Jamming during feeding is one of the most common operational challenges in e-waste shredding operations, requiring systematic emergency response procedures to minimize downtime and prevent equipment damage. Effective jamming resolution combines immediate safety actions, methodical troubleshooting, and proper restoration protocols to ensure both operator safety and equipment integrity. This guide provides comprehensive procedures developed from industry best practices and equipment manufacturer recommendations, covering everything from initial jam detection to preventive measures that reduce future occurrence risks.

Jam Phenomenon Identification and Risk Assessment

Early recognition of feeding jams significantly reduces potential equipment damage and safety hazards. Operators should continuously monitor for unusual auditory cues such as grinding, knocking, or sudden changes in motor sound frequency that indicate resistance in the cutting chamber. Visual indicators include irregular movement of conveyor belts, sudden accumulation of material at the feed opening, or visible smoke from overheated components. Modern shredders incorporate advanced monitoring systems that provide real-time data on motor load, with typical jam conditions showing current spikes exceeding 130% of normal operating parameters, triggering automatic safety shutdowns when thresholds are breached.

Emergency Shutdown Operation Standards

Immediate and proper shutdown procedures are critical when a jam is detected. Operators must first engage the emergency stop button, which immediately cuts power to all moving components while activating holding brakes on rotational elements. Complete isolation requires switching off the main power supply at the distribution panel and placing appropriate lockout/tagout devices to prevent accidental reactivation during maintenance. Critical safety protocols strictly prohibit attempted reversal of rotation while jammed, as this action typically exacerbates the problem and may cause catastrophic damage to cutting components and drive systems.

Preliminary Jam Location Assessment

Accurate identification of jam location streamlines the resolution process and minimizes equipment downtime. Visual inspection through safety-rated observation ports allows initial assessment of material accumulation in the feed throat and primary cutting zone. For internal inspection, industrial borescopes with integrated lighting provide detailed visualization of the cutting chamber without disassembly. Auditory techniques involve carefully listening for impact sounds during manual rotation attempts to locate obstruction points. Simultaneous inspection of discharge areas ensures that downstream blockages aren't mistakenly identified as feeding issues, as conveyor jams often manifest similarly to primary shredder jams.

Standardized Jam Clearing Operation Procedures

Systematic jam resolution follows established safety and technical protocols to protect personnel and equipment during intervention operations. Proper personal protective equipment including face shields, cut-resistant gloves, and protective footwear must be worn by all personnel involved in clearing operations. Specialized tools including non-sparking pry bars, hydraulic jacks, and extraction tools should be readily available at the equipment location. The clearing process involves sequential steps starting from external material removal, progressing to internal component access, followed by thorough inspection before attempting restart procedures.

Manual Clearing Operation Standards

Manual intervention requires strict adherence to safety protocols to prevent injury during jam clearing operations. Non-metallic tools such as polycarbonate pry bars and nylon mallets should be used initially to dislodge jammed material without damaging cutting components. All actions must be performed with energy isolation verified through lockout/tagout procedures, ensuring zero possibility of equipment activation during maintenance. After material removal, visual inspection of the cutting chamber confirms complete clearance before conducting no-load test runs to verify proper operation. Detailed documentation of jam characteristics including material type, location, and resolution method provides valuable data for preventive maintenance planning.

Hydraulic System Assisted Jam Clearing

Modern shredders equipped with hydraulic systems offer controlled jam resolution capabilities that reduce physical effort and minimize potential damage. Activation of the auxiliary hydraulic pump gradually increases pressure to the cutting rotor system, typically achieving maximum force output of 150-200 bar for most industrial shredders. Progressive pressure application allows gradual disengagement of jammed materials without sudden energy release that could cause component damage or material ejection. Continuous monitoring of hydraulic pressure gauges during this process ensures values remain within safe operating parameters, preventing system overpressure situations that could damage hydraulic components.

