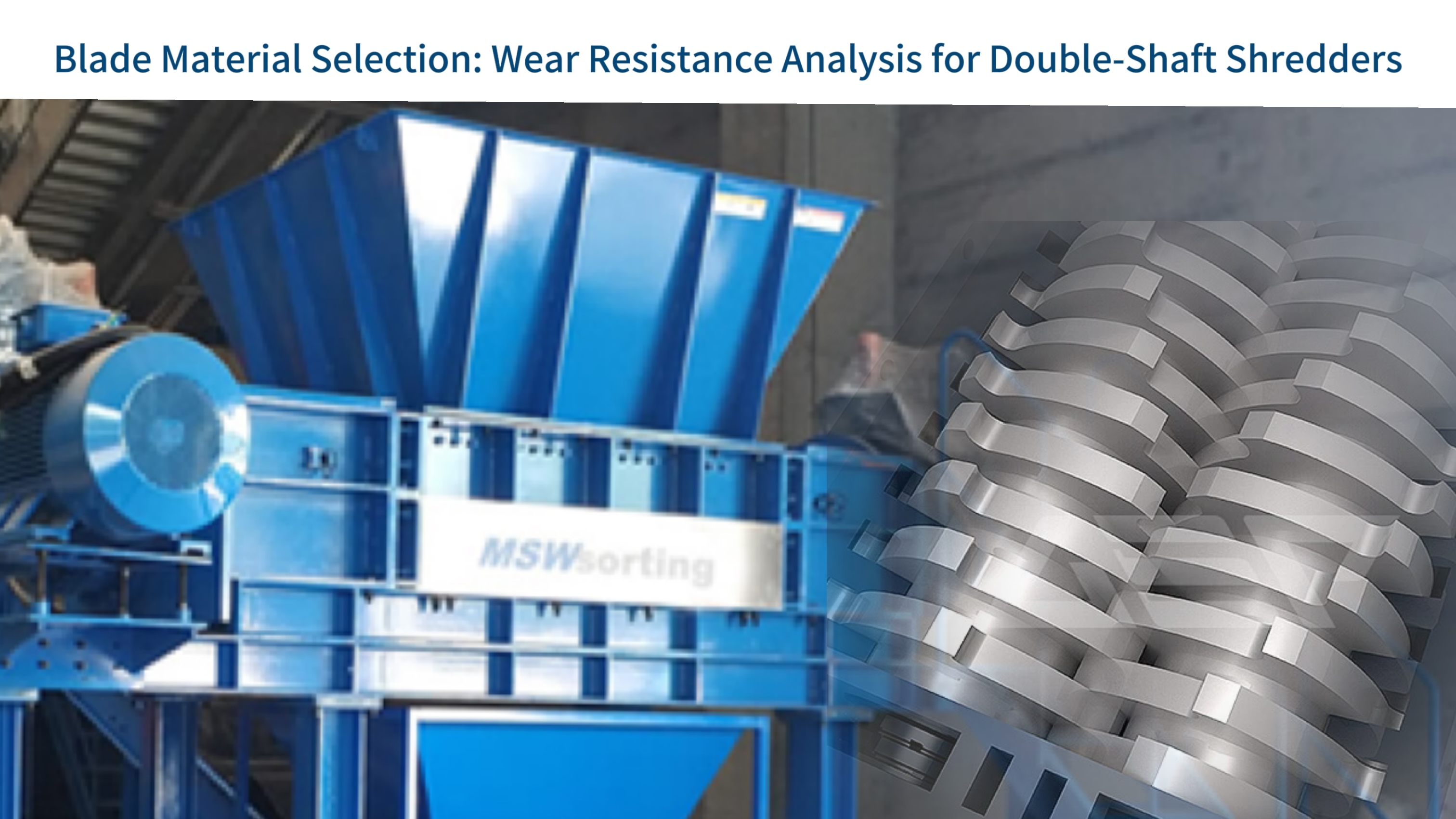

This article provides a comprehensive analysis of blade material selection for industrial double-shaft shredders, focusing on wear resistance optimization. Explore material science innovations, failure mechanism studies, and economic decision frameworks to extend blade lifespan and reduce operational costs. Essential reading for waste management engineers and recycling equipment specifiers.

Core Material Types for Shredder Blades

Industrial shredders rely on specialized blade materials to process diverse materials. Different compositions offer unique advantages for specific shredding challenges. Material scientists continuously develop new alloys to withstand extreme operational stresses encountered in recycling facilities.

