Proper cleaning and maintenance are fundamental requirements for the efficient and safe operation of industrial e-waste shredders. These powerful machines process complex and often abrasive materials, making them susceptible to wear, residue buildup, and component degradation. A comprehensive maintenance program directly impacts operational costs, equipment longevity, and product quality. This guide details the systematic approaches and best practices required to keep an e-waste shredder performing at its peak, ensuring reliability and maximizing return on investment.

The Importance of Shredder Cleaning and Maintenance

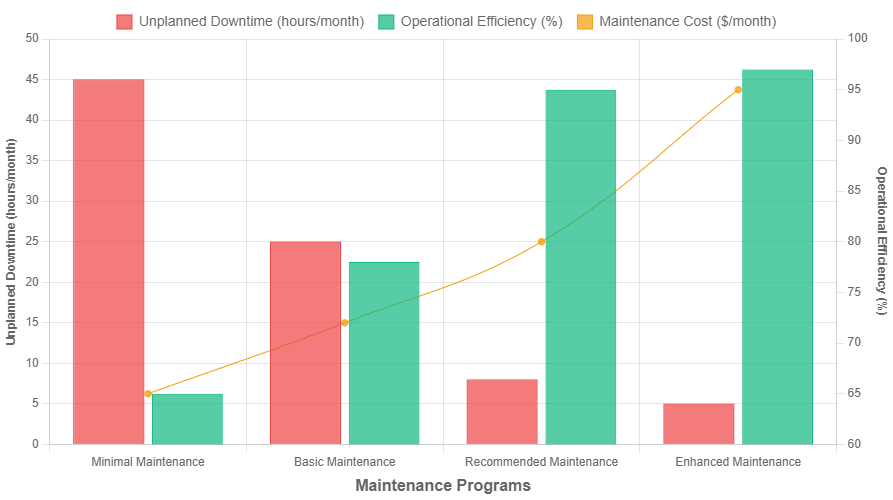

Implementing a rigorous cleaning and maintenance schedule is a critical investment in the shredder's operational life and performance. The abrasive nature of e-waste, which includes fiberglass from PCBs, metal fragments, and various hardened plastics, causes continuous wear on moving components. Without regular intervention, this wear accelerates, leading to premature failure of expensive parts like rotors, bearings, and cutting blades. A well-maintained machine avoids unplanned downtime, which can cost thousands of dollars per hour in lost processing capacity.

Beyond longevity, maintenance is a core component of safety and efficiency. Accumulated dust and debris can pose a fire hazard, especially when processing electronics with residual batteries. Proper cleaning ensures that safety systems, such as the fire suppression system, remain unobstructed and fully functional. Furthermore, a clean machine operates with less resistance and strain, translating to lower energy consumption and more consistent output particle size, which is crucial for downstream sorting processes.

The Role of Regular Cleaning in Reducing Equipment Failure

Scheduled cleaning prevents the accumulation of fine particulate matter that can infiltrate bearings, gearboxes, and hydraulic systems. This contamination is a primary cause of lubricant breakdown and abrasive wear. By removing this debris, the interval between major overhauls can be significantly extended, reducing long-term maintenance costs by up to 30% and preventing catastrophic failures that halt production.

Efficiency Improvements from a Well-Maintained Shredder

A shredder with sharp blades and clean, properly lubricated bearings requires less energy to achieve the same throughput. Sharp blades produce a cleaner cut with less fines generation, while clean bearings reduce friction. This optimization can lead to a measurable increase in processing capacity and a reduction in power consumption, directly improving the operational efficiency and profitability of the recycling line.

Impact of Cleaning on Operator Safety

A clean work environment is a safe work environment. Spilled oils, grease, and accumulated dust around the shredder create slip and fall hazards. More critically, dust from certain e-waste components can be hazardous if inhaled. Regular cleaning mitigates these risks, protecting personnel and ensuring compliance with workplace health and safety regulations (OSHA standards in the US, for example).

Daily Cleaning and Maintenance Procedures

A daily maintenance routine is the first line of defense against premature wear and operational issues. This routine is divided into three distinct phases: pre-startup inspection, operational monitoring, and post-shutdown procedures. Consistency in this daily practice allows operators to identify potential problems at their earliest stages, often before they lead to equipment damage or failure. This proactive approach is far more cost-effective than a reactive one.

