The Technical Role of Double Shaft Shredders in RDF Production

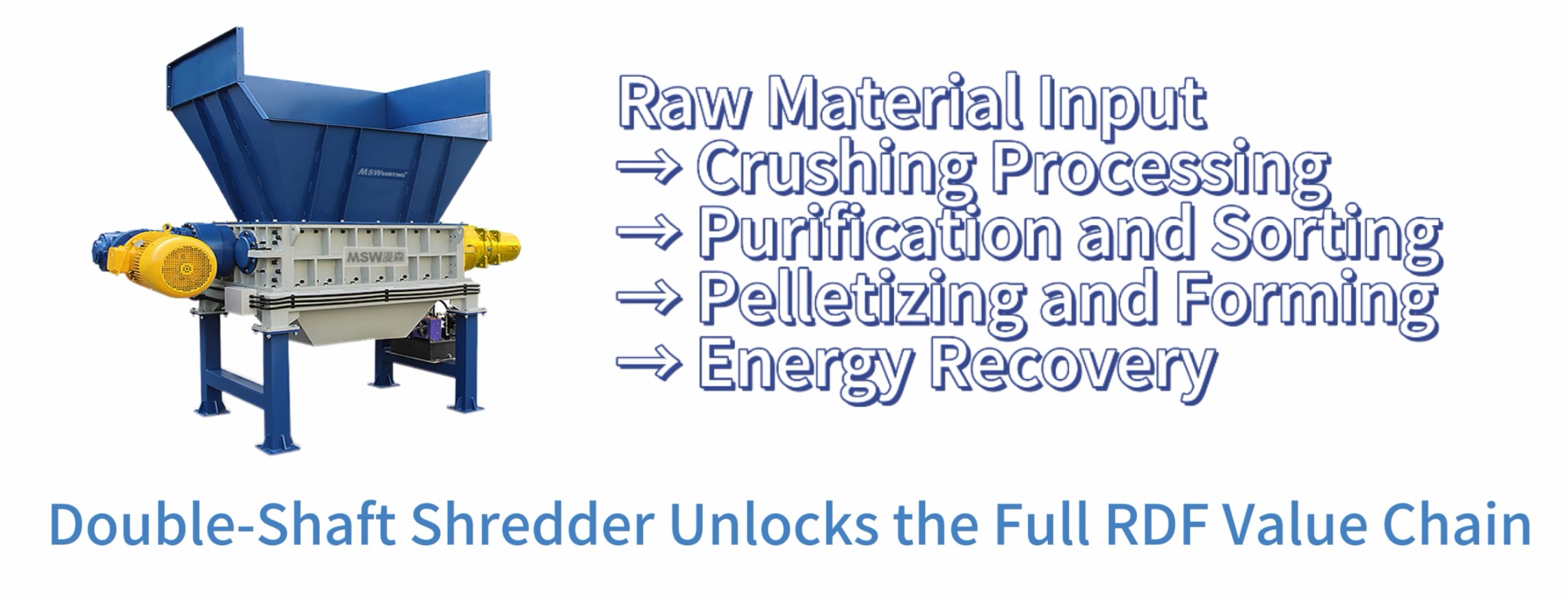

Double shaft shredders play a pivotal role in RDF (Refuse Derived Fuel) production, acting as the critical link between raw waste processing and high-quality fuel pelletizing. Their core strength lies in the synergy between shear-based shredding and precise particle size control. Unlike other crushing machines, double shaft shredders use interlocking blades that tear and cut materials simultaneously, ensuring consistent particle sizes that are essential for efficient pellet formation. This dual action not only reduces waste volume by up to 70% but also prepares materials with the right texture to bind well during pelleting, directly impacting the final RDF’s combustion efficiency.

When comparing shredder types, double shaft models stand out for RDF production due to their versatility. Single shaft shredders, while effective for softer materials, struggle with mixed waste streams common in RDF feedstock. Four shaft shredders offer finer control but come with higher energy consumption. Double shaft shredders strike a balance: they handle diverse materials—from plastic films to wood scraps—with lower energy use than four shaft units and better durability than single shaft designs. This makes them the optimal choice for facilities aiming to process 5 to 50 tons of waste per hour into RDF.

