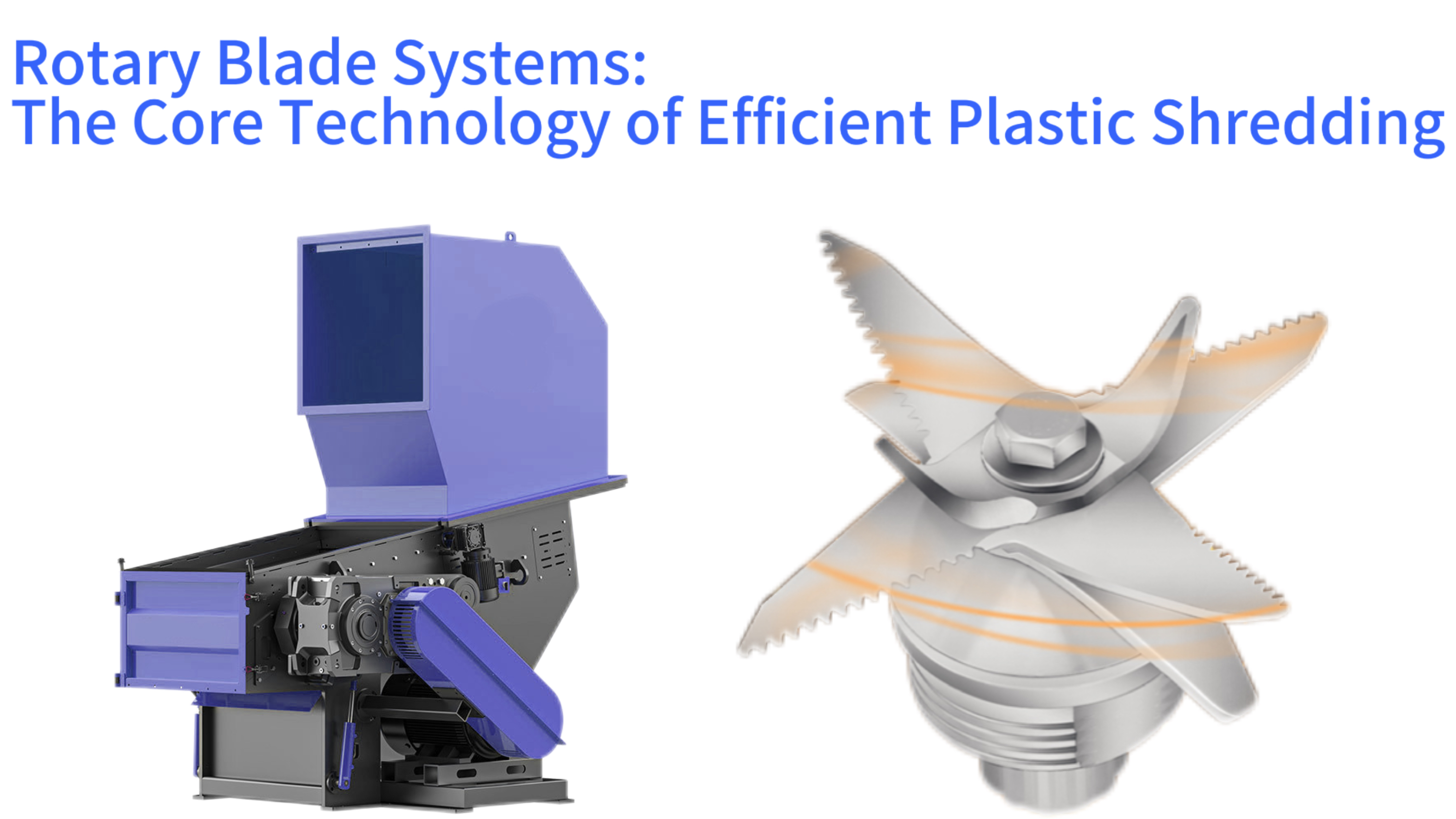

Rotary blade systems represent a revolutionary advancement in plastic shredding technology, serving as the fundamental mechanism that drives modern recycling processes. These sophisticated cutting systems transform plastic waste into uniform granules through precise engineering principles, enabling efficient material recovery and supporting circular economy initiatives. This comprehensive guide explores how innovative blade designs, advanced materials, and intelligent control systems work together to optimize shredding performance across various plastic types and applications.