The pre-startup check involves a visual and physical inspection of the machine's critical components. After operation, the shutdown procedure focuses on removing the day's accumulation of debris and preparing the machine for its next cycle. Adherence to a daily checklist ensures that no critical step is overlooked, creating a documented standard of care for the equipment.

Pre-Startup Inspection of Blades, Bearings, and Key Components

Before energizing the system, operators should visually inspect the cutting chamber for any foreign objects or leftover material from the previous shift. Checking for loose bolts, hydraulic leaks, and the condition of the drive belts is essential. A quick manual rotation of the rotor (if possible) can identify any obstructions or binding before power is applied, preventing potential motor overload.

Monitoring Temperature and Noise Indicators During Operation

During operation, continuous monitoring of key parameters is vital. Operators should regularly check amperage draws on the main motor to ensure it is operating within its designed load range. Abnormal vibrations or changes in acoustic signatures often provide the earliest warning of an imbalance, a loose component, or bearing failure. Monitoring the temperature of bearings and hydraulic fluid can also prevent overheating-related damage.

Residue Removal and Lubrication After Shutdown

Once the machine is fully stopped and locked out (LOTO procedure), the cleaning process begins. Using appropriate tools like brushes, scrapers, and industrial vacuums, operators must remove all residual shreds and dust from the cutting chamber, hopper, and discharge areas. This is also the ideal time to check fluid levels and apply lubrication to specified points according to the manufacturer's manual, ensuring the machine is ready for a smooth start the next day.

Cleaning and Maintenance Methods for Key Components

The longevity of a shredder depends overwhelmingly on the care given to its core components. Each part has specific maintenance requirements tailored to its function and exposure to wear. A targeted approach, focusing on these critical elements, ensures the entire system remains reliable. Using the correct procedures and materials for each component prevents accidental damage during maintenance and maximizes the interval between services.

Blades endure the most direct abuse, constantly shearing and impacting hard materials. Bearings support immense loads and must be protected from contamination. Screening systems control output size and can become blinded by material buildup. A methodical maintenance plan for each of these systems, based on runtime hours rather than calendar time, provides the most accurate scheduling for service and replacement.

Cleaning Adhesions and Sharpening Techniques for Blades

Blades should be inspected regularly for dulling, chipping, or rolling of the cutting edge. Adhesive materials like plastics can melt and coat the blades, reducing their cutting efficiency. Cleaning with specialized solvents may be necessary. Sharpening must be done by a qualified technician to maintain the original cutting angle and balance of the rotor assembly. Unbalanced rotors cause significant vibration and can damage bearings and the machine structure.

Selecting the Appropriate Lubricant and Cycle for Bearings

Bearings in shredders are typically lubricated with high-temperature, high-pressure grease designed to withstand heavy loads and resist washout. The lubrication interval must adhere strictly to the manufacturer's specifications, which are based on bearing type and operating conditions. Over-greasing can be as detrimental as under-greasing, as excess grease can cause overheating. Many modern shredders are equipped with an automated lubrication system to ensure consistency.

Preventing Blockages and Determining Replacement Time for Screens

Screen grates must be kept clear of plugged holes to maintain throughput and prevent material from recirculating unnecessarily, which causes over-shredding and increased wear. Regular removal and cleaning with specialized tools are required. Screens should be replaced when wear enlarges the holes beyond the acceptable output size tolerance or when they become thin and risk breaking under load.

The Relationship Between Common Failures and Cleaning Maintenance

Most mechanical failures in shredders are not sudden events but the culmination of neglect or minor issues that go unaddressed. There is a direct and often predictable correlation between specific maintenance shortcomings and the resulting equipment malfunctions. Understanding these relationships empowers operators to diagnose root causes rather than just treating symptoms, leading to more effective and long-lasting repairs.

Overheating, a common problem, rarely has a single cause but is frequently linked to maintenance-related issues. A drop in processing efficiency often points to wear or obstruction in key areas. Unusual noises are almost always a symptom of a mechanical problem that has developed over time due to a lack of lubrication, component wear, or loose parts. A systematic maintenance log helps trace these issues back to their origin.

Inspecting the Cooling System and Cleaning Heat Sinks During Overheating

When a shredder overheats, the cooling systems should be the first point of inspection. Radiators and heat exchangers can become clogged with dust from the dust extraction system, drastically reducing their efficiency. Ensuring that hydraulic oil coolers and motor cooling fins are clean and that cooling fans are operational is a primary maintenance task to prevent thermal overloads.

