“A single unshredded hard drive can cost companies $4.45 million in data breaches.” This striking statistic, reported by IBM's 2024 report, highlights just how high the stakes of data security have become. In an age where sensitive information is stored across physical and digital media, the failure to completely destroy data-bearing devices poses serious financial and reputational risks.

Conventional data disposal methods such as file deletion or degaussing are no longer sufficient. Deleted files can often be recovered using forensic tools, and magnetic erasure does not affect non-magnetic storage like SSDs or optical media. These limitations leave organizations exposed to potential data leaks long after devices are taken out of service.

Industrial shredders offer a definitive solution. By physically destroying the media—grinding hard drives, slicing through SSDs, and pulverizing optical discs—shredders ensure that data cannot be reconstructed or retrieved. As the only truly irreversible method of destruction, shredding has become a critical final step in any secure data lifecycle.

Global Standards Overview

Industrial shredding follows strict international standards to ensure complete data destruction. Germany's DIN 66399 standard classifies shredding into different security levels, with P-7 representing the highest security through confetti-cut particles (smaller than 5mm²) compared to less secure strip-cut shredding (P-5 level). These specifications determine how thoroughly materials must be destroyed based on their sensitivity.

In the United States, the NSA/CSS 02-01 standard outlines specific requirements for destroying classified media, mandating physical destruction methods that prevent any possibility of data reconstruction. Meanwhile, NIST SP 800-88 provides comprehensive guidelines for media sanitization, helping organizations select appropriate destruction methods based on their security needs and risk assessments.

The consequences of non-compliance can be severe, as demonstrated by a major European bank that faced substantial fines after failing to meet shredding standards. Regulatory authorities discovered improperly destroyed hard drives containing customer financial data, leading to legal penalties and reputational damage. This case highlights why organizations must carefully follow established shredding protocols to protect sensitive information and maintain regulatory compliance.

How Industrial Shredders Achieve Absolute Destruction Technology Breakdown

Industrial shredders achieve complete material destruction through specialized engineering approaches. Shear shredders operate at slow speeds but generate immense torque, using interlocking blades to systematically dismantle hard drives and SSDs. This method ensures storage platters and chips are physically deformed beyond any possible data recovery, while preventing dangerous fragmentation of hazardous components.

Granulators take destruction to microscopic levels, reducing materials to particles smaller than 2mm to meet stringent P-7 security standards. These systems employ multi-stage processing with progressively finer cutting elements, achieving particle sizes that make reconstruction theoretically impossible even with advanced forensic techniques.

Security-focused features complement the mechanical destruction process. Tamper-proof digital logs automatically generate certified destruction records, complete with timestamps, serial numbers, and operator IDs. These audit trails provide legal documentation of compliance with data protection regulations and chain-of-custody requirements.

Advanced containment systems address the often-overlooked risk of data leakage through particulate matter. HEPA filtration systems capture and retain microscopic particles that might contain recoverable data fragments, while negative pressure chambers prevent airborne dispersal. Some high-security models even integrate particle melting systems to further neutralize any residual information-bearing materials.

Sector-Specific Applications Healthcare

Different industries rely on industrial shredders to meet their unique security and compliance needs. In healthcare, HIPAA regulations require the complete destruction of patient records and sensitive medical devices. Specialized medical shredders handle everything from paper charts to implanted devices, ensuring no patient data can be recovered while properly disposing of biohazard materials.

Financial institutions face strict PCI DSS requirements for destroying expired credit cards, decommissioned servers, and outdated backup tapes. High-security shredders in this sector often incorporate magnetic strip destruction verification and produce audit-ready certificates of destruction for regulatory compliance.

Government agencies use NSA-approved shredders that meet the most rigorous standards for classified materials. These machines undergo extensive testing to validate their ability to destroy documents, storage media, and even specialized materials like cryptographic devices beyond any possible recovery.

A particularly interesting application involves defense contractors shredding decommissioned drones. This process prevents potential adversaries from reverse engineering sensitive technology through physical reconstruction. Special drone shredders are designed to handle composite materials and electronic components simultaneously, ensuring complete technological obfuscation while allowing for proper material recycling.

