Choosing the correct industrial shredder is a critical decision for any electronic waste processing operation. The choice between a dual-shaft and a single-shaft system directly impacts efficiency, operational costs, and the quality of the output material. This guide explores the fundamental differences between these two dominant shredder technologies, providing a clear framework for selection based on material composition, desired throughput, and specific processing goals. Understanding these core mechanics is essential for optimizing your e-waste recycling stream.

Understanding the Basic Construction of Dual-Shaft and Single-Shaft Shredders

The primary distinction between these shredders lies in their cutting mechanism's fundamental design and operation. A dual-shaft shredder utilizes two parallel, counter-rotating shafts equipped with interlocking cutting discs. This design creates a powerful shearing and tearing action, much like a pair of scissors, which is highly effective at processing bulky and irregular materials. The slow-speed, high-torque operation minimizes dust and reduces energy consumption during the initial size reduction phase.

In contrast, a single-shaft shredder operates with a single rotating rotor that pushes material against a stationary bed of knives. This design incorporates a hydraulic ram that forces the material towards the rotor, ensuring consistent feeding. The cutting action is a combination of shear and tear, but it often relies more on the rotor's rotational speed and the sharpness of the blades. This configuration is typically suited for processing smaller, more uniform material streams into a controlled output size.

The Advantages of the Dual Rotating Shaft Design

The twin-shaft system provides a self-feeding action where the interlocking cutters grab and pull material into the cutting chamber autonomously. This eliminates the constant need for a hydraulic ram feeder for many applications, simplifying the system. The high torque generated at low rotational speeds allows it to handle tough, ductile materials without stalling, making it exceptionally reliable for mixed e-waste streams containing metals and hard plastics.

The Combination of a Single Rotating Shaft and Fixed Blades

The single-shaft design focuses on creating a precise cutting environment where material is fed against the rotor. The presence of a hydraulic ram is often critical for processing non-uniform e-waste, as it ensures a steady flow of material into the cutting zone. This setup allows for greater control over the final particle size, especially when combined with a screen grate at the discharge, which retains material until it is small enough to pass through.

The Impact of Structural Differences on Material Processing

These construction differences lead to divergent processing characteristics. Dual-shaft shredders excel in coarse shredding, producing a rough, flake-like output ideal for downstream liberation and separation. Single-shaft shredders, particularly granulators, are engineered for size reduction to a specific, smaller particle size, which is necessary for advanced sorting systems like eddy current separators or optical sorters that require a consistent feed.

Characteristics of E-Waste Materials and Processing Requirements

Electronic waste represents one of the most complex and variable material streams for any recycling operation. It is a heterogeneous mix of metals, plastics, ceramics, and glass, each with distinct physical properties. Metals can range from thin aluminum casings to thick copper heat sinks, while plastics vary from brittle ABS to flexible PVC wire insulation. This variability demands a shredder that is not only powerful but also versatile and resilient to abrasive and hard contaminants.

The primary goal of shredding e-waste is to achieve material liberation—breaking composite devices down into individual particles so that valuable materials like copper, gold, and plastics can be effectively separated. This process must also address specific challenges such as the presence of hazardous substances, like batteries, and the absolute necessity for data destruction from storage devices. The shredder is the first and most crucial mechanical step in this chain, setting the stage for all subsequent recovery processes.

The Need for Mixed Metal and Plastic Processing

Very few e-waste items are composed of a single material; most are intricate assemblies of various metals, plastics, and circuit boards. An effective shredder must be capable of reducing this entire mixture without pre-sorting. The machine must have the shear strength to cut through metal brackets and the toughness to fracture plastic housings simultaneously, creating a mixed output stream that can be separated later in the process.

Difficulties in Processing Complex Structures like Circuit Boards

Printed Circuit Boards (PCBs) are particularly challenging. They are composite materials made of layered fiberglass and epoxy, laminated with thin copper traces and populated with a mix of valuable components and hazardous solder. Shredding them requires a precise combination of shear and impact to break them apart without pulverizing the valuable metals into dust. Specialized tungsten carbide cutters are often used to withstand the abrasive nature of the fiberglass.

Special Requirements for Data Security Destruction

Beyond material recovery, many devices require guaranteed data destruction. Hard drives, smartphones, and storage media must be physically destroyed to a degree that data reconstruction is impossible. This requires a shredder capable of reducing these items to very small, confetti-like particles, often below 20mm in size. This specific need often dictates the choice of a high-speed, high-shear hard drive shredder that can be integrated into the primary line.

