Industrial e-waste shredders are powerful machines designed to process a wide variety of materials, from plastics and metals to electronic waste. The heart of any shredder is its cutting system, where tungsten carbide cutters tirelessly break down tough materials like those found in a PCB shredding unit. Monitoring the wear of these blades is not just about maintenance; it is a critical process that directly impacts operational efficiency, cost, and environmental sustainability. For e-waste, which often contains abrasive circuit boards and metals, implementing a scientific approach to blade management can reduce operational costs by up to 20% and significantly increase the machine's lifespan. This guide provides a comprehensive overview of the technologies and strategies used to monitor wear and optimize replacement cycles, ensuring your shredding operation runs at peak performance.

The transition from reactive to predictive maintenance is revolutionizing the recycling industry. Instead of waiting for a blade to fail, which can cause costly unplanned downtime and potential damage to other components like the shredder shaft, operators can now use data to anticipate needs. By understanding wear patterns, facilities can schedule maintenance during natural pauses in production, order replacement parts in advance, and maintain a consistent, high-quality output. This proactive approach is essential for handling the variable and often harsh nature of electronic waste streams, making the entire recycling process more reliable and economically viable.

Core Technologies and System Design for Blade Wear Monitoring

Modern shredders, particularly robust models like the e-waste double shaft shredder, are increasingly equipped with sophisticated monitoring systems that transform them from simple machines into intelligent data hubs. These systems rely on a network of sensors and analytical software to assess the health of cutting components in real-time. The core objective is to capture data that reflects the physical condition of the blades without requiring frequent manual inspections, which can be dangerous and halt production. By integrating technologies like vibration analysis and acoustic emission monitoring, these systems can detect subtle changes in performance that signal the onset of wear long before it becomes a critical problem.

The design of such a system is a multi-layered engineering challenge. It involves selecting the right sensors, determining their optimal placement on the machine's heavy-duty gearbox and frame, and developing algorithms that can filter out operational noise to focus on the signals that matter. This infrastructure turns a standard solid waste shredder into a smart, connected asset, providing a continuous stream of health data that is indispensable for modern, efficient waste processing facilities aiming for maximum uptime.

Vibration Analysis and Wear Detection Technology in Blade Monitoring

Vibration analysis serves as a stethoscope for industrial machinery, listening to the heartbeat of the e-waste shredder. As blades, such as the tire cutter blades or those in a hammer mill shredder, begin to wear down or suffer from micro-fractures, the dynamic forces within the cutting chamber change. These changes manifest as specific, identifiable vibrations. Accelerometers mounted on the bearing housings or the machine frame capture these vibration signals. Advanced software then analyzes the frequency spectrum, looking for anomalies that deviate from the baseline vibrations of a healthy machine.

The practical application of this technology is profound. For instance, a study on large-scale wood shredders showed that vibration monitoring could predict blade wear issues up to 100 operating hours before failure, reducing unexpected downtime by approximately 35%. This is particularly crucial for high-torque applications like a double shaft plastic shredder, where unbalanced wear can lead to severe damage to the rotor assembly and drive train. By catching these issues early, facilities can plan interventions and avoid the cascading effects of a catastrophic failure.

The Role of Intelligent Sensors in Real-Time Wear Monitoring

Intelligent sensors are the nerve endings of a modern shredding system, providing the raw data needed for informed decision-making. Beyond simple vibration sensors, systems can incorporate a suite of monitoring devices. Acoustic emission sensors detect high-frequency stress waves generated by the cracking and deformation of blade material, offering an even earlier warning sign than vibration analysis. Temperature sensors monitor the heat generated at the cutting edges, as excessive heat is a primary accelerator of wear, especially in oil-free cutting systems.

Furthermore, laser displacement sensors can be employed to measure the physical gap between blades and their corresponding counter-knives, providing a direct measurement of wear without disassembling the unit. In a paper shredder, simpler motor current sensors are highly effective; as blades dull, the motor draws more amperage to maintain throughput. This network of sensors feeds into a central PLC control panel, creating a holistic, real-time picture of machine health that is essential for predictive maintenance.

Development of Data-Driven Wear Prediction Models

The true power of sensor data is unlocked through data-driven predictive models. These algorithms, often based on machine learning, analyze historical and real-time data to forecast future wear rates and predict the remaining useful life (RUL) of blade sets. The model ingests thousands of data points: motor load from the gearbox, vibration spectra, material throughput rates, and even the type of material being processed, which for an e-waste shredder can vary dramatically.

