrate multiple separation technologies that achieve recovery rates exceeding 98% while maintaining environmental compliance. The technological evolution in shredding equipment has transformed e-waste recycling from simple waste reduction to sophisticated urban mining operations.

Distribution Characteristics and Recovery Value of Precious Metals in E-Waste

Electronic devices contain varying concentrations of precious metals depending on their age, type, and manufacturing origin. Printed circuit boards typically contain the highest value materials, with gold concentrations ranging from 200-1000 grams per ton, significantly richer than conventional gold ore. Connectors and contact points feature gold plating that, while thin, becomes valuable when aggregated in large volumes. Lithium-ion batteries contain cobalt and lithium worth recovering, while industrial electronics often contain platinum group metals in catalysts and sensors that command premium prices in recycling markets.

Identification of Precious Metal Enrichment Zones

Surface mount devices (SMDs) contain microscopic layers of gold and silver in their termination coatings, requiring precise shredding to liberate these valuable materials. Chip packages feature metal lead frames typically made of copper alloys with gold plating that must be separated from the silicon and packaging materials. Hard drive read/write heads contain platinum and other rare metals that require specialized shredding techniques to recover without contamination. Advanced imaging systems can identify these high-value components before shredding to optimize processing parameters.

Comparative Analysis of Metal Content

Mobile phone motherboards contain approximately 5-10 times higher gold concentration than computer motherboards due to their compact design and high-performance requirements. Different brands show significant variation in precious metal content, with enterprise-grade equipment typically containing more valuable materials than consumer-grade products. Industrial electronic waste often contains specialized metals like tantalum and ruthenium that require tailored shredding and separation processes different from consumer electronics recycling.

Key Functions of Shredders in Precious Metal Recovery Processes

Shredders perform the essential first step in precious metal recovery by physically breaking down electronic components to liberate embedded metals from their plastic and ceramic matrices. Primary shredding opens the structure of circuit boards and components using high-torque, low-speed cutting action that prevents metal deformation. Secondary fine shredding reduces particles to optimal sizes for subsequent separation processes, typically between 0.5-10mm depending on the recovery method. Advanced dust control systems prevent loss of micron-sized metal particles that would otherwise escape through ventilation systems.

Double-Shaft Shredder Applications

Double-shaft shredders excel at processing entire circuit boards and large electronic components through their counter-rotating cutting discs that generate tremendous shearing force. These systems operate at slow speeds of 15-30 RPM while producing torque outputs exceeding 20,000 Nm, sufficient to tear apart the toughest composite materials. The controlled output size of 20-50mm ensures optimal feeding for downstream processes while preventing excessive heat generation that could damage precious metals. Their rugged construction handles the abrasive nature of circuit boards without significant wear component degradation.

Four-Shaft Shredding Solutions

Four-shaft shredders provide the precision particle size reduction needed for highest recovery rates, processing materials down to under 10mm with uniform particle distribution. These systems often integrate eddy current separation modules that immediately remove non-ferrous metals after shredding, preventing re-mixing of materials. The multi-stage cutting action achieves metal liberation rates above 98% by creating clean separation between metal and non-metal components. This configuration is particularly valuable for high-volume processing where maximum recovery efficiency directly impacts profitability.

Precious Metal Separation Processes and Equipment Integration

Integrated separation systems work in concert with shredders to isolate and concentrate precious metals from the shredded e-waste stream. Magnetic separation efficiently removes ferrous metals using overhead magnets that can extract up to 99% of iron and steel components. Eddy current separators eject non-ferrous metals like aluminum and copper through electromagnetic induction principles that distinguish conductive from non-conductive materials. Electrostatic separation further refines the stream by separating remaining metals from plastics based on their surface conductivity differences.

XRF Sorting Technology Applications

X-ray fluorescence (XRF) sorting technology represents a significant advancement in precious metal recovery by enabling real-time composition analysis of shredded materials. These systems can detect and quantify precious metal content instantaneously, allowing automatic adjustment of separation parameters to maximize recovery efficiency. Advanced XRF sorters achieve final product purity exceeding 99.9% by making millions of micro-adjustments per hour based on material composition feedback. This technology is particularly valuable for processing mixed e-waste streams with highly variable metal content.

Pre-Cyanidation Shredding Requirements

Chemical leaching processes using cyanide solutions require extremely fine particle sizes below 0.5mm to ensure complete metal dissolution within economically viable time frames. Shredders must achieve this fine size reduction while minimizing surface oxidation that can reduce leaching efficiency. Specialized cooling systems prevent heat buildup during fine shredding that could create passive oxide layers on metal surfaces. The shredding process must also avoid contaminating the material stream with substances that could interfere with the chemical leaching process or create dangerous reactions.

Environmental Protection and Resource Recovery Balance Strategies

Modern e-waste shredding facilities implement comprehensive environmental protection measures that address dust, water, and air pollution concerns while maximizing resource recovery. Closed-loop dust suppression systems combine water sprays with HEPA filtration to capture over 99.97% of particulate matter, including valuable metal powders. Wastewater treatment systems remove heavy metals through precipitation and ion exchange technologies, allowing water recycling within the process. Exhaust air treatment typically employs activated carbon adsorption followed by catalytic oxidation to destroy organic compounds before atmospheric release.