Integration with upstream and downstream equipment is another key technical advantage. Double shaft shredders seamlessly connect with magnetic separators to remove metal contaminants, ensuring RDF purity. They also pair with air density separators to segregate light materials like paper from heavier components, refining the feedstock. This integration creates a continuous workflow, minimizing downtime and maximizing throughput.

Modern double shaft shredders also feature advanced data connectivity, using protocols compatible with DCS (Distributed Control Systems). This allows real-time monitoring of shredding parameters—such as blade speed and torque—enabling operators to adjust settings remotely for optimal performance. For example, if the system detects an increase in torque due to harder materials, it can automatically slow the blades to prevent damage, ensuring consistent operation and reducing maintenance needs.

Key Parameters in Crushing Chamber Design

The design of the crushing chamber directly influences a double shaft shredder’s efficiency in RDF production. One critical parameter is the number and arrangement of moving blades. Most models use a spiral layout, where blades are staggered along the shafts to ensure even material engagement. This design prevents material buildup and ensures each particle undergoes multiple cuts, resulting in uniform particle sizes—typically between 20 to 50 mm, ideal for RDF pelleting.

Fixed blade thickness and material choice are equally important. Fixed blades (or counter knives) are often made from hardened steel with a wear-resistant coating, such as tungsten carbide, to withstand abrasive materials like glass or concrete fragments in mixed waste. A thickness of 10 to 15 mm balances durability and cutting efficiency; thinner blades wear faster, while thicker ones increase energy consumption by creating more resistance.

Screen mesh size is the primary driver of final particle size. For RDF production, mesh diameters range from 15 to 40 mm, with the choice depending on the desired pellet size. A 20 mm mesh, for instance, produces particles that bind well during pelleting and burn evenly in boilers. Operators can swap out screens to adjust particle size, allowing flexibility for different RDF specifications—from coarse pellets for industrial boilers to finer ones for co-firing in cement kilns.

The pusher plate, which feeds material into the crushing chamber, uses adjustable pressure to handle varying waste densities. For loose materials like cardboard, lower pressure (5 to 10 bar) prevents jamming, while compacted waste (such as bales of plastic) requires higher pressure (15 to 25 bar) to ensure consistent feeding. This adjustability ensures the shredder maintains steady throughput regardless of input material characteristics.

Power System Configuration Strategies

Matching motor power to shredding capacity is foundational for efficient operation. For double shaft shredders processing RDF feedstock, motor power typically ranges from 30 to 200 kW. A general rule is 1 kW per 0.1 to 0.3 tons of hourly capacity—for example, a 50 kW motor handles 5 to 15 tons/hour. Oversized motors waste energy, while undersized ones lead to frequent overloads and increased wear, making this calculation critical for cost and performance.

Hydraulic drive systems add a layer of protection against overloads. These systems use pressure sensors to detect when the shredder encounters unshreddable objects (like rocks) and automatically retract the pusher plate, reducing pressure on the blades. This not only prevents blade damage but also minimizes downtime, as operators don’t need to manually clear jams. Hydraulic systems also allow smooth adjustments to feeding speed, adapting to material density changes in real time.

Variable frequency drives (VFDs) are essential for managing capacity fluctuations. By adjusting motor speed—typically between 50 to 150 RPM—VFDs let operators match shredding speed to material input. For example, when processing tough materials like rubber, slowing the blades to 80 RPM increases torque, ensuring effective cutting without straining the motor. Conversely, for soft materials like paper, speeds can rise to 120 RPM to boost throughput. This flexibility optimizes energy use, reducing operational costs by up to 15% compared to fixed-speed systems.