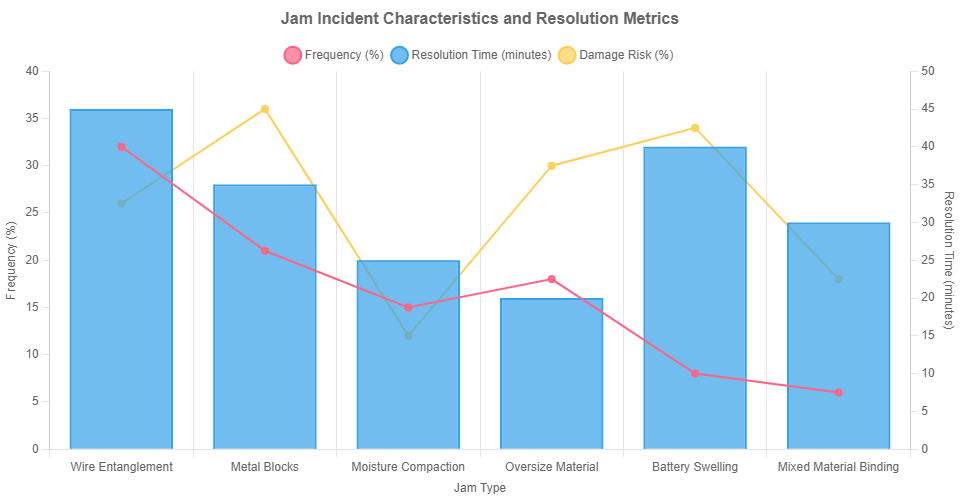

Special Material Jam Handling Solutions

Different material types require specific approaches based on their physical characteristics and potential hazards. Entangling materials like wires and cables present unique challenges due to their tendency to wrap around rotating components, requiring specialized techniques for safe removal. Hard metal blocks often become wedged between cutting components, necessitating careful extraction methods to prevent damage to expensive cutting elements. Moisture-containing materials can compact into dense masses that resist standard clearing methods, while battery leaks create chemical hazards that must be addressed before mechanical clearing can proceed safely.

Entanglement Resolution Techniques

Wire and cable entanglements require specific approaches to safely remove wrapped materials without causing additional damage. Insulated cutting tools specifically designed for electrical applications safely sever conductive materials while protecting operators from potential electrical hazards. Reverse rotation strategies, when approved by equipment manufacturers, can sometimes loosen wrapped materials through controlled backward movement facilitated by hydraulic drive systems. Anti-static sprays reduce friction during extraction operations, particularly valuable when processing materials prone to static buildup. Throughout the process, strict fire prevention measures must be maintained, including having appropriate fire extinguishers readily available near processing areas.

Metal Block Jam Handling

Metallic object jams represent particularly challenging situations that can cause significant damage if improperly addressed. When magnetic separation systems fail to detect or remove ferrous metals, specialized extraction methods become necessary. Pneumatic impact tools deliver controlled vibration to dislodge wedged metal pieces without the direct force application that could damage cutting components. Metal detection and location technologies including handheld metal detectors and boroscopes with magnetic tips help precisely identify jam location before intervention. Post-resolution analysis should focus on improving upstream detection systems, potentially upgrading magnetic separator strength or installing additional sensing technologies to prevent recurrence.

Equipment Reset and Operational Testing

Proper restart procedures following jam resolution ensure safe return to operation while verifying that no latent damage affects equipment performance. Initial no-load testing runs allow operators to verify proper mechanical function without material introduction, typically operating for 5-10 minutes while monitoring for unusual vibrations or sounds. Comprehensive inspection checks include measurement of cutting tool alignment, verification of belt tension specifications, and confirmation that all safety systems function correctly. Dust collection systems must be verified for proper operation, as jams often create abnormal dust generation that requires system balancing before full production resumes.

Load Testing Procedure

Gradual reloading following jam clearance prevents potential overload situations that could cause immediate re-jamming or equipment damage. Staged material introduction begins with 25% of normal feed rate, progressively increasing to full capacity over 15-20 minutes of operation. Continuous monitoring of motor current draw provides real-time feedback on system performance, with operators watching for abnormal fluctuations that might indicate residual issues. Vibration analysis equipment, when available, offers valuable data on mechanical condition during this critical phase. Only after successful operation at full capacity for至少30 minutes should the equipment be considered fully returned to normal production status.

Data Recording and Analysis

Comprehensive documentation of jam events provides valuable information for improving operational reliability and preventive maintenance planning. Each incident should record precise timing, material characteristics, weather conditions if applicable, and resolution methods employed. Equipment downtime tracking calculates production impact in both time and financial terms, helping justify potential preventive investments. Trend analysis of fault codes and jam frequency identifies patterns that might indicate developing mechanical issues or changing material characteristics. This data directly informs maintenance schedule adjustments and operational procedure updates to reduce future jam probability.