Hazardous Material Isolation Technologies

Advanced shredding facilities incorporate automated detection and separation systems that identify and remove hazardous components before they enter the shredding chamber. Battery recognition systems using X-ray and visual imaging prevent lithium-ion batteries from causing fires in the shredder. Mercury-containing devices like fluorescent lamps and tilt switches are diverted to specialized processing lines. These safety systems are complemented by explosion-proof designs that meet ATEX standards for operating in potentially explosive atmospheres.

Resource Utilization Pathways

Shredded and separated metal concentrates can be directly sold to smelters specializing in precious metal recovery, often commanding premium prices due to their high purity. Non-metallic fractions can be processed into refuse-derived fuel (RDF) with calorific values comparable to coal, providing an alternative energy source. The urban mining model enabled by advanced shredding technology recovers 40-50 times more gold from e-waste than from primary ore mining, dramatically reducing the environmental impact of metal production while creating economic value from waste materials.

Cost-Benefit Analysis and ROI Models

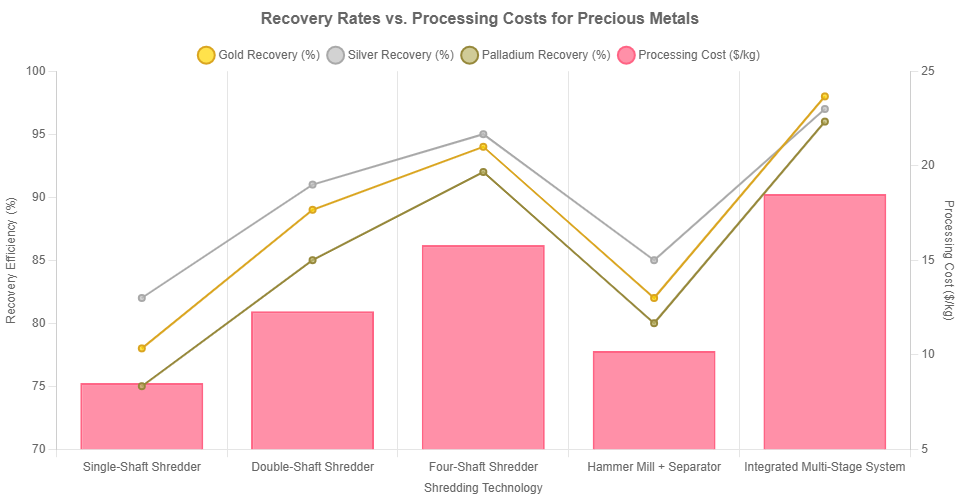

The economic viability of e-waste shredding for precious metal recovery depends on careful analysis of capital investment, operational costs, and revenue streams. Equipment costs for complete shredding and separation systems range from $500,000 to $2 million depending on capacity and automation level. Operational expenses including energy, maintenance, and labor typically account for 30-40% of total costs, while the value of recovered metals constitutes the primary revenue source. ROI periods generally range from 12-24 months depending on processing volume and metal market conditions.

Case Study: Electronic Recycling Enterprise

A specialized e-waste recycling company implemented a dual-shredder system consisting of a primary double-shaft shredder and secondary four-shaft shredder for precious metal recovery. The system processes 5,000 tons annually with gold recovery rates increasing from 70% to 95% compared to their previous equipment. The $1.2 million investment achieved payback in 14 months through increased metal recovery and reduced operational costs. The system also generates carbon credits due to its reduced environmental impact compared to virgin metal mining.

Hidden Cost Control Measures

Blade wear represents a significant operational expense, with tungsten carbide cutters requiring replacement after 800-1,000 hours of operation when processing abrasive circuit boards. Energy consumption optimization through IE4 premium efficiency motors and variable frequency drives reduces electricity costs by 15-20%. Strategic spare parts inventory management ensures minimum downtime while avoiding excessive capital tied up in inventory. These hidden costs often determine the long-term profitability of e-waste recycling operations.

Future Technology Development Trends

The future of e-waste shredding for precious metal recovery lies in intelligent, connected systems that maximize efficiency through automation and data analytics. AI-driven shredding systems will automatically adjust processing parameters based on real-time analysis of input material composition. Nanotechnology approaches may enable particle reduction to microscopic sizes that improve leaching efficiency while reducing chemical consumption. Blockchain technology will provide transparent documentation of metal recovery processes, verifying responsible recycling practices for compliance and customer assurance.

Ultrasonic Shredding Technology Prospects

Ultrasonic shredding technology offers promising advantages for precious metal recovery by achieving micron-level particle size reduction without significant heat generation. This method uses high-frequency vibrations to fracture materials along their natural cleavage planes, creating cleaner separation between different components. The technology significantly reduces chemical consumption in subsequent leaching processes by increasing surface area exposure. Ultrasonic systems show particular promise for processing ceramic capacitors and other challenging materials that conventional shredders struggle to break down effectively.

Automation and IoT Integration

The integration of Internet of Things (IoT) technology enables real-time monitoring of shredder performance and precious metal recovery rates through networked sensors and analytics platforms. Predictive maintenance systems analyze vibration, temperature, and power consumption data to identify potential issues before they cause downtime. These systems can automatically order replacement parts and schedule maintenance during optimal periods. Integration with enterprise resource planning (ERP) systems provides comprehensive business intelligence that optimizes the entire recycling operation from material acquisition to metal sales.