Technical Principles and Core Advantages

Rotary blade systems operate through a combination of shear and tear forces that systematically reduce plastic materials into controlled particle sizes. Unlike traditional crushing methods that rely primarily on impact forces, these systems utilize precisely engineered cutting angles and overlapping blade patterns to achieve clean, consistent fragmentation. The modular design allows for quick adaptation to different material characteristics, from brittle thermosets to flexible elastomers.

The efficiency of modern rotary systems stems from their ability to maintain optimal cutting conditions regardless of material variations. Advanced torque control mechanisms automatically adjust rotational speed and force application based on real-time resistance monitoring. This dynamic response capability ensures consistent particle size distribution while preventing energy waste during operation. The integration of these technologies has significantly improved the granulation process in plastic recycling operations worldwide.

Synergistic Force Application Mechanisms

Blade angle geometry plays a crucial role in determining final particle characteristics. Steeper angles generate greater shearing action for clean cuts, while shallower angles promote tearing for fibrous materials. Modern systems automatically adjust these angles during operation to accommodate mixed material streams.

Dynamic torque management systems monitor resistance levels 1,000 times per second, making micro-adjustments to maintain optimal cutting conditions. This precision prevents motor overload while ensuring consistent particle size distribution across varying material batches.

Wear-Resistant Material Innovations

High-chromium alloy blades maintain cutting sharpness through extended operation periods, resisting the abrasive effects of filled plastics and composite materials. These alloys demonstrate three times the wear resistance of conventional tool steels in standardized testing.

Laser cladding technology applies micron-thin tungsten carbide layers to cutting edges, increasing surface hardness to 70 HRC while maintaining substrate toughness. Temperature-controlled hardening processes prevent structural deformation during manufacturing, ensuring dimensional stability under operational stresses.

Energy Efficiency Optimization

Power consumption correlates directly with material throughput in well-designed systems. Modern shredders achieve linear energy relationships where 30kW motors typically process 800-1,000 kg/hour of rigid plastics, with efficiency improvements of 15% over previous generations.

Smart acceleration algorithms minimize energy waste during startup and idle periods. Variable frequency drives reduce no-load consumption by up to 40% compared to fixed-speed systems, while automatic shutdown features activate during extended pauses.

Safety Protection Systems

Dual-circuit emergency stop systems provide redundant protection against operational hazards. Primary electronic brakes halt blade rotation within 2 seconds, while mechanical backup systems engage if electrical systems fail.

Explosion suppression systems detect pressure waves indicative of dust ignition, deploying inerting agents within milliseconds to prevent catastrophic events. Quick-lock blade change mechanisms enable safe maintenance without specialized tools, reducing downtime during routine service.

Material Adaptability Research

Plastic shredding systems must accommodate tremendous material diversity, from flexible packaging films to rigid engineering resins. Each material category presents unique challenges that require specialized processing approaches. Understanding these material characteristics enables proper system configuration and operational parameter selection.

Polyolefins like PE and PP require different handling than brittle materials such as PS or filled composites. Modern shredders automatically detect material types through power consumption patterns and adjust accordingly. This adaptability is particularly valuable for high-toughness materials that traditionally challenged conventional equipment.

Thermoplastic Processing Characteristics

Polyethylene's tendency to deform rather than fracture requires specially designed cutting geometries that prevent material wrapping around shafts. Cryogenic assistance systems cool certain materials below their glass transition temperatures to induce brittle behavior for cleaner fragmentation.

PET crystallization control maintains optimal molecular structure during shredding, preserving material properties for subsequent reprocessing. Crystalline content monitoring ensures consistent quality in recycled flakes for food-grade applications.

Elastomer Processing Solutions

Rubber materials present exceptional challenges due to their elastic recovery and abrasion resistance. Special anti-wrapping designs incorporate staggered blade arrangements and fixed counter-knives that prevent material accumulation around rotating components.

Silicone products require pre-treatment to reduce tackiness before shredding. Dedusting systems remove separating powders after processing, ensuring clean output material. TPU materials benefit from heated cutting chambers that reduce elasticity during size reduction.

Composite Material Separation

Fiber-reinforced plastics undergo progressive size reduction that separates matrix materials from reinforcement fibers. Multi-stage systems first liberate components through coarse shredding, then refine materials to target specifications.