Application Advantages of Dual-Shaft Shredders in E-Waste Processing

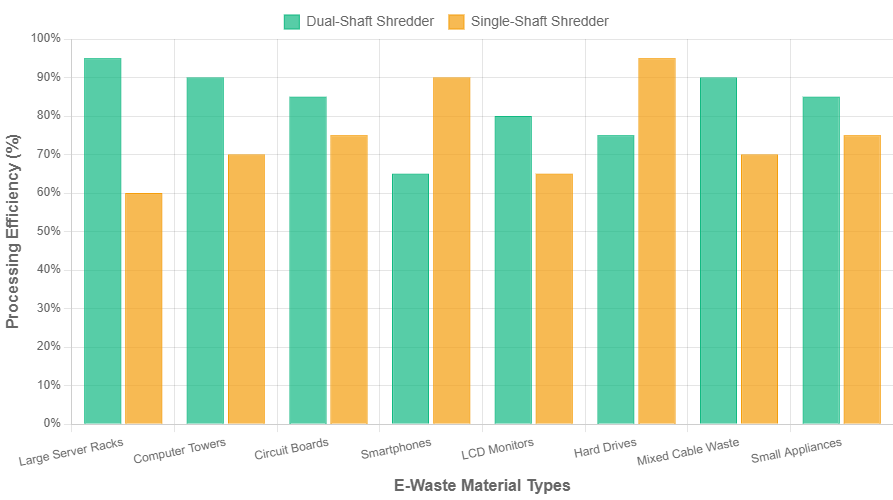

Dual-shaft shredders are considered the workhorses of primary e-waste size reduction. Their robust, low-speed, high-torque design makes them uniquely suited for the initial breaking down of large, unpredictable electronic equipment. They are engineered to handle the shock load of processing a whole computer tower one moment and a bundle of cables the next, providing consistent performance and protecting downstream equipment from oversized or problematic items.

The key advantage of a dual-shaft system is its volumetric reduction capability. By tearing and shearing large items into smaller, more manageable fragments, it significantly reduces the volume of the waste stream. This not only optimizes transportation and storage costs but also prepares the material for more efficient and precise secondary processing. The output from a dual-shaft shredder is typically a strip-like or flake-like material that exposes surfaces for better separation in downstream magnetic separators and eddy current systems.

Case Study: Processing Large Computer Servers

Large server racks and data center equipment, with their thick steel chassis and dense internal components, are a prime example of where a dual-shaft shredder excels. The machine's powerful hydraulic ram feeder and interlocking cutters can crumple and shear the entire unit, efficiently liberating the valuable internal components like motherboards, power supplies, and wiring from their protective enclosures in a single pass.

Efficiency Analysis in Crushing Circuit Boards

When configured with closely spaced, high-strength cutting discs, a dual-shaft shredder can effectively fracture PCBs. The shearing action breaks the boards along the copper traces, liberating the valuable metals from the non-metallic substrate without excessive heat generation, which can be a concern with high-speed hammer mills. This controlled fragmentation is crucial for maximizing the yield of precious metals in subsequent refining steps.

Flexibility in Handling Mixed Electronic Waste

The versatility of the dual-shaft design is its greatest asset for modern e-waste facilities that receive a broad range of material. The same machine can process everything from large white goods and CRT monitors to small appliances and mixed loose components. This flexibility simplifies the inbound logistics and pre-processing requirements, allowing for a more continuous and efficient operation.

Applicable Scenarios for Single-Shaft Shredders in E-Waste Processing

Single-shaft shredders, particularly granulators, serve a different but equally vital role in the e-waste recycling chain. They are typically deployed as secondary shredders, taking the pre-broken material from a primary dual-shaft machine and reducing it to a fine, uniform granulate. This precision size reduction is critical for advanced sorting technologies that require a consistent feed particle size to function at peak efficiency and accuracy.

These machines operate at higher rotational speeds than their dual-shaft counterparts and are often equipped with a screen grate at the bottom of the cutting chamber. This screen ensures that no material is discharged until it is smaller than the screen's mesh size, guaranteeing a controlled output. This makes them ideal for applications where the final product size is a critical specification for marketability or further processing, such as creating a clean plastic granulate for remanufacturing.

Advantages in Processing Small Devices like Smartphones

For streams consisting primarily of small, homogeneous e-waste like mobile phones, a robust single-shaft granulator can sometimes serve as a primary shredder. Its ability to precisely control output size is beneficial for liberating and recovering the small but valuable components, such as microchips and camera modules, contained within these devices without over-processing them into dust.