For example, a model might learn that processing a high volume of fiberglass-rich PCB material causes wear to accelerate by 40% compared to shredding pure plastic casings. By correlating these input variables with actual wear measurements from maintenance records, the model becomes increasingly accurate. These predictions allow managers to move from time-based replacement schedules to condition-based ones, optimizing inventory by ordering tungsten carbide cutters only when needed and maximizing the use of every blade set, thereby reducing waste and cost.

Optimization Strategies for Blade Replacement Cycles

Optimizing replacement cycles is the ultimate goal of any monitoring system, transforming data into actionable business intelligence. The strategy moves beyond a simple "replace when broken" or "replace every X hours" mentality. Instead, it involves creating a dynamic schedule that considers the actual condition of the blades, the upcoming production schedule, and cost factors. For a high-volume operation using a four-shaft shredder, the optimal point might be to replace blades when wear reaches 80% of their usable life, scheduling the maintenance during a planned weekend shutdown.

This optimization has a direct financial impact. Industry data suggests that optimized replacement cycles can extend blade life by 15-25% by ensuring that no blade is replaced prematurely. Furthermore, it prevents the hidden costs of running dull blades, which can increase energy consumption by up to 10% due to the higher strain on the rotor and drive motor. For a tire shredder dealing with steel-belted radials, a well-timed change of cutter blades ensures clean cuts that improve the efficiency of downstream magnetic separators for wire recovery, showcasing how blade management affects the entire recycling line.