Carbon fiber composites require controlled cutting conditions that preserve fiber length for value recovery. Orientation-specific shearing maximizes fiber liberation while minimizing energy consumption. Co-extruded materials utilize differential cutting speeds to delaminate layers without contamination.

Microplastic Pollution Prevention

Particle classification systems separate fines from primary output streams using air separation and vibrating screens. Electrostatic precipitators capture airborne particles down to 2 microns, preventing environmental release.

Closed-loop material handling systems maintain negative pressure to contain dust during transfer operations. Multi-stage filtration ensures operational emissions remain well below regulatory thresholds for particulate matter.

System Integration and Intelligent Upgrades

Modern shredding systems incorporate comprehensive monitoring networks that optimize performance through data-driven decisions. IoT connectivity enables real-time parameter adjustment based on material conditions, while predictive maintenance algorithms prevent unexpected downtime.

Digital twin technology creates virtual replicas of physical systems for operational testing and optimization. These simulations accurately predict performance under various conditions, allowing engineers to refine processes before implementation. The integration of these technologies has transformed control systems in plastic recycling operations.

Intelligent Sensor Networks

Vibration monitoring arrays detect abnormal patterns indicating bearing wear or blade imbalance weeks before failures occur. Thermal sensors track temperature gradients across critical components, identifying developing issues through heat pattern analysis.

Current monitoring systems establish baseline power consumption profiles, flagging deviations that suggest material changes or mechanical problems. These systems typically employ 12-16 monitoring points throughout the shredding assembly.

Adaptive Control Algorithms

Material recognition systems analyze power consumption signatures to automatically adjust operational parameters. Machine learning algorithms continuously refine these adjustments based on historical performance data.

Energy consumption models dynamically update based on real-time efficiency calculations, identifying optimal operating points for current material conditions. Fault pattern recognition trains systems to anticipate and prevent recurring issues.

Remote Maintenance Platforms

Equipment health scoring systems quantify overall condition through weighted analysis of multiple parameters. These scores trigger maintenance alerts when predetermined thresholds are exceeded, prioritizing interventions based on urgency.

Component life prediction algorithms calculate remaining useful life for wear parts based on operational history and current conditions. Augmented reality interfaces overlay repair instructions onto physical equipment during maintenance procedures.

Sustainability Tracking Integration

Blockchain-based energy recording creates tamper-proof records of power consumption for carbon accounting purposes. Material tracing systems document processing history from input to output, enabling verified recycled content claims.

Automated ESG reporting compiles operational data into standardized sustainability formats, reducing administrative burden while improving reporting accuracy. These systems typically integrate with enterprise resource planning platforms for comprehensive data management.

Typical Application Scenarios and Case Studies

Rotary blade systems serve diverse applications across the plastics recycling industry, each requiring specific configurations and operational approaches. From post-consumer packaging to industrial scrap, these systems adapt to various material streams and production requirements.

Automotive recycling operations demonstrate particularly advanced applications, where systems must handle mixed material components containing metals, fabrics, and multiple plastic types. Electronic waste processing presents additional challenges regarding material separation and hazardous component management. These applications highlight the versatility of separation technology in complex recycling scenarios.

Packaging Material Recycling Systems

Film materials require specialized feeding systems that prevent material wrapping and ensure consistent throughput. Tension control mechanisms maintain proper web handling through the cutting chamber, while anti-static systems prevent charge buildup.

Rigid container processing utilizes pre-breakage systems that reduce whole containers into manageable pieces before fine shredding. Color-sorting systems often integrate with shredding lines to separate materials by polymer type and color before size reduction.

Automotive Manufacturing Waste Processing

Bumper recycling involves multi-stage size reduction that separates painting layers from substrate materials. Hydrocyclone systems often follow shredding operations to separate materials based on density differences.

Seat material processing requires fiber liberation from foam matrices through controlled tearing actions. Metal detection systems automatically stop processing when detecting frame components, preventing damage to cutting elements.

Electronic Waste Processing Solutions

Printer housing processing incorporates de-inking systems that remove surface coatings during shredding. Waterless cleaning methods use friction-based surface treatment to prepare materials for reprocessing.