Application in Laboratories or Small-Scale Recycling Stations

The relatively smaller footprint, lower initial investment, and quieter operation of some single-shaft models make them a practical choice for research institutions, testing laboratories, or small-scale recycling operations. They are suitable for processing limited batches of specific e-waste materials where high throughput is not the primary objective, but controlled destruction and output consistency are.

Analysis of Maintenance Costs and Cycle

While single-shaft shredders require precise maintenance of the rotor blades and the bed knife alignment, their maintenance cycle can be more predictable than that of a primary shredder. The wear on components is often more uniform due to the controlled feed of pre-shredded material. However, the replacement of the screen grate and the sharpening of a larger set of blades are recurring costs that must be factored into the operational budget.

Key Factors to Consider When Selecting a Shredder

The decision between a dual-shaft and single-shaft system is multifaceted

and must be based on a thorough analysis of the operational requirements. The most significant factor is the incoming material profile. A facility processing whole, bulky items

will invariably need a powerful primary e-waste double-shaft shredder, while a plant focusing on

further refining already broken material might prioritize a high-capacity granulator.

Beyond the input, the desired output specification is equally critical. The required particle size for downstream sorting or sale directly influences the technology choice. Financial considerations extend beyond the purchase price to include installation costs, energy consumption, maintenance downtime, and the cost of wear parts. A comprehensive analysis of the total cost of ownership (TCO) over the machine's lifespan provides the most accurate financial picture.

Selecting the Appropriate Shredder Model Based on Throughput

Throughput requirements, measured in tons per hour, directly dictate the size and power of the shredder needed. A dual-shaft shredder for a large-scale operation might process 10-25 tons per hour of mixed e-waste, while a secondary granulator might handle 5-10 tons per hour of pre-shredded material. Under-sizing a machine leads to bottlenecks, while over-sizing results in unnecessary capital expenditure and higher operating costs.

The Influence of Output Size on Subsequent Recycling Processes

The particle size after shredding determines the efficiency of every subsequent step. For instance, air separation and eddy current separation require a controlled and consistent feed size to achieve optimal purity rates. An output that is too large may not have achieved sufficient liberation, while an output that is too fine may have turned valuable materials into unrecoverable dust or may cause sorting equipment to clog.

Balancing Long-Term Operational Costs with Return on Investment

The most energy-efficient and low-maintenance machine might have a higher upfront cost but provide a superior return on investment over five years. Key metrics to calculate include the cost per ton processed, which factors in electricity, labor, maintenance, and wear parts. Investing in features like a modern cooling system or automated lubrication can significantly reduce long-term operational expenses.

Practical Case Studies of Shredder Selection

Analyzing real-world applications provides invaluable insight into the shredder selection process. A successful case study often highlights a facility that meticulously matched its equipment to its specific material stream and business goals. These cases demonstrate how a correctly specified shredder becomes the foundation of a profitable and efficient operation, maximizing material recovery and minimizing downtime.

Conversely, examining selection errors reveals common pitfalls, such as choosing a machine based on price alone or underestimating the abrasiveness of the material. These lessons underscore the importance of thorough material testing and vendor consultation before making a capital investment. The future of e-waste shredding points towards smarter, more connected machines with improved energy recovery and automated adjustment features to handle an ever-evolving waste stream.

Case Study: Successful Selection of a Dual-Shaft Shredder at an E-Waste Recycling Plant

A North American e-waste recycler processing over 30,000 tons per year of mixed electronics successfully implemented a large dual-shaft shredder as their primary reduction unit. By selecting a model with a hydraulic ram feeder and customizable cutting discs, they achieved a 40% increase in throughput and a 15% improvement in metal liberation rates compared to their previous system, significantly boosting their revenue from recovered commodities.

Case Study: Productivity Decline Due to Improper Selection

A European facility mistakenly used a standard single-shaft granulator as a primary shredder for whole LCD monitors. The machine was unable to handle the combination of glass, plastics, and metal frames, leading to frequent jams, catastrophic blade damage, and excessive downtime. The error resulted in lost processing time and high repair costs, ultimately requiring the purchase of a dedicated primary shredder to resolve the issue.

Future E-Waste Processing Trends and Shredder Selection Directions

The industry is moving towards integrated shredding and sorting lines with high levels of automation and data collection. Future shredders will likely feature IoT sensors for predictive maintenance, adaptive control systems that adjust cutting parameters based on the load, and even more robust designs to handle new challenges like lithium-ion batteries. Selecting equipment from manufacturers investing in this R D ensures a system remains viable and efficient for years to come.