Dual motor synchronization is a advanced feature in larger double shaft shredders. By linking two motors to drive the parallel shafts, manufacturers ensure balanced torque distribution, preventing uneven wear on blades and gears. Synchronization is achieved via precision gearboxes and sensors that monitor shaft speed differences; if one shaft lags by more than 2 RPM, the system adjusts power input to balance them. This technology extends equipment life and maintains consistent particle size, critical for RDF quality.

Precision Control in Front-End Shredding Processes

Front-end shredding sets the foundation for high-quality RDF, making precision control essential at this stage. Raw waste often contains contaminants—such as rocks, metals, or wet organic matter—that can disrupt shredding and reduce RDF value. Preprocessing steps, like manual sorting stations or automated optical sorters, remove these contaminants before they reach the shredder. Homogenization is equally important: mixing different waste types (plastics, paper, wood) ensures consistent shredding, preventing uneven particle sizes that can hinder pelleting.

Feeding methods significantly impact shredder efficiency. Automatic feeding systems, using conveyor belts with level sensors, maintain a steady material flow into the shredder, preventing overloads or underfeeding. This consistency reduces energy spikes and blade wear, making automatic systems ideal for large-scale operations (10+ tons/hour). Manual feeding, while cheaper to install, leads to irregular input, increasing the risk of jams and inconsistent particle sizes. For small facilities, a hybrid approach—manual loading into a hopper with automatic feeding—strikes a balance between cost and performance.

Shredding rhythms, whether continuous or intermittent, depend on downstream processes. Continuous operation suits facilities with constant pelleting, using buffer hoppers to store shredded material and maintain a steady feed to pelletizers. Intermittent operation, where the shredder runs in batches, works better for smaller plants or when processing variable waste streams. Batch processing allows operators to adjust settings between runs—for example, changing screen sizes for different waste types—ensuring each batch meets RDF specifications.

Particle size distribution is a critical output of front-end shredding. A normal distribution (most particles clustered around a target size) is ideal for RDF, as it ensures uniform burning and pelleting. Achieving this requires precise control of blade speed, screen size, and feeding rate. In contrast, a skewed distribution—with too many fine or coarse particles—can lead to uneven pellet hardness or excessive dust in storage. Shredders with adjustable settings let operators tweak these variables, ensuring the desired distribution for their specific RDF application, whether for industrial boilers or cement kilns.

Solutions for Specialized Materials

High-humidity materials, such as food waste or wet cardboard, pose unique challenges in shredding due to their tendency to clump and stick to blades. To address this, some double shaft shredders integrate steam preprocessing: injecting low-pressure steam (100–120°C) into the feed hopper softens fibers and reduces surface moisture, preventing clumping. Alternatively, heated shredder chambers—maintained at 40–50°C—evaporate surface moisture during shredding, keeping blades clean. These technologies reduce jams by up to 30% in humid waste streams, maintaining consistent throughput.

Shredding flammable materials—like paint-soaked wood or solvent-contaminated plastics—requires strict safety measures to prevent fires or explosions. Shredders handling these materials must meet ATEX certification standards, which govern equipment for explosive atmospheres. Key features include spark detection systems that activate water sprays at the first sign of ignition, and inert gas purging (using nitrogen) to reduce oxygen levels in the crushing chamber. Non-sparking blades, made from brass or bronze alloys, further minimize ignition risks, ensuring safe processing of flammable feedstock.

Fibrous materials, such as textile scraps or coconut husks, often wrap around shredder blades, causing jams and reducing efficiency. To combat this, manufacturers design double shaft shredders with reverse-rotation blades: one shaft spins clockwise, the other counterclockwise, creating a shearing action that cuts fibers instead of wrapping them. Some models also include "cleaner blades"—smaller blades mounted perpendicular to the main shafts—that slice through wrapped fibers, keeping the main blades free. These designs reduce downtime for manual cleaning by up to 50% when processing fibrous waste.