Preventive Maintenance and System Optimization

Proactive measures significantly reduce jam frequency and severity while improving overall operational efficiency. Enhanced pre-sorting systems remove problematic materials before they reach the shredder, incorporating advanced detection technologies like X-ray fluorescence and color sorting. Cutting tool maintenance programs establish regular inspection and replacement intervals based on actual usage rather than time elapsed, preventing unexpected failures that can lead to jams. Conveyor system upgrades including automatic tracking correction and wear monitoring maintain proper material flow to the primary shredder, reducing feed-related jam incidents.

Material Preprocessing Enhancement Measures

Upstream material handling improvements represent the most effective approach to reducing shredder jamming incidents. Magnetic separation systems should be optimized for both strength and precision, with modern overband magnets capable of removing ferrous contaminants as small as 0.5mm. Metal detection systems with automatic rejection capabilities prevent non-ferrous metals from entering the shredding chamber, while moisture management through pre-drying or drainage systems addresses material compaction issues. Strict enforcement of size limitations through pre-screening and size reduction equipment ensures only appropriately sized material enters the primary shredder, preventing oversize-related jams.

Equipment Modification Solutions

Strategic equipment upgrades can significantly enhance jam resistance and simplify resolution when jams do occur. Quick-change tooling systems reduce downtime during maintenance operations, with some advanced systems allowing complete cutting element replacement in under two hours compared to traditional methods requiring 8-12 hours. Automated feed throat adjustment mechanisms respond to material characteristics in real-time, preventing overfeeding that often leads to jams. Backup power systems maintain critical monitoring and control functions during main power interruptions, preventing material stall situations that can harden into difficult jams during power restoration.

Typical Case Analysis and Experience Summary

Real-world incident reviews provide practical insights into effective jam resolution strategies and common pitfalls to avoid. Circuit board jamming incidents often involve layered materials that separate during processing, creating bridging conditions that require specific clearing techniques. Cable entanglement cases demonstrate the importance of proper preprocessing and the effectiveness of specialized tools designed specifically for wire extraction. Metallic object incidents highlight the critical role of detection systems and the potential costs of undetected metal entering the shredding chamber.

Failure Case Lessons

Analysis of unsuccessful jam resolution attempts provides valuable learning opportunities for improving procedures and training. Attempted forced reversal without proper manufacturer approval frequently results in catastrophic damage to drive systems and cutting components, with repair costs often exceeding $50,000 and downtime extending to several weeks. Electrical safety violations during clearing operations have caused serious injuries, emphasizing the critical importance of complete energy isolation before any intervention. Residual energy incidents, particularly in hydraulic systems, demonstrate the need for comprehensive pressure release verification before beginning maintenance activities.

Best Practice Sharing

Successful operations implement comprehensive jam management systems that address prevention, response, and continuous improvement. Standardized clearance procedure cards posted at each equipment station provide quick reference during high-stress situations, ensuring consistent approach across all shifts. Regular emergency response drills maintain operator proficiency, with simulated jam scenarios conducted至少quarterly to reinforce proper techniques. Dedicated tool kits containing all necessary equipment for jam resolution, stored at strategic locations, prevent delays during actual incidents. Operator certification programs ensure only properly trained personnel attempt jam clearance, significantly reducing safety incidents and equipment damage.

Safety Standards and Compliance Requirements

Regulatory compliance and safety standards establish the framework for all jam resolution activities, ensuring protection of personnel, equipment, and the environment. Operations in potentially explosive atmospheres require ATEX-compliant equipment and procedures, including use of specially designed tools that prevent spark generation. Confined space entry protocols mandate specific permits, atmospheric monitoring, and rescue preparedness for any internal access to shredding chambers. Personal protective equipment standards must meet or exceed regulatory requirements, with specific enhancements based on risk assessment of each jam scenario.

Hazardous Material Handling Special Regulations

Specific procedures address the unique challenges presented by hazardous materials commonly found in e-waste streams. Lithium battery jams require immediate fire watch implementation, thermal monitoring, and specialized extraction tools that prevent short circuiting during removal. Mercury-containing components demand spill containment preparedness and specialized personal protective equipment to prevent exposure during clearance operations. Dust explosion risk management protocols include atmospheric monitoring, controlled access, and specialized fire suppression systems ready for immediate activation. All waste generated during jam resolution must be properly characterized, contained, and disposed according to environmental regulations, with particular attention to potentially hazardous materials dislodged during clearance operations.