Clearing the Feed and Discharge Ports When Efficiency Declines

A noticeable decrease in throughput often indicates a blockage or restriction. The feed hopper can develop bridges of material that prevent flow into the cutting chamber. Similarly, the discharge area can become obstructed, causing material to back up. Regular visual inspections and clearing of these areas are simple but effective maintenance tasks that maintain consistent material flow and processing rates.

Checking Wear on Bearings and Gears When Abnormal Noise Occurs

Abnormal noises such as grinding, squealing, or knocking are critical warnings. Grinding often indicates bearing failure due to lack of lubrication or contamination. Squealing can point to misaligned belts or sheaves. Knocking or banging may suggest loose hammers, broken blades, or severe rotor imbalance. Immediate shutdown and investigation are required to prevent further, more extensive damage to the equipment.

Selection of Cleaning Tools and Materials

The effectiveness of cleaning and maintenance is heavily dependent on using the correct tools and consumables for each task. Standardized toolkits should be assembled for daily, weekly, and monthly maintenance tasks. Using improper tools can damage components; for example, using a metal scraper on a precision-machined surface can score it and create a wear point. The selection of cleaning agents and lubricants must be approved by the equipment manufacturer to avoid chemical incompatibility that could damage seals or corrode components.

Safety is paramount when selecting equipment. Tools should allow the operator to perform tasks without putting themselves in harm's way. Furthermore, the environmental impact of cleaning agents and waste materials, such as used grease and contaminated rags, must be considered. Proper disposal methods in accordance with local environmental regulations are an integral part of the maintenance process.

Use of Specialized Cleaning Tools such as Brushes and Industrial Vacuums

A maintenance toolkit should include an array of brushes (nylon, brass, and steel bristle for different applications), plastic scrapers, picks for cleaning blade grooves, and high-powered industrial vacuums rated for metal dust. The vacuum is particularly critical for removing fine, abrasive particles from electrical cabinets and around bearings to prevent contamination.

Choosing Environmentally Friendly and Efficient Cleaners and Lubricants

Biodegradable, non-toxic cleaning solvents are preferred for both operator safety and environmental responsibility. Lubricants should be selected based on their specified properties (e.g., NLGI grade, viscosity index) for the specific application, whether it be for high-load bearings, open gears, or hydraulic systems. Using a general-purpose grease for all applications will lead to premature component failure.

The Importance of Wearing Safety Helmets, Gloves, and Other Protective Gear

Maintenance personnel must always wear appropriate Personal Protective Equipment (PPE). This includes safety glasses, hearing protection, cut-resistant gloves, steel-toed boots, and hard hats, especially when working on or around large machinery. When performing tasks like blade changing or dealing with hydraulic systems, additional protective measures like face shields and hydraulic fluid-resistant gloves are necessary to prevent injury.

Maintenance Record Keeping and Tracking

Comprehensive documentation is the backbone of a professional maintenance program. A detailed log transforms maintenance from a reactive exercise into a proactive, data-driven strategy. This record should chronicle every service activity, from daily inspections to major component replacements. Tracking this history provides invaluable insights into the machine's performance trends, wear rates, and operational costs over time.

Modern maintenance often utilizes digital Computerized Maintenance Management Systems (CMMS) to schedule tasks, track parts inventory, and record service history. These systems can generate work orders, send automated reminders for scheduled services, and analyze data to predict future maintenance needs. This level of organization ensures that no service interval is missed and provides a clear audit trail for compliance and management review.

The Value of Maintenance Records for Equipment Management

Well-kept records provide a complete life-cycle history of the shredder. This is crucial for warranty claims, troubleshooting recurring problems, and calculating the total cost of ownership. This data is also essential for justifying capital expenditure on repairs or upgrades, as it provides concrete evidence of the machine's maintenance history and performance.

Recording Detailed Maintenance Information for Traceability

Each entry in the maintenance log should be precise, including the date, runtime hours, a description of the work performed, the parts replaced (including batch numbers if applicable), the name of the technician, and any observations on component condition. This detail allows for complete traceability if a replaced part fails prematurely and helps identify patterns that might indicate a larger underlying issue.

Adjusting Maintenance Cycles and Content Based on Equipment Performance Changes

Maintenance schedules are not static. By analyzing records, operators can optimize service intervals. If a specific bearing requires replacement well before the scheduled time, the lubrication interval or type of grease can be adjusted. If a certain component shows less wear than anticipated, its service interval can be safely extended, reducing downtime and maintenance costs without risking failure.