Hard materials, like ceramic fragments or thick plastic pipes, accelerate blade wear in standard shredders. For these applications, specialized blade materials and designs are critical. Blades made from H13 tool steel, known for high wear resistance, last 2–3 times longer than standard steel blades when processing hard materials. Reinforced blade edges, with tungsten carbide inserts, further extend life. Additionally, adjusting shredder settings—slower blade speed and higher torque—reduces impact forces on blades, minimizing chipping and wear. These adaptations ensure consistent performance even with abrasive feedstock, maintaining RDF production schedules.

Applications of Intelligent Monitoring Systems

Intelligent monitoring systems are transforming shredder maintenance, starting with real-time blade wear detection. Acoustic emission sensors mounted on the crushing chamber analyze sound waves generated during shredding; changes in frequency indicate blade dulling or damage. For example, a sharp blade produces high-frequency sounds, while a dull blade creates lower frequencies. By tracking these changes, the system alerts operators to replace blades before they fail, reducing unplanned downtime by up to 40% compared to scheduled maintenance alone.

Early warning algorithms are another core function of intelligent systems. These algorithms analyze changes in motor current, torque, and feed rate, identifying patterns that may cause overloads. For example, if the feed volume suddenly increases while the torque rises by 20%, the system will automatically slow down the feeding speed or temporarily stop feeding to prevent the motor from overloading. By predicting these fluctuations, the system reduces downtime by 25% and extends the life of the motor and gearbox. Operators can also view load trends through the HMI interface, optimizing feed scheduling and further improving efficiency.

Energy consumption data collection is essential for optimizing operational costs. Intelligent systems track kWh usage per ton of shredded material, identifying inefficiencies like excessive idle time or overfeeding. For example, data might reveal that the shredder uses 20% more energy during morning shifts, prompting adjustments to feeding rates or maintenance schedules. By linking energy data to production KPIs (如 tons processed per hour), facilities can set benchmarks and reward teams for meeting efficiency targets, driving continuous improvement.

Remote diagnostic platforms enable experts to support multiple facilities from a central location. These platforms use cloud connectivity to collect real-time data—including sensor readings, error codes, and performance metrics—from shredders worldwide. If a facility encounters an issue, technicians can access the platform to review data, run simulations, and guide on-site staff through repairs. This reduces the need for expensive on-site visits and cuts troubleshooting time from days to hours. Some platforms even use machine learning to predict failures, suggesting proactive maintenance before issues arise.

Technical Positioning of Double Shaft Shredders in RDF Production

Double shaft shredders play a core role in RDF (Refuse Derived Fuel) production, with their technical value rooted in the synergistic mechanism of shear crushing and particle size control. Unlike simple crushing equipment, they use two intermeshing shafts with rotating blades to apply shear and tearing forces, breaking down complex waste materials into uniform particles. This not only reduces the volume of raw waste by 60-80% but also ensures the particle size distribution meets the strict requirements of subsequent RDF pelletizing—typically 20-50mm, which balances pellet forming efficiency and combustion performance.

When comparing different types of shredders, double shaft models stand out in RDF production. Single shaft shredders, relying on a single rotating shaft with fixed blades, struggle with tough or mixed waste streams, often causing jams. Four shaft shredders offer finer particle control but come with higher energy consumption and maintenance costs. Double shaft shredders, however, strike a perfect balance: they handle diverse materials (plastics, paper, wood, and municipal solid waste) efficiently, with lower energy use than four shaft units and better durability than single shaft designs, making them ideal for medium to large-scale RDF production lines.

Process integration is another key technical advantage. Double shaft shredders seamlessly connect with magnetic separators to remove ferrous metals, ensuring RDF purity and avoiding damage to downstream pelletizing equipment. They also integrate with air density separators to separate light materials (like foam) from heavy ones, optimizing the calorific value of the feedstock. This integrated design creates a continuous workflow, minimizing manual intervention and maximizing production efficiency.

Modern double shaft shredders also feature advanced data interfaces, supporting communication protocols compatible with DCS (Distributed Control Systems). This allows real-time monitoring of key parameters such as blade speed, torque, and throughput, enabling remote adjustments to maintain optimal performance. For example, if the system detects an increase in torque due to harder materials, it can automatically adjust the feed rate or blade speed, preventing overloads and ensuring consistent particle size output.