Circuit board shredding requires specialized containment systems to capture precious metals while preventing hazardous material release. Dedicated filtration systems manage brominated flame retardant emissions during processing.

Construction Template Recycling

Wood-plastic composite separation utilizes differential shredding techniques that liberate components without excessive fiber damage. Water-free cleaning systems use air classification and friction washing to remove contaminants.

Template residue processing involves precise cutting conditions that preserve material properties for reuse in similar applications. Homogenization systems ensure consistent particle size distribution for extrusion and molding applications.

Future Technology Development Trends

Shredding technology continues evolving toward finer particle control, improved energy efficiency, and expanded material capabilities. Emerging applications in extreme environments and advanced materials present new challenges that drive innovation in blade design and system integration.

Nanotechnology applications enable particle size reduction previously achievable only through chemical processes. Biological material handling requires developing new approaches that preserve molecular structures during mechanical processing. These advancements will redefine composite material processing in coming decades.

Ultra-Fine Shredding Technology

Sub-millimeter particle control requires revolutionary blade designs that operate at microscopic clearances. Cryogenic assistance systems enable brittle fracture mode for materials that normally exhibit ductile behavior.

Nanoscale dispersion systems integrate surface modification during size reduction, creating functionalized materials ready for composite applications. These systems typically operate in inert atmospheres to prevent oxidation during processing.

Bio-Based Plastic Processing

PLA hydrolysis control maintains molecular weight during shredding through precise temperature and humidity management. Advanced drying systems remove crystallization water without causing material degradation.

PHA processing requires specialized handling to prevent thermal degradation during size reduction. Modified blade geometries reduce cutting forces that typically cause temperature spikes in biological materials.

Extreme Environment Applications

Deep-sea mining operations utilize pressure-compensated shredding systems that process plastic waste at depth. Corrosion-resistant materials and special seals enable operation in high-pressure saline environments.

Polar research stations employ cold-weather shredders that operate reliably at -50°C. Heating systems prevent material embrittlement while maintaining flexibility in cutting components.

Circular Economy Integration

Plastic bank systems interface with shredding equipment to automatically track and credit processed materials. Blockchain integration creates immutable records of material recovery for carbon credit calculations.

Carbon market data systems automatically calculate emission reductions achieved through recycling activities. These systems typically integrate with international carbon trading platforms for seamless credit monetization.

Equipment Selection and Maintenance Optimization

Proper shredder selection requires careful consideration of material characteristics, production requirements, and operational constraints. Maintenance planning significantly impacts total operating costs and equipment longevity, making proactive strategies essential for economic operation.

Capacity matching ensures equipment size appropriate for expected material volumes without excessive capital investment. Lifecycle cost analysis helps identify the most economical solutions considering energy consumption, maintenance requirements, and expected service life. These considerations are particularly important for hydraulic systems that power modern shredding equipment.

Capacity Matching Parameters

Feed rate calculations consider material bulk density, particle size, and flow characteristics to determine optimal throughput rates. Screen size selection directly influences final particle size and system capacity, requiring careful matching to application requirements.

Motor power requirements depend on material hardness, toughness, and desired reduction ratio. Empirical models typically recommend 0.5-1.5 kW per kg/hour capacity depending on material characteristics and desired particle size.

Blade Life Prediction Models

Three-dimensional scanning technology measures wear patterns with micron-level accuracy, predicting remaining useful life based on historical wear rates. Neural network algorithms incorporate operational data to refine these predictions over time.

Dynamic replacement scheduling adjusts maintenance intervals based on actual usage conditions rather than fixed time periods. Automated ordering systems trigger spare part requests when inventory levels approach minimum thresholds.

Lubrication System Optimization

Dry lubrication technologies eliminate oil contamination risks in plastic processing applications. Solid film lubricants provide protection in high-temperature environments where conventional oils would degrade.

Lubricant selection matrices consider operating temperatures, speeds, and environmental conditions to identify optimal products for specific applications. Automated lubrication systems deliver precise amounts at predetermined intervals, reducing consumption while improving reliability.

Spare Parts Management

RFID tracking enables real-time inventory management of critical components. Automated reordering systems maintain optimal stock levels based on consumption patterns and lead times.

Blockchain-based maintenance records create tamper-proof service histories for equipment valuation and warranty purposes. Supplier performance monitoring ensures consistent quality and delivery reliability for critical components.