Understanding material properties helps engineers select optimal blades. Key factors include wear resistance, impact toughness, and corrosion protection. Each material category serves distinct purposes in shredding operations across industries.

Work-Hardening Manganese Steel

Manganese steel blades become harder during shredding operations through unique crystal structure changes. When subjected to impact forces, the material's surface develops protective hardening layers. This self-strengthening property extends blade lifespan significantly.

The Hadfield steel variant contains 12-14% manganese, creating exceptional impact resistance. These blades perform best in applications involving mixed waste streams with unpredictable contaminants. Their ability to absorb energy makes them ideal for crushing reinforced materials.

Alloy Tool Steel Optimization

Grades like D2 and SKD11 contain precise chromium and molybdenum ratios that enhance durability. Through controlled heat treatment, metallurgists create balanced microstructures. This process maximizes carbide formation while maintaining structural integrity.

Recent innovations focus on vanadium additions that refine grain boundaries. The improved carbide distribution resists microfractures during metal shredding. Such blades demonstrate superior performance in continuous operations processing appliances and automotive scrap.

Powder Metallurgy Superiority

Powder-based manufacturing creates blades with uniform carbide distribution impossible in conventional casting. The process involves atomizing molten steel into fine droplets that solidify instantly. This prevents carbide clustering that weakens traditional alloys.

These blades feature microscopic carbide particles embedded throughout the steel matrix. When processing electronic waste containing circuit boards, they resist abrasive glass fibers better than conventional options. Their consistent performance justifies higher initial costs in demanding applications.

Hardness-Toughness Balancing Techniques

Blade engineers constantly navigate the trade-off between durability and fracture resistance. Optimal shredder performance requires materials that maintain sharp edges without chipping. Advanced metallurgical techniques now achieve previously impossible property combinations.

Temperature control during manufacturing critically influences this balance. Precise cooling rates determine final microstructure characteristics. Modern shredders increasingly incorporate monitoring systems that track blade conditions in real-time.

Geometric Edge Design Principles

Blade profile significantly influences stress distribution during material cutting. Finite element analysis helps designers optimize angles for specific materials. Automotive tire shredders use curved edges that reduce stress concentrations on blade tips.

Double-shaft shredders benefit from intermeshing tooth designs that distribute loads evenly. These geometric innovations reduce localized wear when processing reinforced plastics. Proper edge geometry can double operational lifespan between sharpening cycles.

Cryogenic Treatment Advancements

Deep freezing processes transform retained austenite into martensite at -196°C. This phase change enhances structural completeness throughout the blade material. Treated components demonstrate 30-100% longer service life in wood shredding applications.

The ultra-low temperatures create finer carbide formations within the steel matrix. This microscopic transformation improves wear resistance without compromising impact strength. Shredder operators report reduced downtime after implementing cryogenically treated blades.

Understanding Wear Failure Mechanisms

Shredder blades face multiple simultaneous degradation processes during operation. Identifying dominant wear modes helps select appropriate materials. Modern recycling facilities experience increasingly complex wear scenarios with mixed material streams.

Material scientists categorize wear into five primary mechanisms. Each requires specific countermeasures in blade design and composition. Understanding these failure patterns informs predictive maintenance schedules.

Abrasive Particle Interactions

Three-body abrasion occurs when loose particles grind between blades and processed materials. Concrete dust in construction waste creates particularly destructive conditions. Hardened carbide particles in electronic waste accelerate this wear mode significantly.

Material selection focuses on exceeding the hardness of common contaminants. Tungsten carbide coatings provide effective solutions for e-waste shredders processing circuit boards. Surface treatments must withstand constant scratching from silica and mineral residues.

Corrosive Wear Environments

Chemical reactions accelerate material loss in moist or acidic conditions. Food packaging residues create corrosive microenvironments during plastic shredding. Stainless steel blades offer protection but require careful alloy selection.

Marine-grade alloys containing nickel and chromium resist saltwater corrosion when processing fishing nets. Specialized shredders for medical waste employ cobalt-based superalloys that withstand disinfectant chemicals. Surface passivation treatments further enhance corrosion resistance.

Industry-Specific Material Applications

Different recycling sectors present unique challenges for shredder blades. Material scientists develop specialized solutions for each operational environment. Successful implementations demonstrate measurable improvements in throughput and maintenance intervals.