Key Parameters in Crushing Chamber Design

The design of the crushing chamber directly impacts the efficiency and output quality of a double shaft shredder. One critical parameter is the number and arrangement of moving blades. Most models use a spiral layout, where blades are staggered along the two parallel shafts to ensure continuous material engagement. For example, a 1.5-meter-long shaft might feature 12-15 blades arranged in a spiral, each offset by 30 degrees from the previous one. This design prevents material buildup and ensures each particle undergoes multiple cuts, resulting in uniform particle sizes essential for RDF pelletizing.

Fixed blade thickness and wear-resistant material selection are equally important. Fixed blades (or counter blades) are typically 10-15mm thick, with wear-resistant coatings such as tungsten carbide to withstand abrasive materials. For processing high-abrasion waste (like glass-contaminated MSW), manufacturers use hardened steel (e.g., H13) for fixed blades, extending their lifespan to 1,000-1,500 operating hours—twice that of standard steel blades. The choice of material balances durability and cost, ensuring long-term performance without excessive expense.

Screen mesh size and its relationship to crushed particle size are critical for meeting RDF specifications. The mesh acts as a sieve, allowing only particles smaller than the mesh diameter to exit the chamber. For RDF production, mesh sizes range from 15mm to 40mm: 15-25mm for fine pellets used in small boilers, and 25-40mm for coarser pellets for cement kilns. This direct mapping ensures consistent particle size, which is vital for uniform combustion and pelletizing efficiency. Operators can quickly swap out screens to adjust particle size, adapting to different RDF requirements.

Pusher plate pressure adjustment range is key to handling varying material densities. The pusher plate forces material into the rotating blades, with pressure ranging from 5-30 bar depending on the material. For light materials like foam or paper, 5-10 bar is sufficient to prevent jamming. For dense materials like compacted plastic bales, 20-30 bar ensures effective feeding. Modern shredders feature hydraulic systems with adjustable pressure settings, allowing operators to fine-tune pressure based on real-time material conditions, optimizing throughput and reducing energy use.

Power System Configuration Strategies

Matching motor power to shredding capacity is fundamental for efficient operation. The general formula is: motor power (kW) = 0.5-1.0 × hourly capacity (tons/hour). For example, a shredder processing 10 tons/hour requires a 5-10kW motor, while a 50-ton/hour unit needs 25-50kW. This ensures the motor has enough power to handle the load without excessive energy consumption. Oversized motors waste energy during light loads, while undersized motors struggle with heavy loads, leading to overheating and premature failure.

Hydraulic drive systems provide critical overload protection. These systems use pressure relief valves to detect when the shredder encounters unshreddable objects (e.g., rocks or metal chunks). When pressure exceeds a set threshold (typically 30-40 bar), the valve opens, redirecting hydraulic fluid to retract the pusher plate and stop material feeding. This prevents damage to blades and motors, reducing repair costs by 30-50% compared to shredders without hydraulic protection. The system resets automatically once the obstruction is removed, minimizing downtime.

Variable frequency drives (VFDs) optimize energy use during capacity fluctuations. VFDs adjust motor speed (50-150 RPM) based on material input, reducing energy consumption by 10-15% compared to fixed-speed motors. For example, during peak hours with high material flow, the VFD increases speed to 120-150 RPM to boost throughput. During off-peak times with lighter loads, it slows to 50-80 RPM, saving energy. This flexibility also reduces mechanical stress on components, extending their lifespan by 20-25%.

Dual motor synchronization technology ensures balanced performance in large shredders. By connecting two motors to drive the parallel shafts, manufacturers distribute torque evenly, preventing uneven wear on blades and gears. Synchronization is maintained via precision sensors that monitor shaft speed differences; if one shaft lags by more than 2 RPM, the system adjusts power to the motors to balance them. This technology is critical for shredders processing 20+ tons/hour, ensuring consistent particle size and extending equipment life by 30% compared to single-motor designs.