Choosing the Right Shredder for Data Security

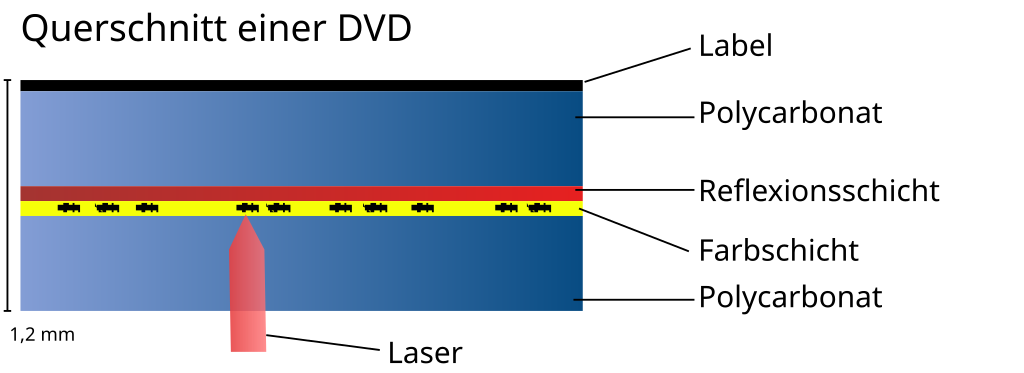

When selecting a shredder for data security, the type of material being destroyed plays a critical role. Hard drives, for instance, come with different platter compositions. Traditional aluminum platters are relatively easy to shear or crush, while newer ceramic-based platters are much harder and require specialized equipment to ensure complete destruction. Optical media such as CDs and DVDs also demand special attention. Because these discs store data on reflective surfaces, cross-cut shredding is essential to render the data irretrievable.

There is also a key trade-off between shredding capacity and the level of security achieved. High-volume shredders, such as those used by industrial vendors like Vecoplan, are designed to process massive amounts of material quickly and efficiently. These are ideal for bulk disposal but may use shredding patterns that are less secure. On the other end of the spectrum, ultra-secure single-pass units offer finer cuts and are often compliant with strict regulatory standards, but they typically process material at a slower rate. Organizations must balance throughput requirements with their need for assured data destruction.

Beyond Shredding: Integrated Security Protocols

To ensure secure material handling and maintain transparency in regulated industries, many shredding operations now use RFID-tagged bins. These bins are embedded with small radio-frequency identification chips that enable real-time tracking throughout the entire shredding process. This creates a verifiable chain of custody, allowing organizations to generate audit trails that prove when, where, and how sensitive materials were destroyed. This added layer of accountability is especially important for industries that handle confidential data or hazardous waste.

When it comes to material destruction, organizations must often choose between on-site and off-site shredding solutions. On-site shredding offers immediate destruction at the point of collection, reducing the risk of data leaks during transport and allowing clients to witness the process. However, it may require more investment in equipment and logistics. Off-site shredding, by contrast, allows for large-scale processing at centralized facilities, which can be more cost-effective but introduces more touchpoints where security breaches could occur. Each method has its advantages, depending on the sensitivity of the materials and the industry's regulatory requirements.

As technology evolves, so do the risks. One emerging threat is the possibility of “shredder reconstruction,” where advanced AI systems attempt to digitally piece together shredded documents or materials. Though this may sound like science fiction, early experiments have shown that machine learning can sometimes identify patterns in fragmented pieces. To counter this, modern shredding practices are being re-evaluated. Using cross-cut or particle-cut shredders, applying multiple destruction methods, or mixing materials during shredding are some strategies to make reconstruction significantly more difficult—even for sophisticated algorithms.

Future Trends in Secure Data Destruction

As regulatory demands grow and data threats evolve, the future of secure data destruction is becoming increasingly sophisticated. One emerging innovation is blockchain-verified shredding. By recording each destruction event on an immutable digital ledger, organizations can produce tamper-proof audit trails that satisfy even the most stringent compliance requirements. This level of transparency is especially valuable in industries such as finance, healthcare, and defense.

Another promising development is the integration of self-destructing media into the Internet of Things (IoT). Devices are being designed with embedded kill-switches or chemical agents that render onboard data unreadable when triggered. However, physical shredding remains the only failsafe. As IoT adoption expands, industrial shredders are being positioned as the final safeguard—capable of destroying legacy components that might otherwise escape secure disposal protocols.

Artificial intelligence is also transforming how shredding systems handle complex waste streams. Modern AI-powered shredders can now identify and prioritize sensitive materials—such as labeled hard drives or optical media—within mixed loads. This capability not only enhances data protection but also improves operational efficiency by automating what was once a highly manual sorting process.

To find out what kind of shredder you need, contact us! Our sales managers will be at your service.