Leading shredder manufacturers now offer material-specific blade configurations. These purpose-engineered solutions optimize performance while reducing operational costs. Industry partnerships drive continuous improvement in blade technology.

Electronic Waste Processing

Shredding circuit boards requires blades that withstand abrasive fiberglass and ceramics. Tungsten carbide inserts provide critical wear protection at contact points. The extreme abrasiveness of silicon components demands maximum hardness materials.

Specialized tungsten carbide cutters maintain sharp edges through extended operations. Their superior performance justifies higher costs in electronics recycling facilities. Dust extraction systems prevent particle buildup that accelerates wear.

Tire Shredding Solutions

Reinforced steel belts in tires require blades with exceptional impact resistance. Modified D2 tool steel withstands sudden impacts from bead wires. Special heat treatment creates graduated hardness profiles through blade cross-sections.

Advanced shredders feature tire cutter blades with replaceable carbide tips. This modular design reduces replacement costs by 40%. Magnetic separators immediately remove liberated steel wires from the cutting chamber.

Surface Enhancement Technologies

Modern coating processes significantly extend base material performance. These treatments create surface properties impossible in bulk materials. Leading shredder operators report 3-5x lifespan improvements with optimized coatings.

Coating selection depends on specific wear mechanisms in each application. Deposition technologies continue advancing, offering new solutions. Proper surface preparation remains critical for coating adhesion and longevity.

Laser Cladding Innovations

Precision laser deposition builds wear-resistant surfaces with metallurgical bonding. This process applies powdered alloys to critical blade edges with pinpoint accuracy. The resulting composite structure combines substrate toughness with surface hardness.

Recent developments enable in-situ repairs on worn components. This capability reduces replacement costs for large shredder blades. Clad layers resist material adhesion when processing sticky substances like rubber.

Vapor Deposition Techniques

PVD and CVD coatings create micron-thin protective layers on blade surfaces. These ceramic films achieve extreme hardness up to 3500 HV. Aluminum chromium nitride coatings resist oxidation at high operating temperatures.

The deposition process requires careful temperature control to prevent substrate degradation. Treated blades demonstrate reduced friction coefficients when processing plastics. This technology proves particularly valuable for granulator blades in recycling facilities.

Economic Evaluation Methods

Blade selection involves comprehensive cost-benefit analysis beyond initial pricing. Advanced calculation models quantify operational impacts of material choices. These economic tools help justify investments in premium materials.

Total ownership costs include maintenance downtime, replacement labor, and production losses. Leading recyclers now implement IoT monitoring to gather real-time performance data. This information drives continuous improvement in material selection.

Lifecycle Cost Modeling

LCC analysis compares materials using operational hours per dollar metrics. Advanced models incorporate scrap value of worn components. Tungsten carbide blades often demonstrate superior economics despite higher initial costs.

These calculations must account for material-specific sharpening requirements. Some alloys permit multiple regrinds before replacement. Proper documentation of maintenance history improves model accuracy over time.

IoT Performance Monitoring

Sensors track blade temperature, vibration, and power consumption patterns. Machine learning algorithms detect early wear signatures before failure occurs. This predictive capability optimizes maintenance scheduling.

Real-time data enables dynamic operational adjustments to extend blade life. Some systems automatically reduce feed rates when detecting hard contaminants. The technology pays for itself through reduced unplanned downtime.

Emerging Material Technologies

Cutting-edge research promises revolutionary improvements in shredder blade performance. Laboratories worldwide are developing next-generation solutions. These innovations could dramatically change recycling economics in coming decades.

Material science advances combine with digital technologies for accelerated development. Computer simulations now predict performance characteristics before physical prototyping. This approach shortens development cycles significantly.

Self-Healing Composite Materials

Microcapsule technology embeds healing agents within blade matrices. When cracks form, these capsules rupture and release liquid polymers. The repairing agent fills fractures through capillary action.

Current prototypes demonstrate 70% recovery of original strength after damage. Industrial implementation requires solving challenges related to high-temperature stability. This technology shows particular promise for shredder components processing abrasive materials.

Biomimetic Structural Designs

Researchers study natural wear-resistant systems like rodent teeth and mollusk shells. These biological models inspire innovative blade architectures. Gradient structures mimicking tooth enamel demonstrate exceptional fracture resistance.

Some prototypes feature self-sharpening mechanisms inspired by beaver teeth. The alternating hard/soft layers maintain cutting efficiency as material wears. Such designs could revolutionize wood shredder operations in forestry applications.