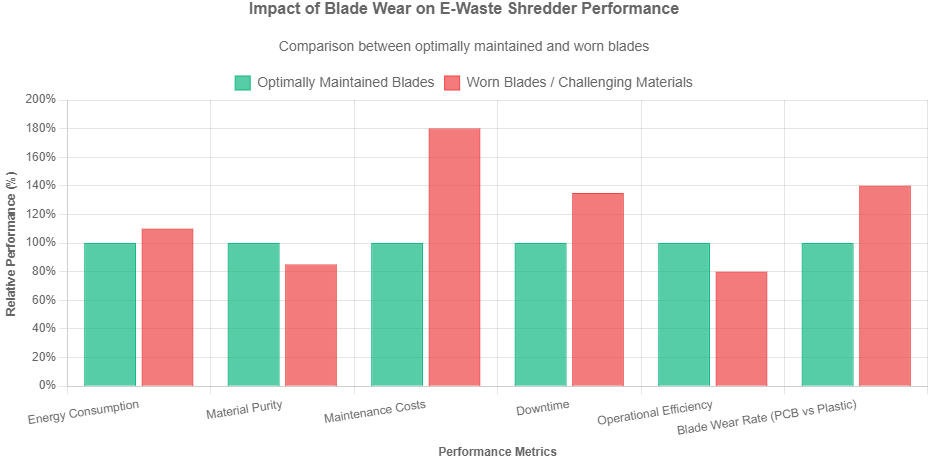

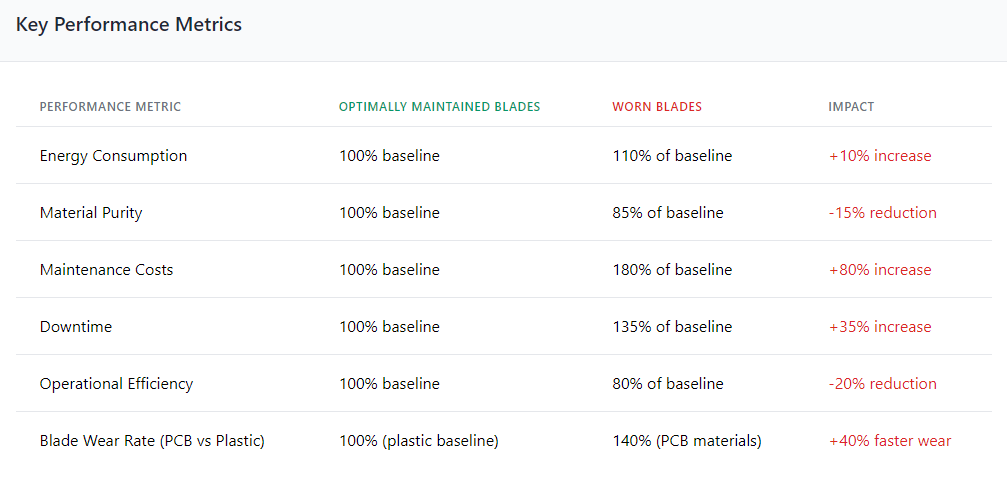

Analysis of the Impact of Blade Wear on Equipment Performance

Blade wear is an inevitable process, but its consequences extend far beyond the cutting components themselves, affecting the entire shredding system's performance, efficiency, and economics. A worn blade does not simply cut less effectively; it changes the fundamental mechanics of the shredding process. In a plastic shredder, dull blades tear and stretch material instead of shearing it cleanly, creating irregular flakes that are less valuable for recycling. Understanding these impacts is crucial for justifying investments in advanced monitoring and maintenance systems.

The ripple effects of neglected wear can be measured in increased energy bills, higher maintenance costs for associated components, reduced output quality, and greater safety risks. For instance, in a metal shredder, a worn blade can cause uncrushable materials to put immense stress on the shafts and anvil bars, potentially leading to catastrophic failure. Therefore, a comprehensive analysis of wear impact is the first step toward implementing a proactive and cost-effective maintenance strategy.

Direct Impact of Wear on Shredding Efficiency and Precision

The most immediate effect of blade wear is a decline in shredding efficiency and output precision. Sharp blades in a single-shaft paper shredder create clean, consistent confetti-like particles ideal for secure destruction and compact baling. As these cutting blades dull, they produce more dust and uneven shreds, compromising security and increasing the load on the dust extraction system. Similarly, in plastic recycling, the precision of the cut directly influences the quality of the regrind.

Precision is equally critical in an e-waste four-shaft shredder, where the goal is to liberate different materials for separation. Worn blades may fail to break apart composite materials cleanly, leaving metals embedded in plastics. This reduces the purity and thus the market value of the separated materials. Studies have shown that a 20% reduction in blade sharpness can lead to a 15% drop in material purity after separation, directly impacting the profitability of the recycling operation by yielding lower-grade commodities.

The Impact of Wear on Energy Consumption and Operating Costs

Dull blades require significantly more energy to achieve the same shredding task, making energy consumption a key performance indicator for blade health. A shredder's motor must work harder to force material against blunted edges, drawing more electrical current. For a large hammer mill shredder, this can translate to a measurable increase in power usage. Data from operational facilities indicates that operating with worn blades can increase energy consumption by 8% to 12%, a substantial cost over time for a machine that may run 20 hours a day.

This increased energy draw also creates more heat, straining the shredder's cooling system and potentially reducing the lifespan of electrical components. The financial impact is twofold: higher direct electricity costs and increased indirect costs from accelerated wear on the drive system, including the gearbox and motor. Therefore, maintaining sharp blades is not just a maintenance issue but a direct energy conservation and cost-saving strategy.

The Impact of Wear on Equipment Lifespan and Maintenance Costs

Blade wear acts as a catalyst for the wear of other expensive components. In a double shaft tire shredder, unbalanced wear on one set of cutter blades can create violent vibrations that are transmitted through the entire machine. These vibrations place abnormal stress on bearings, seals, the shredder shaft, and even the structural frame, leading to premature failure of these components. The cost of replacing a set of bearings and a shaft can be many times greater than the cost of a proactive blade replacement.

The cumulative effect on the machine's lifespan is significant. A shredder that is consistently operated with sharp, well-maintained blades and proper lubrication may operate reliably for decades. In contrast, one subjected to the constant stress of dull blades may require major overhauls years earlier. The maintenance costs shift from predictable, planned expenses for consumable blades to unpredictable, costly repairs of core components, disrupting budgets and production schedules.

The Impact of Wear on Safety Performance

Safety is the paramount concern in any industrial setting, and blade wear introduces several critical hazards. Dull blades increase the likelihood of material jamming or rebounding. In a disc wood chipper, a dull blade can fail to cleanly cut a branch, causing it to be pulled in and then violently thrown back out by the rotor—a phenomenon known as kickback. Modern equipment incorporates kickback prevention devices, but blade sharpness remains a first line of defense.

Furthermore, excessive wear can lead to catastrophic mechanical failure. A severely worn or cracked blade in a high-torque metal shredder can shatter, turning metal fragments into high-velocity projectiles that could breach the machine's housing. This risk underscores the necessity of robust safety and containment systems and a rigorous wear monitoring protocol. Preventing such failures through predictive maintenance is not only economically sound but also a fundamental ethical responsibility to protect workers.